Biomass carbon-based flue gas demercuration adsorbent and preparation method thereof

A technology of biomass carbon and adsorbent, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high preparation cost and low mercury removal efficiency, and achieve simple preparation methods, high mercury removal efficiency, Wide variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

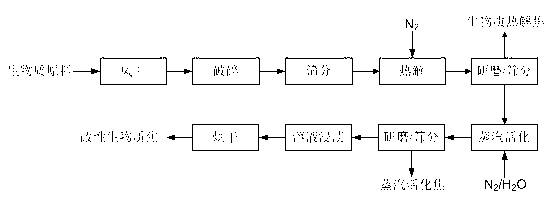

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, mulberry branches (MT) are used as raw materials, and the raw materials of mulberry branch particles with a particle size of less than 3 mm are made through pretreatment processes such as air-drying, crushing and screening. Weigh about 150g of mulberry branch particles and quickly put them into a fixed-bed heating furnace with a pyrolysis temperature of 400, 600 or 800°C and continuous nitrogen flow (flow rate of 5L / min). Turn off the heater after pyrolysis for 10 minutes, and Cool to room temperature under atmosphere. After crushing, grinding and sieving, pyrolysis coke of mulberry branches with a particle size of less than 0.3 mm (such as MT400, MT600 and MT800) is obtained, and put into a reagent bottle for use.

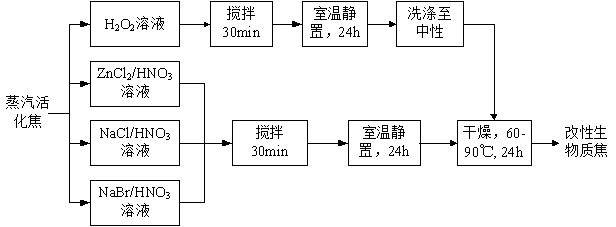

[0038] Weigh about 50g of mulberry branches and pyrolyze coke, put it into a fixed-bed heating furnace with an activation temperature of 800°C, continuously feed nitrogen and water vapor into the furnace, and the nitrogen flow rate is 5L...

Embodiment 2

[0041] In this example, walnut shells (NS) are used as raw materials, and after pretreatment processes such as air-drying, crushing and sieving, walnut shell particles with a particle size of less than 3 mm are made; about 150 g of walnut shell particles are quickly put into the pyrolysis temperature of 600 ℃ and continuously fed with nitrogen (flow 5L / min) in a fixed-bed heating furnace, turn off the heater after pyrolysis for 10 minutes, cool to room temperature under a nitrogen atmosphere, and finally obtain a particle size smaller than 0.3mm walnut shell pyrolysis (NS600).

[0042] Add about 50g of walnut shell pyrolysis coke into a fixed-bed heating furnace with an activation temperature of 800°C and continuous flow of nitrogen and water vapor, where the nitrogen flow rate is 5L / min, N 2 :H 2 The molar ratio of O(g) is 1:1, the steam activated walnut shell coke (NS600-A ).

[0043] Weigh about 5g of steam-activated mulberry branch coke into 100mL of 10% and 30% H 2 o ...

Embodiment 3

[0045] In this example, wheat straw (WS) is used as the raw material, and after pretreatment processes such as air-drying, crushing and screening, the raw material of wheat straw particles with a particle size of less than 2mm is made; about 150g of wheat straw particles are quickly put into the pyrolysis temperature of 600°C In a fixed-bed heating furnace with nitrogen gas (flow rate 5L / min) continuously fed in, the heater is turned off after pyrolysis for 10 minutes, cooled to room temperature under a nitrogen atmosphere, and finally crushed, ground and sieved to obtain a particle size of less than 0.3 mm of straw pyrolysis (WS600).

[0046] Add about 50g of wheat straw pyrolysis coke into the fixed-bed heating furnace with an activation temperature of 800°C and continuous flow of nitrogen and water vapor, where the nitrogen flow rate is 5L / min, N 2 :H 2 The molar ratio of O(g) is 1:1, the water vapor is cut off after constant temperature activation for 30 minutes, cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com