A production method of recycled asphalt mixture with high construction waste aggregate content

A technology for construction waste and recycled asphalt, which is used in construction, roads, road repair and other directions to achieve the effects of controlling pollution emissions, high and stable performance, and reducing resource occupation.

Active Publication Date: 2020-10-16

ANHUI TRANSPORT CONSULTING & DESIGN INST

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

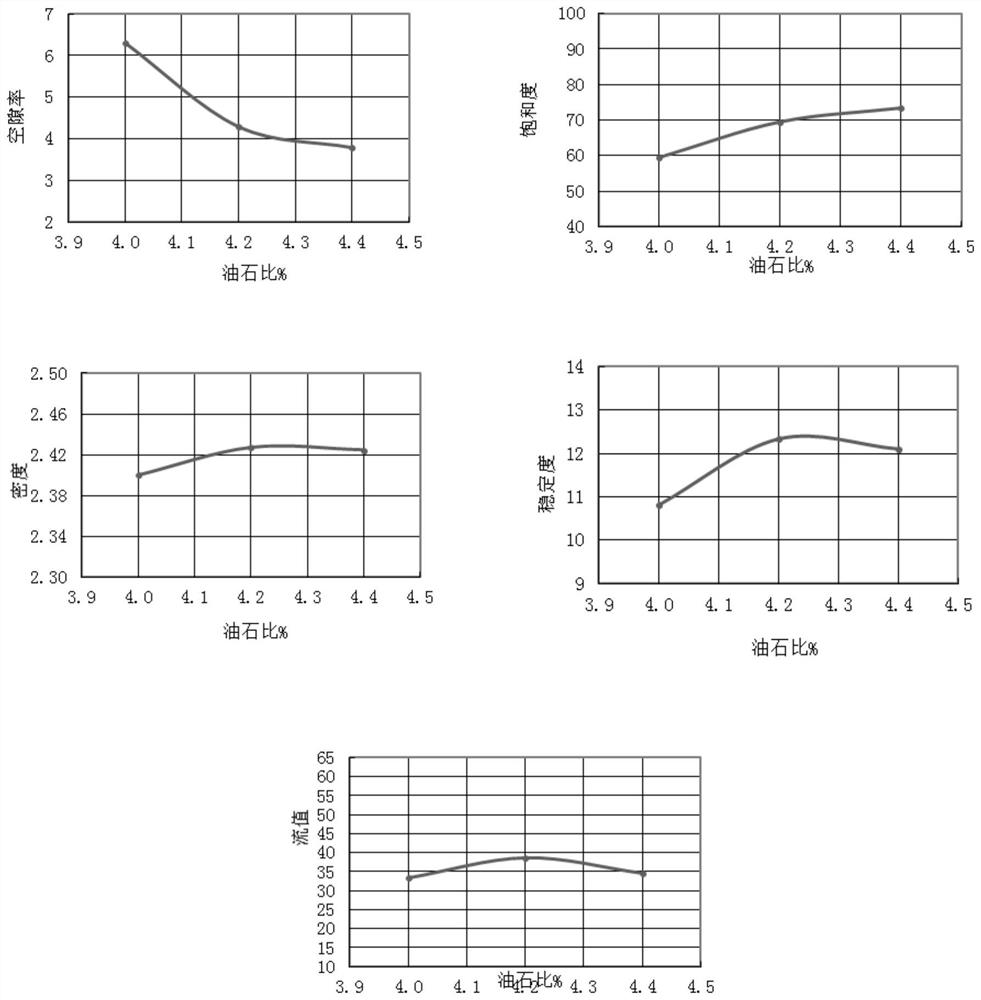

[0004] However, the existing construction waste is different from the traditional rolled gravel after all. For example, the absorption of asphalt by the construction waste aggregate is obviously stronger than that of the traditional rolled gravel. Therefore, the asphalt ratio and the relevant parameters of the asphalt mixture must be different. How to determine The optimal asphalt ratio, reducing the waste of asphalt resources, increasing the amount of construction waste in the recycled asphalt mixture and reducing the variability, and producing a high-performance and stable recycled asphalt mixture have become urgent problems for those skilled in the art. technical problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0049] No. 70 matrix asphalt is selected, and the performance indicators of the asphalt are shown in Table 1 below:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

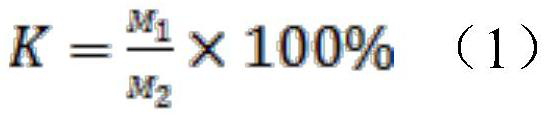

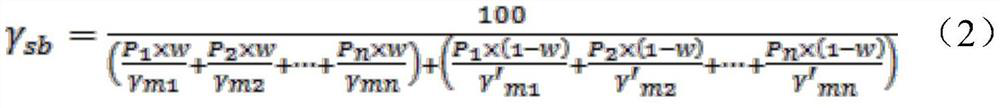

The invention belongs to the technical field of asphalt mixture preparation, and particularly relates to a production method of a high construction waste aggregate mixing amount recycled asphalt mixture. The production method comprises the steps that a key sieve pore passing rate correction coefficient of construction waste aggregates is determined; the passing rates of all grades of the construction waste aggregates are corrected according to the correction coefficient, and the passing rates of all grades of the construction waste aggregates are combined with the passing rate of all grades ofaggregate materials to synthesize the passing rate of the recycled asphalt mixture; the volume parameters of the recycled asphalt mixture are measured and the relative density of the synthetic wool volume of design graded mixed aggregates is determined; the optimum asphalt-aggregate ratio Pa1 of similar grading is determined under the same grading condition and a discreet value of the optimal asphalt-aggregate ratio of the design grading is calculated accordingly; and after a Marshall test piece is formed, the optimal asphalt-aggregate ratio of a target mixture ratio is determined, and finally the recycled asphalt mixture is mixed and prepared. The production method is based on the consideration of the influence of the construction waste aggregates on the synthetic wool volume relative density of the mixed mineral aggregates, the Marshall test piece is formed, the similar graded asphalt-aggregate ratio is used as a standard for estimating and designing the optimal asphalt-aggregate ratio, the using amount of asphalt is saved, and the production cost is reduced.

Description

technical field [0001] The invention belongs to the technical field of road engineering asphalt mixture preparation, and in particular relates to a production method of recycled asphalt mixture with high construction waste aggregate content. Background technique [0002] Construction waste mainly refers to waste concrete and waste bricks generated from the demolition of housing facilities, etc., as well as waste cement concrete generated during road construction and renovation. Construction waste is mainly composed of inorganic substances such as broken concrete, broken brick and tile, and broken sand and gravel. Its chemical composition is silicate, carbonate, hydroxide and sulfate, etc. , toughness, frost resistance, water stability, chemical stability, and does not shrink when exposed to water, and the damage of frost heave is small. With the continuous acceleration of urbanization in my country, the amount of construction waste generated and discharged in cities is also...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01C19/02E01C19/05E01C19/10

CPCE01C19/02E01C19/05E01C19/10E01C19/1068

Inventor 毛洪强张玉斌牛京涛鲍世辉任园邵静王春红谢敏

Owner ANHUI TRANSPORT CONSULTING & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com