Combustion chamber of aero-engine and its aero-engine

A technology of aero-engine and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., to achieve the effect of shortening length, ensuring reliable operation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

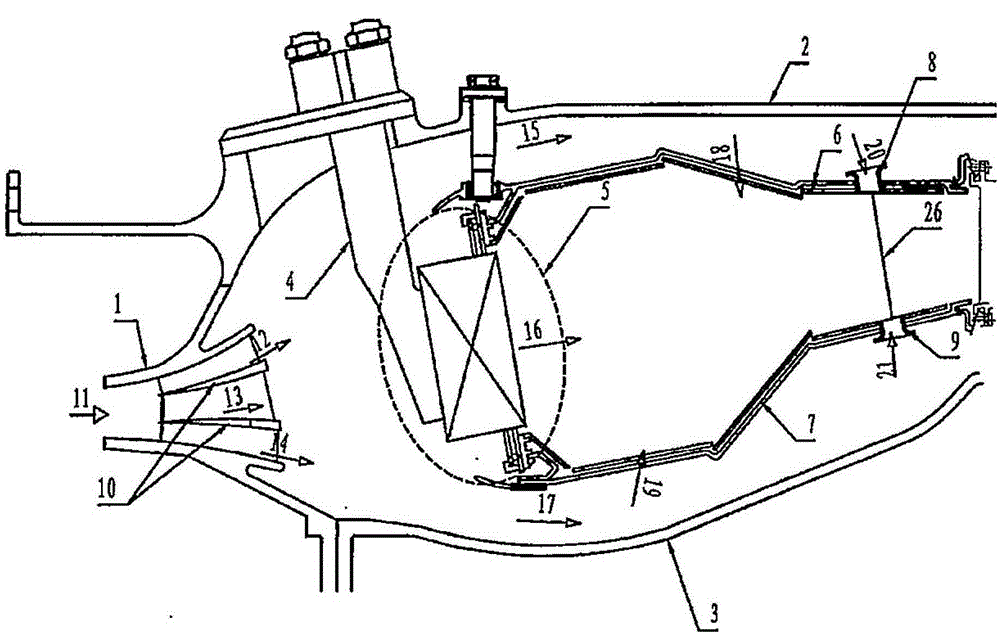

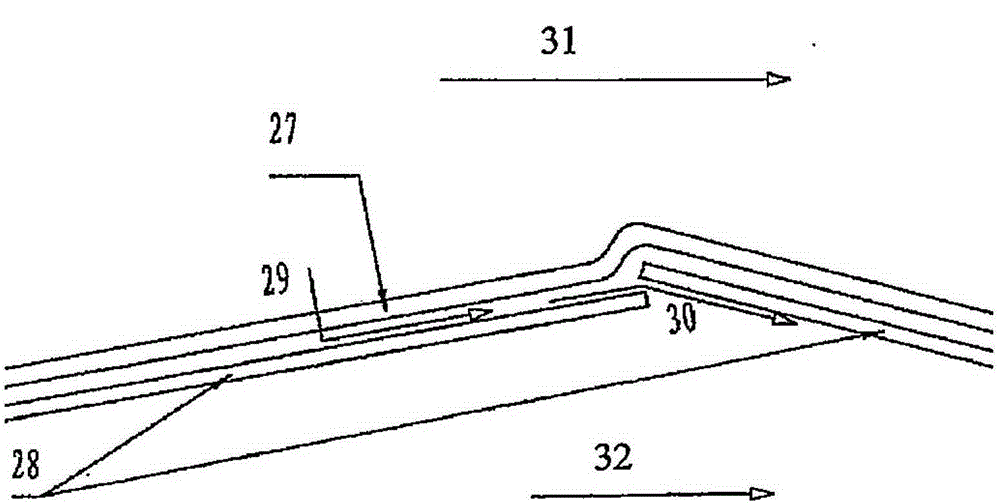

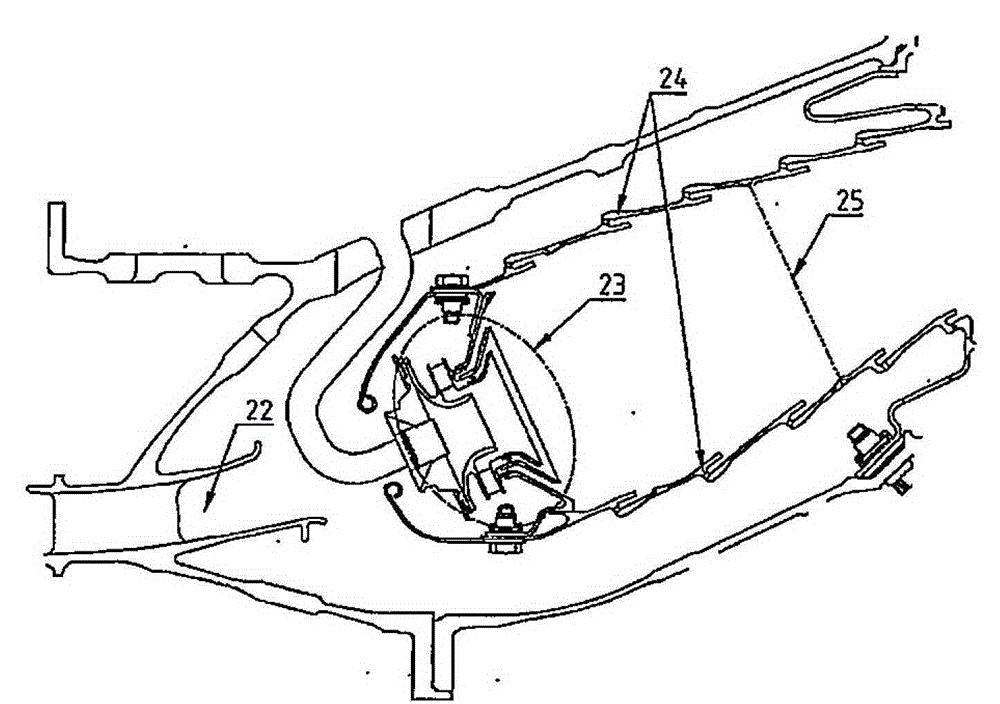

[0045] figure 1 Shown is an aeroengine combustor according to an exemplary but non-limiting embodiment of the present invention: multi-channel inlet diffuser, center staged lean head, ceramic matrix composite floating walls, flame tube volume reduction And the shape of the flame tube that shrinks quickly in the rear section and the hedging and mixing hole array.

[0046] see figure 1 , the aero-engine combustor consists of a multi-channel inlet diffuser 1, a combustor outer casing 2, a combustor inner casing 3, a fuel nozzle 4, and a flame tube. Fuel enters the flame tube through the fuel nozzle 4, and the flame tube is located between the outer casing 2 and the inner casing 3, including the flame tube head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com