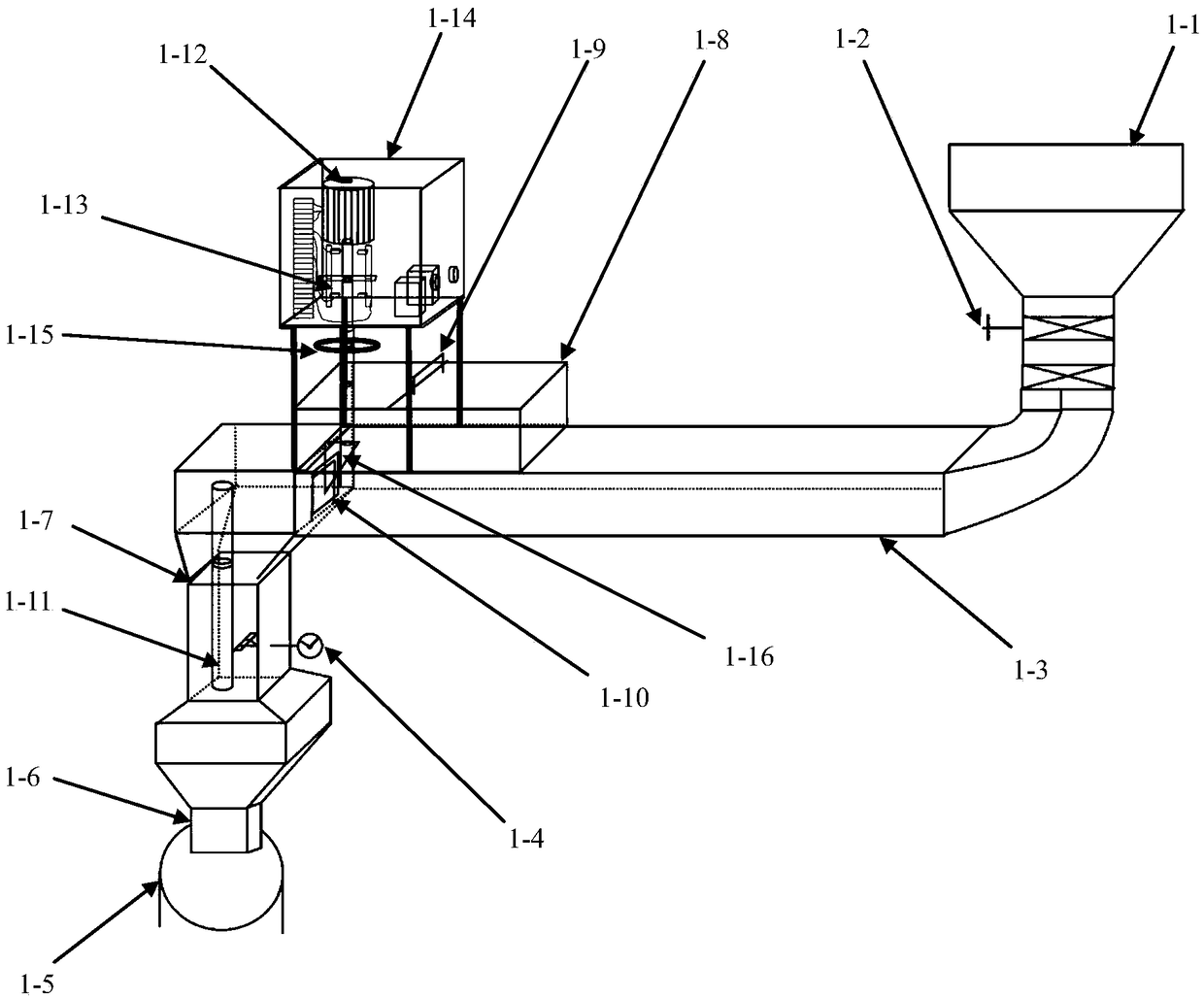

An alumina feeding system

A technology of alumina and feeding port, applied in the field of electrolytic aluminum, to reduce labor intensity, improve work efficiency, and shorten feeding adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

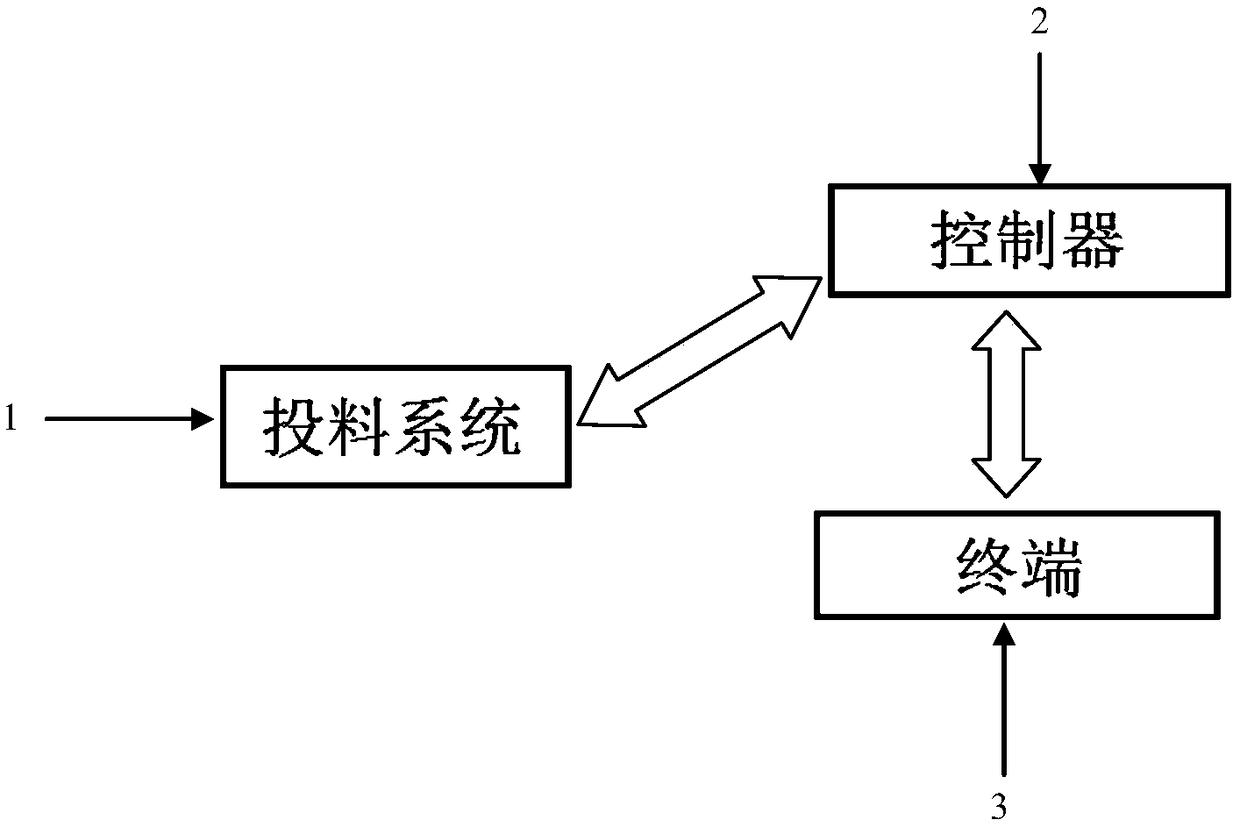

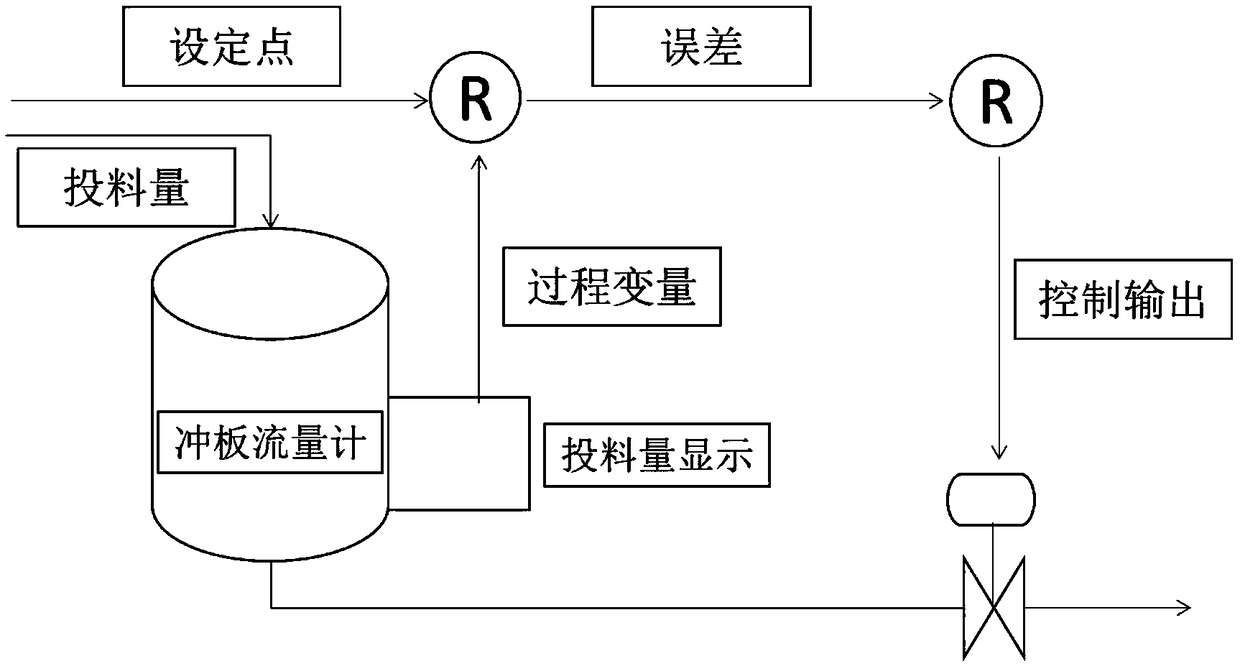

Method used

Image

Examples

Embodiment 1

[0043] Combine below Figure 4 Describe in detail the actual adjustment process and the effect after use of an alumina feeding system of the present invention:

[0044] Figure 4 After the alumina feeding system of the present invention is put into use, it is the data collected during a 2-hour random inspection from 10:00 am to 12:00 on a normal working day of the feeding production line, and the sampling time interval is once every 10 minutes;

[0045] Before starting the feeding control, set the standard lower limit of the feeding value to 4.5t, the standard upper limit of the feeding value to 5.5t, and the adjustment range to 0.5t on the program panel of the terminal 3, and then transmit the control data to the controller 2, and the controller communicates Feedback control mode controls the speed and direction of the geared motor 1-12 in the feeding system 1 in real time, so as to control the actual feeding value in real time, from Figure 4 It can be seen that the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com