Device and method for reducing oil leakage of supercharger compressor

A compressor and supercharger technology, which is applied to the parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of compressor efficiency reduction and reduce oil leakage and efficiency Influence, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

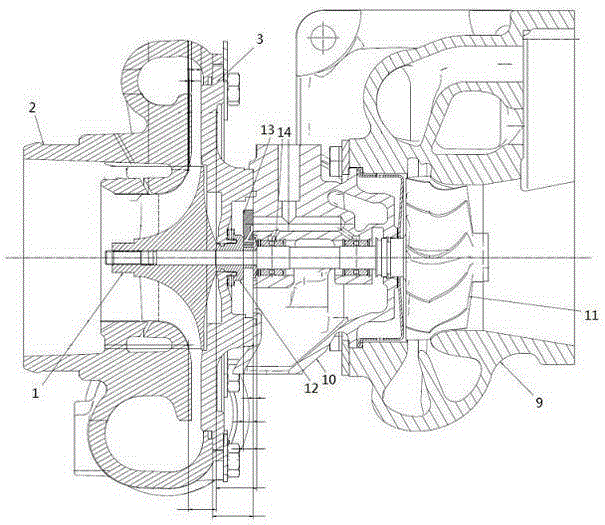

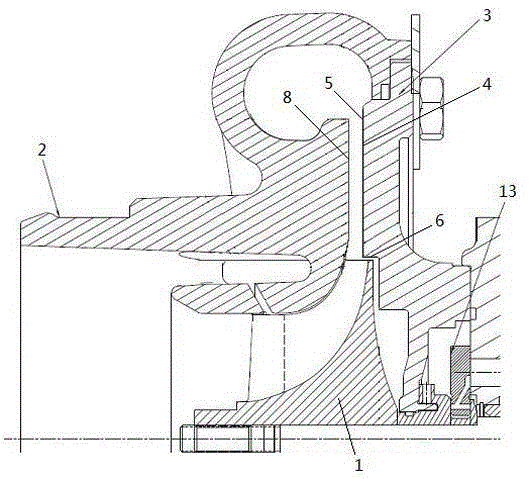

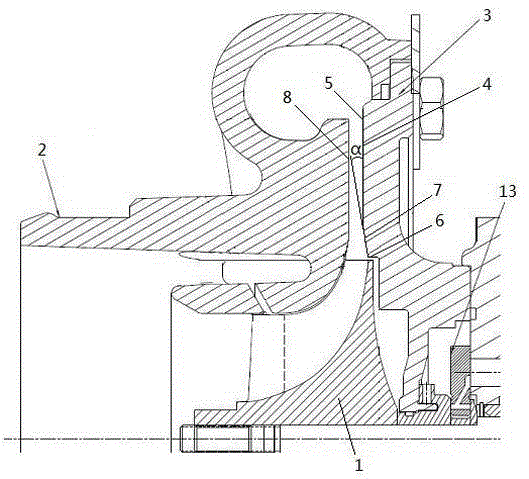

[0022] The present invention reduces the device of turbocharger compressor oil leakage, such as figure 2 , 3 As shown, it includes a compressor main body mainly composed of an impeller 1, a compressor volute 2 and a compressor back plate 3. At the position of the impeller outlet, the upper end of the compressor back plate 3 protrudes outward, and the size of the protruding part 4 has Continuous and varying degrees, so that the compressor back plate 3 and the impeller 1 overlap to different degrees at the position of the impeller outlet, so that the compressor back plate 3 blocks the air flow at the impeller outlet to different degrees.

[0023] The distribution of the outlet pressure of the compressor impeller varies along the circumferential direction. In order to achieve small or no overlap at positions with small oil leakage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com