Highly integrated riveting machine hydraulic device

A technology of hydraulic device and riveting machine, which is applied in the direction of fluid pressure actuating device, mechanical equipment, fluid pressure actuating system components, etc. The effect of making and reducing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

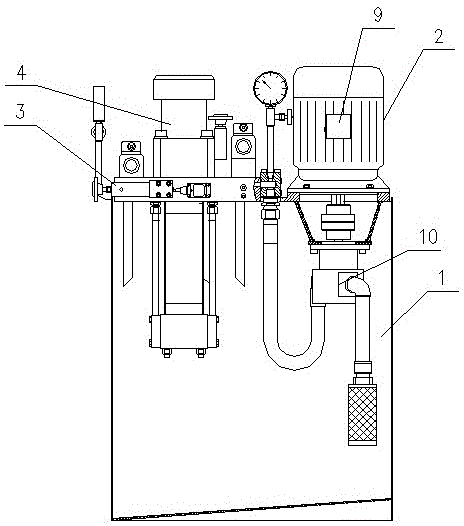

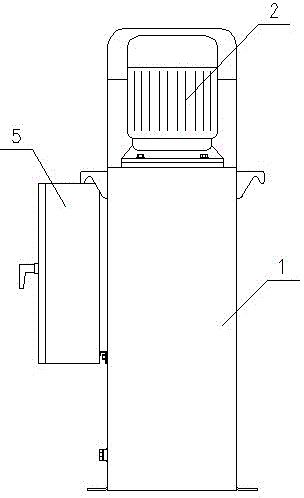

[0017] Such as figure 1 , 2 As shown in , 3, a highly integrated riveting machine hydraulic device includes a fuel tank 1, an oil pump motor device 2, an electrical control device 5 and a boost control device, and the electrical control device 5 is fixed on the side of the fuel tank 1. The oil pump motor device 2 includes an oil pump 10 and a motor 9. The motor 9 is installed vertically on the upper cover of the fuel tank. It can reduce noise and reduce heat; the booster device 4 and the oil pressure integrated control device 3 are installed together through a high-precision oil pressure integrated block to form a booster control device, and the booster control device is installed on the upper cover of the fuel tank.

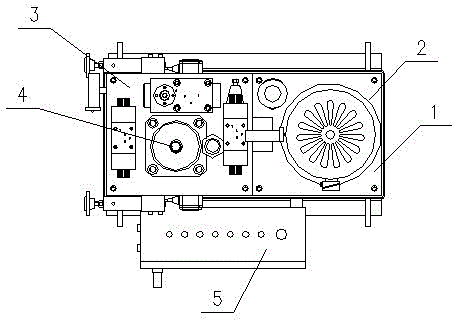

[0018] Such as Figure 4 , 5 As shown, the overflow valve 13, the main reversing valve 14, the pressure boosting reversing valve 16, and the rivet switching valve 22 are integrated on the upper surface of the high-precision oil pressure manifold 25; the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com