High-engaging-degree gear set of miniature gear pump and machining method of gears

A processing method and gear pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of unreasonable gear set design and insufficient gear machining accuracy, and achieve self-priming ability, high hardness, and good finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

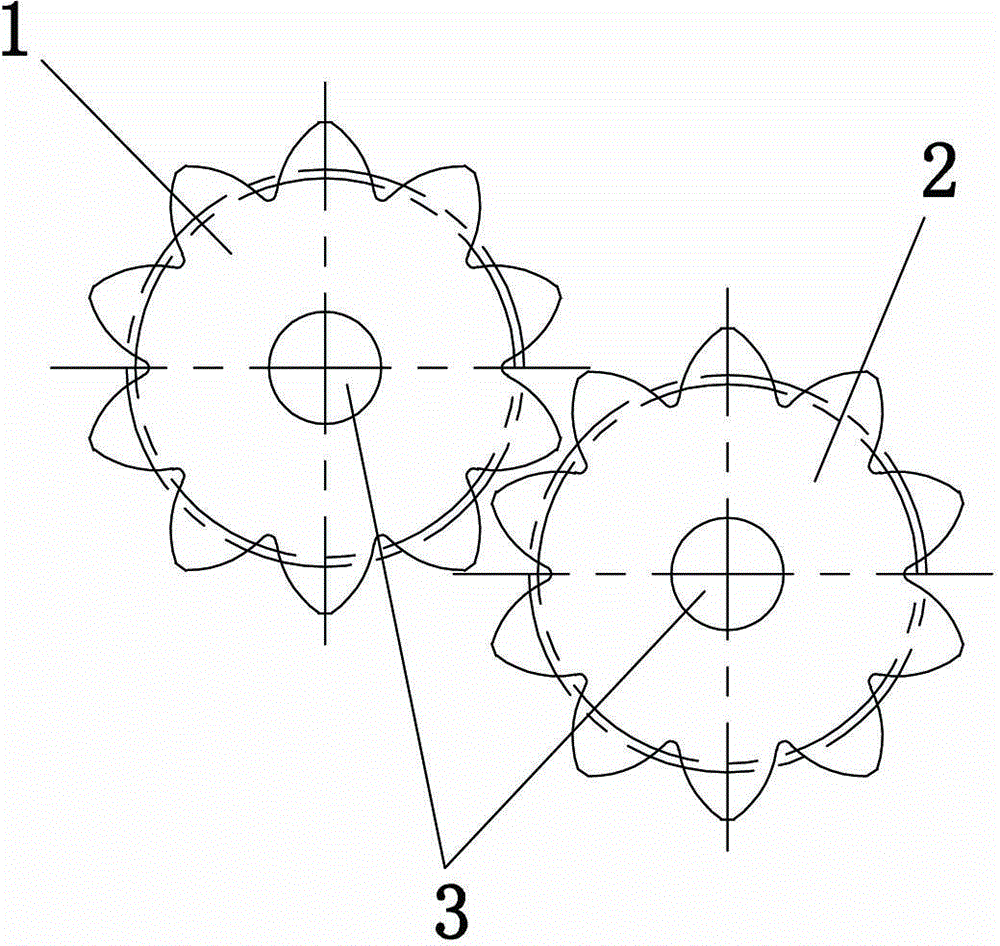

[0024] A high meshing gear set of a micro gear pump, including two gears meshing with each other, the two gears are the driving gear 1 and the driven gear 2, both of which are involute spur gears and the parameters of the two gears Similarly, the number of teeth of each gear is 10, the modulus is 2.5, the pressure angle is 25°, the diameter of the addendum circle is 37mm, the diameter of the index circle is 30mm, and the diameter of the root circle is 26mm. is 2.1. The gears are made of PEEK material, and each gear is fixed with a ceramic shaft 3 .

[0025] A processing method for the gears in the above gear set, the steps are:

[0026] 1) Make a fixture for fixing the standard mold, the inner surface of the fixture matches the outer surface of the standard mold, and the upper surface of the fixture is a horizontal plane.

[0027] 2) First heat the outside of the fixture with a heater at 80°C for more than 30 minutes to expand the fixture, place the standard mold in the fixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com