Injection molding machine with efficient clamping mechanism

An injection molding machine and mold locking technology, which is applied in the field of high-efficiency mold clamping mechanism injection molding machines, can solve the problems of large footprint of machine tools, insufficient mold clamping, and troublesome mold installation, so as to improve work efficiency, accuracy, and firmness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

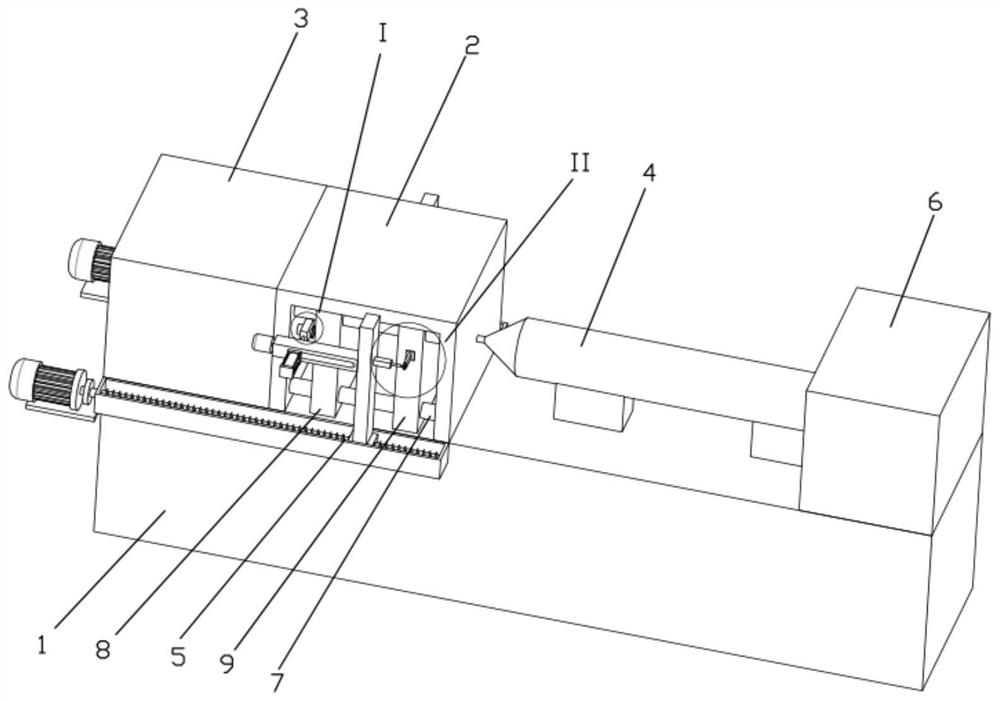

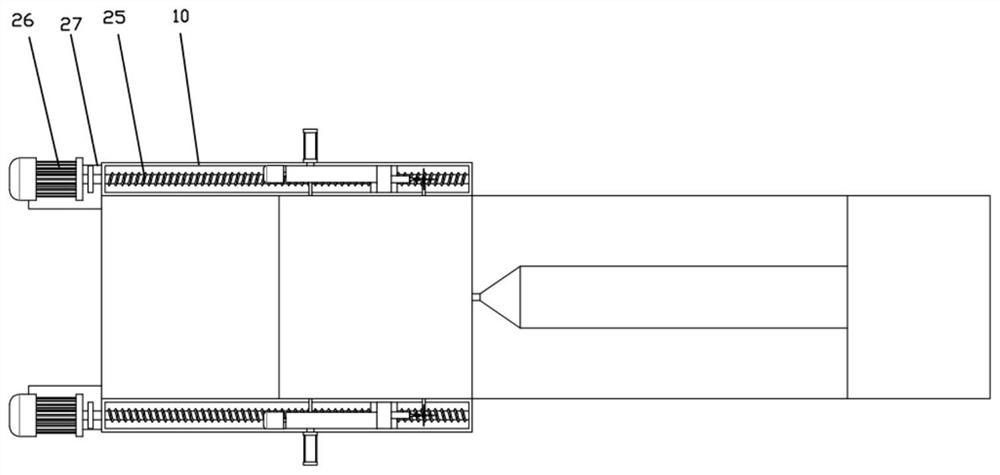

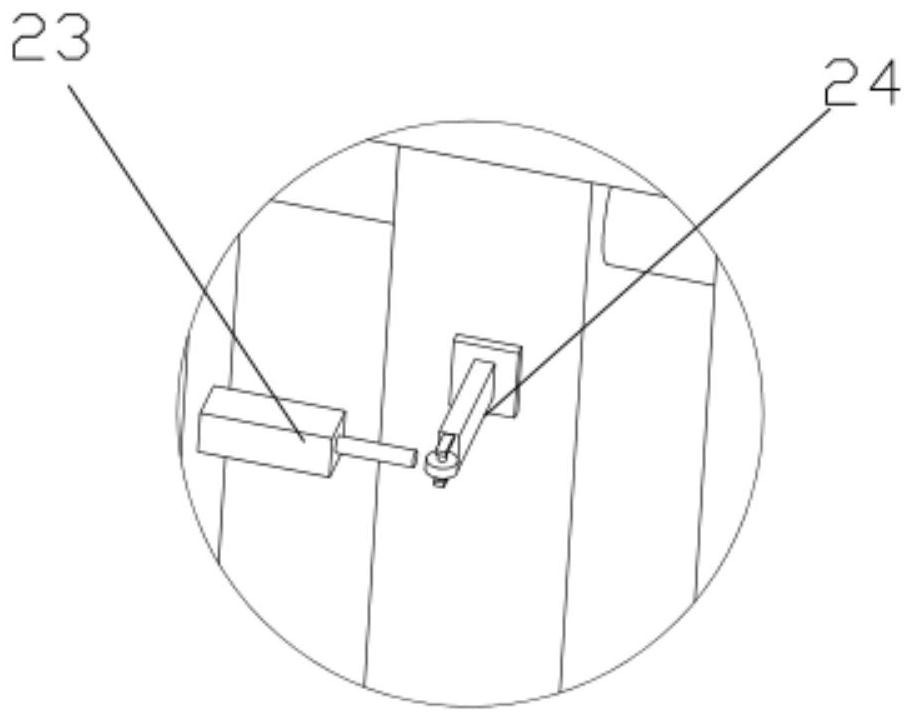

[0025] Please also refer to Figure 1 to Figure 5 , the high-efficiency clamping mechanism injection molding machine of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The high-efficiency clamping mechanism injection molding machine includes a base 1, a mold box 2, a mold driving structure 3, an extrusion cylinder 4, and a clamping assembly 5. The extrusion cylinder 4 is fixed on the upper end of the base 1, and the extrusion cylinder 4 is at the extrusion end. Connect the mold box 2, the other end is connected with the feed structure 6, the mold driving structure 3 is connected with the mold box 2, fixed on the upper end of the base 1, the mold box 2 is fixed with a guide rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com