Automatic transmission mechanism of hydraulic motor

A hydraulic motor, automatic shifting technology, applied in steering mechanism, servo motor, variable displacement engine, etc., can solve problems such as poor handling feeling, poor acceleration feeling, and large deviation of shifting timing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

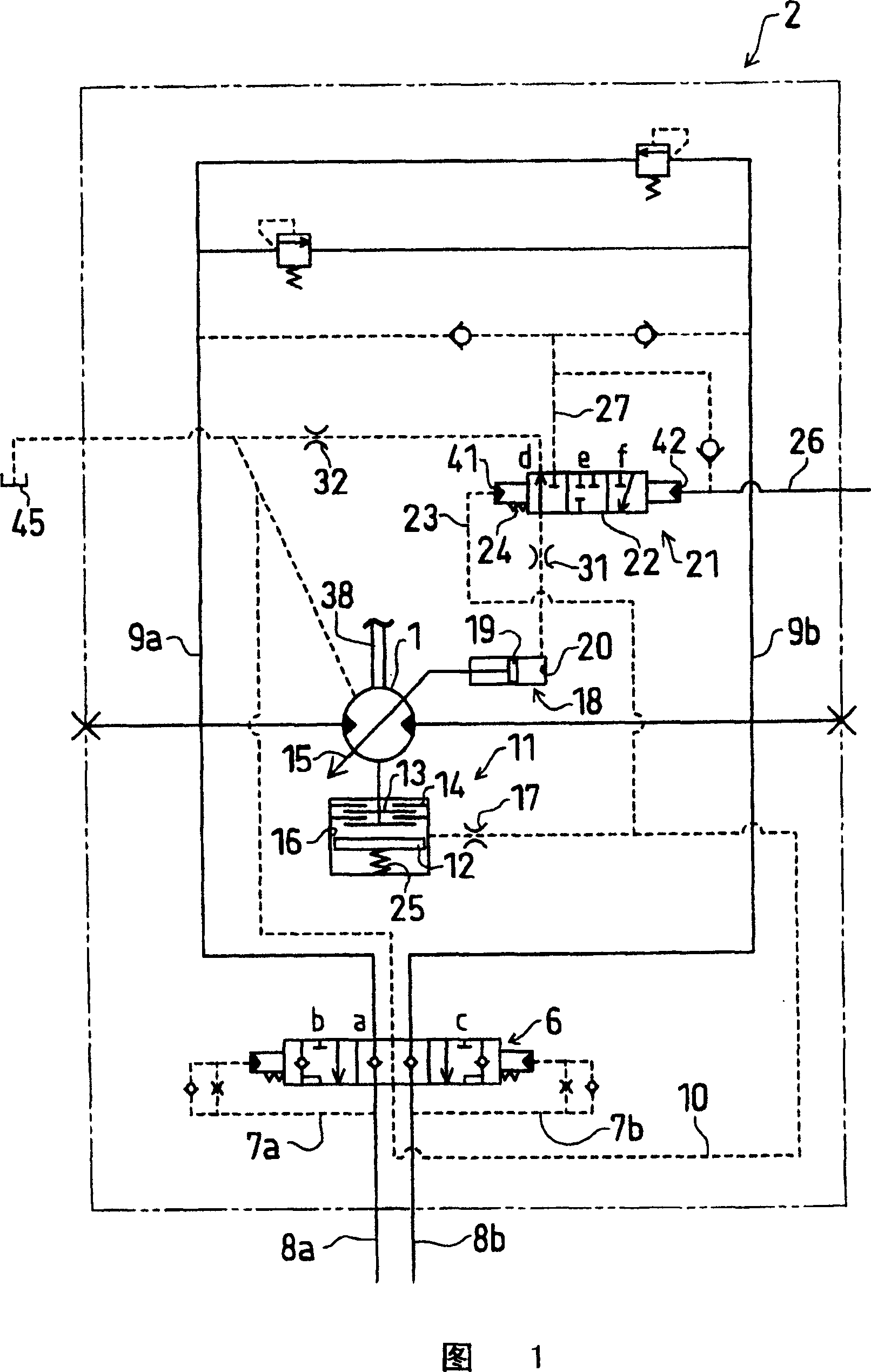

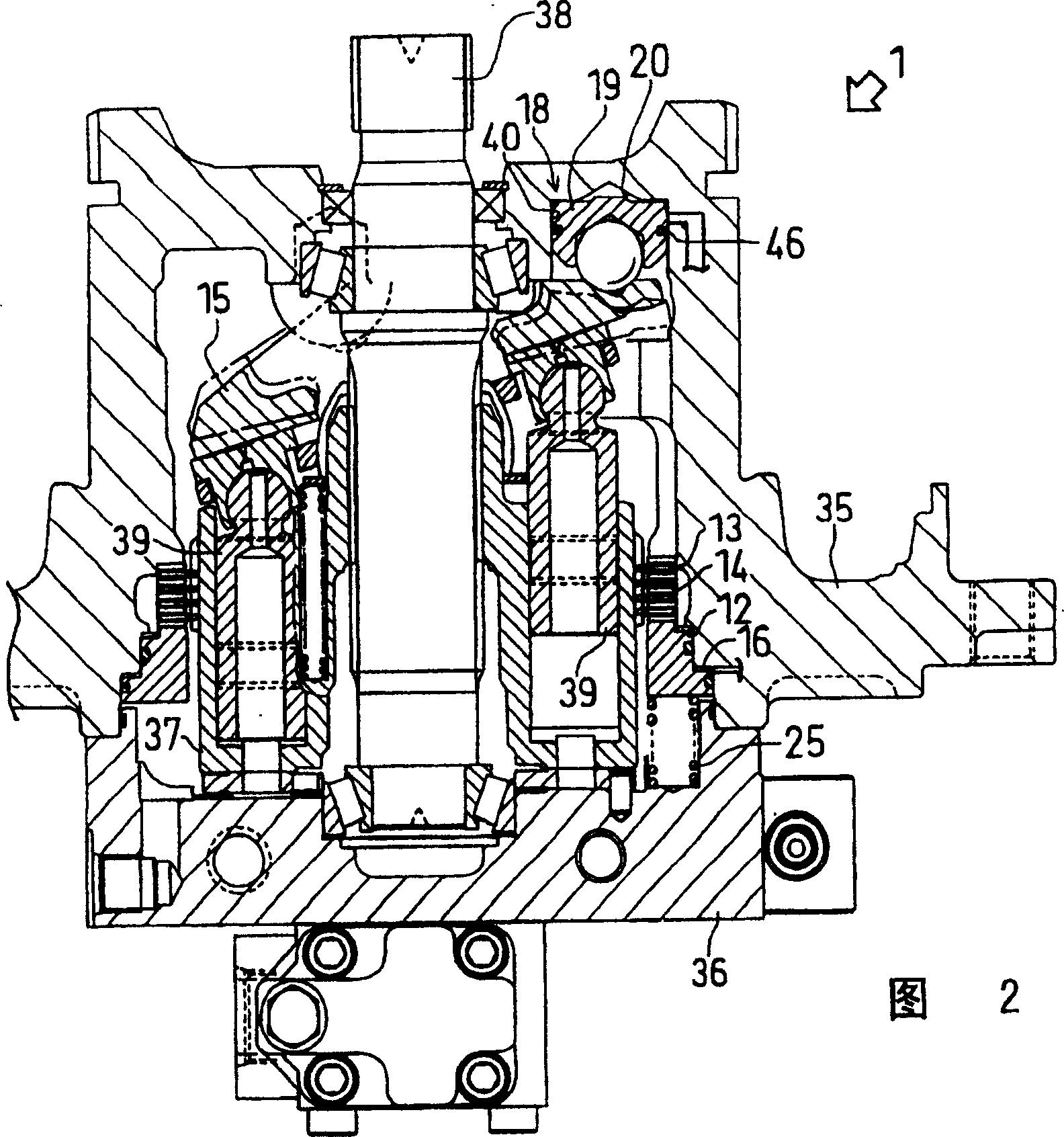

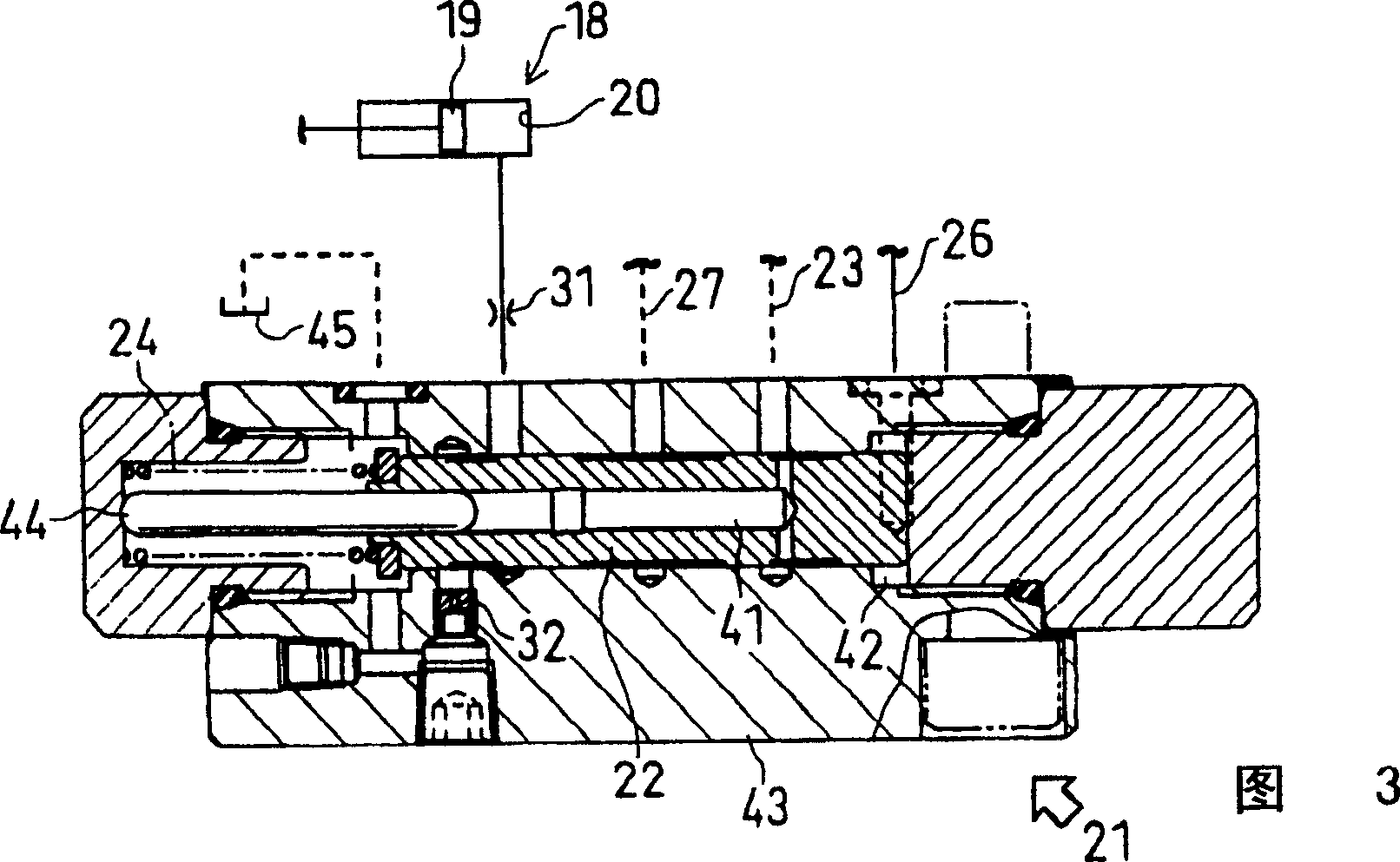

[0038] Embodiments of the present invention are described below. FIG. 1 is a hydraulic circuit diagram showing the overall configuration of an automatic transmission mechanism according to an embodiment of the present invention. Fig. 2 is a sectional view showing a specific configuration of the hydraulic motor. Fig. 3 is a cross-sectional view showing a specific configuration of a capacity switching valve. Fig. 4 is a graph showing the variation of the movable swash plate angle and the driving pressure when the present invention is configured to steer on the ground.

[0039] As shown in FIG. 1 , the hydraulic circuit 2 has a variable displacement hydraulic motor 1 . The hydraulic motor 1 is driven by the pressure oil supplied to the oil passages 9a and 9b, and applies driving force to the traveling axle of the construction machine. Oil supply and discharge passages 8a and 8b are provided for introducing pressurized oil into the aforementioned oil passages 9a and 9b, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com