High-efficiency hybrid white OLED (Organic Light Emitting Diode) with high color rendering index

An electroluminescent device, high color rendering technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of complex structure, high cost, and improved preparation process requirements, so as to reduce the number, improve device efficiency, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The structure of the prepared hybrid white organic electroluminescent device A with high efficiency and high color rendering index is: ITO / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / 26DCzPPy:DDCzTrz(5nm,10 %) / 26DCzPPy:Ir(dmppy) 2 (dpp): Ir(piq)3(10nm,1:15%:1%) / 26DCzPPy:DDCzTrz(10nm,10%) / TmPyPB(50nm) / Cs 2 CO 3 (1nm) / Al(200nm).

[0029] A hybrid white light organic electroluminescent device A with high efficiency and high color rendering index of the present invention is prepared by the following method:

[0030] The structure of the device A is composed of the following layers from bottom to top:

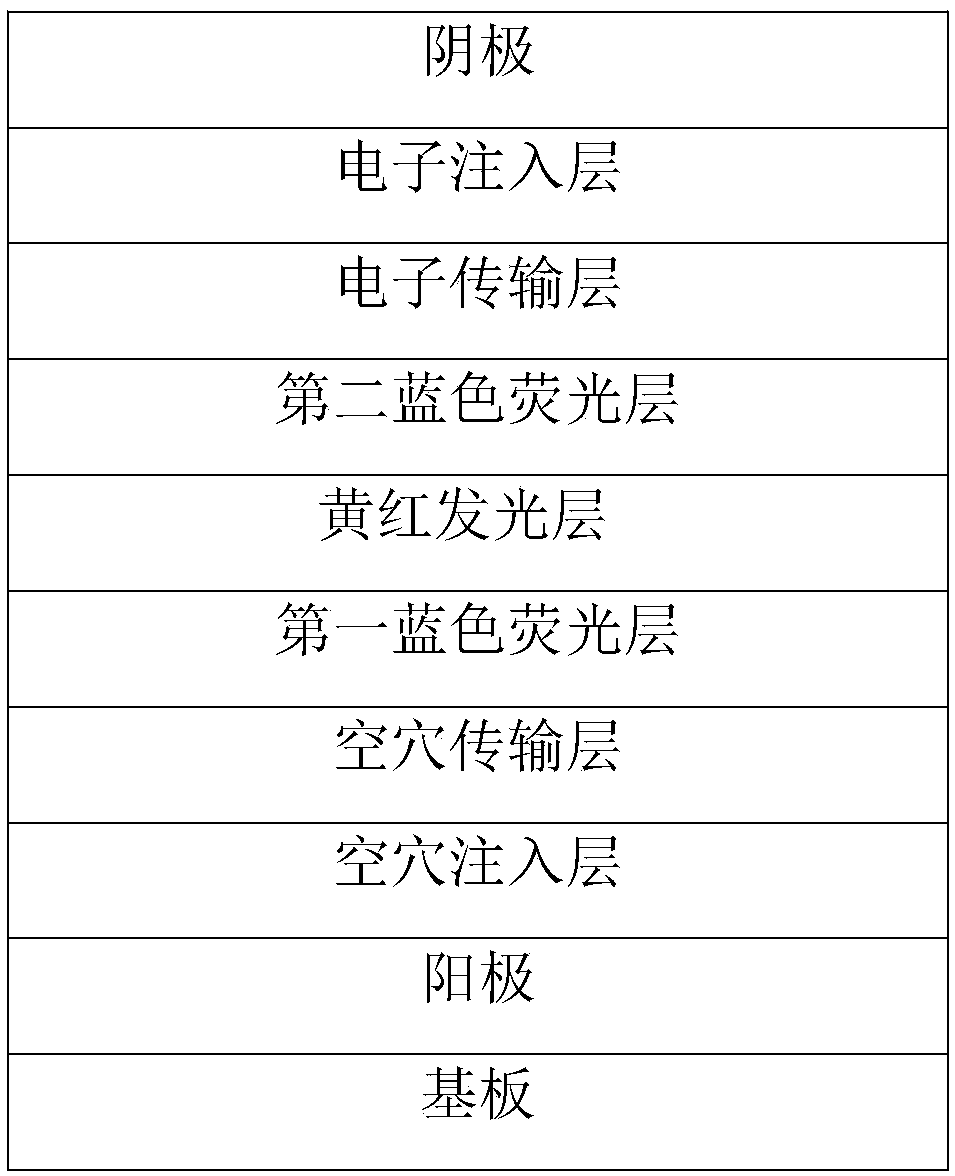

[0031] Substrate, anode, hole injection layer, hole transport layer, first blue fluorescent layer, yellow-red phosphorescent layer, second blue fluorescent layer, electron transport layer, electron injection layer, cathode.

[0032] The aforementioned substrate is glass.

[0033] The above-mentioned anode is an ITO thin film.

[0034] The above-mentioned hole injection layer is a...

Embodiment 2

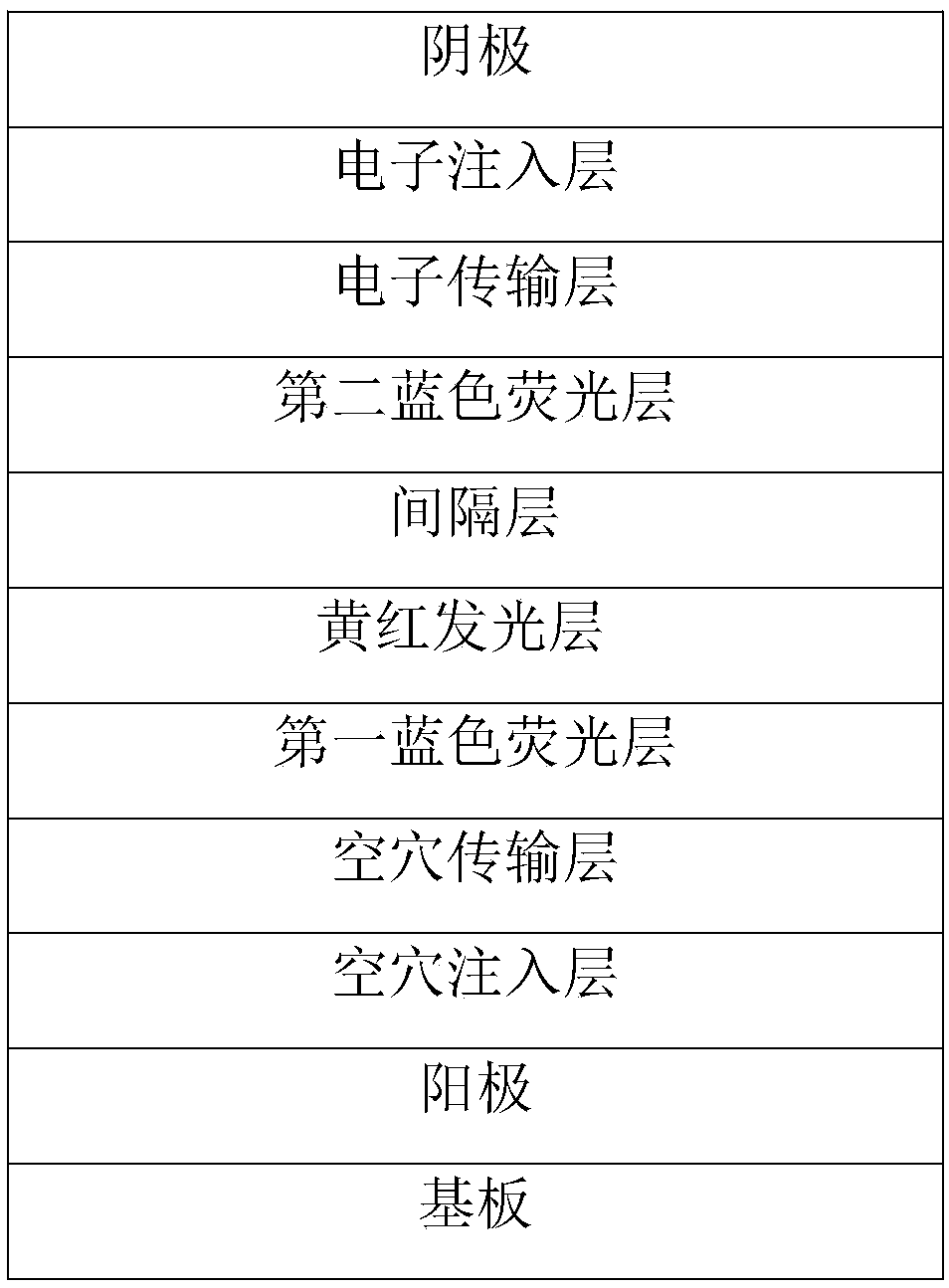

[0056] The difference between embodiment 2 and embodiment 1 is that a spacer layer is provided between the yellow-red light emitting layer and the second blue fluorescent layer.

Embodiment 3

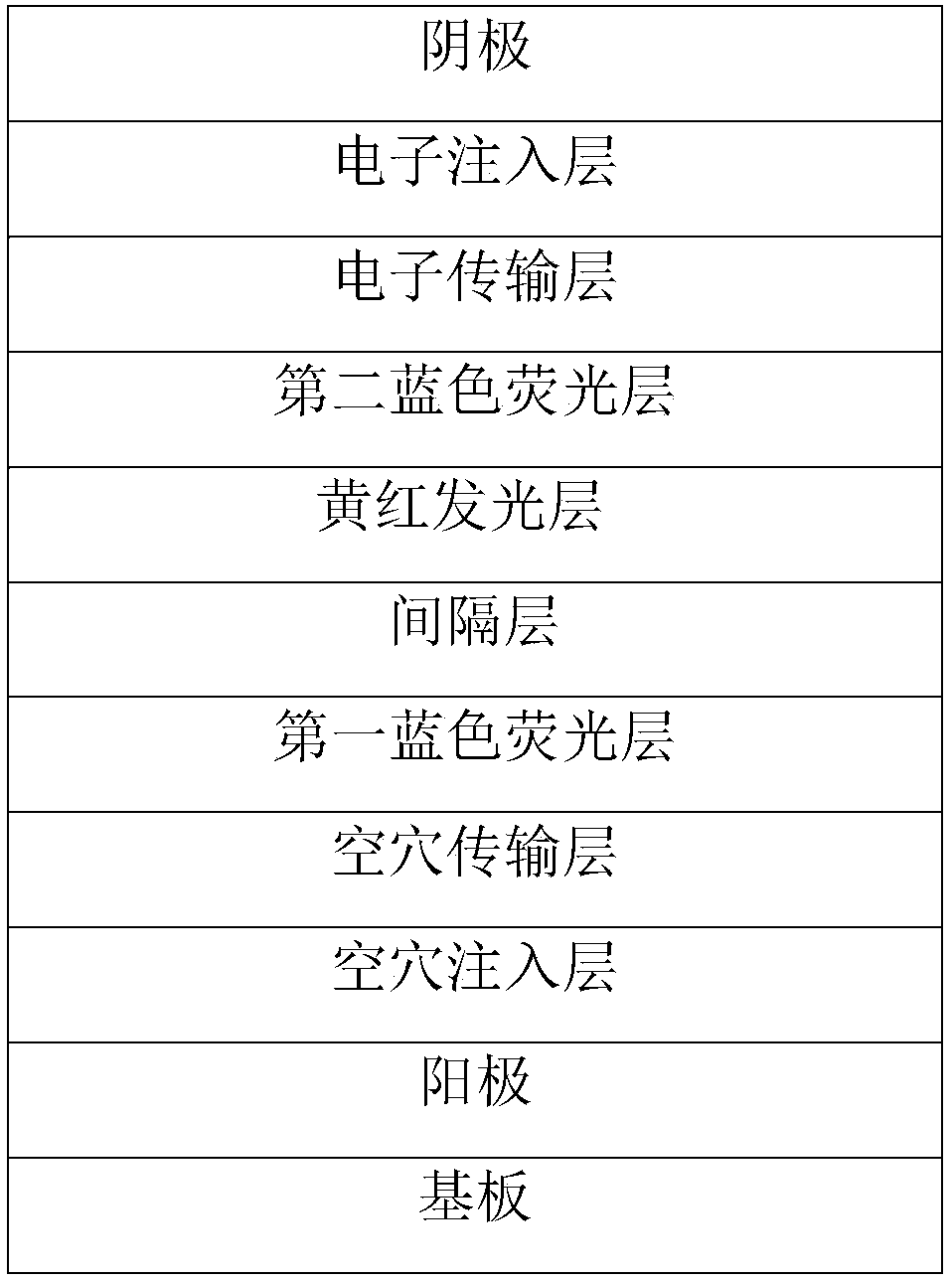

[0058] The difference between embodiment 3 and embodiment 1 is that a spacer layer is provided between the yellow-red light emitting layer and the first blue fluorescent layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com