Organic compound and electronic element using organic compound and electronic device

A technology of organic compounds and chemical formulas, applied in the field of organic compounds, electronic components and electronic devices, to achieve good hole blocking performance, favorable directional alignment, enhanced injection and transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0216]In the synthesis examples described below, all temperatures are in degrees Celsius unless otherwise stated. Some reagents were purchased from commercial suppliers such as Aldrich Chemical Company, Arco Chemical Company and Alfa Chemical Company, and were used without further purification unless otherwise stated. The compounds of the synthetic methods not mentioned in this application are all raw material products obtained through commercial channels.

[0217] During purification, the chromatographic column is a silica gel column, and silica gel (100-200 mesh) is purchased from Qingdao Ocean Chemical Factory.

[0218] In each synthesis example, the measurement conditions of low-resolution mass spectrometry (MS) data are: Agilent 6120 quadrupole HPLC-M (column model: Zorbax SB-C18, 2.1 * 30mm, 3.5 microns, 6min, flow rate is 0.6mL / min. Mobile phase: 5%-95% (acetonitrile containing 0.1% formic acid) in (water containing 0.1% formic acid) ratio), using electrospray ionizat...

Embodiment 1

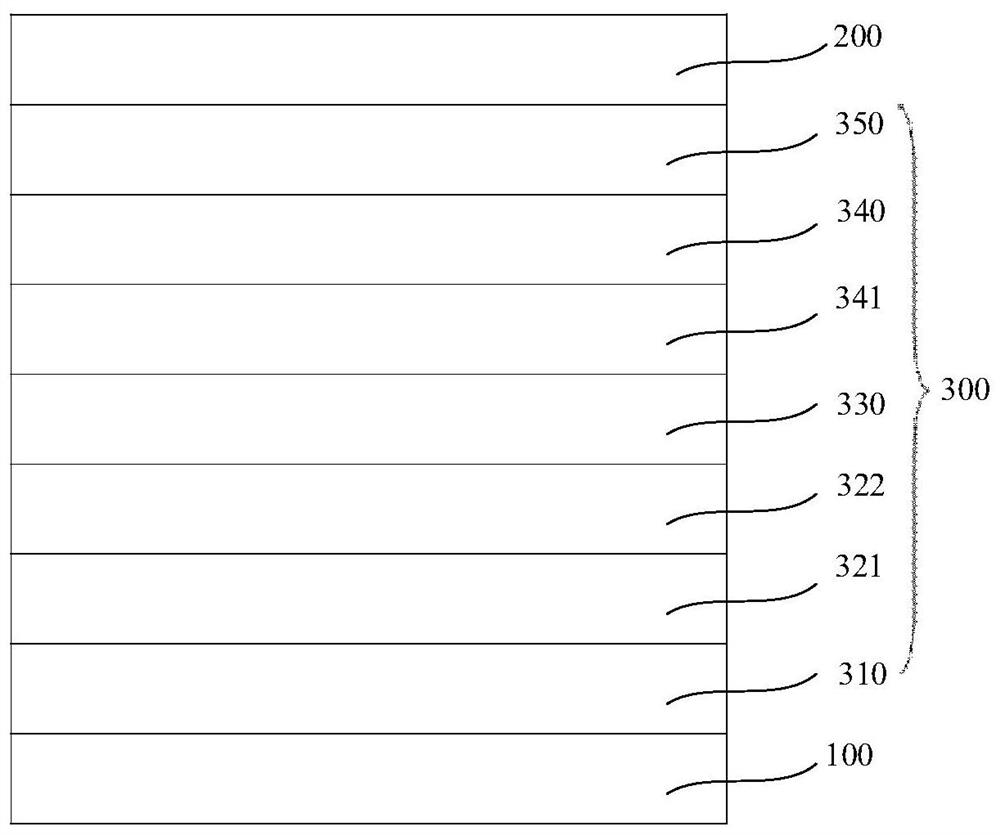

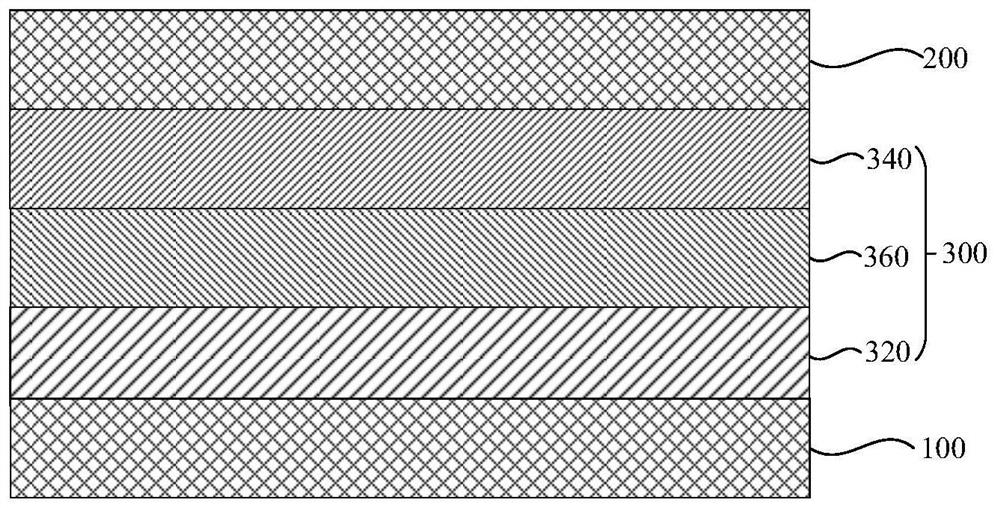

[0342] Embodiment 1 blue organic electroluminescent device

[0343] The anode was prepared by the following process: the thickness was The ITO substrate (manufactured by Corning) was cut into a size of 40mm × 40mm × 0.7mm, and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by using a photolithography process, using ultraviolet ozone and O 2 : N 2 Plasma surface treatment was performed to increase the work function of the anode (experimental substrate) and to remove scum.

[0344] F4-TCNQ was vacuum evaporated on the experimental substrate (anode) to form a thickness of The hole injection layer (HIL), and HT-01 is evaporated on the hole injection layer to form a thickness of hole transport layer.

[0345] Vacuum-deposit HT-02 on the hole transport layer to form a thickness of electron blocking layer.

[0346] On the electron blocking layer, BH-01 and BD-01 are co-evaporated at a ratio of 98%: 2%, forming a thickness of...

Embodiment 2~32

[0351] An organic electroluminescent device was prepared in the same manner as in Example 1, except that the compound shown in Table 11 below was substituted for Organic Compound 2 of the present application, except when forming the electron transport layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com