Cross-winding device for a textile machine which produces cross-wound bobbins

A traversing device and cross-winding technology, applied in the direction of transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve the problems of unfavorable effects of yarn material accumulation, adverse effects of unwinding characteristics, etc., and achieve spring characteristics smooth curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

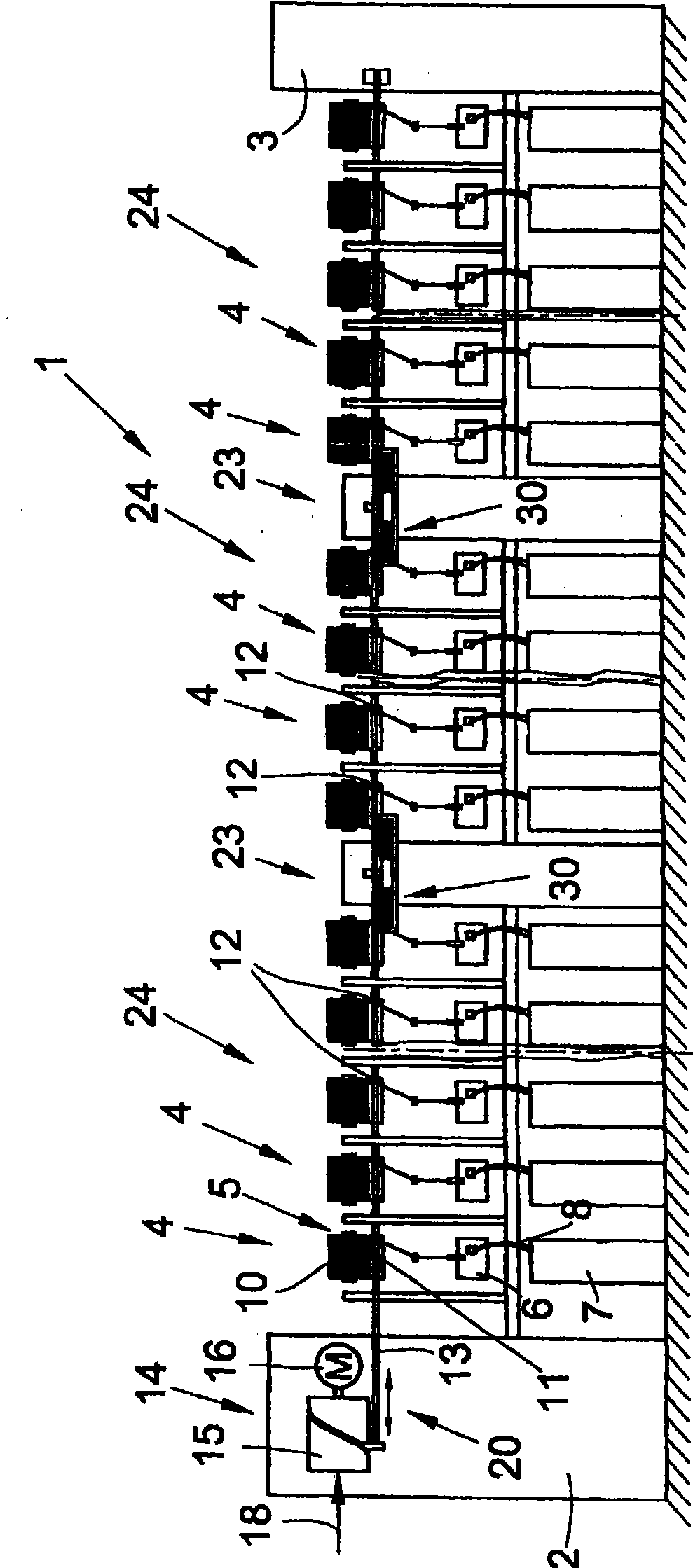

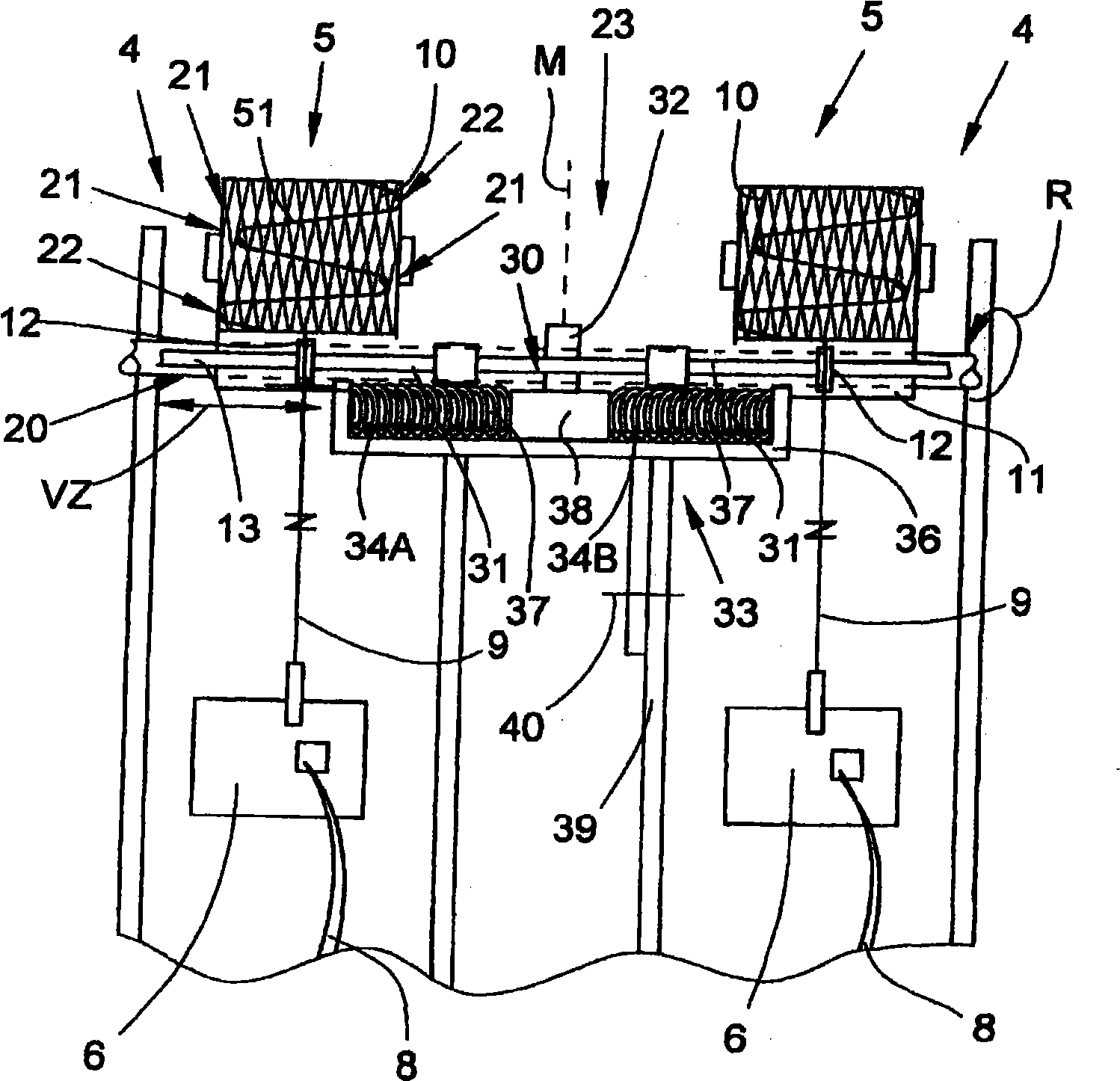

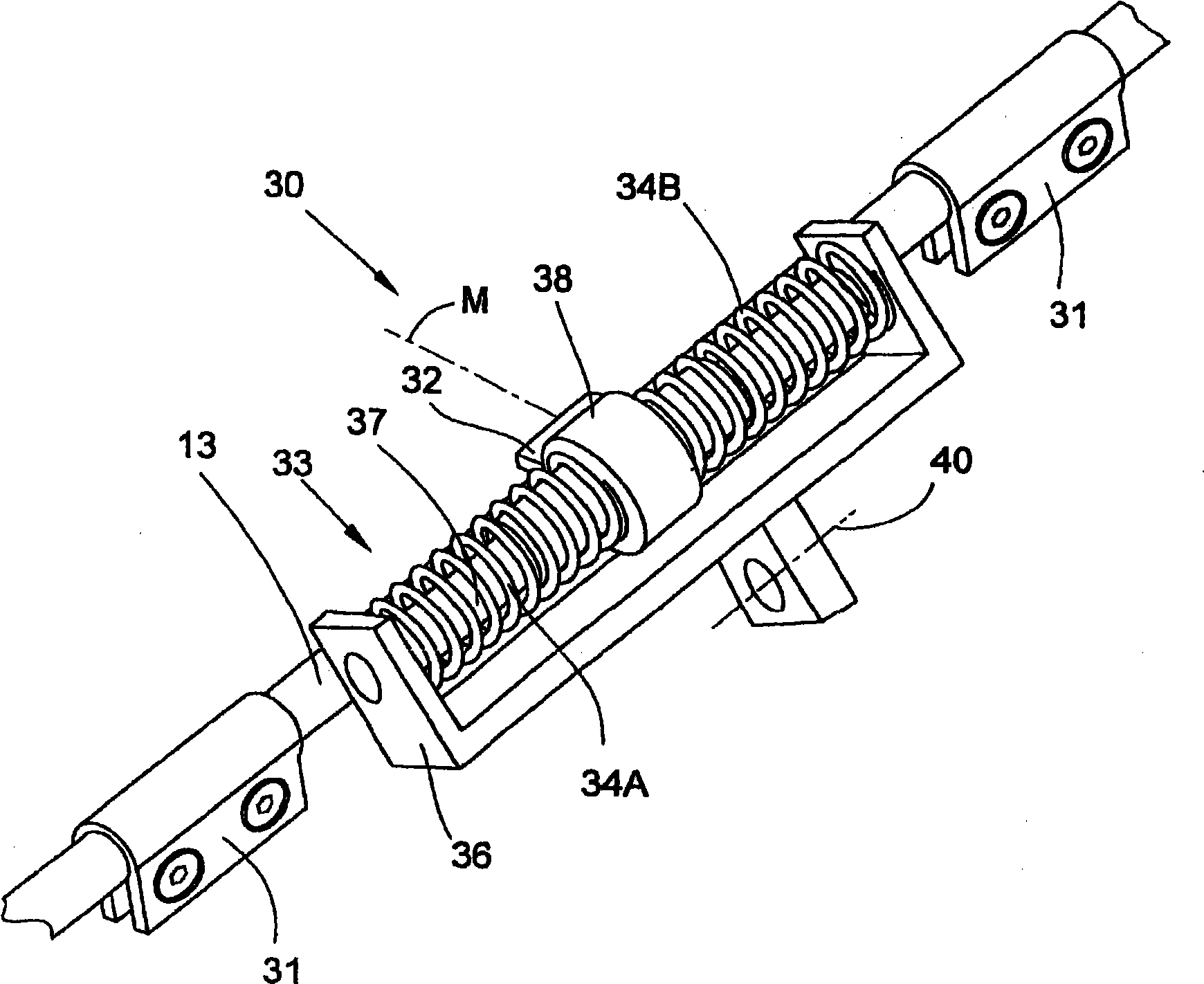

[0034] figure 1 The front view schematically shows a textile machine (in this example an open-end rotor spinning machine) for manufacturing cross-winding bobbins. Such a textile machine 1 generally has end frames 2 , 3 and a plurality of work stations 4 arranged between the end frames 2 , 3 . Here, the individual workstations 4 are arranged in sections, ie, for example, 24 workstations 4 form a machine section 24 , of which 12 are arranged at the machine front and 12 at the machine rear. The machine segments 24 are each mounted on a machine support 39 in the region of their segment boundaries 23 .

[0035] Each station 4 has an open-end spinning device 6 and a winding device 5, wherein the fiber sliver 8 provided in the spinning barrel 7 is converted into a yarn 9 in said spinning device 6, and then the yarn 9 A cross bobbin 10 is wound on the winding device 5 . Here, the crosswinding drum 10 is held rotatably in a creel, not shown, and is rotated by means of a drive roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com