Method and device for reducing feedwater dissolved oxygen of CCPP waste heat boiler

A waste heat boiler, dissolved oxygen technology, applied in separation methods, feed water heaters, chemical instruments and methods, etc., can solve the problems of large amount of fresh water replenishment, lax steam condensation and return water system, and excessive dissolved oxygen in feed water. The effect of avoiding the danger of burst pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

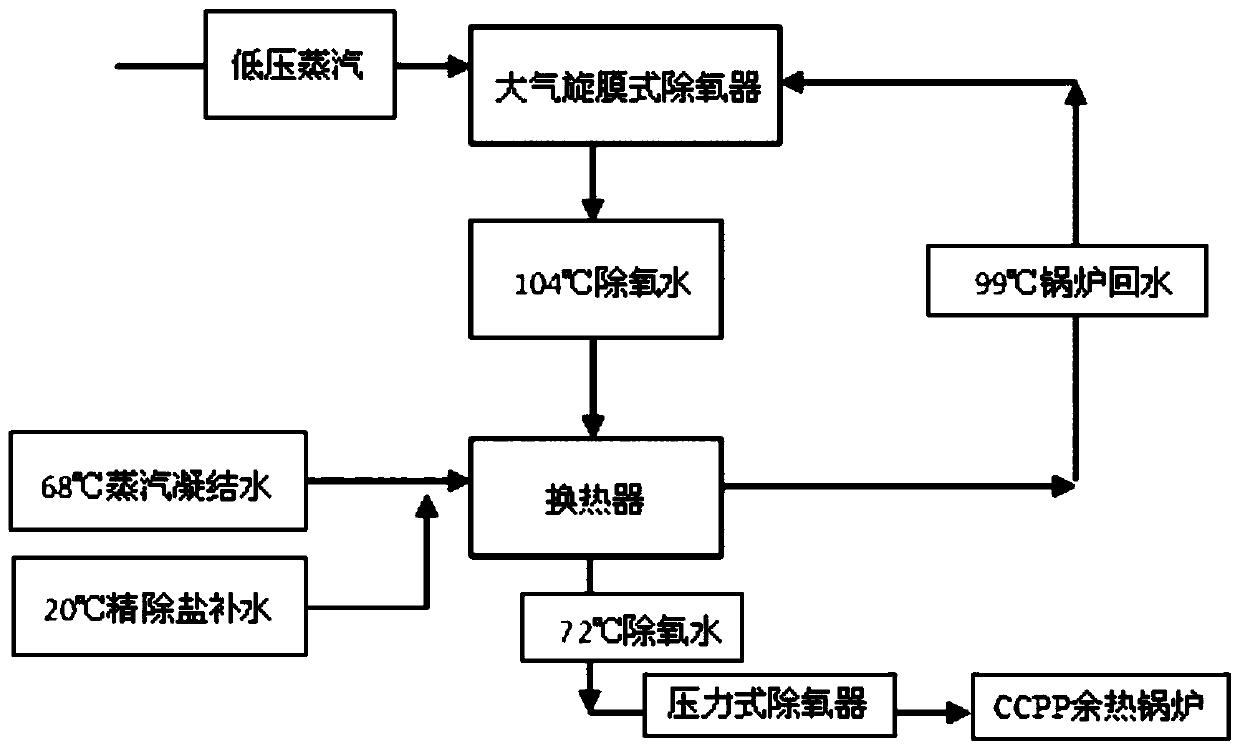

[0029] In this example, a method for reducing dissolved oxygen in CCPP waste heat boiler feed water is applied to a CCPP waste heat boiler equipped with a pressure deaerator. The process requirement for dissolved oxygen at the inlet of the pressure deaerator is below 50 μg / L. Boiler return water includes steam turbine generator exhaust or extraction, steam condensate at 68°C (the fifth temperature is 60°C to 70°C) obtained after heat exchange by users such as seawater desalination and heat exchange stations, and 20°C (the fifth temperature is 60°C to 70°C) steam condensate Sixth, the temperature is normal temperature, about 15°C to 25°C) The refined desalinated water is used as boiler make-up water.

[0030] see figure 1 , the method for reducing dissolved oxygen in CCPP waste heat boiler feed water comprises the following steps:

[0031] The boiler return water at the first temperature (about 20°C-68°C) is heated to the second temperature (about 99°C) through the heat exchan...

Embodiment 2

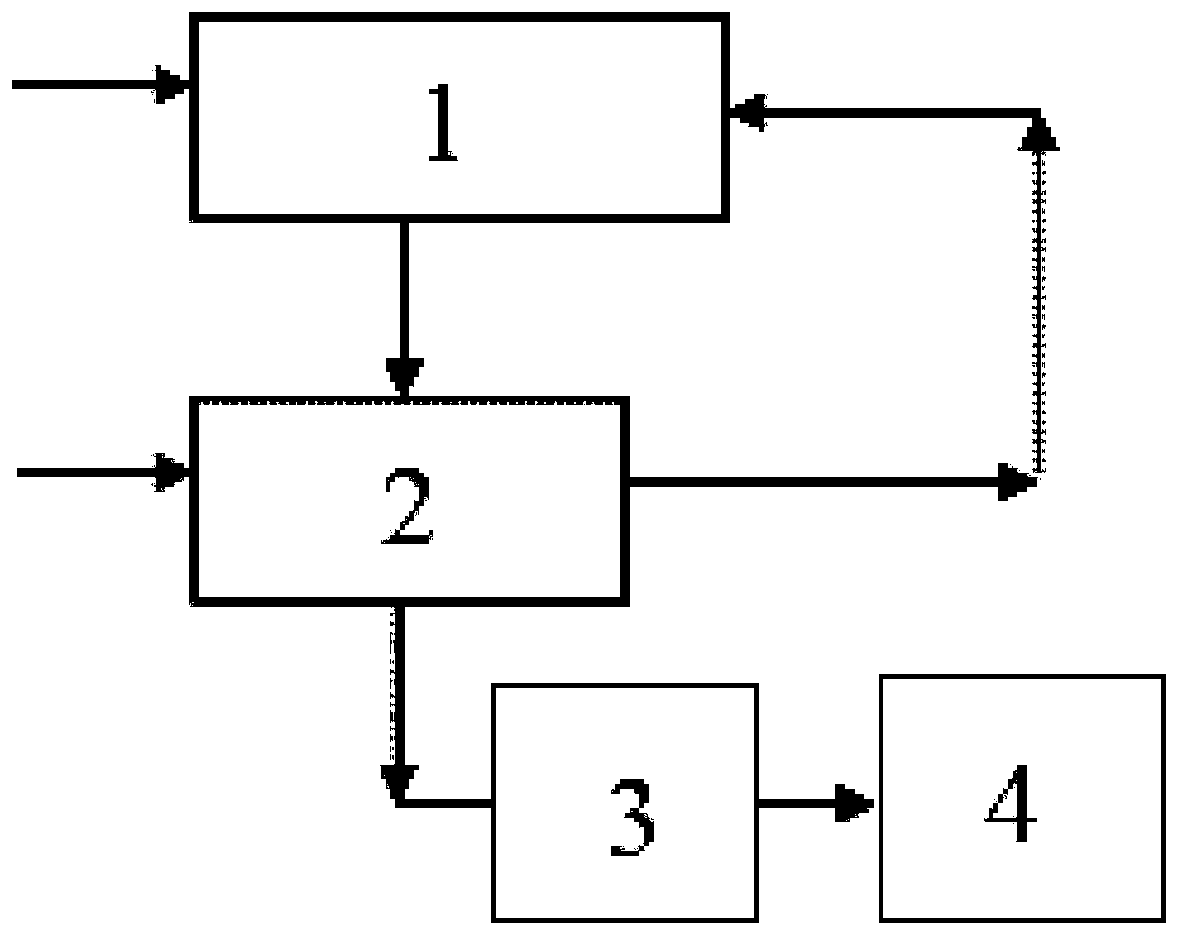

[0037] Based on the same inventive concept, the present invention provides a device for reducing dissolved oxygen in CCPP waste heat boiler feed water, see figure 2 , the device includes a heat exchanger 2, a first deaerator 1 and a second deaerator 3, wherein: the cooling water outlet of the heat exchanger 2 communicates with the water inlet of the first deaerator 1, and the first deaerator The water outlet of 1 is connected with the heat medium inlet of the heat exchanger 2, the heat medium outlet of the heat exchanger 2 is connected with the water inlet of the second deaerator 3, and the water outlet of the second deaerator 3 is connected with the CCPP waste heat boiler.

[0038] The first deaerator 1 can be an atmospheric cyclone membrane deaerator or a pressure deaerator. Considering the high cost of the pressure deaerator and the requirement for dissolved oxygen in the feed water, in this embodiment, the first deaerator Oxygenator 1 adopts large cyclonic membrane deaera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com