Method and apparatus for operating a textile machine which produces crosswound bobbins

A cross-winding, textile machine technology, applied in the field of textile machine devices, can solve the problems of distinguishing, only considering the entry sequence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

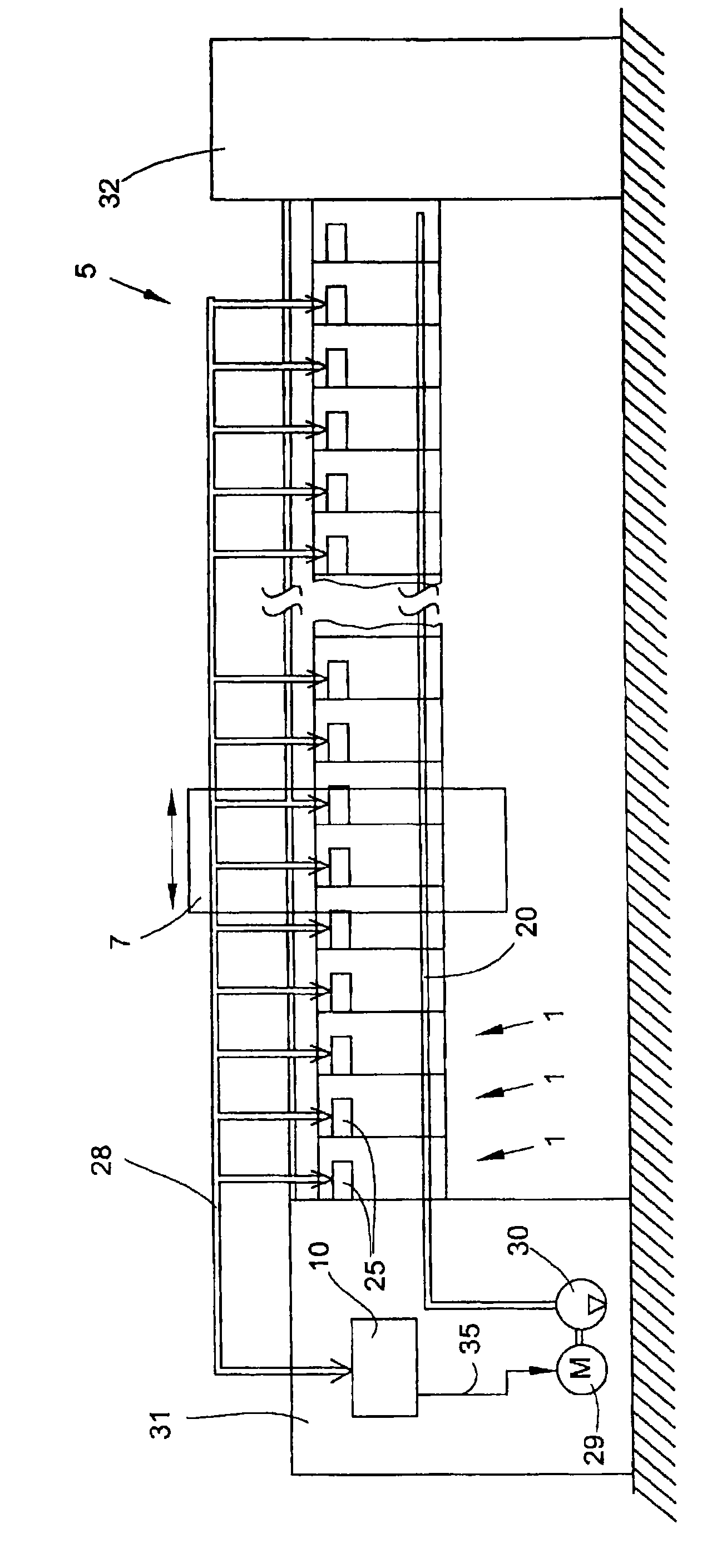

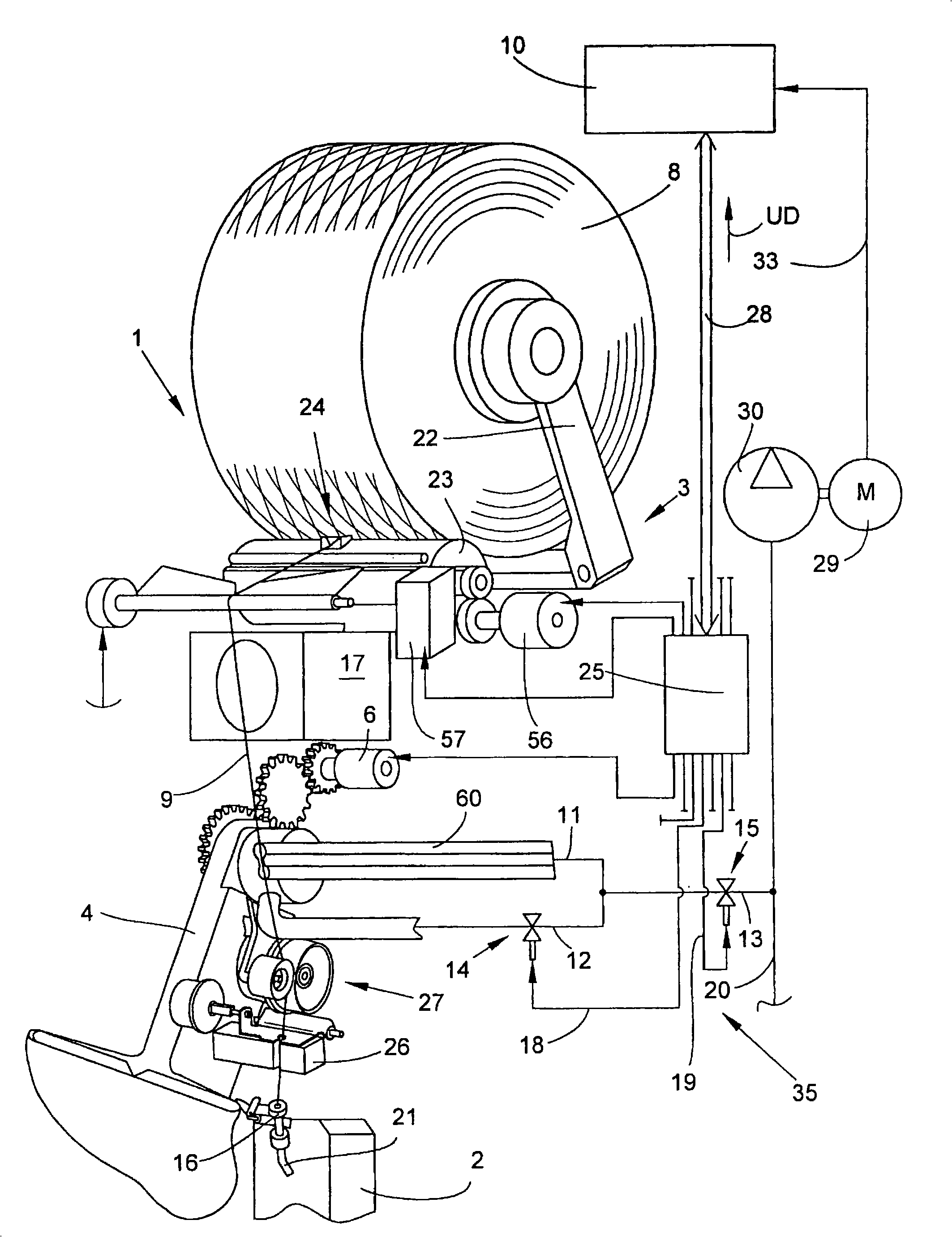

[0029] figure 1 The front view schematically shows a textile machine for producing cross-winding bobbins, in this embodiment an open-end rotor spinning machine 5 . This textile machine has a plurality of identical stations 1 between its end frame 31,32, will combine below figure 2 These stations 1 are further described.

[0030] The vacuum source 30 of the machine's own suction system 20 is arranged in one of the end frames of the free-end rotor spinning machine 5 . The vacuum source 30 is driven here by an electric motor drive 29 whose rotational speed can be adjusted in a predetermined manner by means of a frequency converter. Such as figure 1 As shown in , for this purpose the drive 29 or the associated frequency converter is connected via a control line 33 to the central control unit 10 of the textile machine 5 . Such as figure 1 As further shown, the central control unit 10 is also connected to each control device 25 of a plurality of workstations 1 via a bus system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com