Sealing assembly and pump with a sealing assembly

A sealing device and sealing element technology, which is applied to the components of the pumping device for elastic fluid, the sealing of the engine, the pump, etc., to achieve the effect of firm sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

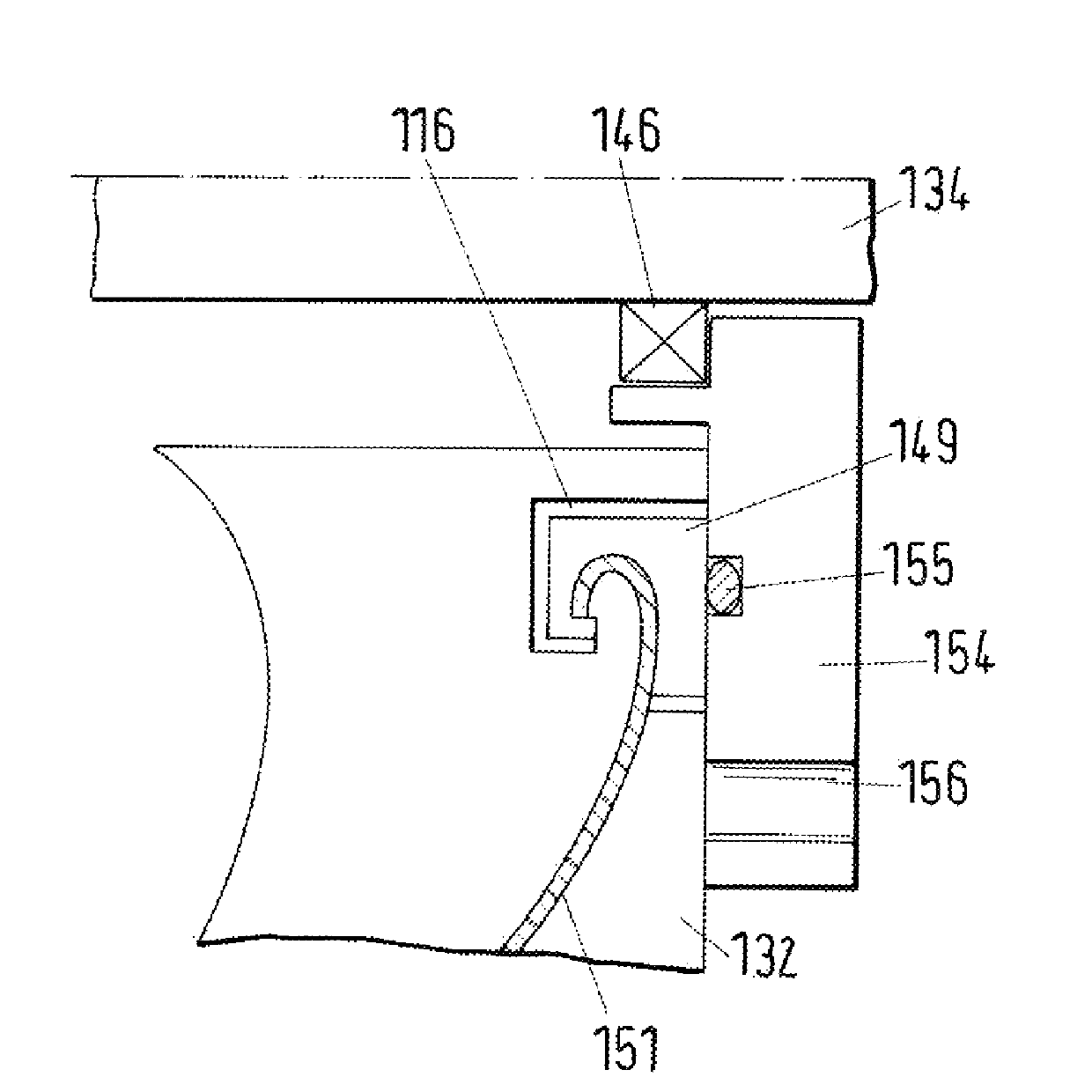

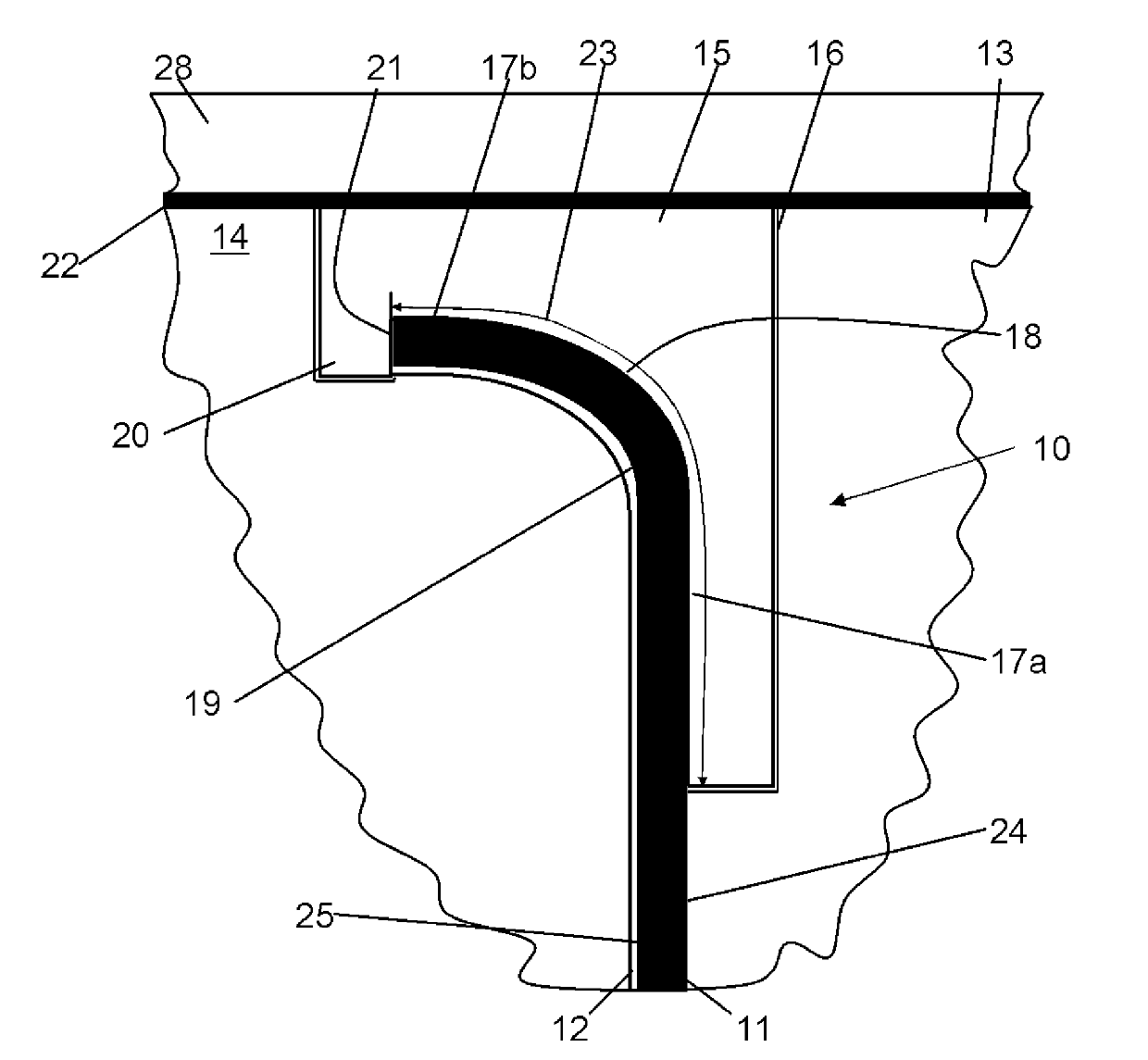

[0031] according to figure 1 The sealing device 10 has an elongated flexible sealing element 11 in the form of an endless rope, which is made of elastomer. The sealing element 11 is arranged in the groove 12 of the planar surface 14 of the first member 13, which is only partially shown. The plane surface 14 is opposite to the first member 13 in the installed state figure 1 The second member not shown in the figure forms a flat contact surface.

[0032] Furthermore, the sealing device 10 has an end element 15 which is arranged in a cutout 16 of the plane surface 14 of the first member 13. Likewise, the end element 15 is made of elastomer, wherein it is designed to be harder than the sealing element 11. The cut 16 is not deep enough so that the tip 16 can be completely received therein. During installation figure 1 For the second element not shown in, the end element 15 is slightly compressed for this reason. Therefore, it performs the sealing function between the two components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com