High-temperature pyrolysis incineration equipment

A high-temperature pyrolysis and equipment technology, used in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of insufficient combustion and high use cost of low-temperature pyrolysis incineration equipment, and achieve high temperature and block black smoke, moving Convenient, full-burning and complete results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

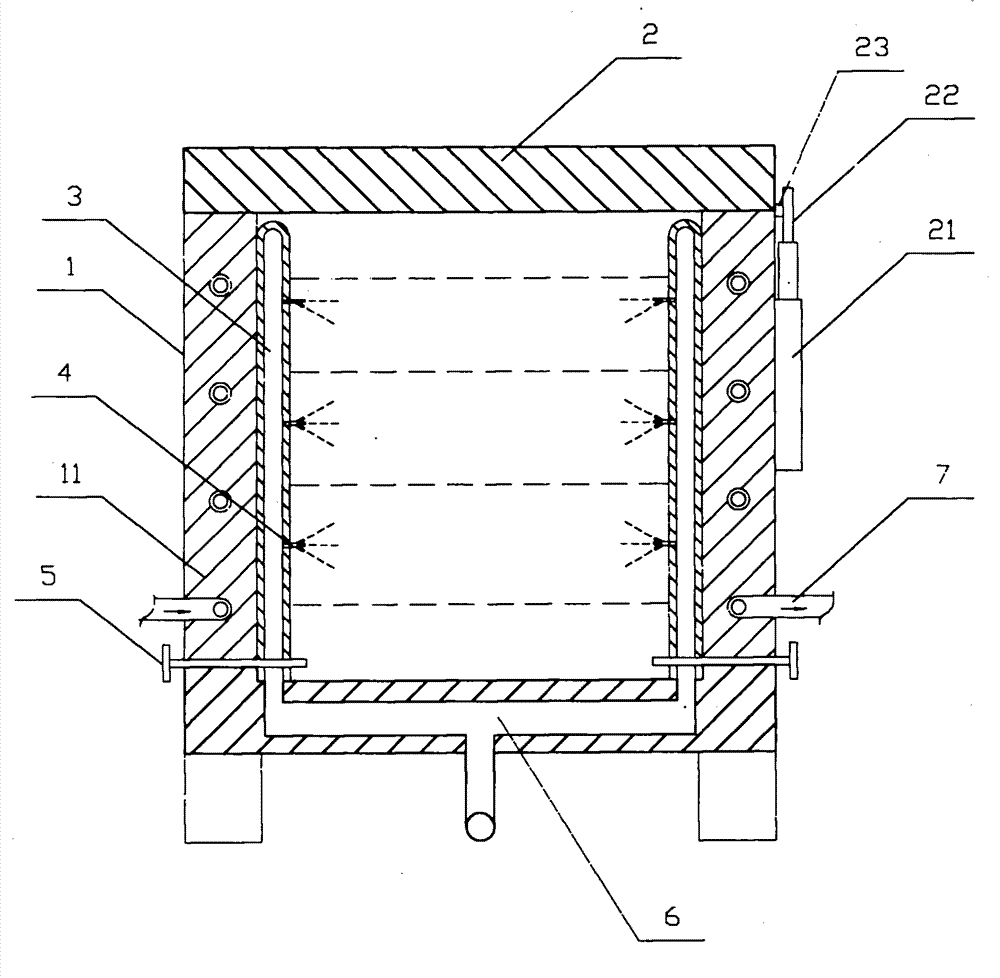

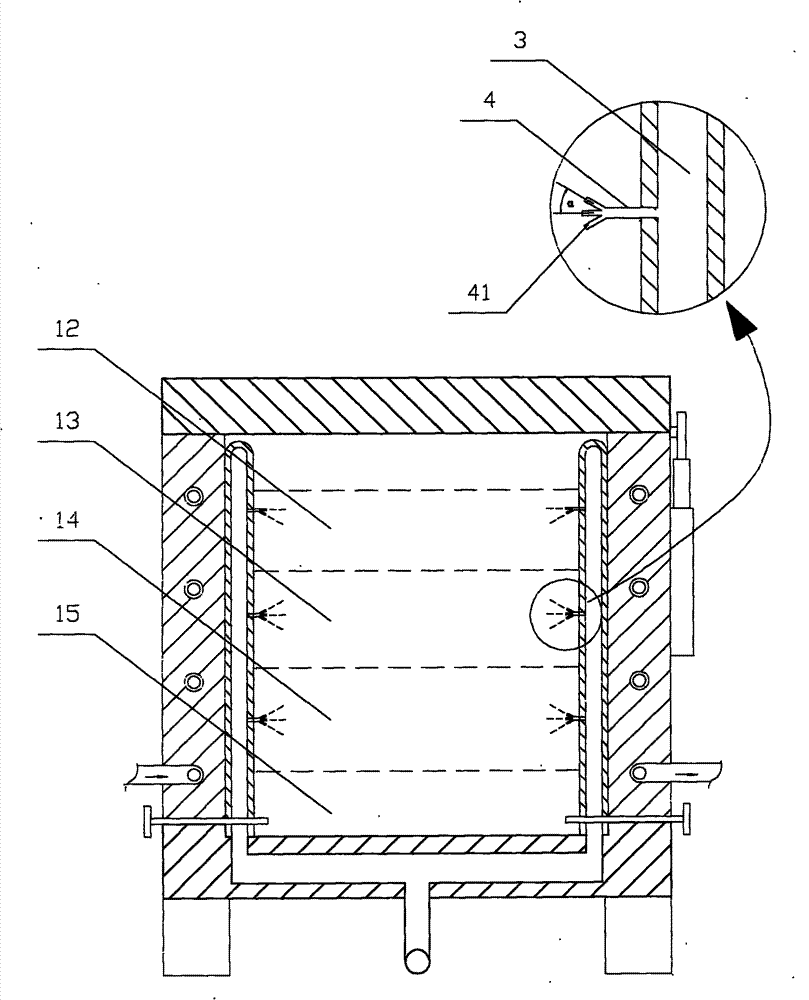

[0026] Embodiment 1: A kind of high-temperature pyrolysis incineration equipment of this embodiment 1 is used for high-temperature treatment of pollution-free organic matter, such as figure 1 and figure 2 As shown, it includes a combustion chamber 1 for accommodating and incinerating the processed objects. The combustion chamber is surrounded by double double insulation walls 11, and a heat dissipation pipe 9 surrounding the entire combustion chamber is embedded in the double insulation wall. The heat dissipation pipe is externally connected with a waste heat recovery device for the production of hot water or heating gas; a top cover 2 is installed on the upper part of the combustion chamber for putting in the processed objects and exporting the exhaust gas, and a top cover opening device is designed on the top cover And the heat flow prevention device of the combustion chamber, the top cover opening device includes a jacking cylinder 21, a conversion bracket 22 and a rotatin...

Embodiment 2

[0029] Embodiment 2: A kind of high-temperature pyrolysis incineration equipment in this embodiment 2 includes a combustion chamber for accommodating and incinerating the processed objects. Two rows of air supply pipes are installed in the combustion chamber and are attached to the wall. Each There are three nozzles installed on the branch air duct, and several nozzles are designed on the nozzles. The angle α between the nozzle axis and the nozzle axis is 30°. The number of nozzles on the top nozzle is three, and the directions of the three nozzles are respectively front , left and downward, forming a horizontal left and downward airflow, the number of nozzles in the middle nozzle and the bottom nozzle is five, and the nozzles evenly surround the axis of the nozzle, and the five nozzles are directed upward, downward, left, right, Straight ahead, a radially dispersed airflow is formed, and the top nozzles on the multiple air supply pipes facing each other in the combustion chamb...

Embodiment 3

[0030] Embodiment 3: A high-temperature pyrolysis incineration equipment of this embodiment 3 is used for high-temperature treatment of pollution-free organic matter, including a combustion chamber for accommodating and incinerating the processed objects, and a combustion device and an air supply device are installed in the combustion chamber , the air supply device is also designed with a heat exchanger, the low-temperature side of the heat exchanger is connected to the air inlet main pipe, the high-temperature side of the heat exchanger is connected to the flue gas outlet part of the top cover, and the high-temperature flue gas and the low-temperature inlet air perform wall heat exchange , the inlet air temperature is improved, and the temperature in the combustion chamber can be kept from falling while the air is supplied for combustion, so that the incineration in the combustion chamber is more complete and thorough, the processing speed is accelerated, and precious energy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com