Hazardous waste incineration flue gas treatment system and hazardous waste incineration flue gas treatment method

A hazardous waste and incineration flue gas technology, which is applied in the field of hazardous waste incineration flue gas treatment and hazardous waste incineration flue gas treatment system, can solve the problems of heater flue gas corrosion, flue gas heat loss, and high processing costs, and reduce emissions Concentration, increase the inlet air temperature, reduce the effect of oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0038] The hazardous waste incineration flue gas treatment system of the present invention is used for treating the flue gas produced by the rotary kiln incinerating hazardous waste, recovering heat from the flue gas and removing harmful substances therein.

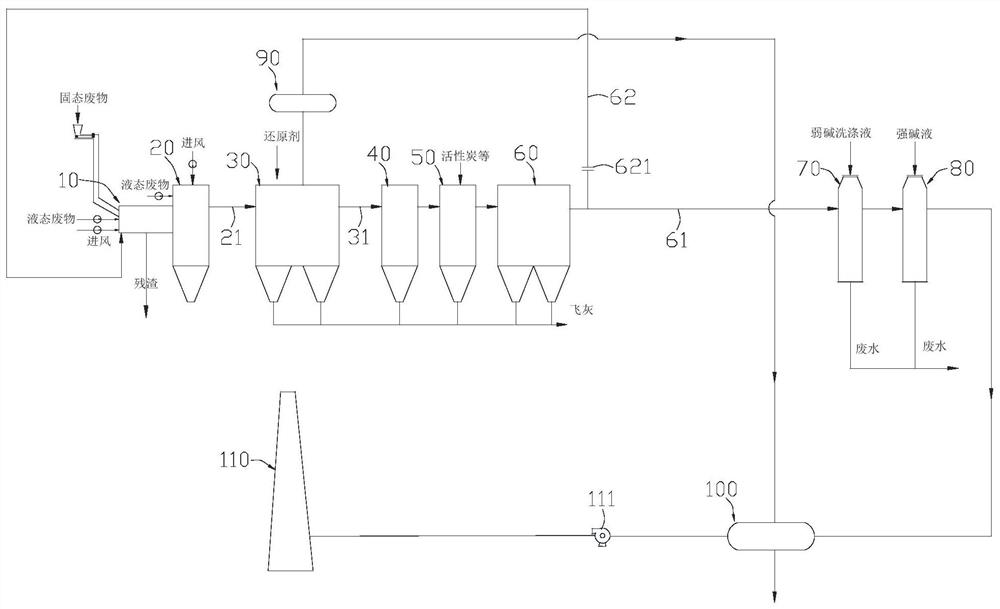

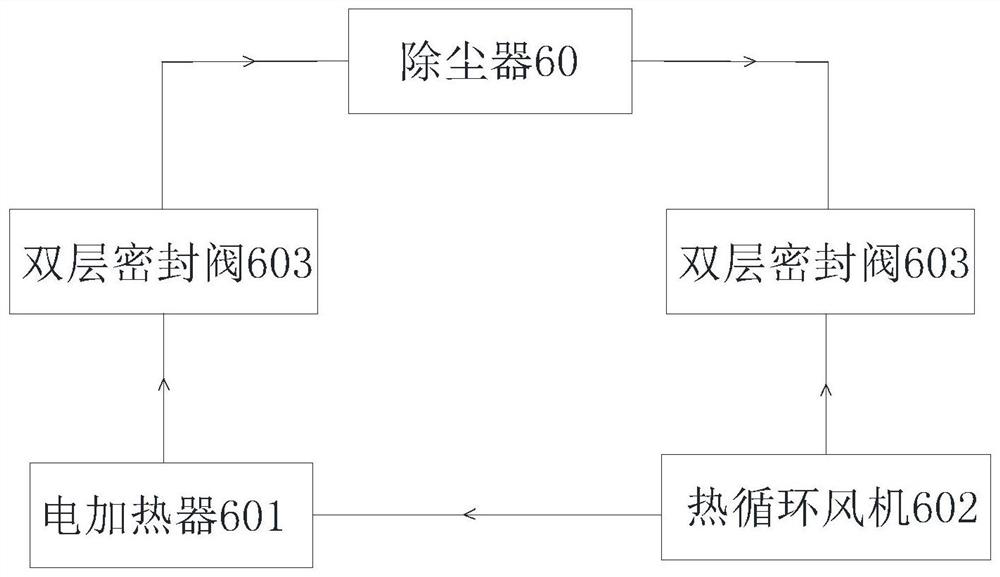

[0039] Such as figure 1 As shown, the hazardous waste incineration flue gas treatment system according to an embodiment of the present invention includes a rotary kiln 10, a secondary combustion chamber 20, a waste heat boiler 30, a rapid cooling tower 40, and a dry deacidification tower 50 sequentially connected along the direction of progress of the flue gas. , dust collector 60, washing tower 70 and wet deacidification tower 80.

[0040] Among them, the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com