Steam exhaust cooling system of driving steam turbine of thermal power plant and thermal power unit

A technology for driving steam turbines and cooling systems, which is applied in steam engine installations, machines/engines, steam/steam condensers, etc., to achieve the effects of improving utilization, increasing cold air temperature, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

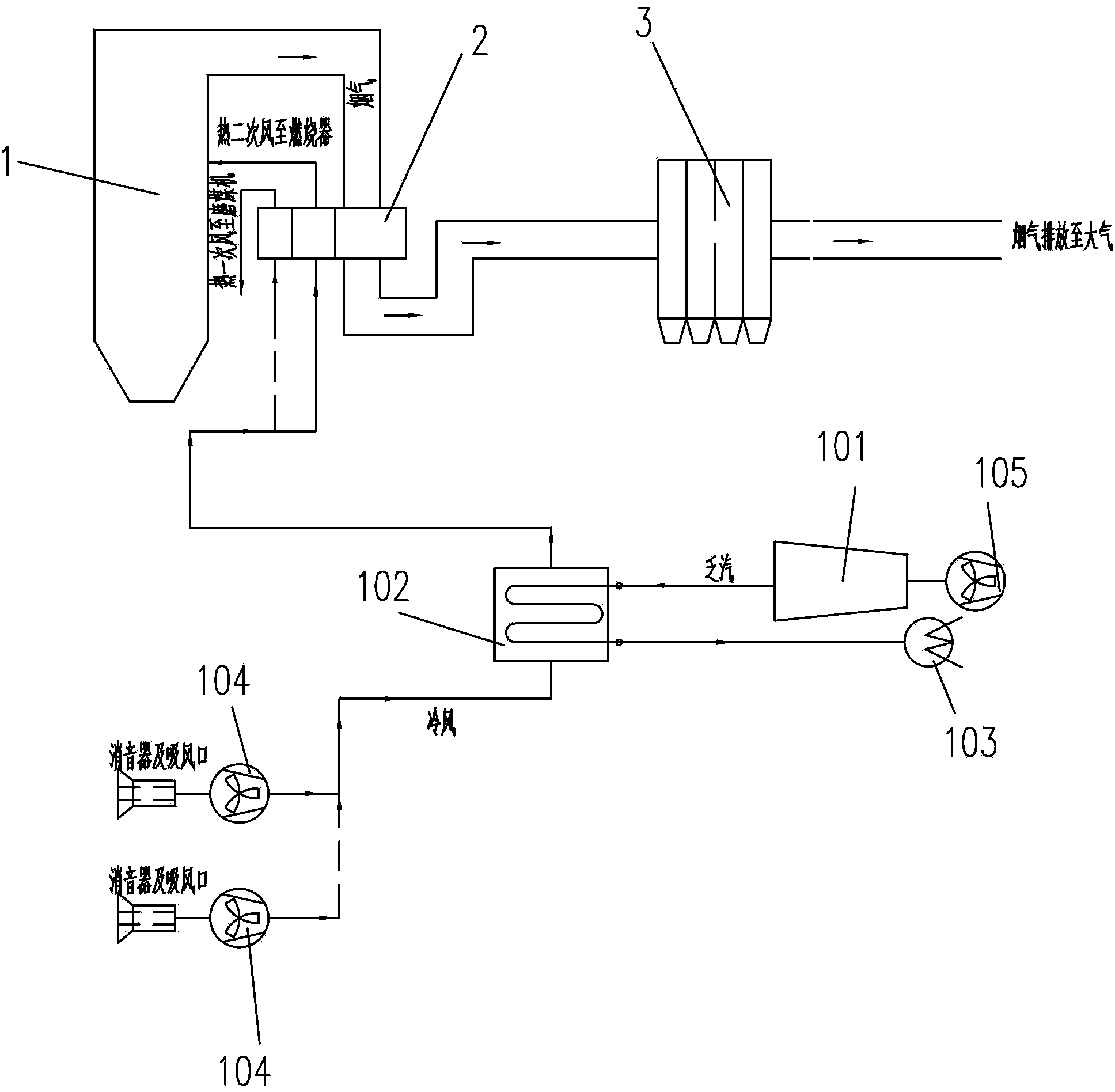

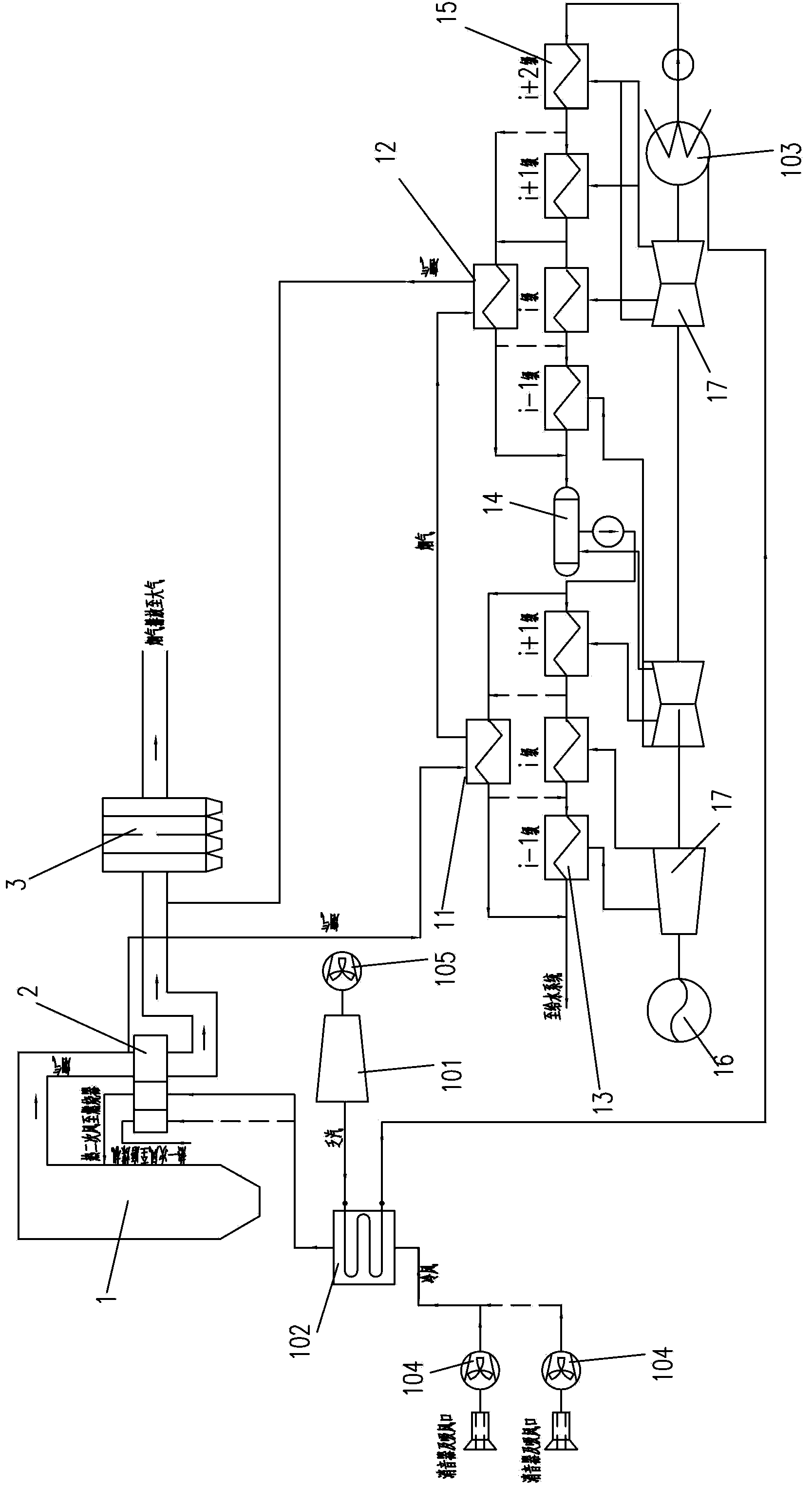

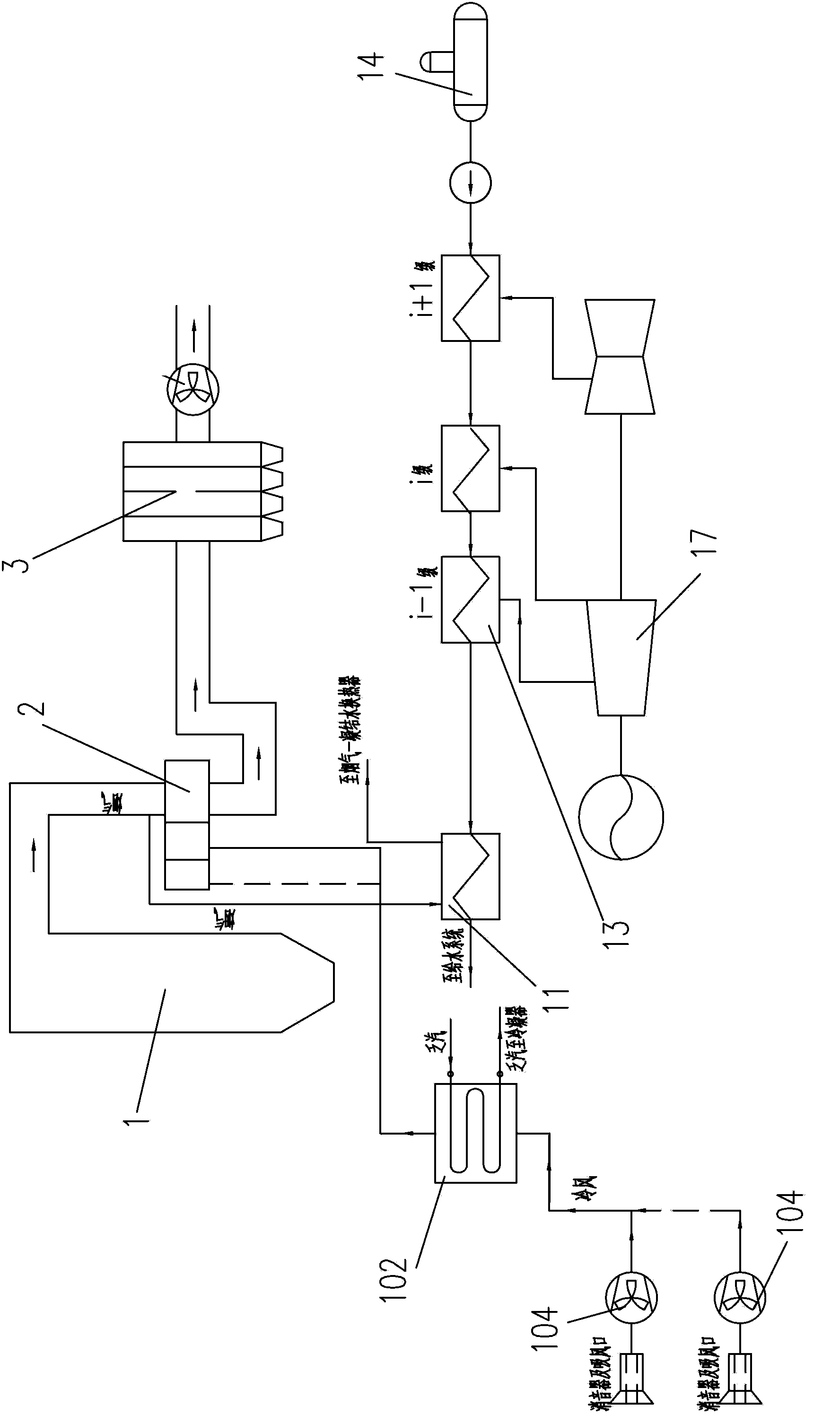

[0056] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention. The same or similar parts in the figures are denoted by the same reference numerals.

[0057] Hereinafter, main technical terms of the present invention will be described.

[0058] Herein, the boiler mainly includes a boiler device. The boiler device is not specifically limited, as long as it does not limit the purpose of the present invention, it is known to those skilled in the art. It can use π-type boilers (or Pai-type boilers), tower boilers, inverted U-shaped boilers, etc., coal-fired boilers, oil-fired boilers, etc., natural circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com