Quick-hardening cementing material as well as preparation method and application thereof

A cementitious material and rapid hardening technology, used in construction, building maintenance, building construction, etc., can solve the problems of long repair cycle, high heat generation of resin materials, and reduced durability performance, and achieve small strength loss in the later stage, condensation and hardening. The effect of fast speed and increased coagulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

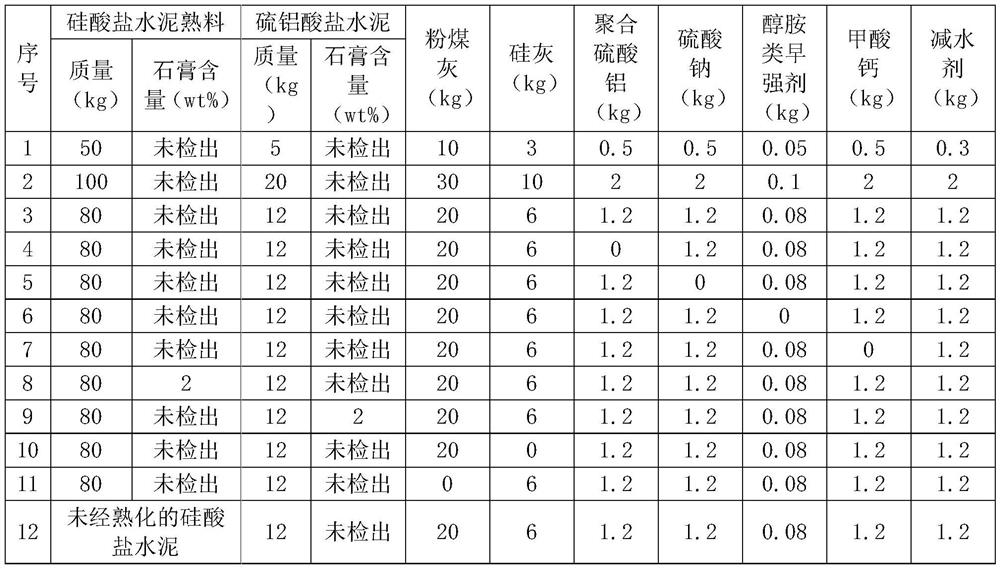

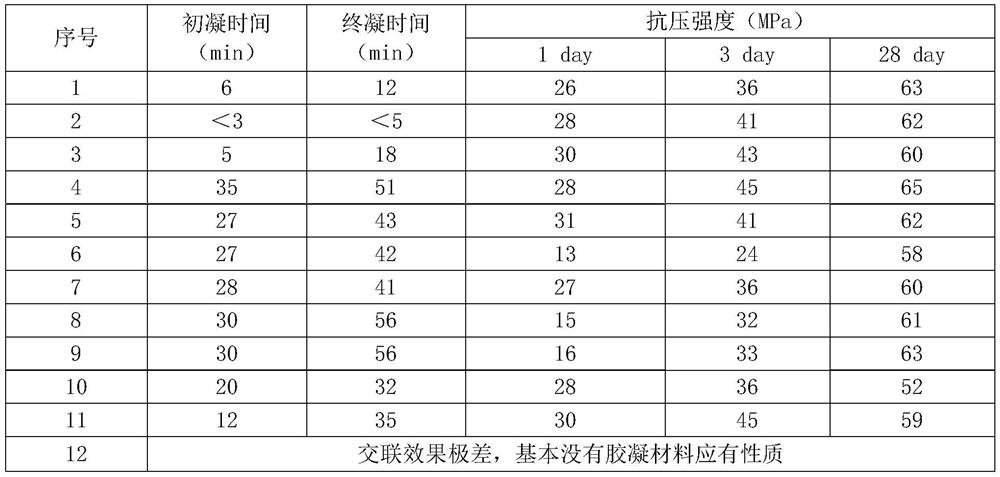

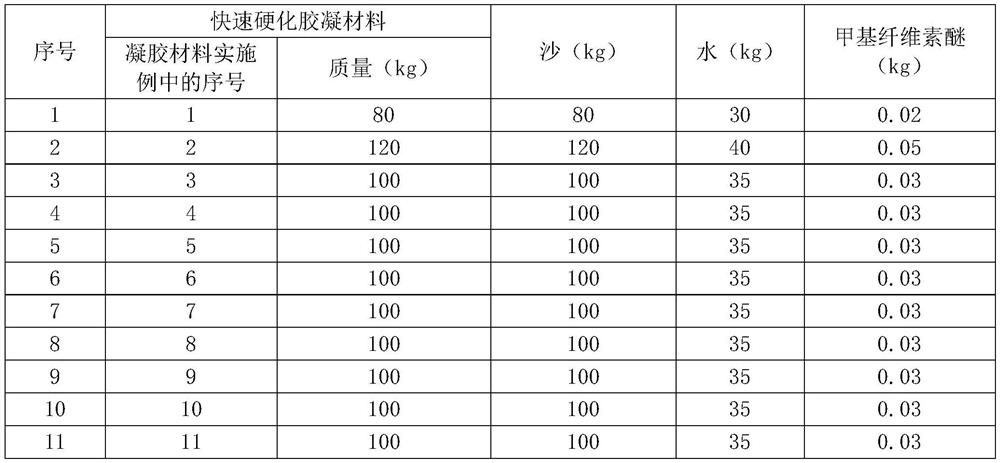

[0025] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0026] The core of this application is the formula and preparation method of the fast-hardening gelling material. In the first embodiment, it is mainly described. Since the efficacy of the formula can only be tested or detected after the formula is prepared, this embodiment Clarified in the form of a method:

[0027] The raw materials used in the rapid hardening cementitious materials have the following requirements:

[0028] The fly ash is Class I fly ash or Class II fly ash, the water demand ratio is ≤95%, and other physical and chemical performance indicators should meet the national standard "Used for Fly Ash in Cement and Concrete" (GB / T 1596- 2017) requirements; the specific surface area of the silica fume is not less than 20000m 2 / kg, the activity index is not less than 85%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com