Condensation type demister having vanes with non-uniform wettability and preparation method of vanes

A wettability and non-uniform technology, which is applied in the energy-saving device for eliminating liquid droplets and fine particles in wet flue gas, the preparation of condensing demisters and blades, and the field of eliminating white smoke in wet flue gas, so as to achieve less power consumption, Reduction of heat dissipation and significant energy-saving advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

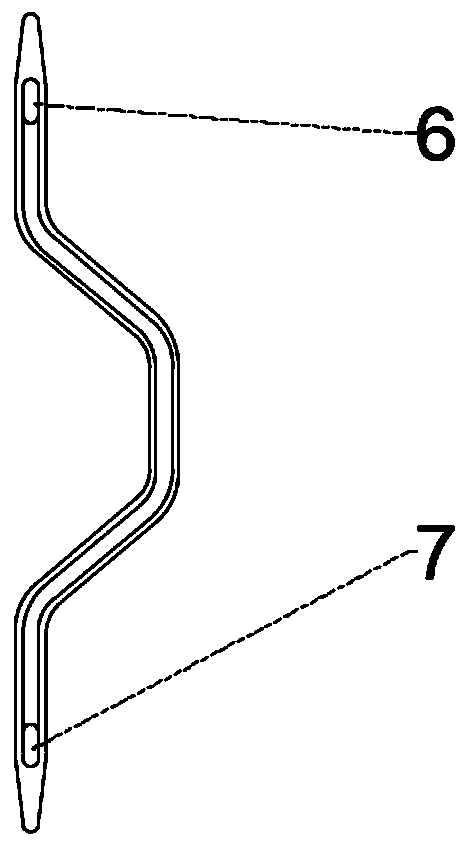

[0052] A method for preparing blades with non-uniform wettability, comprising the following steps:

[0053] Step 1. Cleaning: Rinse the aluminum blade with ethanol solution and deionized water to remove oil and floating dust on the surface, and then dry it for later use.

[0054] Step 2. Fabricate a rough structure on the exposed surface of the blade not covered by the mask:

[0055] Cover the dried blade with the mask plate with the designed pattern, soak the blade covered with the grinding plate in a NaOH solution with a temperature of 40 ° C and a concentration of 0.5 mol / L for 1 hour, take it out, and wash it with ethanol solution and deionized water Soak and clean the leaves, then soak the leaves in a hot water pool at 95°C for 2 hours, take them out and dry them.

[0056] Step 3, grafting low surface energy substances onto the surface of the rough structure:

[0057] After immersing the dried leaves in a 1% fluorosilane ethanol solution at a temperature of 50°C for 1 h...

Embodiment 2

[0061] A method for preparing blades with non-uniform wettability, comprising the following steps:

[0062] Step 1. Grind the stainless steel blade with sandpaper from small to large meshes to remove the oxide layer, then rinse with ethanol solution and deionized water to remove oil and floating dust on the surface, and then dry it for later use.

[0063] Step 2. Cover the dried leaves with the mask plate with the designed pattern, use HGL laser processing equipment, the working voltage is 220V, the focal length can be adjusted in the range of 140-180mm, the output current is 11-12A, and the diameter of the irradiation spot is 20 -30μm, the processing method is diamond-shaped grid linear processing, and the processing distance is 120μm.

[0064] Step 3. Put the blades into ethanol and pure water for ultrasonic cleaning for 5 minutes in order to remove impurities produced by laser processing. Afterwards, the cleaned leaves were immersed in a 3% stearyl mercaptan solution for 2...

Embodiment 3

[0067] A method for preparing blades with non-uniform wettability, comprising the following steps:

[0068] Step 1. Wash the titanium blades by immersing them in a low-concentration acid solution for 15 minutes to remove natural oxides and impurities on the surface, then rinse them with ethanol and deionized water in sequence to remove oil and floating dust on the surface, and then dry them for later use.

[0069] Step 2. Tightly cover the mask plate with the designed pattern on the surface of the blade, and vertically immerse it in the 0.05mol / L NaOH electrolyte solution as the anode, use the platinum plate as the cathode facing the mask blade, adjust the current and electrolysis Time to prepare micro-nano structures.

[0070] Step 3. Put the anodized leaves into ethanol and pure water for ultrasonic cleaning for 5 minutes, then dry them, then put them into a magnetron sputtering machine and fix them. The sputtering target material is polytetrafluoroethylene, and the sputteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com