Inflatable thermoforming process of boron steel pipe

A hot forming and steel pipe technology, applied in the high-pressure gas bulging and quenching process of boron steel pipes at high temperature, and in the field of gas expansion thermoforming technology, it can solve the problem of limited strength of pipe fittings, limited product shape, and difficulty in exceeding 1000MPa in tensile strength and other problems, to achieve the effect of increasing the elongation rate and reducing the forming force of the press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: The inflation thermoforming process of the boron steel pipe, the material of the boron steel pipe is: boron steel 22MnB5, the material thickness is 2.6mm, the outer diameter of the equal section is 100mm, and the length is 850mm;

[0051] The above-mentioned workpieces are specifically processed through the following steps:

[0052] 1. Boron steel straight pipe preparation, material thickness 2.6mm, outer diameter 100mm, length 1000mm;

[0053] 2. Heating to 900°C in the heating device to completely austenitize the boron steel pipe;

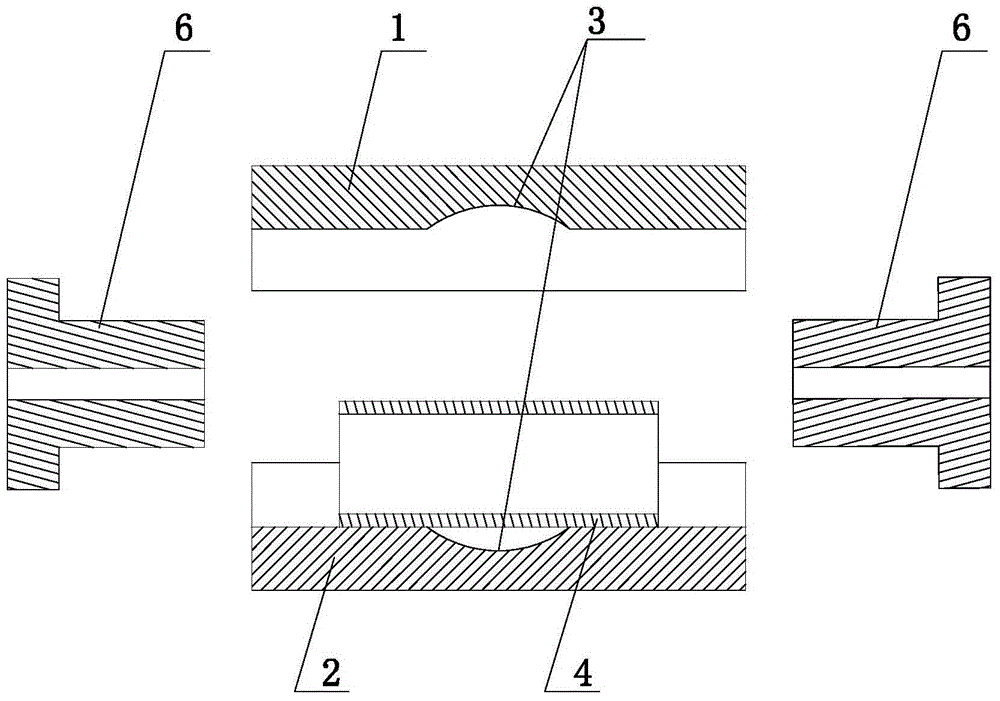

[0054] 3. If Figure 1a As shown, the boron steel pipe material is placed in the mold within 6 seconds, the initial opening height of the press is 800mm, and it is closed and formed at a speed of 300mm / s;

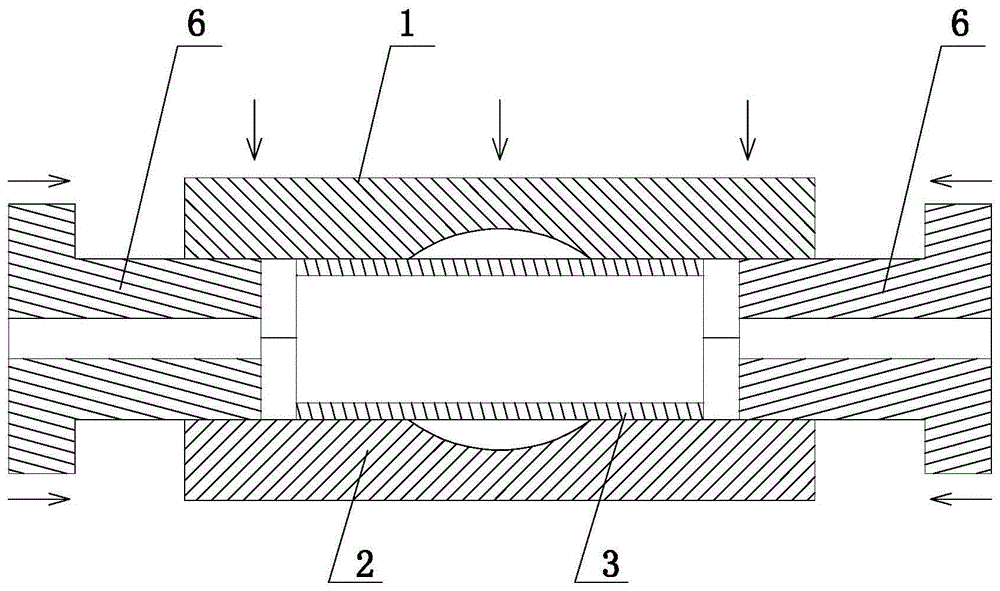

[0055] 4. If Figure 1b As shown, the axial cylinders on both sides of the mold push the front head to seal the pipe fittings to form a closed cavity;

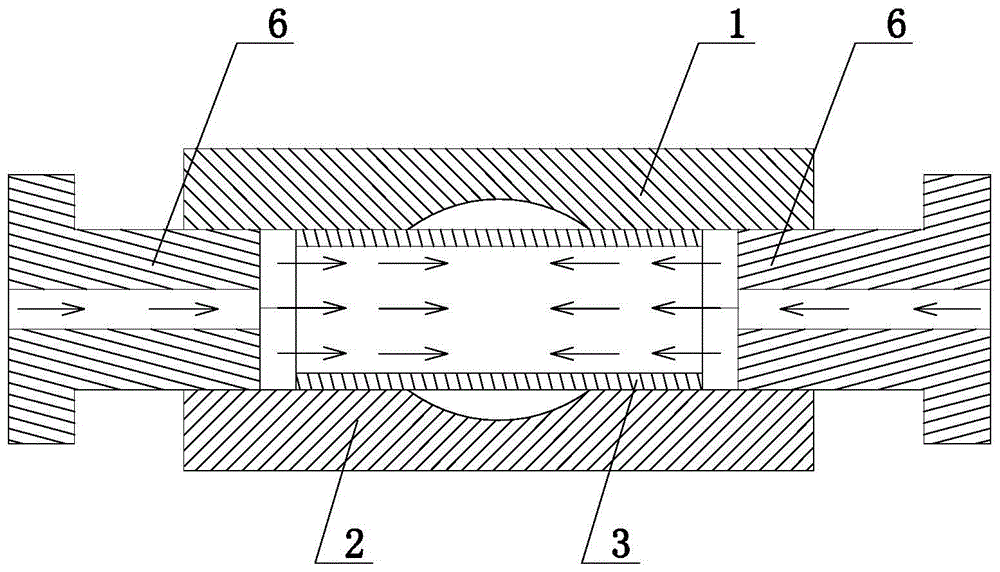

[0056] 5. If Figure 1c , Figure 1d , Figure 1e As shown, th...

Embodiment 2

[0060] Embodiment 2: The inflation thermoforming process of the boron steel pipe, the material of the boron steel pipe is boron steel 22MnB5, the material thickness is 2mm, the cross-sectional outer diameter is 129.94-133.17mm, and the developed length is 1050mm.

[0061] The above-mentioned workpieces are specifically processed through the following steps:

[0062] 1. Boron steel straight pipe preparation, material thickness 2.0mm, pipe outer diameter 130mm, length 1200mm;

[0063] 2. Heating to 900°C in the heating device to completely austenitize the boron steel pipe;

[0064] 3. If Figure 1a As shown, the boron steel pipe material is placed in the mold within 6 seconds, the initial opening height of the press is 800mm, and it is closed and formed at a speed of 300mm / s;

[0065] 4. If Figure 1b As shown, the axial cylinders on both sides of the mold push the front head to seal the pipe fittings to form a closed cavity;

[0066] 5. If Figure 1c , Figure 1d , Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com