Production device of heat molding and water cooling process of uniform-section boron steel pipes

A production equipment and thermoforming technology, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of inability to form martensitic structure, low cooling efficiency, and tight fit of molds, so as to achieve uniform mechanical properties and press Reduced forming force and effects of uniform martensitic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

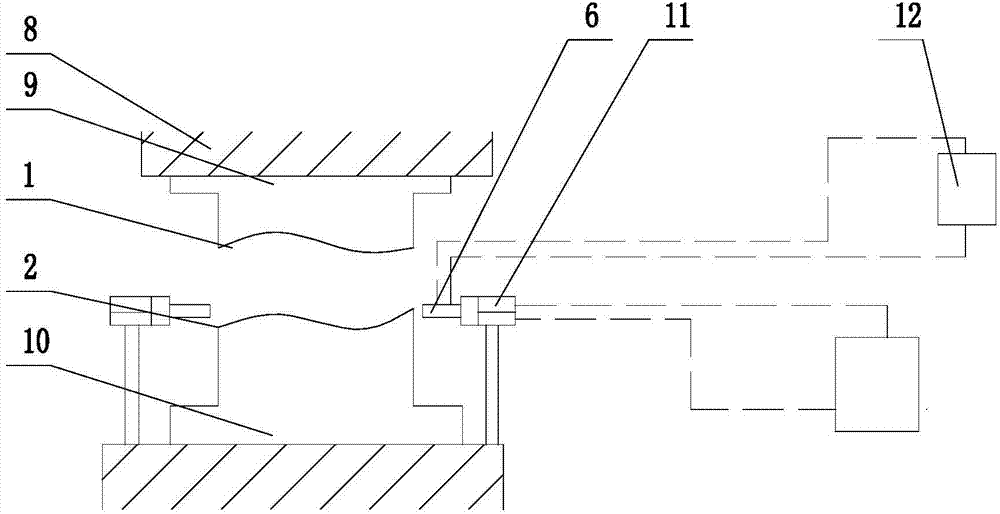

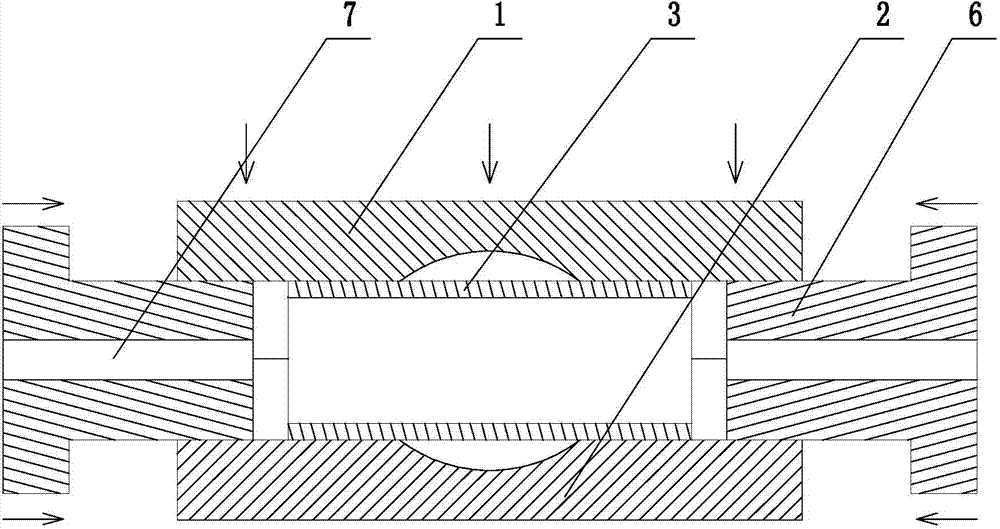

[0034] Embodiment 1: The inflation thermoforming process of the boron steel pipe, the material of the boron steel pipe is boron steel 22MnB5, the material thickness is 2.6mm, the outer diameter of the constant section is 100mm, and the length is 850mm;

[0035] The above-mentioned workpieces are specifically processed through the following steps:

[0036] 1. Boron steel straight pipe preparation, material thickness 2.6mm, outer diameter 100mm, length 1000mm;

[0037] 2. Heating to 900°C in the heating device to completely austenitize the boron steel pipe;

[0038] 3. Place the boron steel pipe material in the mold within 6 seconds. The initial opening height of the press is 800mm, and it is closed and formed at a speed of 300mm / s;

[0039] 4. The axial cylinders on both sides of the mold push the front end head to seal the pipe fittings to form a closed cavity;

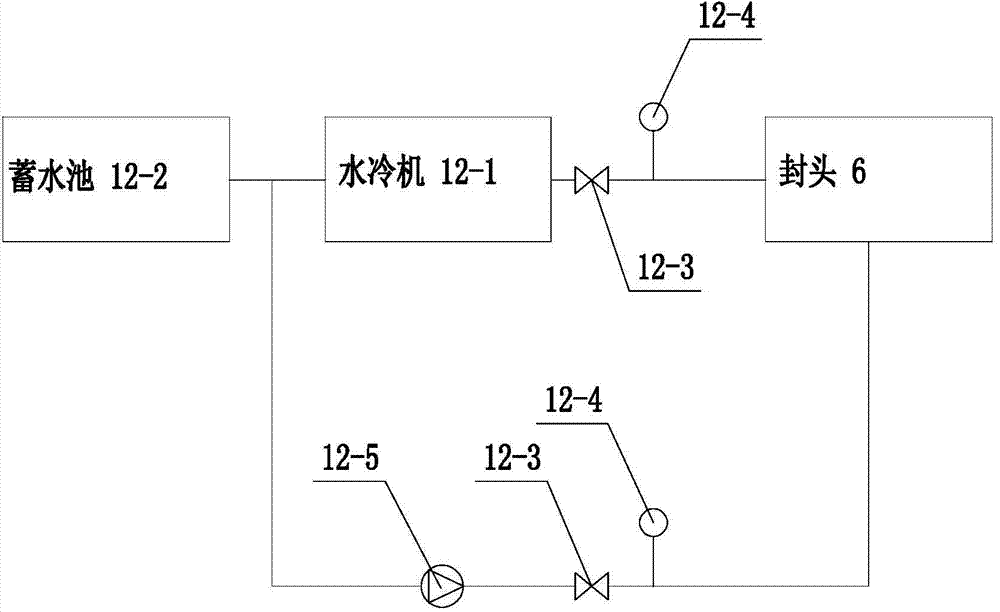

[0040] 5. Through the cooling water channel at the front end of the mold head, fill the closed cavity of the pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com