Distilling apparatus for making wine

The technology of a distillation device and a distillation barrel is applied in the field of winemaking, which can solve the problems of waste and insufficient distillation of alcohol, and achieve the effects of uniform heating and increased speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

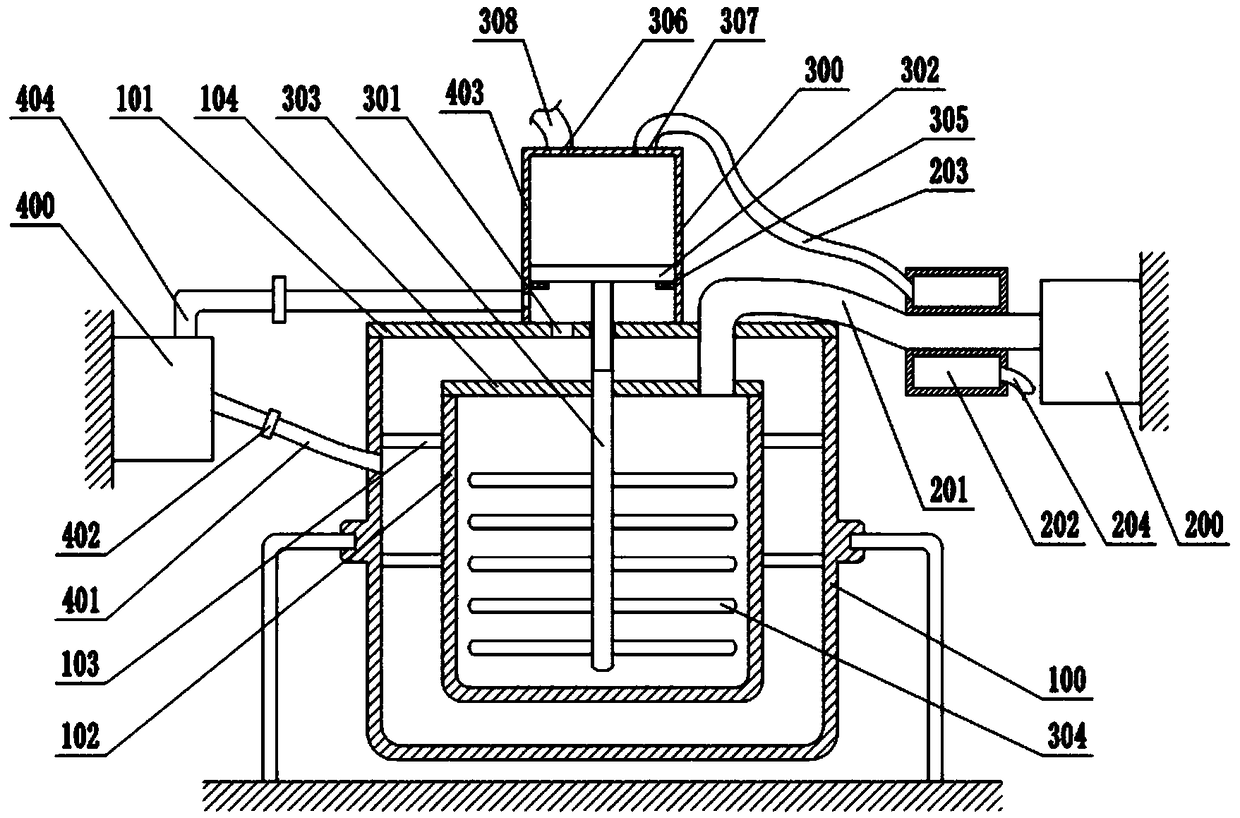

[0027] The reference numerals in the drawings of the description include: heating barrel 100, first cover 101, distillation barrel 102, reinforcing rib 103, second cover 104, wine storage 200, steam pipe 201, cooling ring 202, water inlet pipe 203 , water outlet pipe 204, cylinder body 300, through hole 301, piston 302, piston rod 303, stirring rod 304, boss 305, water inlet check valve 306, water outlet check valve 307, drainage pipe 308, water supply tank 400, water supply Pipe 401, flow control valve 402, air outlet 403, exhaust pipe 404.

[0028] The embodiment is basically as figure 1 Shown:

[0029] A wine distillation device, the device includes a frame, a heating barrel 100 is fixed on the frame, the top of the heating barrel 100 is hinged with a first cover 101, and a heater is arranged at the bottom of the heating barrel 100. In this embodiment, A resistance heater, a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com