Supercritical carbo dioxide corrosion experimental apparatus

A technology for carbon dioxide and corrosion experiments, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the needs of high temperature and high pressure dynamic corrosion experiments that cannot be simulated. and other issues to achieve the effect of simple structure, increased stability and safety, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

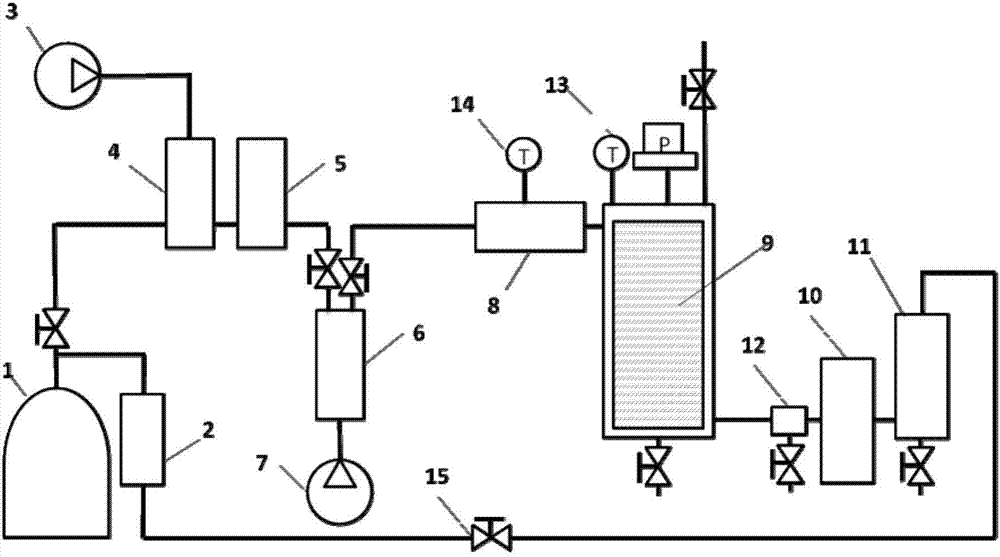

[0022] see figure 1 , the present invention includes a carbon dioxide gas supply system, a preheating furnace 8 and a corrosion reaction kettle 9 connected in sequence through pipelines, the carbon dioxide comes from a 99.9998% carbon dioxide gas source 1 and carbon dioxide dried by a dryer 2; the carbon dioxide gas supply system includes a carbon dioxide gas Source 1, the outlet of carbon dioxide gas source 1 is connected to the booster pump 4 through the valve, and the booster pump 4 is connected to the air compressor 3; the gas source enters the high-pressure storage tank 5 after being boosted by the booster pump 4; the outlet of the high-pressure storage tank 5 It is connected with the inlet of the quantitative injection container 6, the outlet of the quantitative injection container 6 is connected with the inlet of the preheating furnace 8, and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com