Ultra-high temperature air conditioner cooling cycle system

An air-conditioning refrigeration and circulation system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as condensation temperature approaching or reaching the critical point, technical level cannot meet work requirements, and incomplete condensation, etc., to achieve Meet the man-machine environmental requirements of special environments, good working performance and economic performance, and improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

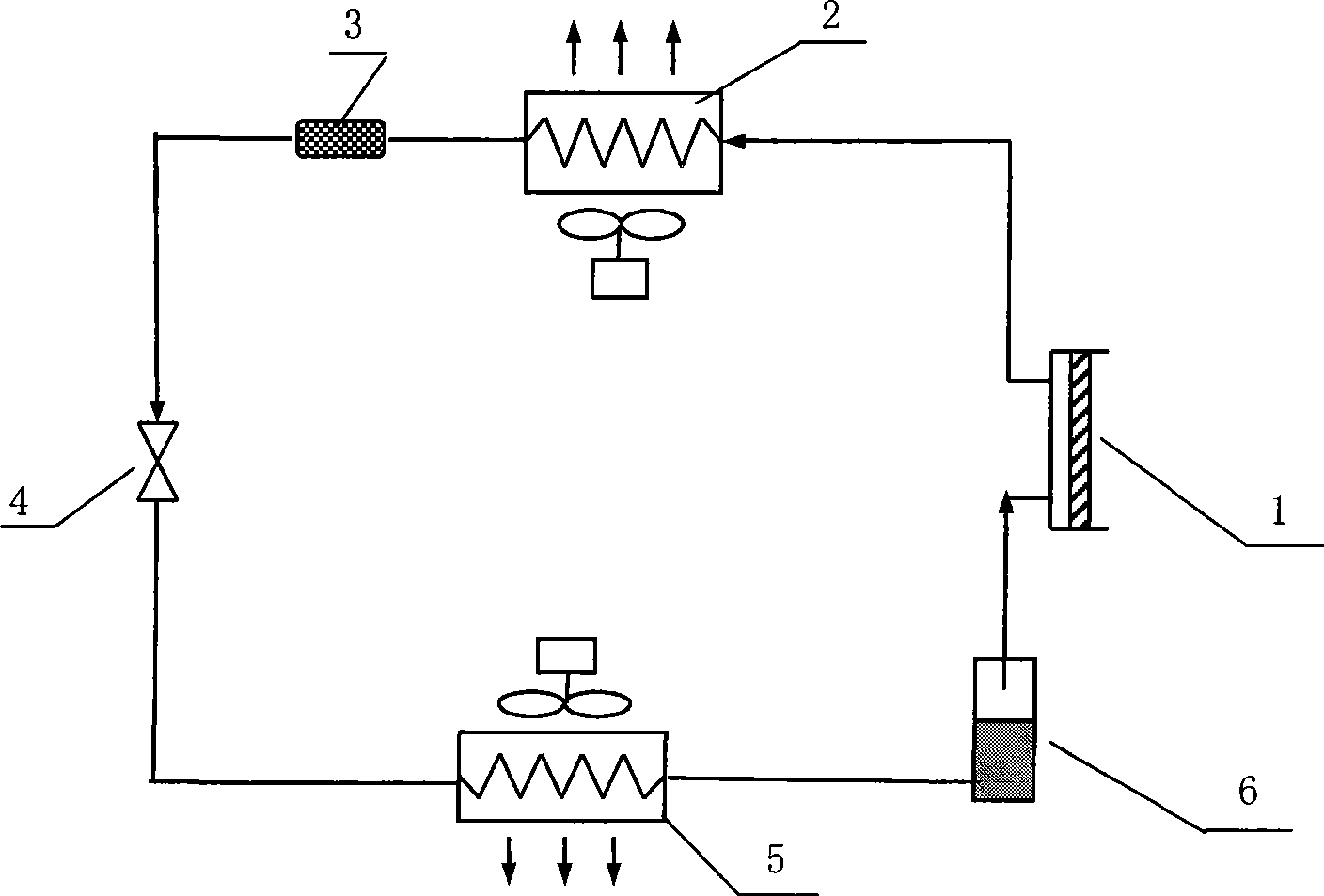

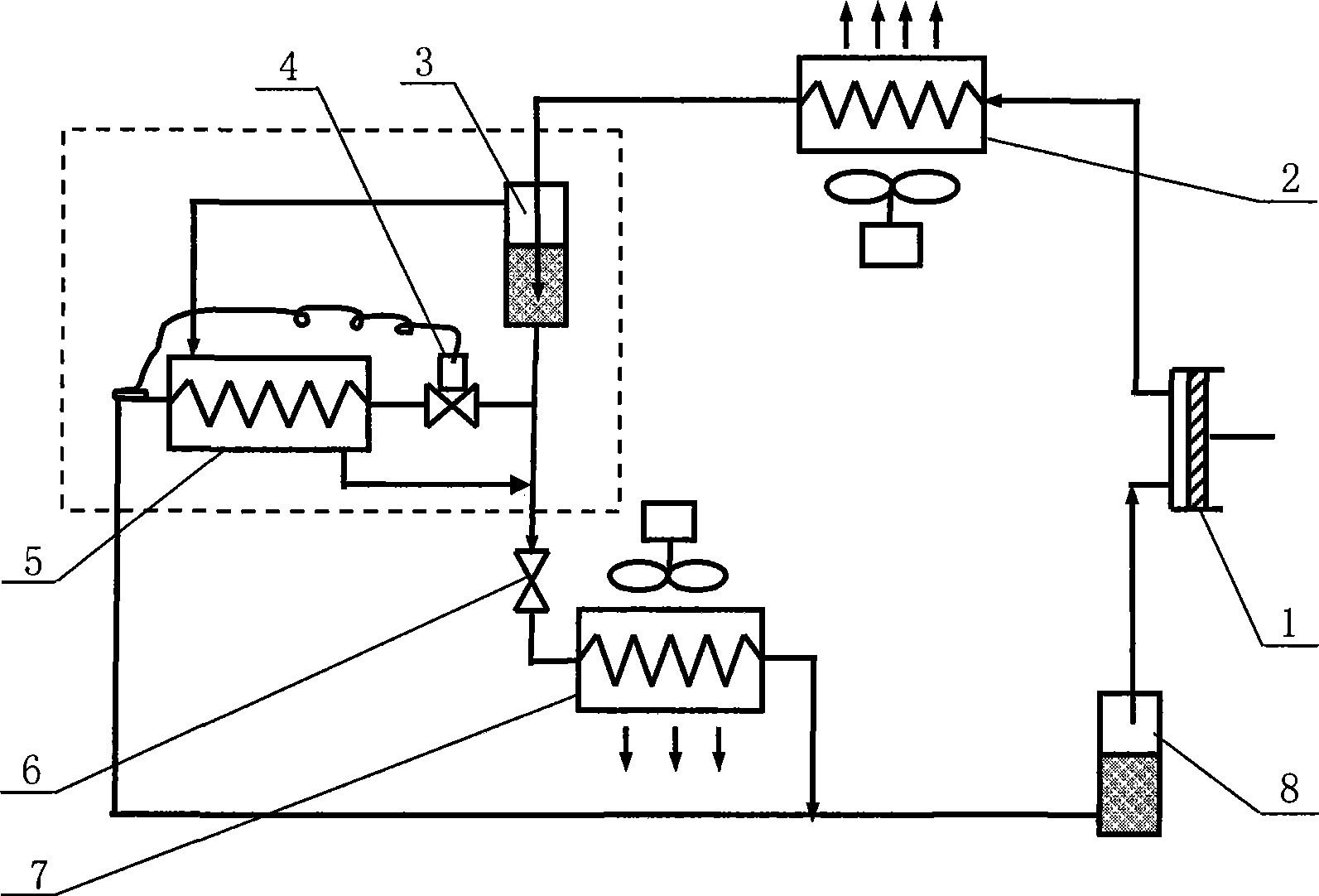

[0028] In this embodiment, the ultra-high temperature air-conditioning refrigeration system uses a mixed working medium composed of high-temperature refrigerant and medium-temperature refrigerant, and the structure of the circulation system is set as follows:

[0029] In the main circuit where the compressor 1 is located, the compressor 1, the condenser 2 on the outlet side of the compressor, the gas-liquid separator 3 on the outlet side of the condenser, and the gas-liquid separator 3 on the front end are arranged in sequence according to the refrigerant flow direction. An expansion valve 6, an evaporator 7 and a back-end gas-liquid separator 8 at the outlet of the liquid phase;

[0030] An inner cascade loop composed of evaporative condenser 5 is provided, wherein the inlet of the condensation branch of the evaporative condenser 5 communicates with the gas phase outlet of the front-end gas-liquid separator 3, and the outlet of the condensation branch is connected to the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com