Multi-stage centrifugal compression system and optimization method thereof

A technology of centrifugal compression and system optimization, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of fluctuations in system gas production and operating conditions, large pressure loss of interstage coolers, and reduced system reliability. problems, to achieve reliable and stable system operation, stable gas production, and stable intake conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

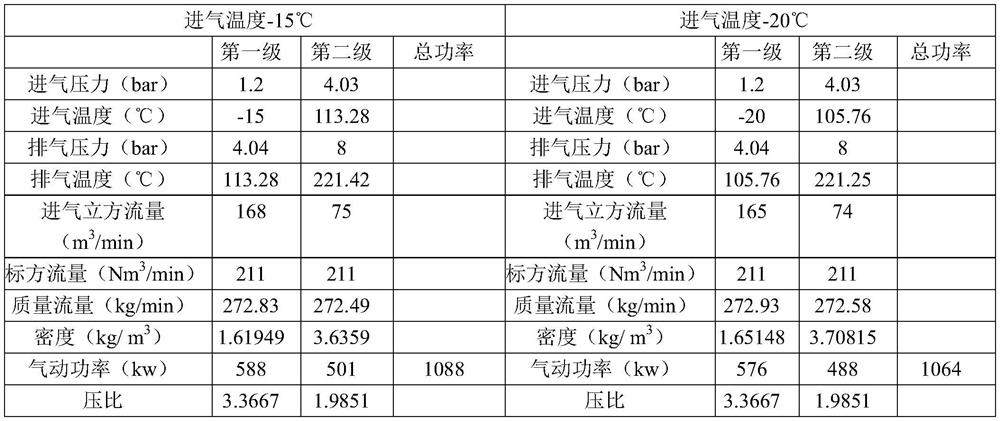

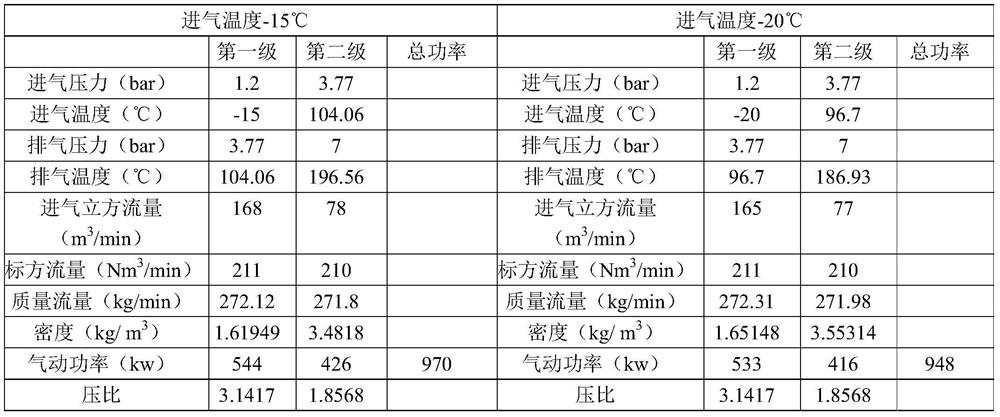

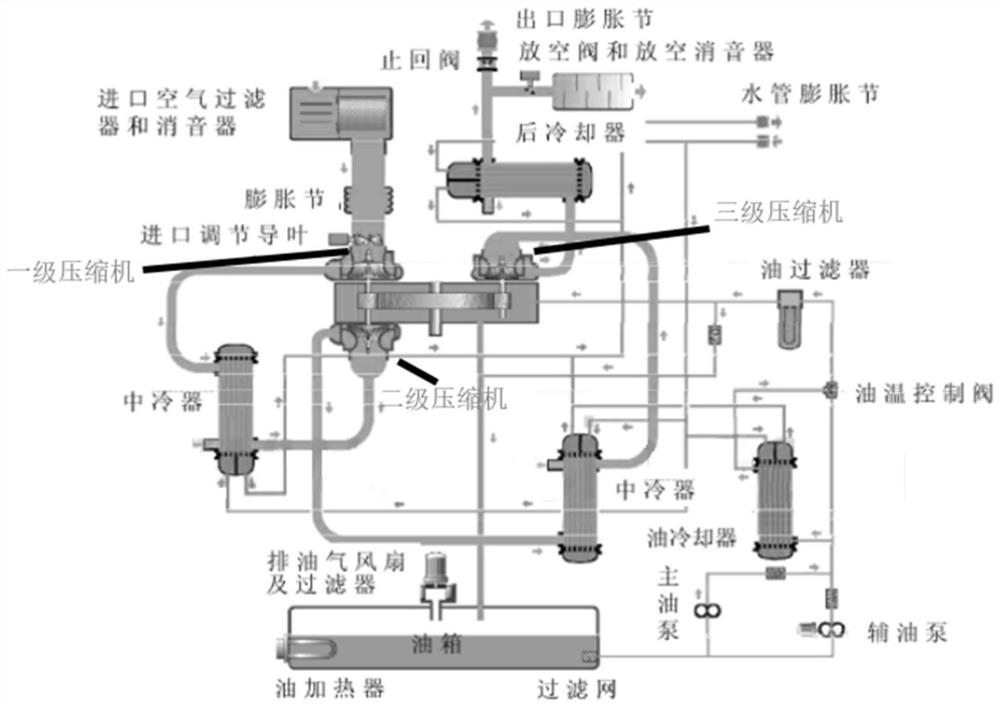

[0034] figure 1 It shows a typical three-stage centrifugal compression system commonly used at present. It can be seen from the figure that the multi-stage compressor is driven by a motor, and the system is complicated. device, etc.) to the cooling box connection, such as figure 2 As shown, this leads to further complexity of the system, and at the same time, the pressure loss between multiple stages is large, resulting in the actual pressure ratio of the system being smaller than the theoretical pressure ratio. For example: a three-stage compression system, the pressure ratios of the compressors are 2.5, 1.8, 1.8, the theoretical pressure ratio is 8.1, the actual measured final exhaust pressure is only 6.6kg, and the intake pressure is atmospheric pressure, that is, the resulting pressure ratio is only 6.6, and the interstage pressure loss leads to a significant pressure ratio loss.

[0035] The present invention cools the intake air of the centrifugal compression system, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com