Patents

Literature

94results about How to "Stable gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

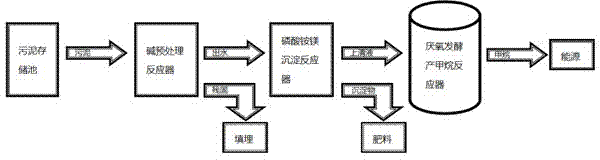

Method for processing residual sludge with integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on magnesium ammonium phosphate method and methane production based on anaerobic digestion

ActiveCN103693828AReduce consumptionGive full play to the role of alkaline hydrolysis pretreatmentWaste based fuelSludge processingChemical oxygen demandMagnesium salt

The invention discloses a method for processing residual sludge with an integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on a magnesium ammonium phosphate method and methane production based on anaerobic digestion. The method comprises the steps of: preprocessing residual sludge with a secondary alkaline hydrolysis method to obtain supernate, adding a magnesium salt solution to separate precipitates, subjecting the supernate to anaerobic processing, and drying the precipitates naturally to obtain crude magnesium ammonium phosphate; injecting the supernate into an anaerobic reactor, and inoculating with 10-60% anaerobic granular sludge, wherein the volumetric loading is controlled to be 0.30-0.75kg COD (Chemical Oxygen Demand) / (m<3>.d), and the productivity of methane reaches 200-400mL CH4 / gCOD within 72h. The method disclosed by the invention has the advantages that nutrition elements in the residual sludge are utilized comprehensively, the process is simple and is consistent in flow with low chemical consumption and electricity consumption, methane is recovered while crude magnesium ammonium phosphate is obtained, moreover, residual alkaline solids are beneficial to subsequent processing, and the reduction, stabilization and recycling of the residual sludge are realized comprehensively.

Owner:SOUTH CHINA UNIV OF TECH

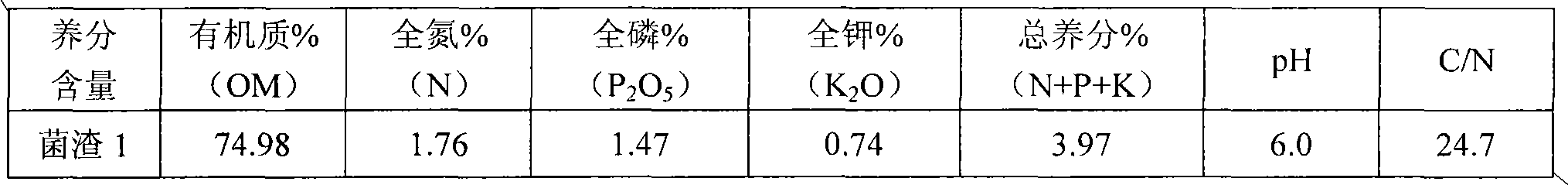

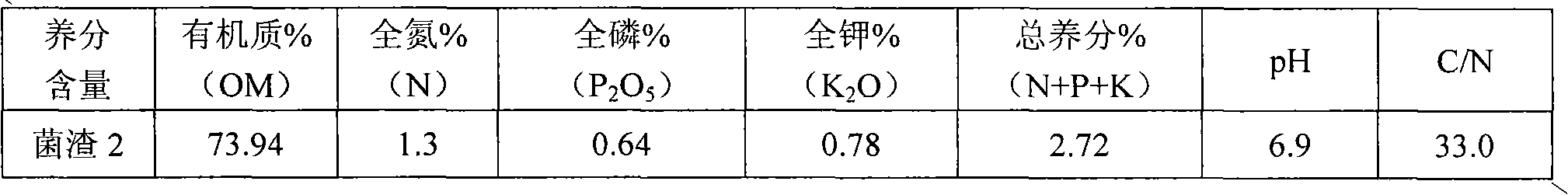

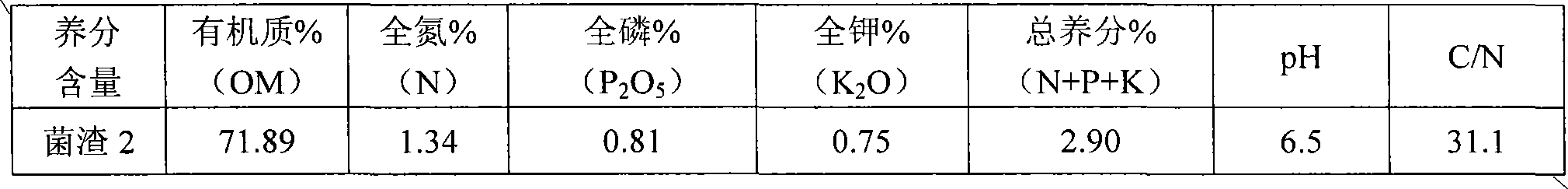

Method for producing marsh gas by utilizing corn cob fungi slag as raw material through anaerobic fermentation

InactiveCN102153261AIncrease profitSolve the problem of random discarding and polluting the environmentBio-organic fraction processingWaste based fuelBiotechnologySlag

The invention discloses a method for producing marsh gas by utilizing corn cob fungi slag as a raw material through anaerobic fermentation. The method comprises the following steps: mixing the fungi slag wasted after corn cob is used as a main raw material to cultivate edible fungus with pig manure or cow dung, adding a methane reagent, and carrying out pile fermentation; and putting fermentationraw materials in a household methane-generating pit or an anaerobic reactor, wherein the addition amount of the raw materials is 80-130 kg per cubic meter of pit volume. In the invention, generation of methane via anerobic fermentation is achieved by carrying out reasonable proportioning, pretreatment, pile outside the pit, fermentation starting and the like on the fermentation raw materials, thereby effectively solving the problem that the pollution is caused by discarding the fungi slag at random and simultaneously turning waste into wealth. After the method is utilized, the gas can be normally generated by the fungi slag in the household, and the method is simple with no need of special equipment and can be applied and disseminated in edible fungus cultivating households.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

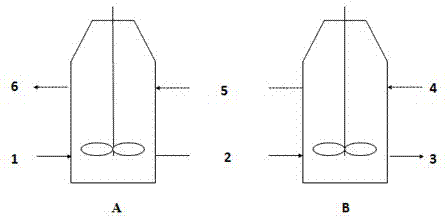

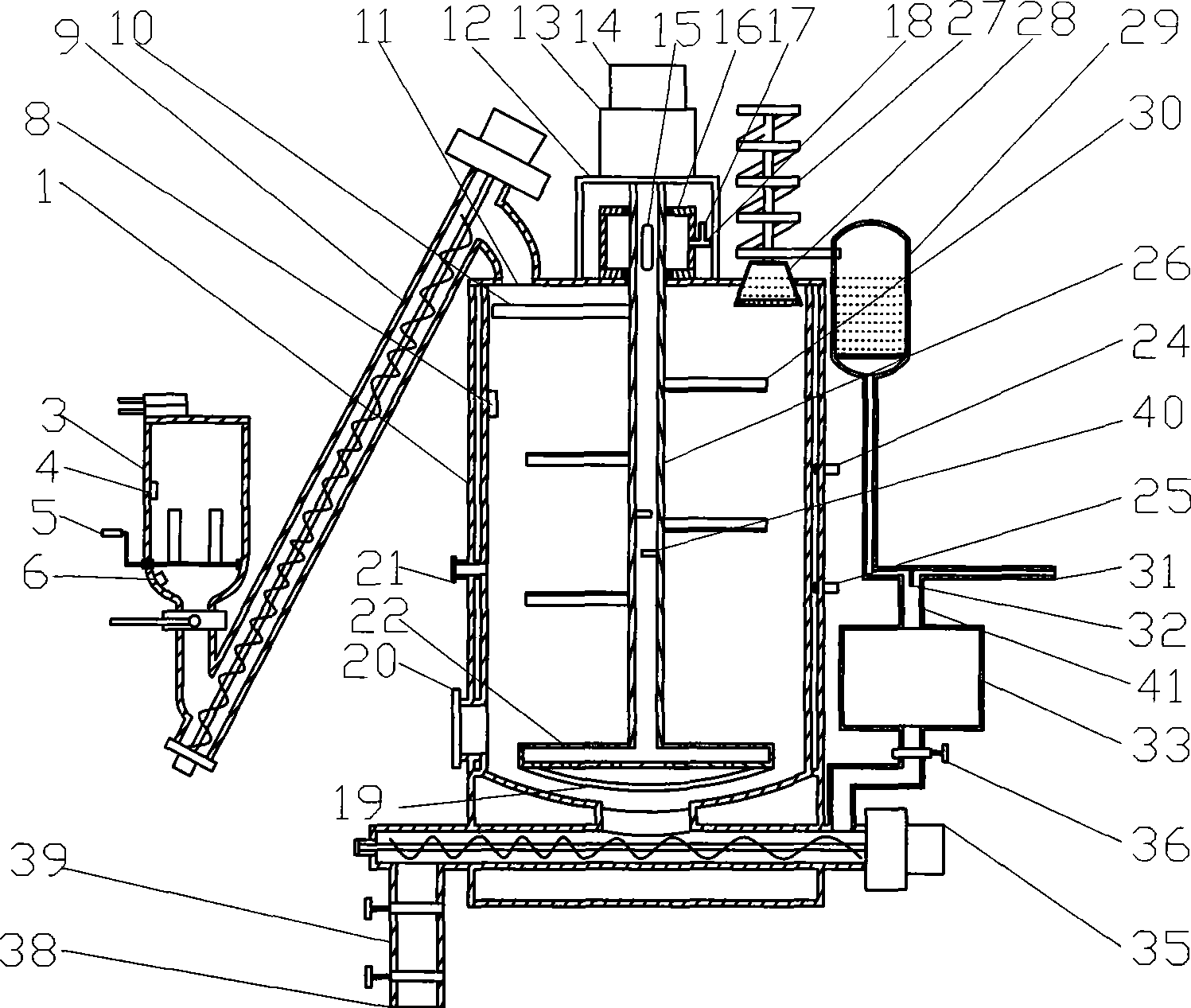

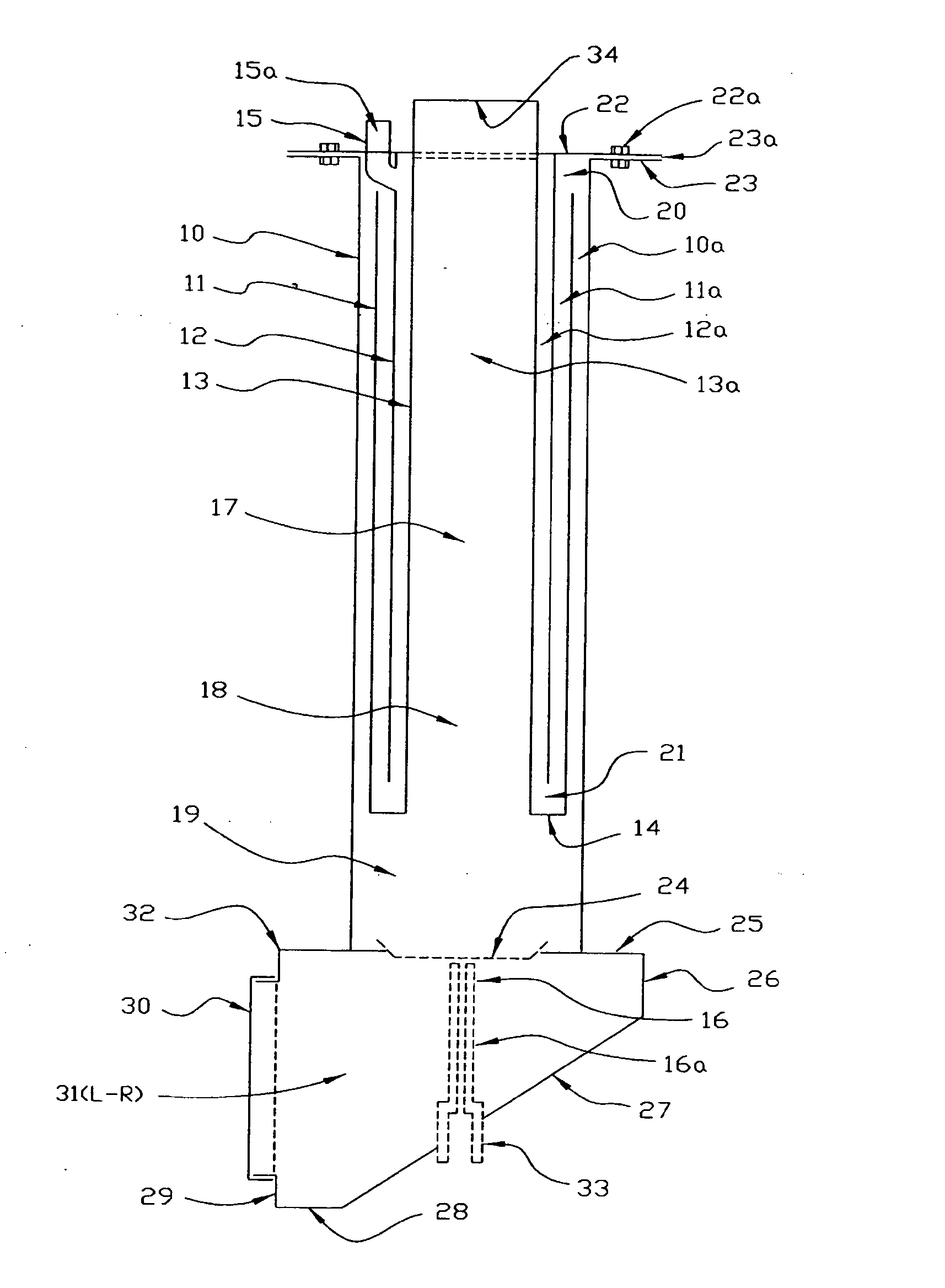

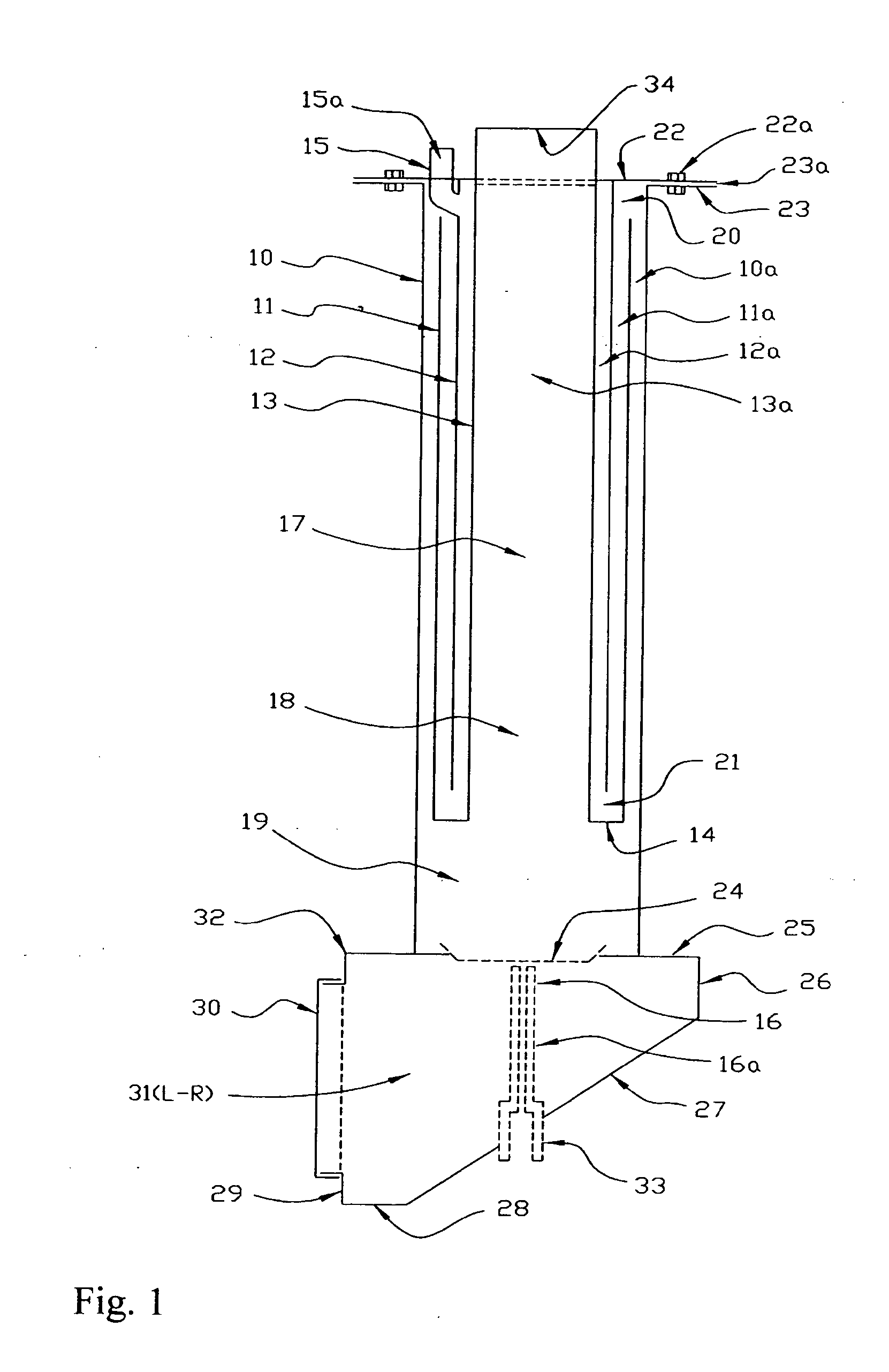

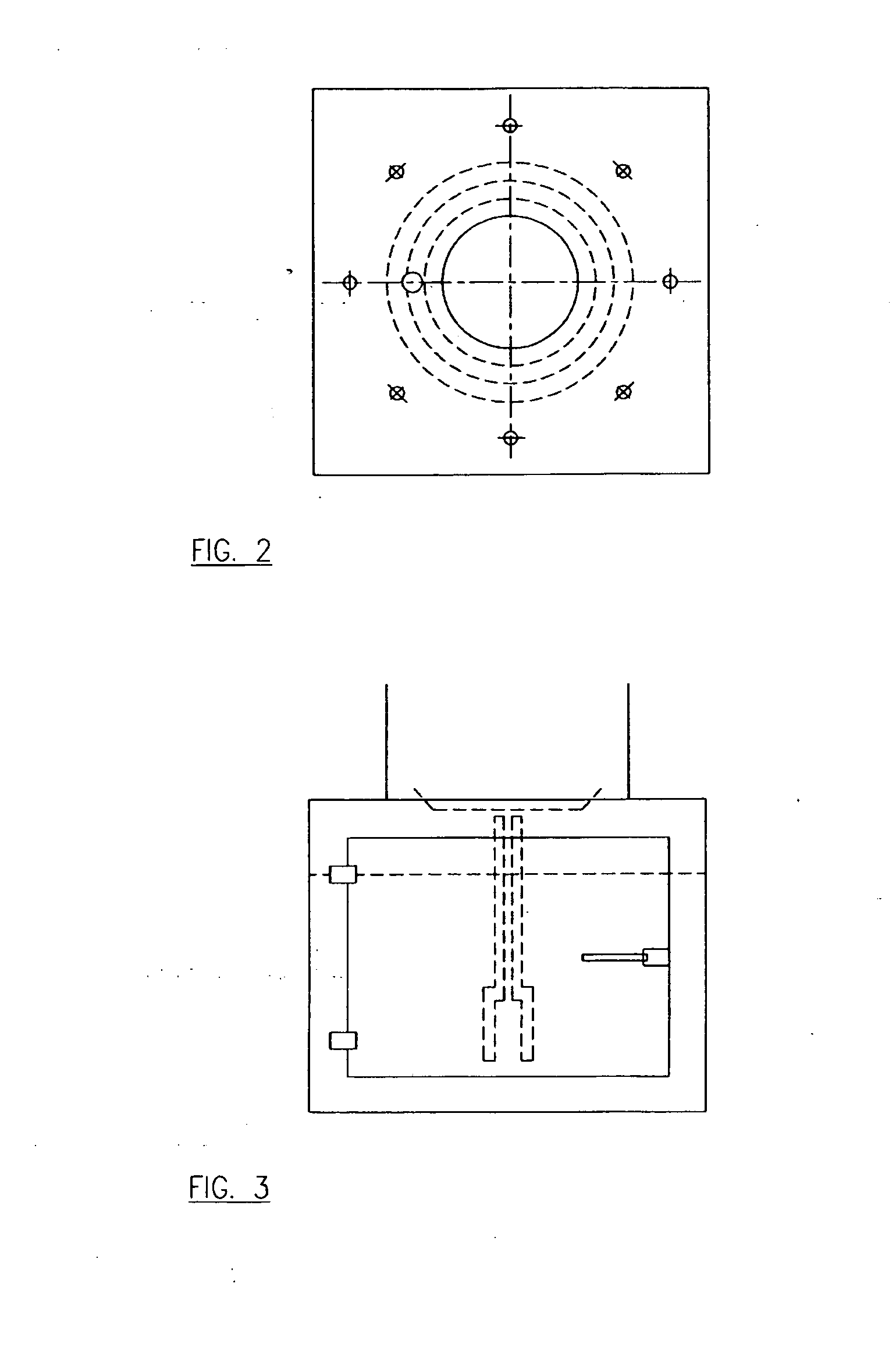

Vertical continuous anaerobic dry fermentation method

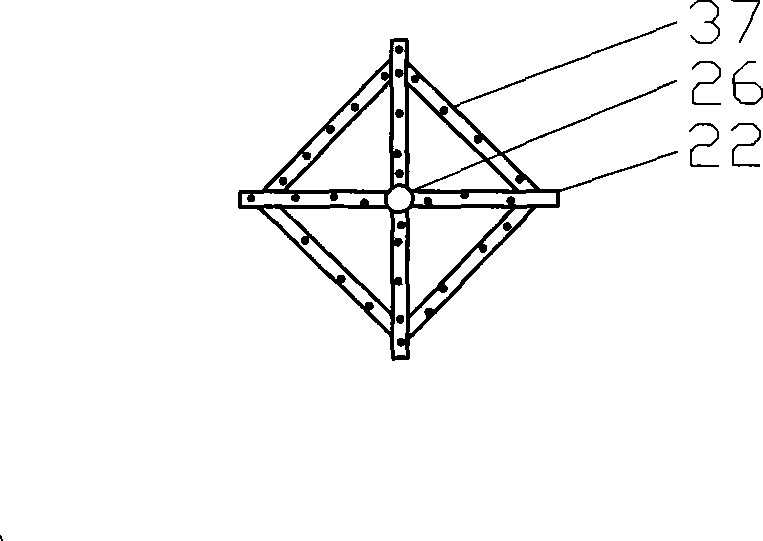

InactiveCN106434763AContinuous gas productionStable gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsMixed materialsSolid content

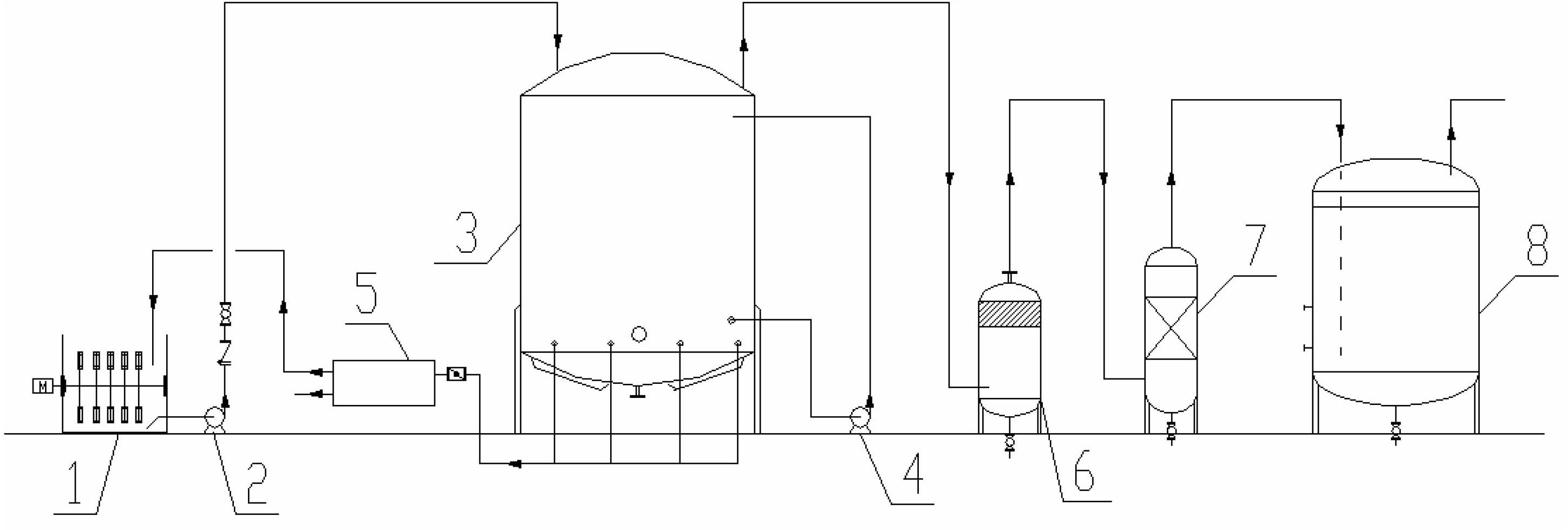

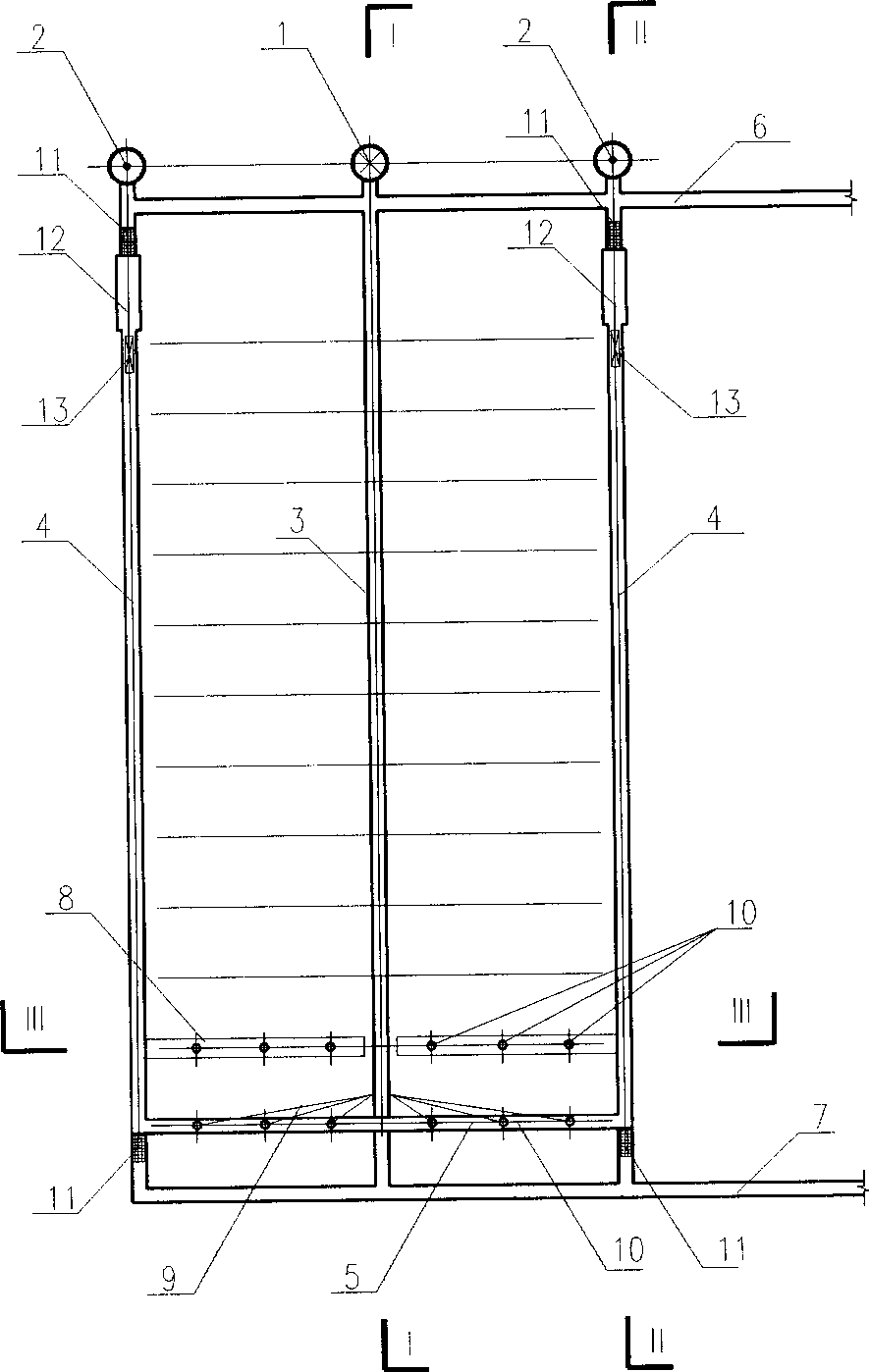

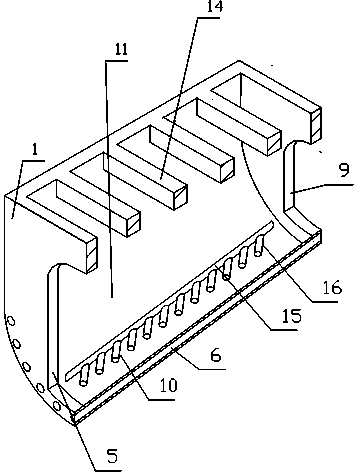

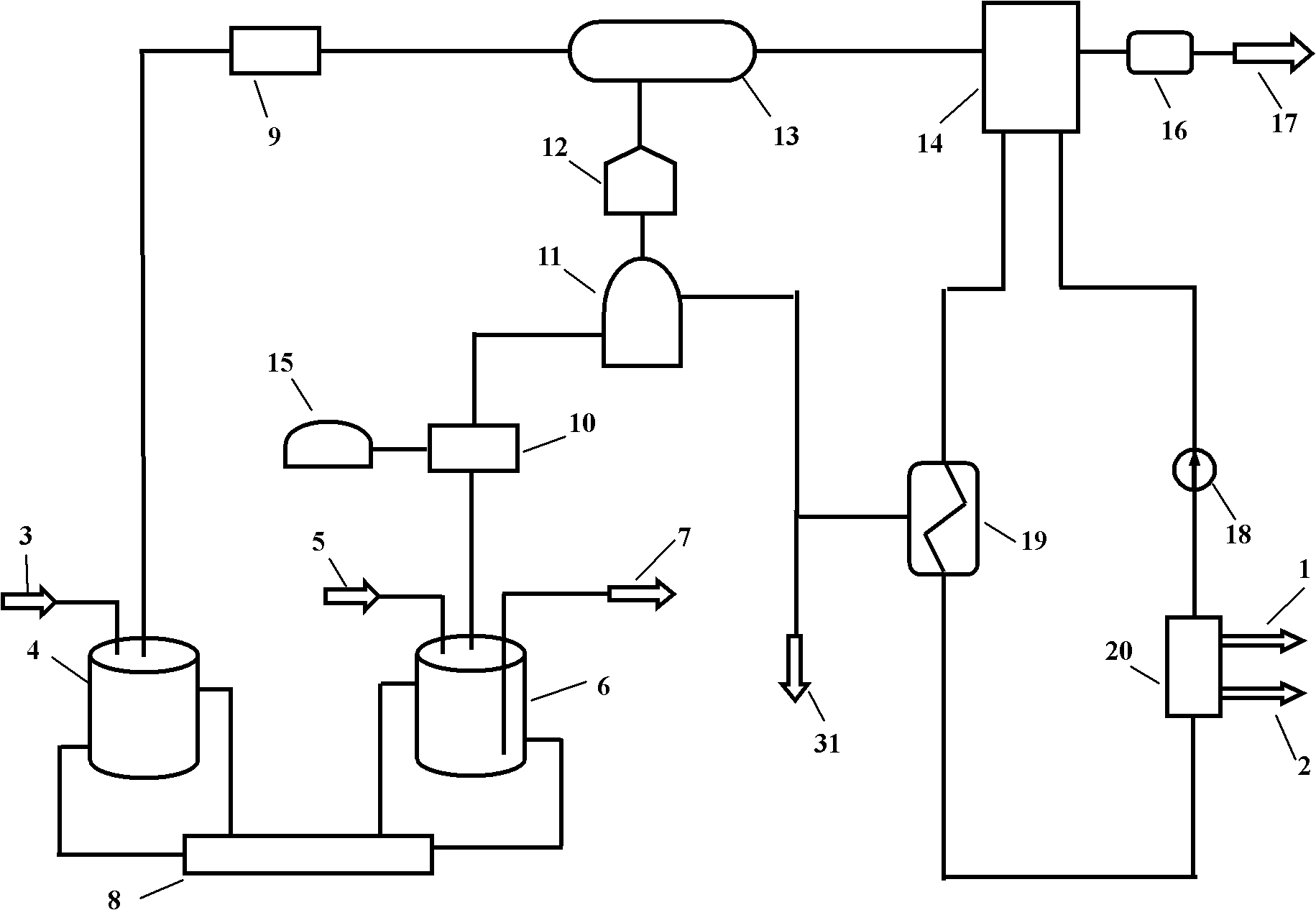

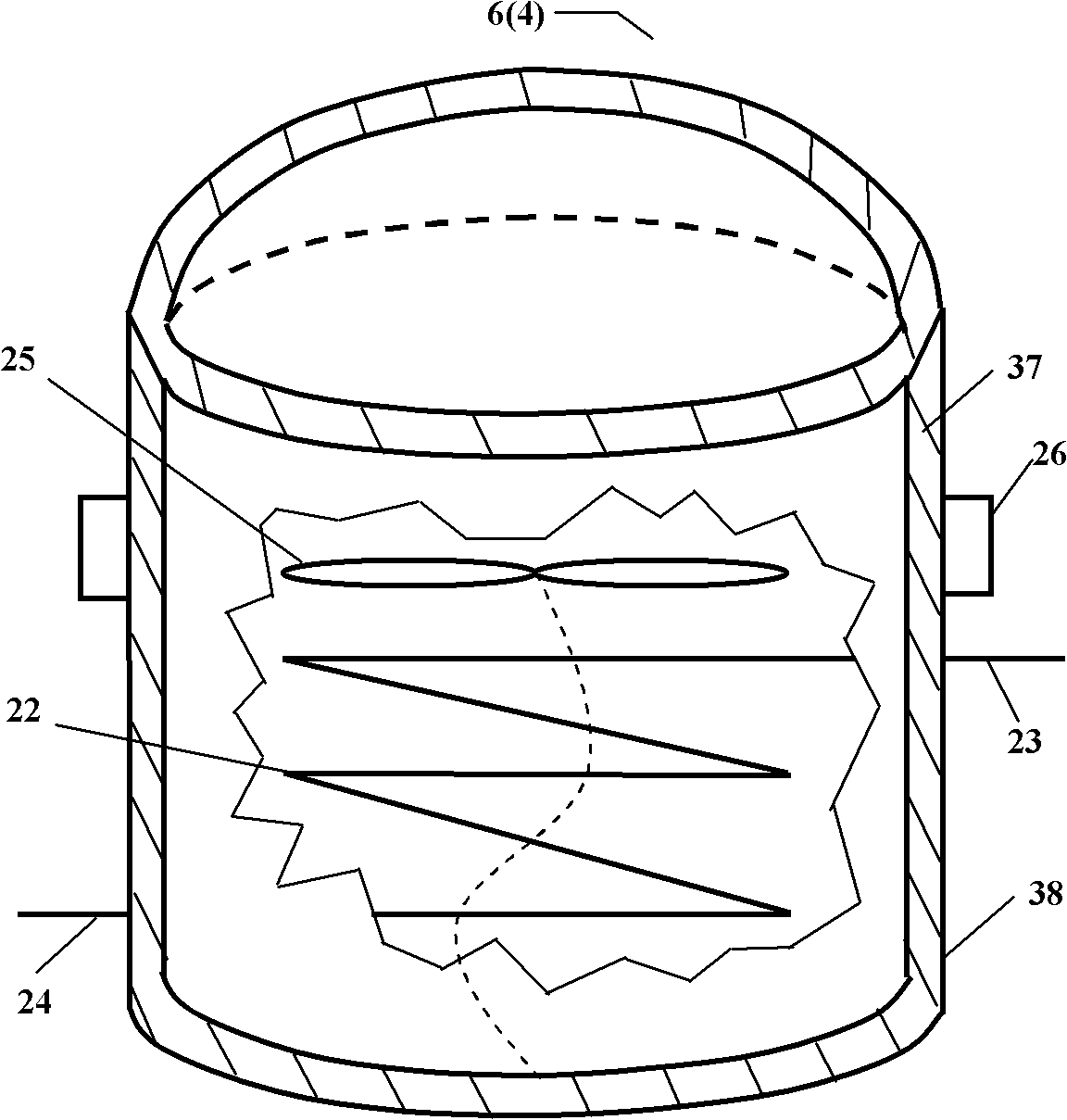

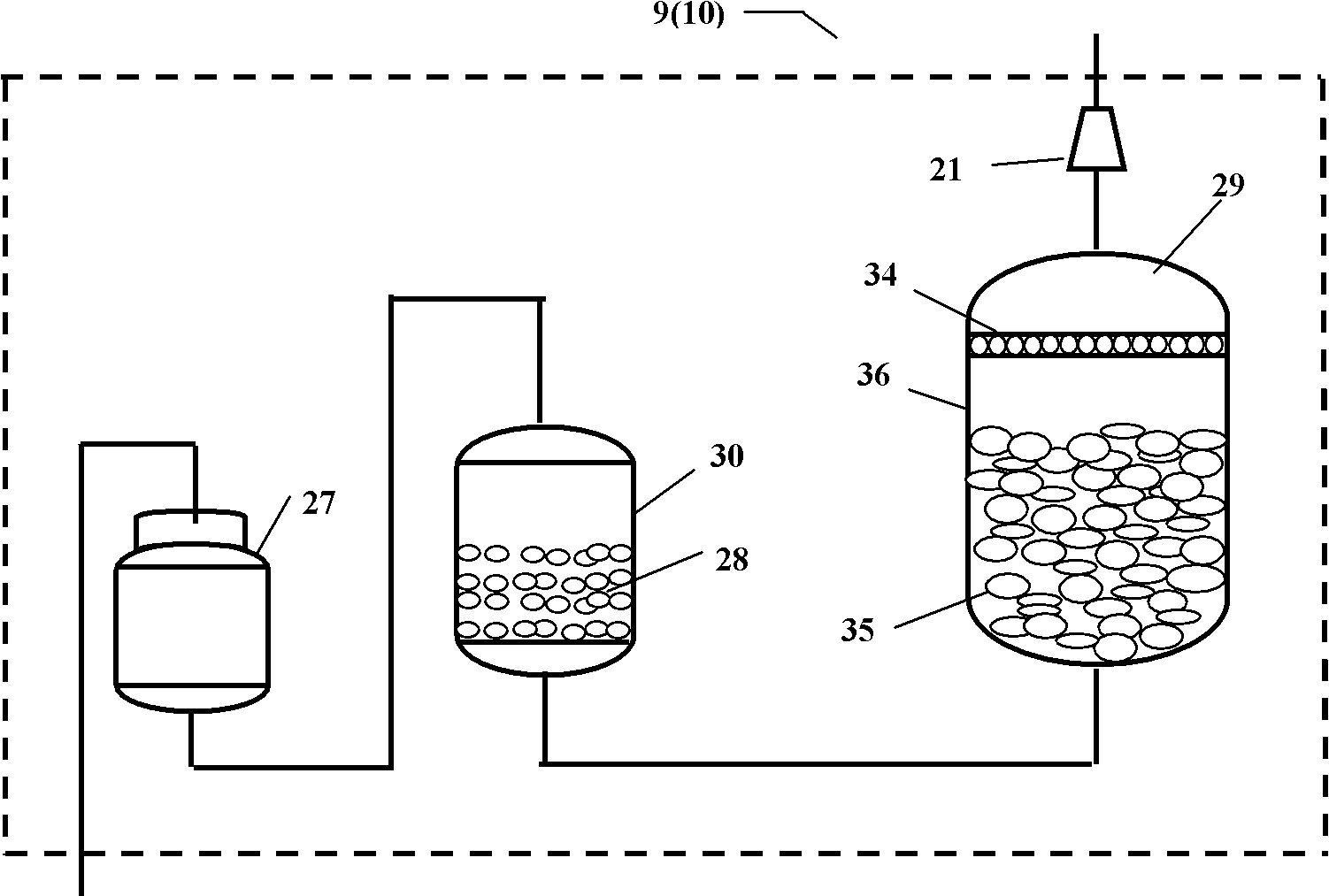

The invention discloses a vertical continuous anaerobic dry fermentation method and device. The method comprises steps as follows: a high-solid-content waste and an inoculum are fully mixed in a homogenization tank, and a mixed material is formed; the mixed material enters an anaerobic fermentation tank via a continuous feeding device; the mixed material is subjected to an anaerobic fermentation reaction in the anaerobic fermentation tank to produce biogas; a residual material after anaerobic fermentation is continuously discharged out of the fermentation tank through a screw discharging device at the bottom of the fermentation tank; a fermentation residue is subjected to solid-liquid separation in the screw discharging device to form biogas residues and biogas slurry; part of the biogas residues flow back to the homogenization tank to serve as an inoculum; part of the biogas slurry sequentially passes through a biogas slurry pump, a biogas slurry buffer tank and a spray pump to be sprayed into the fermentation tank again. With the adoption of the dry fermentation method and device, continuous feeding of the high-solid-content material subjected to anaerobic dry fermentation can be completed, the anaerobic fermentation tank can produce biogas continuously and stably, and the construction cost of the anaerobic fermentation biogas supply device is reduced. Meanwhile, the structure is simple, the investment is low, and operation and maintenance costs are low.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

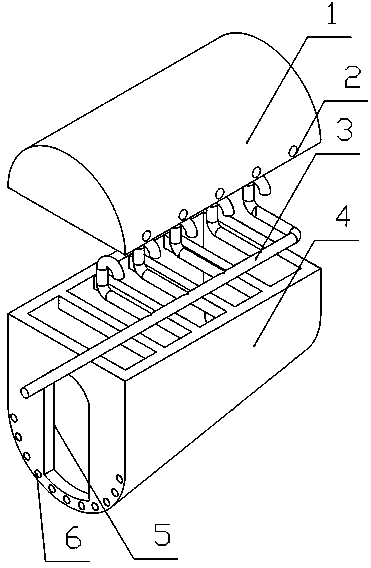

Biomass gasification furnace

InactiveCN101481630AIncrease contentAdjustable temperatureCombined combustion mitigationCombustible gas productionCombustionWater vapor

The invention relates to a biomass gasification furnace which comprises a furnace body, a feed inlet opened on the top of the furnace body, a filter embedded on the top of the furnace body, a fire observation hole and a lighting-up hole which are arranged on the side wall of the furnace body, a radiator connected with the filter, a purifier connected with the radiator, an exhaust pipe connected with the purifier, an ash hole communicated with the bottom of the furnace body, a mixer shaft arranged inside the furnace body, stirring teeth arranged on the mixer shaft, a mixer shaft motor arranged outside the furnace body, a feeding storage hopper that is connected at the front end of the feed inlet and can control the inlet and outlet materials, and a ash discharge hopper that is used for communicating the ash hole and the bottom of the furnace body and can control the inlet and outlet ash. The invention has the advantages that the biomass gasification furnace can continuously supply gas when the material is added and the ash is discharged, the gas dust in the furnace is not discharged outside, the position of a gasification layer in the furnace is unchangeable, water vapor can be used for combustion-supporting, etc.

Owner:蒋启富

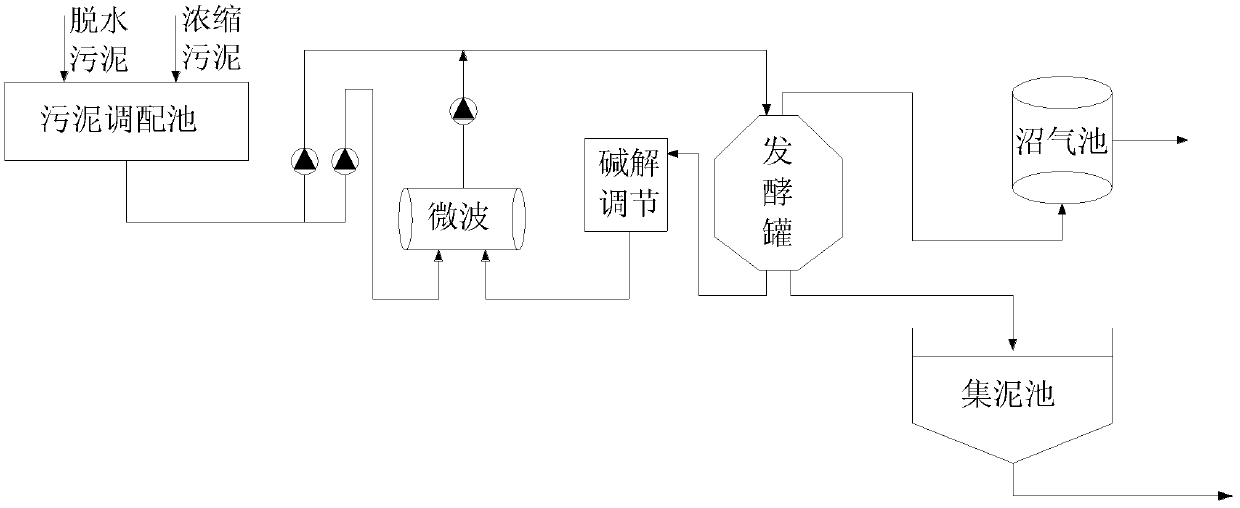

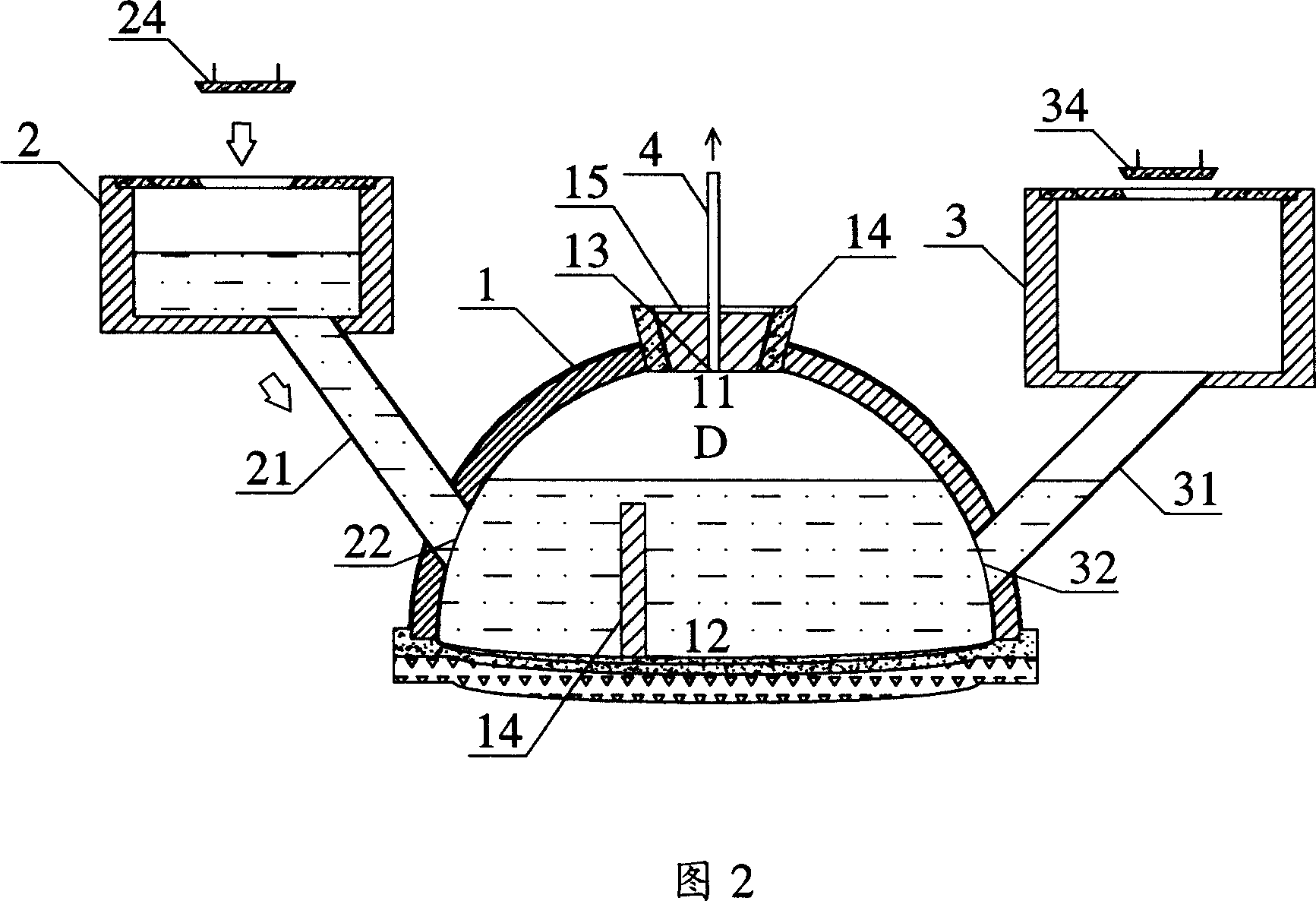

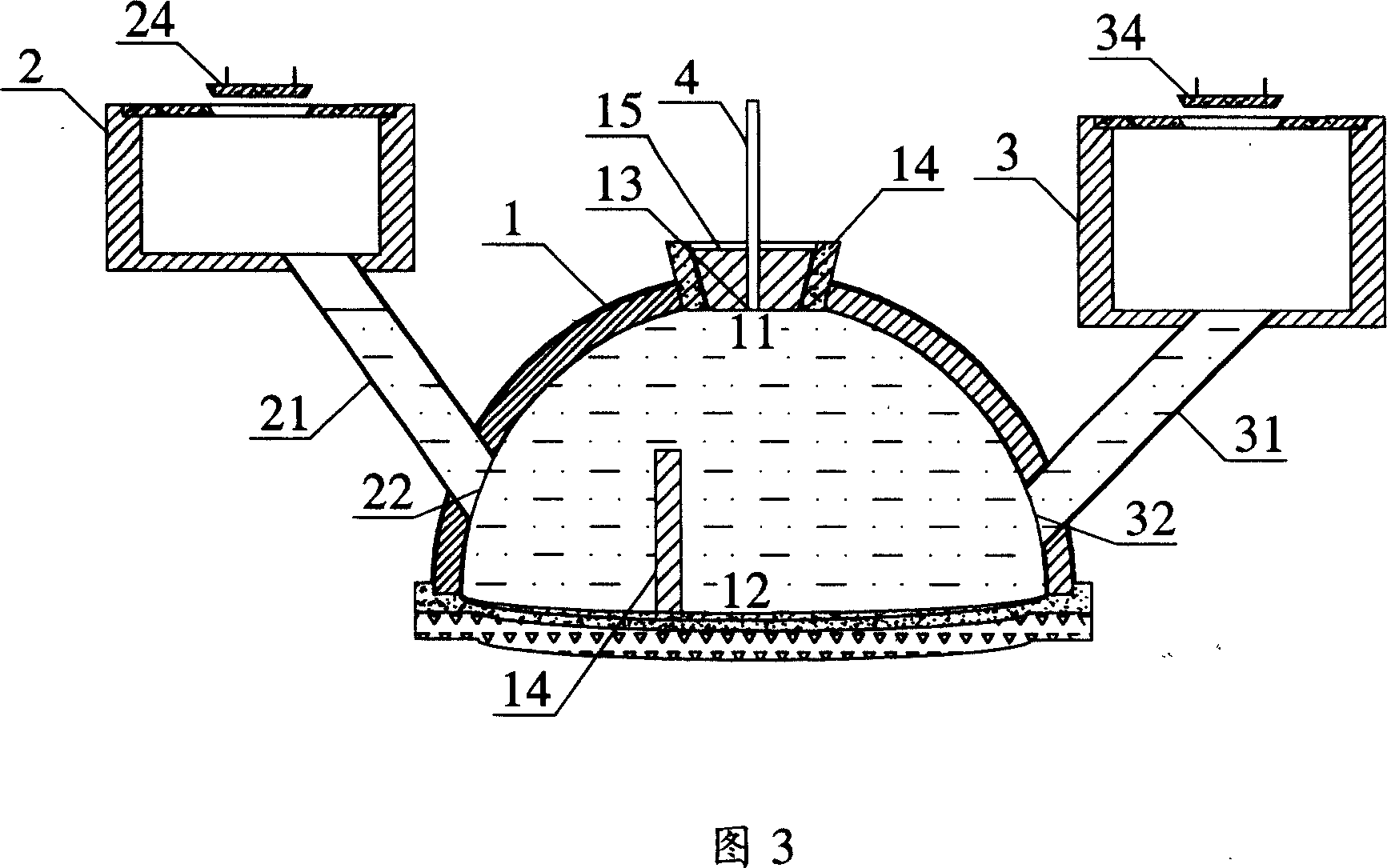

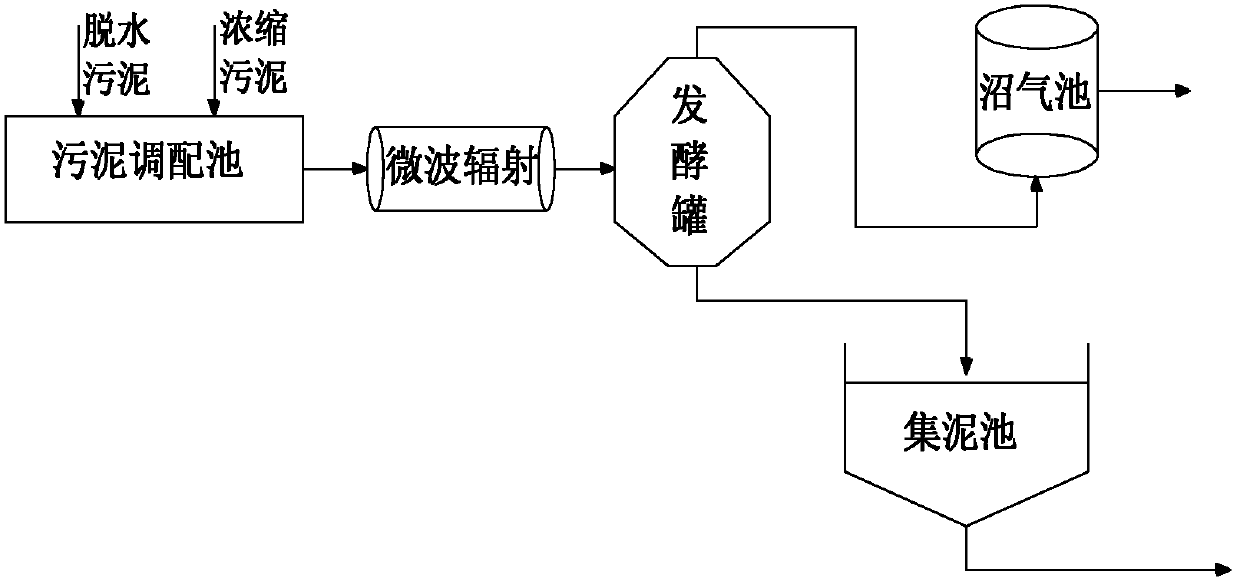

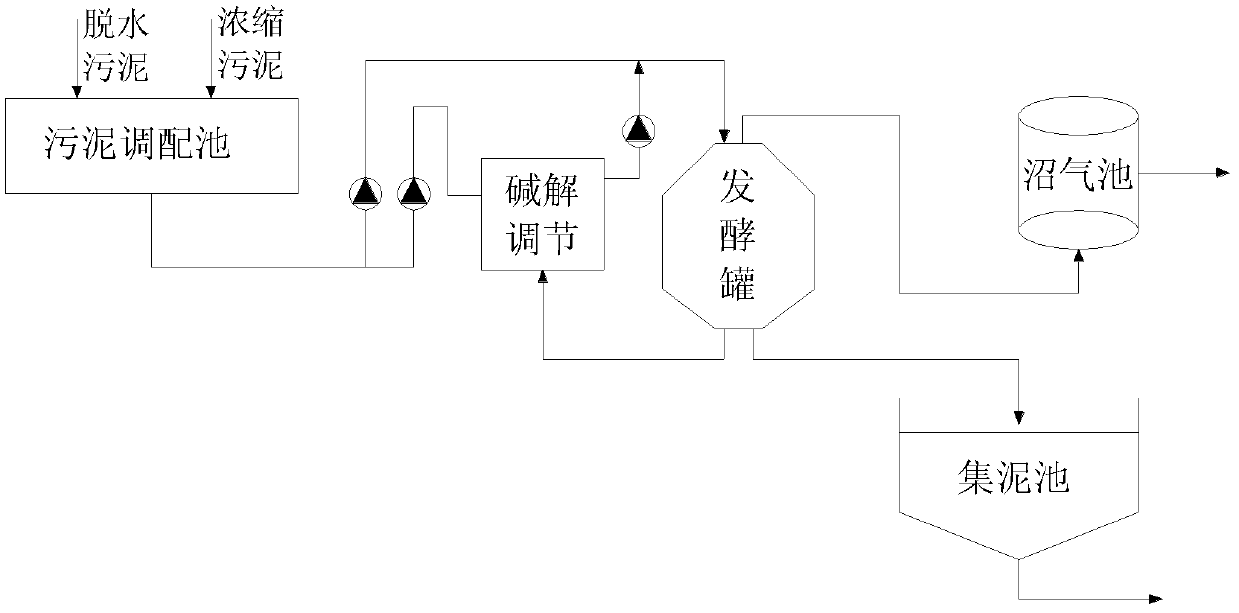

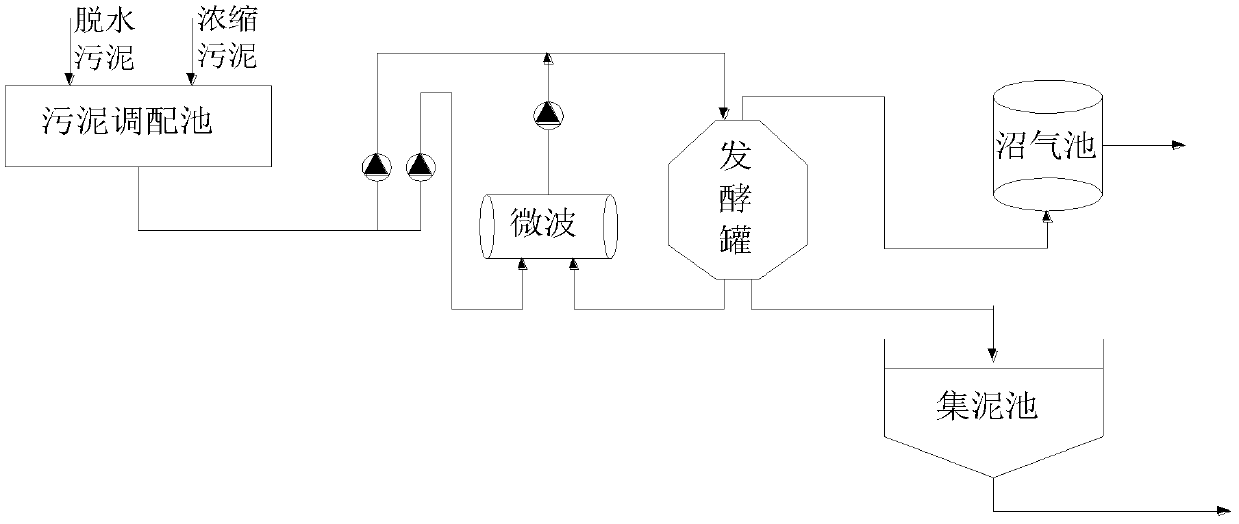

Method for producing biogas by aid of intensified anaerobic fermentation of circular backflow sludge in microwave and alkali combined treatment

ActiveCN102603135AImprove energy recoveryPromote resource utilizationWaste based fuelBiological sludge treatmentMicrowaveFermentation

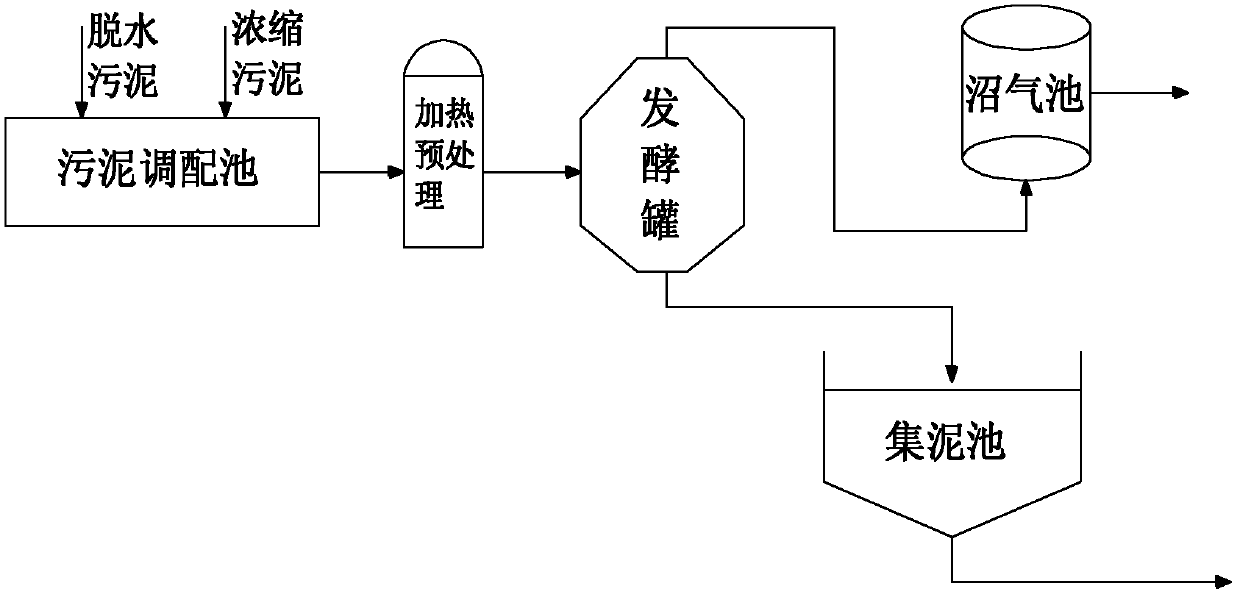

The invention belongs to the technical field of solid waste reclamation, and discloses a method for producing biogas by the aid of intensified anaerobic fermentation of circular backflow sludge in microwave and alkali combined treatment. The method includes steps: preparing concentrated sludge and dewatered sludge into mixed sludge; taking the mixed sludge as a fed material for anaerobic digestion; discharging sludge with the same volume; simultaneously repeatedly carrying out anaerobic digestion after the backflow sludge is in microwave and alkali combined treatment; and collecting the biogas. By the aid of the method, recovery ratio of anaerobic fermentation biomass energy of the sludge is increased, gas yield is stabilized, application is convenient, and sludge reclamation of the sludge is further promoted.

Owner:TONGJI UNIV

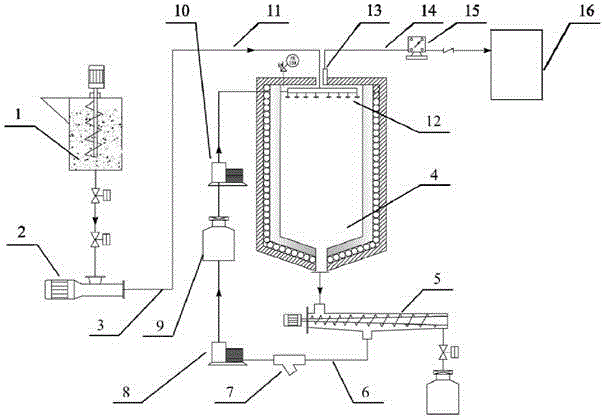

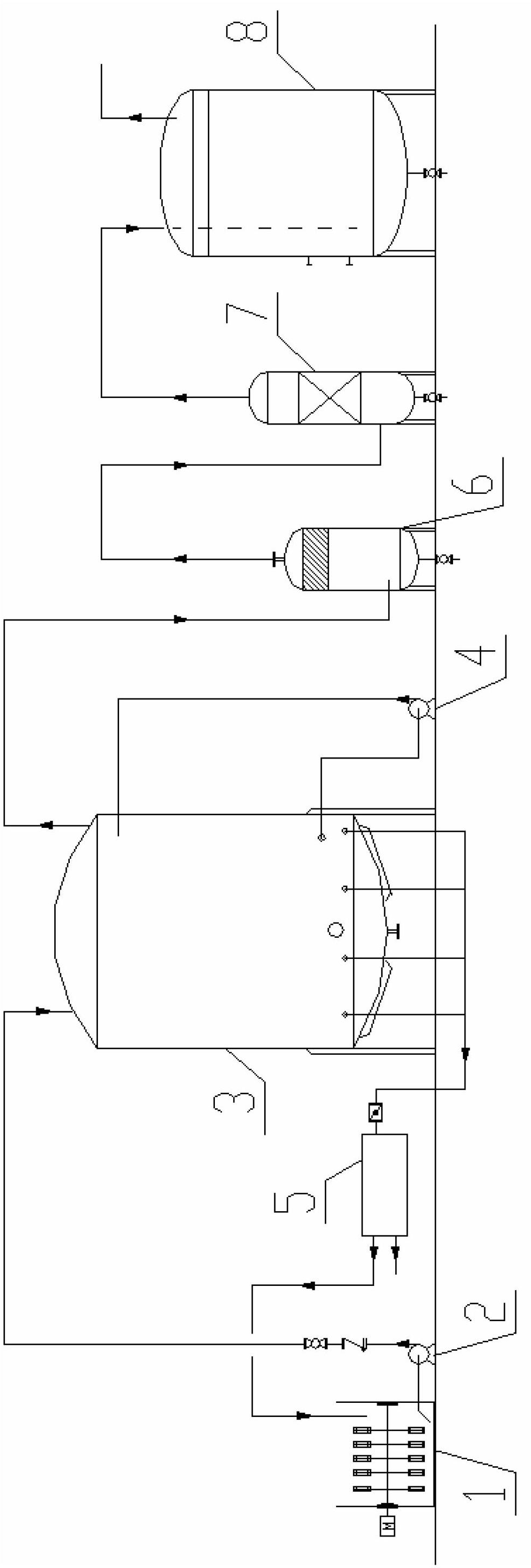

Method and device for preparing biogas by utilizing traditional Chinese medicine (TCM) dregs

InactiveCN102676588AEfficient use ofFast fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsFungicideBiochemical engineering

The invention provides a method and device for preparing high-quality biogas by utilizing traditional Chinese medicine (TCM) dregs. The method comprises the following steps: firstly breaking waste TCM dregs, adding water to wet the waste TCM dregs, then adding an inoculum fungicide and a nitrogen source for adjusting carbon-nitrogen ratios of the dregs to the wet dregs and then replenishing water into the dregs, stacking the dregs after stirring the dregs uniformly, covering the dreg stack with a plastic cloth to preferment the dregs for at least 2-3 days, then adding the stacked and retted dregs to a material mixing pond, delivering the dregs to a fermentation tank via a charging pump after adding biogas slurry and water to the material mixing pond to be stirred uniformly, sealing the fermentation tank for three-five days and generating crude biogas and then purifying the crude biogas in a gas-liquid separation tank and a devulcanizer or in an acid gas absorption device, thus obtaining the purified biogas. The method has the following positive effects: the waste TCM dregs are effectively utilized and turned into wealth, thus overcoming the difficulty that the previous TCM dregs are hard to process, are stacked nowhere and pollute the environment; and the preprocessed TCM dregs have high fermentation speed and gas production speed, the initial gas production time is shortened to about three days and the scope of application is wide.

Owner:XINDI ENERGY ENG TECH

Resource utilization method for combined production of biogas and cultivation matrix through utilizing tobacco stalk fermentation

InactiveCN102851318AModerate granularityQuality improvementBio-organic fraction processingInternal combustion piston enginesSocial benefitsResource utilization

The invention provides a resource utilization method for the combined production of a biogas and a cultivation matrix through utilizing tobacco stalk fermentation. The method comprises the following steps: carrying out anaerobic fermentation of a main fermentation raw material which is waste tobacco stalks generated in the tobacco threshing redrying line to produce the biogas; carrying out solid-liquid separation of a biogas slurry and the tobacco stalks to obtain a tobacco stalk biogas residue and a biogas slurry; purifying the biogas to prepare clean fuels or to be used for electricity generation to provide partial energy for a plant area; and decomposing the tobacco stalk biogas residue, and carrying out dry molding to prepare the cultivation matrix, wherein the biogas slurry returns to a fermentation system to be recycled or to be used as a liquid organic fertilizer. The method provided by the invention has the advantages of simple production operation, concentrated and stable raw material, scale production benefiting, low production cost, realization of no pollution, zero discharge and cycle utilization of waste tobacco stalk resources of a threshing redrying plant, and generation of good economic, ecological and social benefits.

Owner:ZHENGZHOU UNIV

Pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw

InactiveCN106701836APromote degradationLarge specific surface areaBiofuelsSolid fuelsPretreatment methodBiofuel

The invention discloses a pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw, and relates to the field of comprehensive utilization of all components of plant straw, wherein the pretreatment method comprises the steps: plant straw after being cut into sections is successively subjected to washing treatment for two times before and after steam explosion, steam explosion treatment, extrusion treatment, crushing treatment, pre-enzymolysis treatment, cracking treatment, and enzymolysis treatment, and finally a pre-product for preparing the biomass fuels is obtained; a straw washing liquid obtained after washing treatment and an extrusion liquid obtained after extrusion treatment are used for producing marsh gas, and a liquid, gas and solid biomass fuels can be obtained after the pre-product is treated. The method realizes separation and high-valued complete utilization of the all components of the plant straw, namely hemicellulose, cellulose, lignin and a small amount of components, can achieve no pollutant emission, and has the advantages of easy industrialization operation, good economic benefits, and remarkable comprehensive social benefits.

Owner:北京利晟新能生物科技中心(有限合伙)

Lane control gas supply side line underground gasification furnace

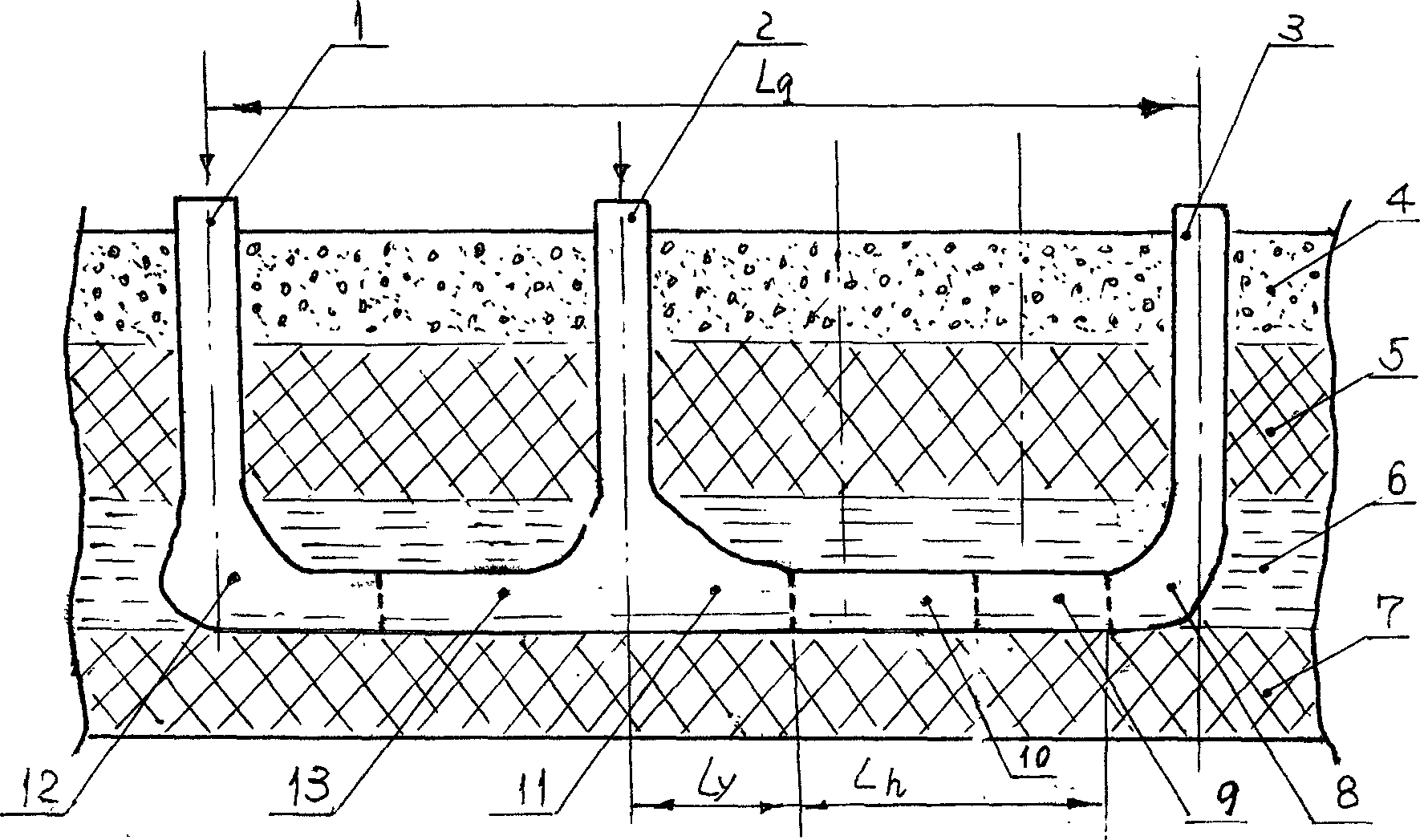

InactiveCN101382062AControllable gas supply pointIncrease gasification strengthConstructionsCoal gasificationProcess engineeringEngineering

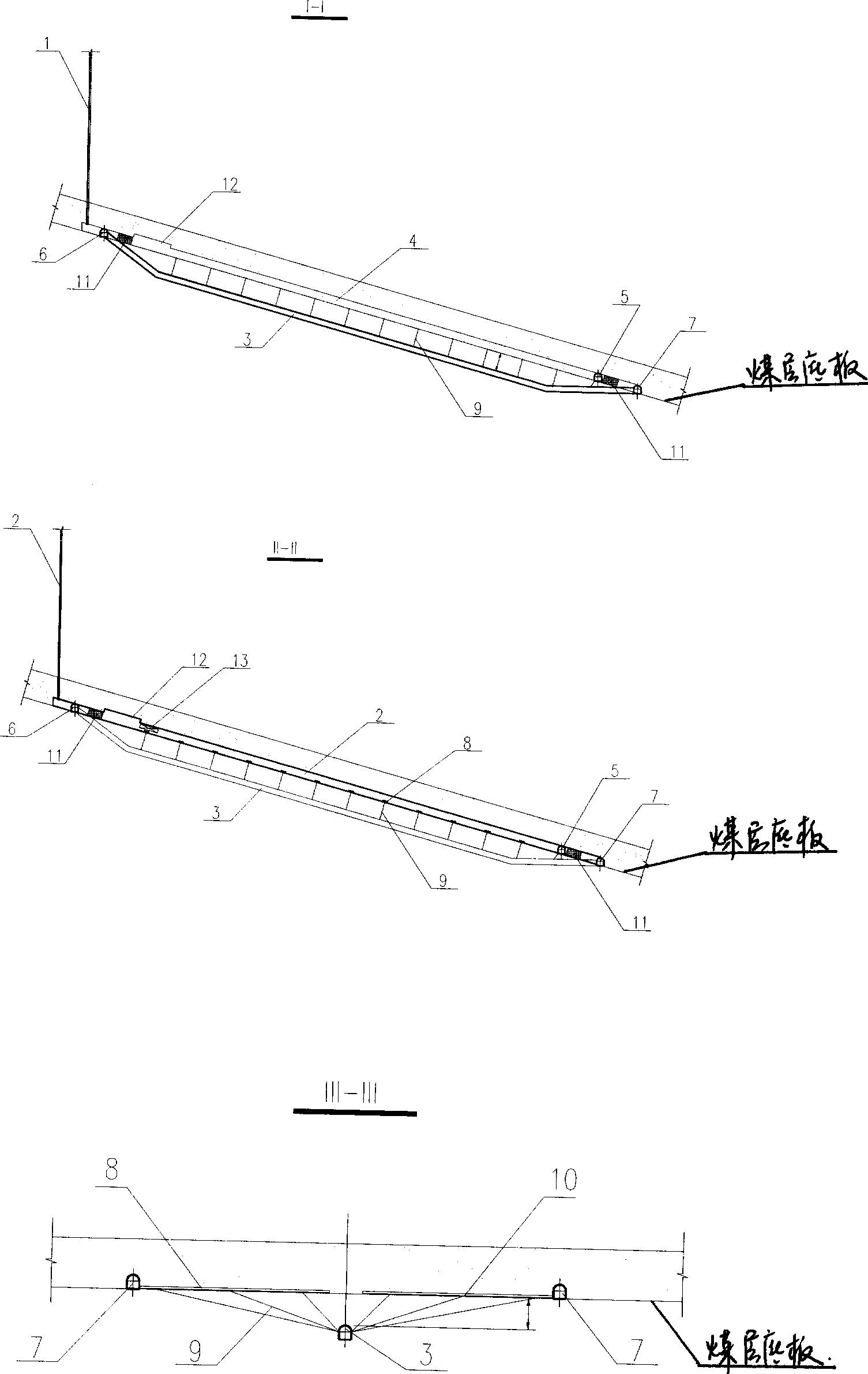

The invention provides an underground lane control gas supply side line gasification furnace. The furnace comprises a coal gas passage, multi-drill holes which are drilled directionally on the bottom of a coalbed in the coal gas passage, a gas supply lane, a gas supply pipe and a plurality of temperature pressure and flow testing instrument valves arranged in a base plate rock of the coalbed, and a gas supply branch pipe between the gas supply lane and the multi-drill holes. The system has a simple structure, easy configuration and reliable operation. The furnace capable of carrying out simultaneous multi-point gasification has the advantages of higher output, gas supply protection, controllability, adjustment as required, and the like. The furnace can solve a plurality of problems of poor gasification effect, discontinuous and unstable gas production, small gas output, low gasification rate, and the like.

Owner:ENN SCI & TECH DEV

Formation method for lithium ion battery with long storage life

ActiveCN109599595AControl film formation speedAffect qualityCell electrodesFinal product manufactureLithium-ion batteryCarbonate

The invention provides a formation method for a lithium ion battery with a long storage life. An anode active substance in the lithium ion battery consists of LiNi0.7Mn0.2Ni0.1O2; the electrolyte of the lithium ion battery comprises additive consisting of vinylene carbonate (VC) and fluoroethylene carbonate (FEC), wherein the VC occupies 0.5-1% of the total volume of the electrolyte, the FEC occupies 1.5-4% of total volume of the electrolyte, and the volume content ratio FEC / EC of the FEC and the VC is above 2. The formation method comprises a staged formation technology and a staged exhaust technology, a stable SEI (Solid Electrolyte Interphase) membrane is formed, anode surface metal can prevent from being dissolved in a battery storage process, and a self-discharge phenomenon is avoided.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

Biomass pool and automatic slagoff method for the same

InactiveCN101054548AFacilitate flowAvoid slaggingGas production bioreactorsWaste based fuelMethane productionEngineering

The present invention relates to methane production apparatus field. The object of the present invention is to overcome the deficiency of existing technology and provides a reasonably designed, highly safe methane pool capable of removing crust of methane fluid and automatically discharging dregs and its usage method. The methane pool comprises ferment pool, feeding pool and output pool etc. The feeding pool is communicated with ferment pool through feeding tube and output tube. The feeding pool is not lower than output pool. The output pool bottom is in same level or slightly lower than ferment pool top whose feeding tube port is higher than that of output pipe. The ferment pool top is installed with gas exhaust port. The character of the present invention : (A+B+C)*1.08=V=(A+B+C)*0.92 . V represents the volume of ferment pool feeding tube port top to ferment pool top inside, A represents the volume of feeding pool, B represent the volume of output pool, C represents the feeding tube volume from ferment pool top to feeding pool bottom.

Owner:陈观梯 +2

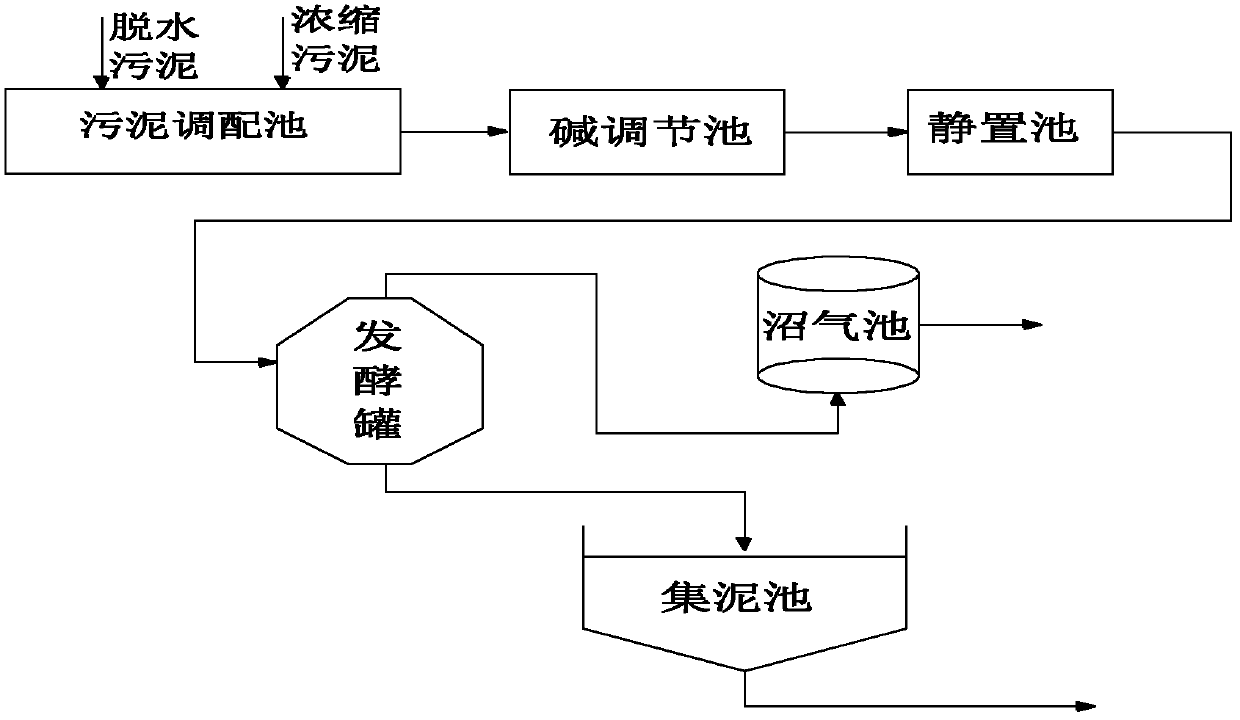

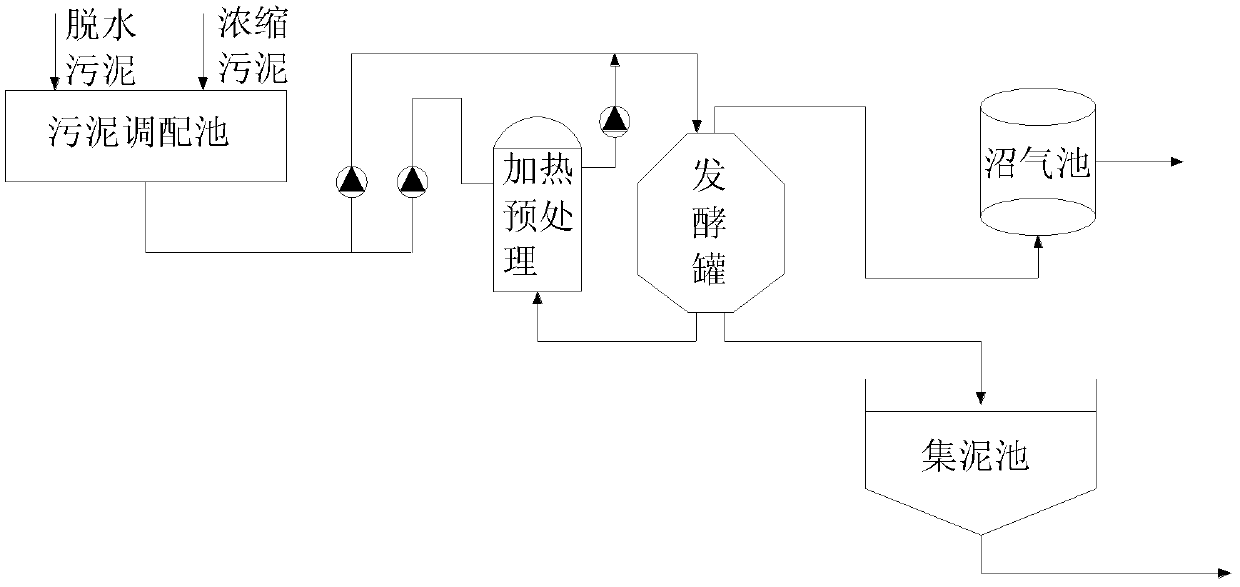

Method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment

InactiveCN102603141AImprove the efficiency of anaerobic fermentation gas productionPromote resource utilizationWaste based fuelBiological sludge treatmentStart timeMethane yield

The invention belongs to the technical field of solid waste reclamation, and discloses a method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment. The method comprises the following steps of: preparing concentrated sludge and dewatered sludge into mixed sludge for pretreatment; carrying out anaerobic fermentation on the mixed sludge as a feedstock and discharging sludge the volume of which is the same as that of the mixed sludge; and collecting methane. By using the method, the efficiency of producing methane by anaerobic fermentation of the low organic matter sludge is improved, methane production quantity is stable, the energy consumption is low, the application is convenient, and further, and the sludge reclamation is further promoted; the anaerobic starting time of the low organic matter sludge is shortened, the total quantity of methane produced by anaerobic digestion of the low organic matter sludge is increased, and the reclamation utilization of the low organic matter sludge is promoted.

Owner:TONGJI UNIV

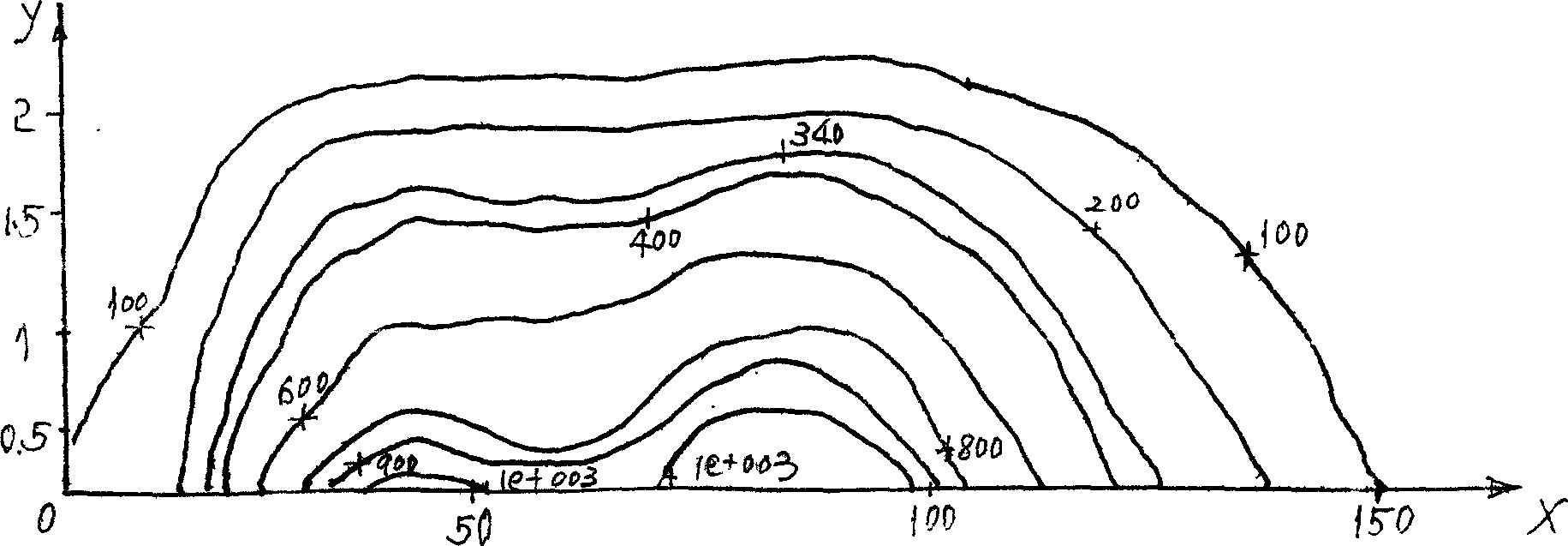

Symbolic gas detecting, regulating and controlling method for underground coal gasification

InactiveCN1667241AHigh calorific valueExtend service hoursSurveyFluid removalProcess engineeringCoal gas

The invention relates to a detecting and controlling method for coal underground gasification indicating gas that belongs to underground coal developing. The invention supplies an enforceable controlling method for coal underground gasification producing. And a new aspect is supplied for the developing of coal industry.

Owner:LIAONING TECHNICAL UNIVERSITY

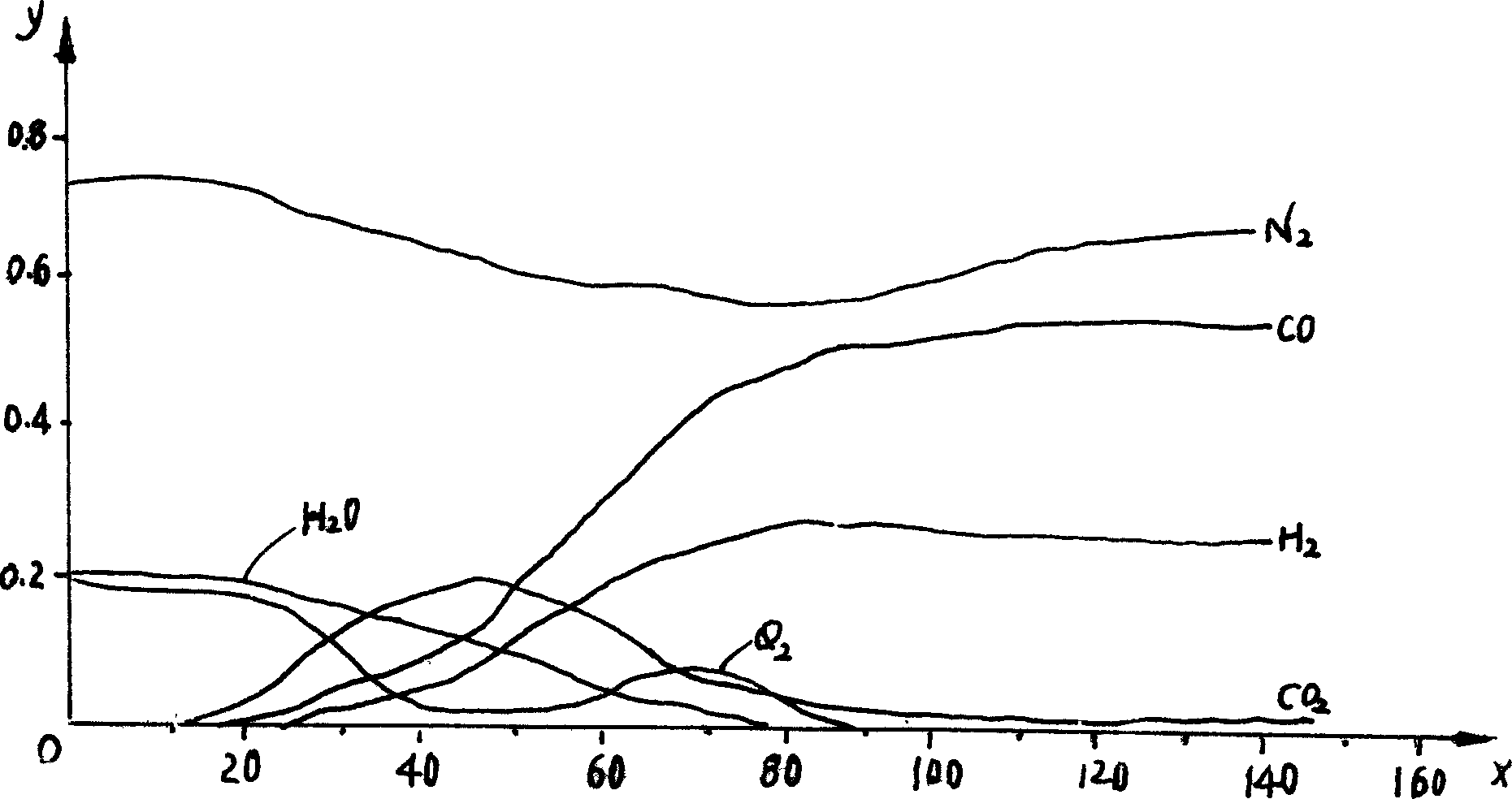

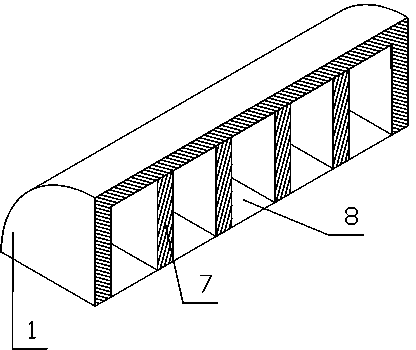

Multi pass gasifier

InactiveUS20070089367A1Reduce necessityIncrease temperatureProductsReagentsInternal combustion engineScrubber

Apparatus and method for high temperature, auto thermal gasification of solid material are disclosed. Resulting in a clean burning uniform gas usually referred to as Producer Gas. The apparatus is comprised of an outer chamber encircling a multi fold gas-path chamber that is suspended. The center of said chamber also serves as a continuous feed stock inlet. Combustion oxidizer is introduced to the lower portion of said chamber through a nozzle, just below a fire grate or screen, producing a high velocity oxidizer flow resulting in a high temperature localized heat zone. Flow is vertical through the combustion zone and into the descending feed stock, resulting in a counter-current flow. Gases and volatized tar and oil flow vertically in the space between the labyrinth and shell where said gas flow velocity is reduced considerably. Some tar and oil condensing takes place and said tar and oil flows downwardly to the heat zone to be further cracked. Said velocity reduction also inhibits particulate flow in said gas stream. Said gases enter the labyrinth as a reduced gas flow where further condensing of remaining tar and oil also takes place in the labyrinth where they will flow downwardly to the concentrated heat zone, resulting in a distilling, reducing, reacting environment. This process is repeated through the several labyrinth passes that produce the conditions and time necessary for complete cracking of the hydrocarbon compounds to a stable gas eliminating the need for tar removal equipment and or scrubbers. This utilizes more of the total B.T.U. available in the solid fuel. Evolved gases are eventually drawn off as a very uniform clean burning synthesis gas, filtered for particulates and fed directly to an internal combustion engine. Below the gasification chamber is an ash collection region, which allows for collection and removal of ash produced in the gasification process

Owner:GODDARD EDWARD PASCAL

Method for producing biogas by aid of intensified anaerobic fermentation of pretreated circular backflow sludge

ActiveCN102603142AImprove energy recoveryPromote resource utilizationWaste based fuelBiological sludge treatmentRetention timeDewatered sludge

The invention belongs to the technical field of solid waste reclamation, and discloses a method for producing biogas by the aid of intensified anaerobic fermentation of pretreated circular backflow sludge. The method includes steps: preparing concentrated sludge and dewatered sludge into mixed sludge; taking the mixed sludge as a fed material for anaerobic digestion; discharging sludge with the same volume; simultaneously, repeatedly carrying out anaerobic digestion after the backflow sludge is pretreated; and collecting the biogas. By the aid of the method, total gas yield by the aid of anaerobic digestion of the sludge is increased, the retention time of the sludge is shortened, and the volume of a sludge anaerobic fermentation tank is reduced.

Owner:TONGJI UNIV

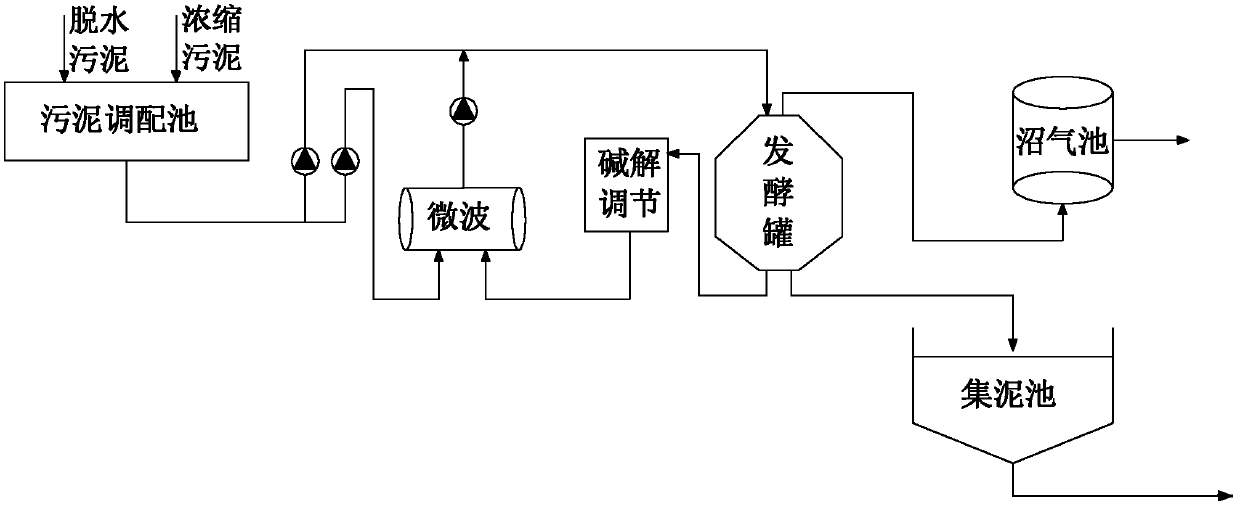

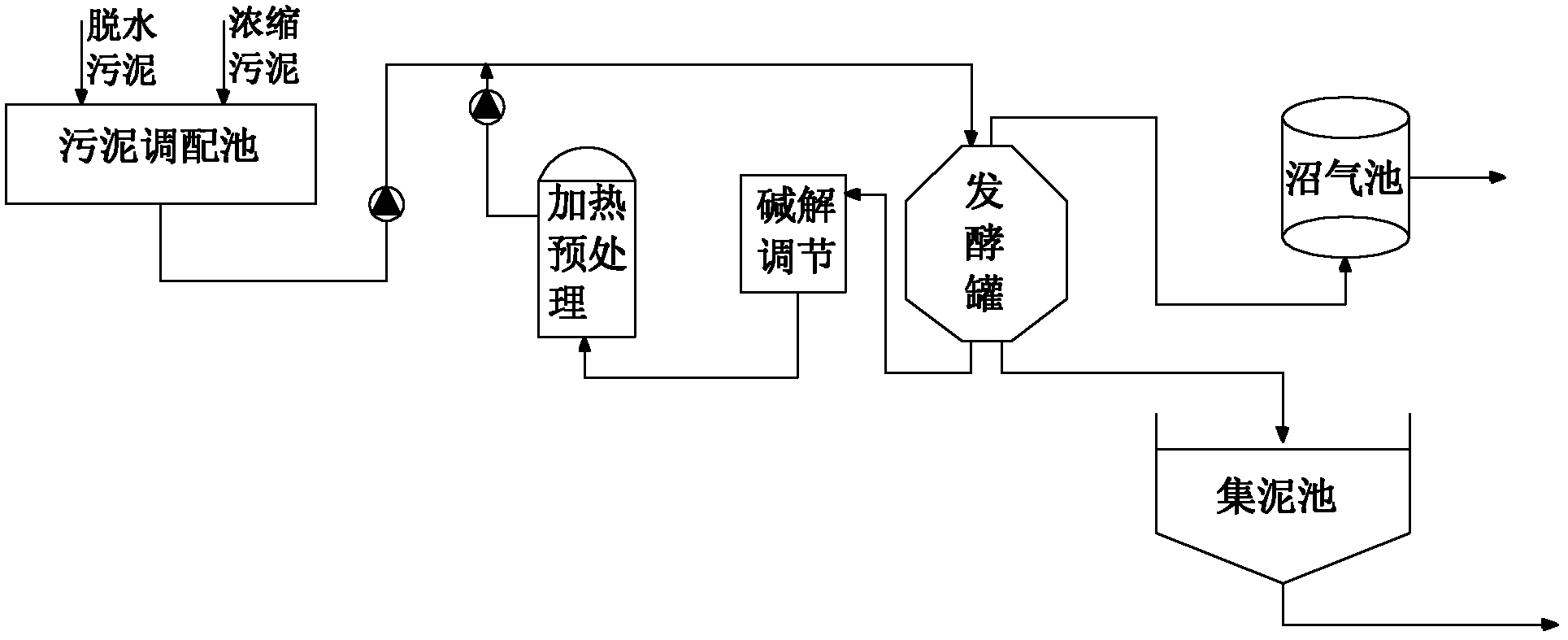

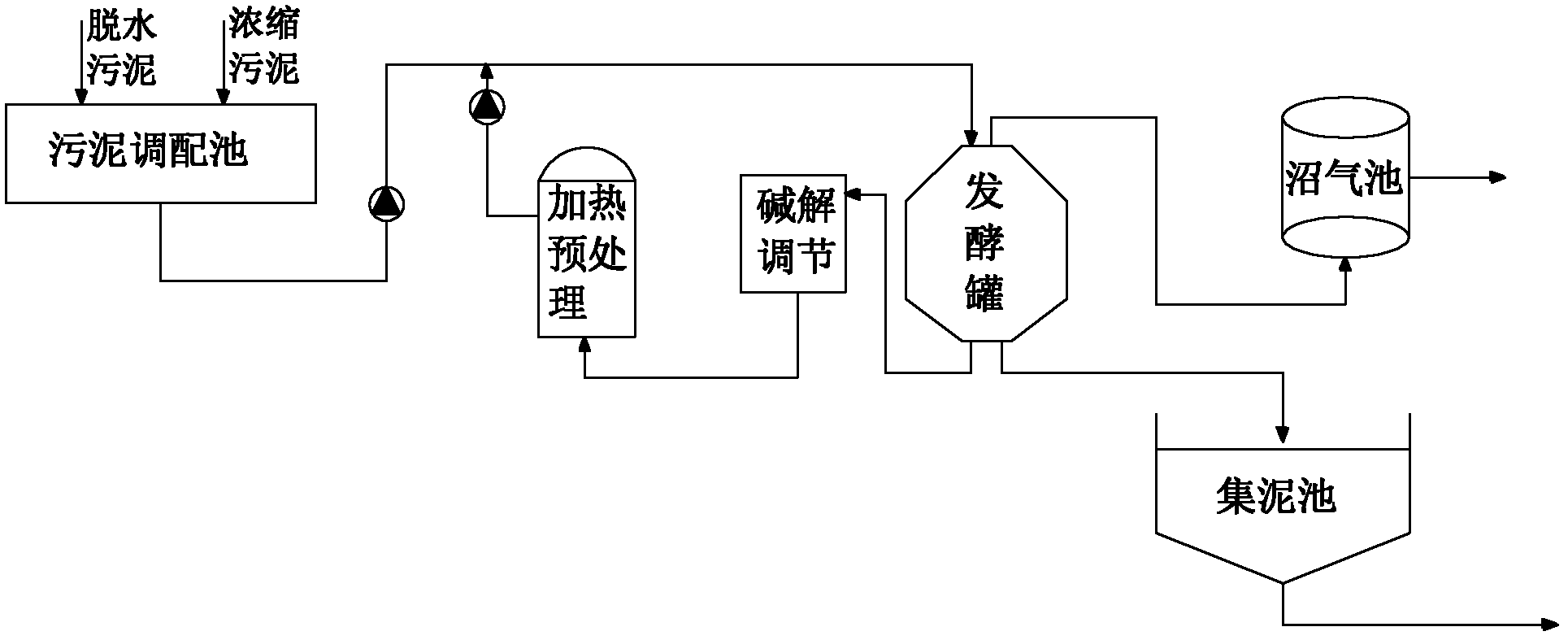

Method for generating methane by enhancing anaerobic digestion of reflux sludge after heat and alkaoline combined treatment and circulation

InactiveCN102583932APromote resource utilizationStable gas productionWaste based fuelBiological sludge treatmentRefluxDissolution

The invention belongs to the technical field of recycling of solid wastes and discloses a method for generating methane by enhancing anaerobic digestion of reflux sludge after heat and alkaoline combined treatment and circulation. The method comprises the following steps: preparing mixed sludge from concentrated sludge and dehydrated sludge; feeding the mixed sludge and performing anaerobic digestion; discharging the sludge with the same volume; performing heat and alkaoline combined pretreatment on the reflux sludge; circulating and performing anaerobic digestion; and collecting the methane. In the method, a heat and alkaoline combined pretreatment circulation reflux sludge system is provided, so the mixed effect of a fermentation system is enhanced, dissolution of solid organic matters is enhanced, and the reactor can operate efficiently and stably.

Owner:TONGJI UNIV

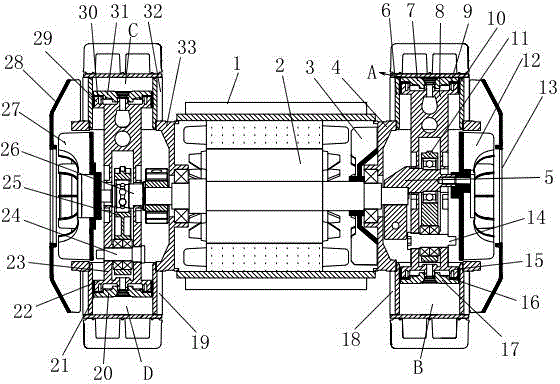

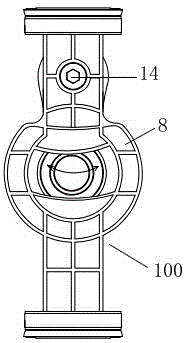

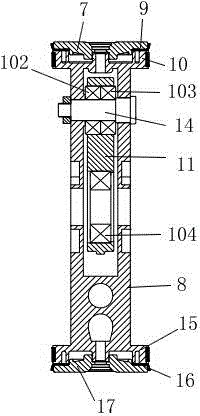

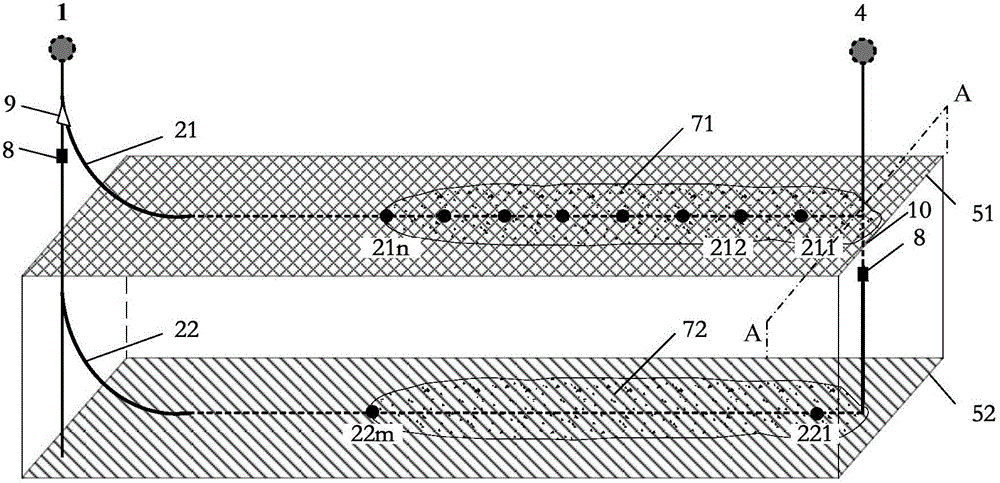

Oilless compression device with multiple cylinders and opposite pistons

ActiveCN104153963AEase frictionExtended service lifePositive displacement pump componentsPiston pumpsLubricationDrive motor

The invention relates to an oilless compression device with multiple cylinders and opposite pistons. The oilless compression device comprises a driving motor, a cylinder and an air guiding cover, and is characterized in that an output shaft of the driving motor is connected with a group of piston subassemblies which share a shaft, are opposite to one another and freely move in the cylinders in a reciprocating manner; the piston subassemblies are connected to crankshafts which are connected with the output shaft of the driving motor; a crankcase is arranged between each crankshaft and the driving motor; and the piston subassemblies are driven by the crankshafts to regularly move vertically in a reciprocating manner. Compared with a like compressor, the oilless compression device has the advantages that the design thought is fashionable; the traditional oil lubrication mode or the traditional compression lubrication mode is changed; the structure of the oilless compression device is novel; each double-head piston is provided with a guiding ring and a piston cup, the crankshafts are arranged perpendicularly in a staggered manner, the two cylinders are opposite to each other, and uniform and pure compressed air can be yielded; and the oilless compression device is reliable and compact in structure, low in cost, high in efficiency, low in leakage, long in service life and high in stability.

Owner:杨柳

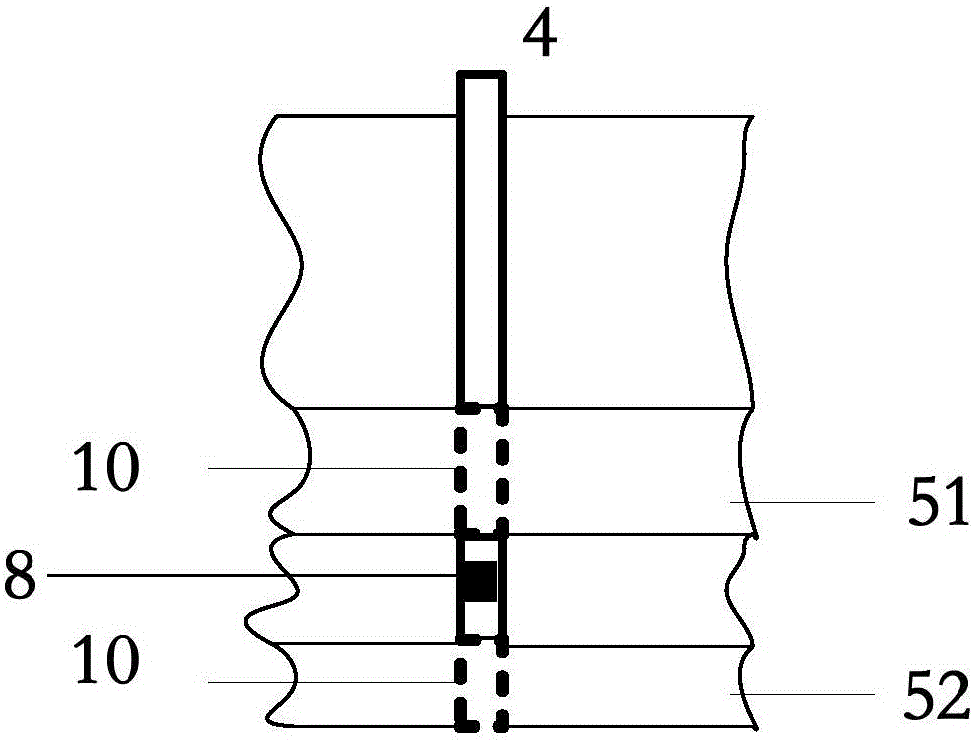

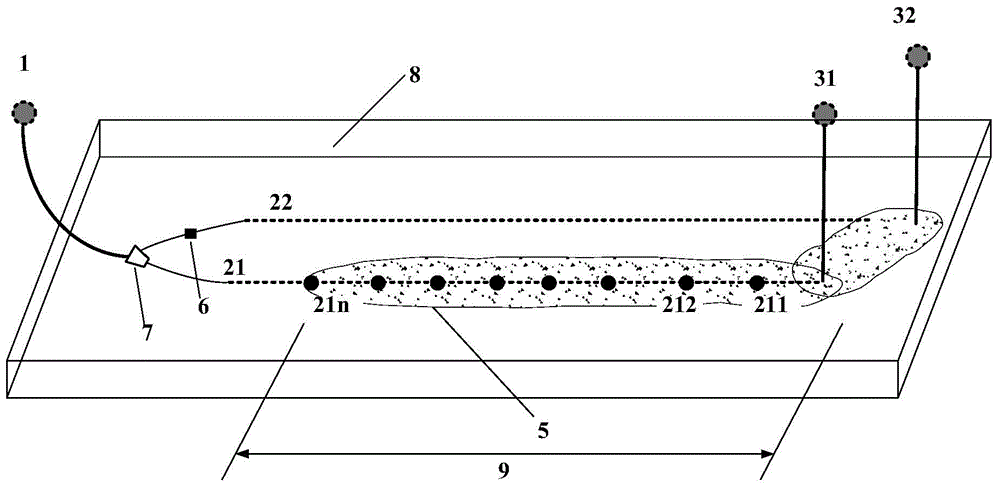

Multilayer coal seam gasification furnace and coal seam gasification method

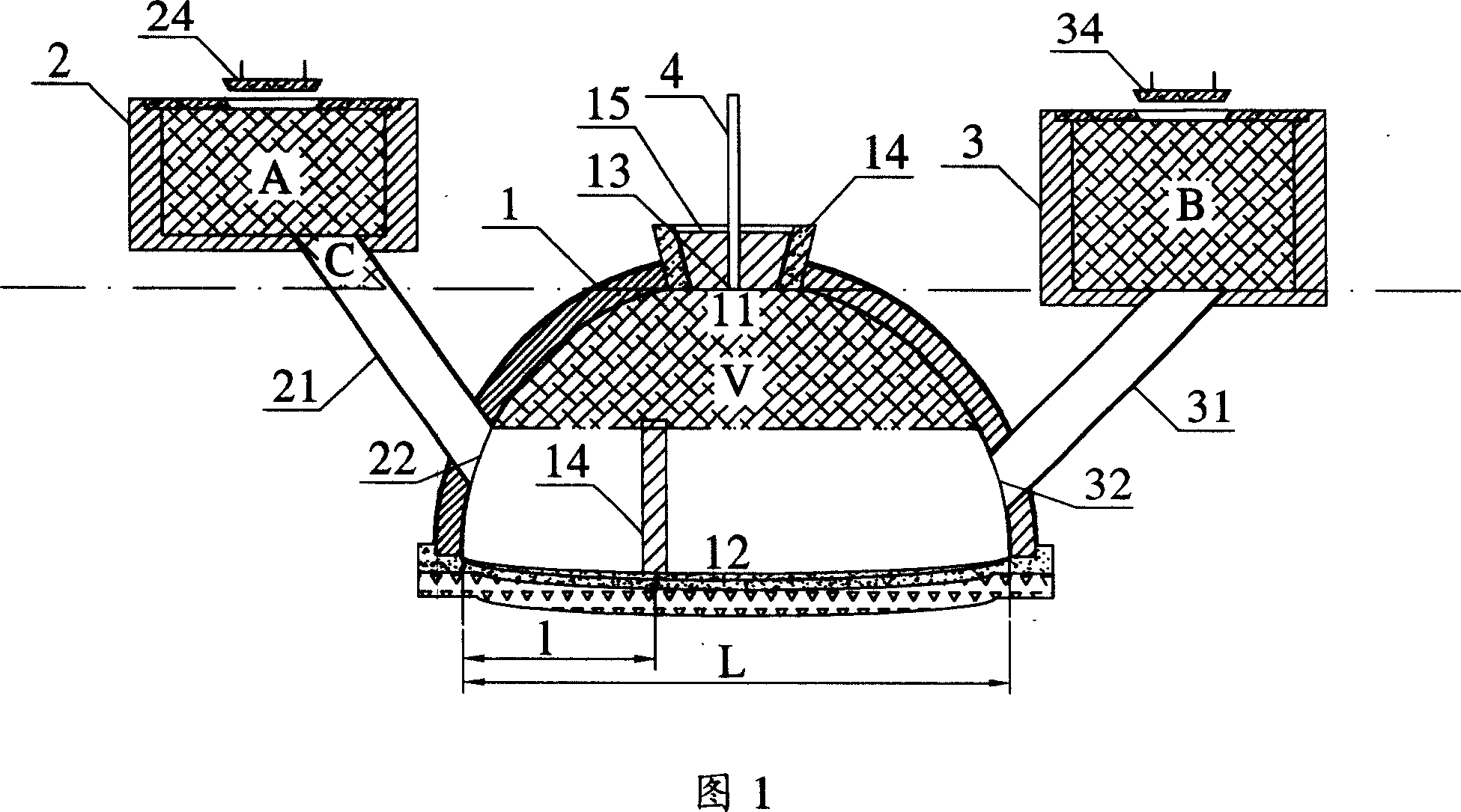

ActiveCN105041290AControllable gasification processImprove recovery rateConstructionsCoal gasificationInjection wellCoal

The invention discloses a multilayer coal seam gasification furnace and coal seam gasification method; the coal seam gasification furnace comprises the following structures: a gas-injection well, and each coal seam at least comprises one branch well connected with the gas-injection well; a gas outlet well; a gasification path; a blocking device; a guide device; a gas injection device. The blocking device is placed to a branch window of the branch well and used for blocking the branch well; the guide device is placed in the branch window of the branch well, and used for guiding the gas injection device into the branch well; the blocking device can separate and control different branch wells; the gas injection device can control a gasification process of different coal seam zones through different gas injection points of different branch wells under the guide device effect, thus realizing gasifying agent fixed point and quantification injection, controlling the gasification process of the multilayer coal seam, and preventing mutual interferences between the coal seams in the coal seam gasification process; the multilayer coal seam gasification furnace and coal seam gasification method are stable in a gas production process, improve coal seam recovery rate, reduce drilling well quantity, and reduce gasification exploitation cost.

Owner:ENN SCI & TECH DEV

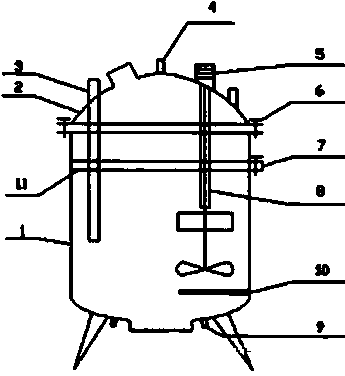

Invisible multistage methane tank capable of producing methane evenly

ActiveCN103923822AReduce stressExtended service lifeGas production bioreactorsWaste based fuelMethaneWaste management

The invention relates to an invisible multistage methane tank capable of producing methane evenly, which aims at solving the technical problem that the existing methane tank has short service life, has low yield of methane, provides methane unstably and is inconvenient to use and maintain. The methane tank comprises a tank wall and a tank bottom below the wall, wherein the joint of the tank wall and the tank bottom of the methane tank is smoothly connected; the methane tank also comprises an arch tank top, which is internally provided with clapboards dividing the tank top into at least two air collection chambers; the methane tank is also provided with a spraying and stirring mechanism, which comprises a liquid pump, an air inlet pipeline and an air outlet pipeline. The invisible multistage methane tank has the beneficial effects of having long service life as smooth arc transition reduces stress at the joint, being capable of maintaining on line, producing methane evenly, and occupying small land; in addition, the tank top has a plurality of air chambers and a plurality of sets of air outlet pipes, so that if one air chamber leaks air, the other air chambers are not affected, the continuity of methane supply is improved; the spraying and stirring mechanism washes the methane tank at the right time, so as to avoid crusting and increase the yield of methane.

Owner:郭群然

System for combined supply of electricity, thermal fertilizer and cold fertilizer through generation of hydrogen and biogas via anaerobic digestion of biomasses

ActiveCN102491613AIncrease profitIncrease gas production rateBioreactor/fermenter combinationsBio-organic fraction processingAerobic digestionBiomass

The invention relates to system for the combined supply of electricity, a thermal fertilizer and a cold fertilizer through the generation of hydrogen and biogas via the anaerobic digestion of biomasses. The system is characterized in that the system comprises: a hydrogen anaerobic digestion raw material conveying end, a hydrogen anaerobic digestion pool, a first gas purifying apparatus and a hydrogen storage apparatus which are sequentially communicated; a biogas anaerobic digestion raw material conveying end, a biogas anaerobic digestion pool, an organic biogas fertilizer conveying end, a second gas purifying apparatus, a greenhouse, a high pressure gas storage cabinet, a fuel modification apparatus, a fuel cell set, an inverter communicated with the and an electricity consumption apparatus which are sequentially communicated; a combustion gas boiler, a thermal load and a cycle pump which are sequentially communicated; and a solar energy and / or geothermal energy thermal source which is communicated with internal heating coilers in the hydrogen anaerobic digestion pool and the biogas anaerobic digestion pool. The system can fully utilize the geothermal energy and / or the solar energy, and the biomasses to stably and continuously generate electricity, supply heat or refrigerate, and supply organic fertilizers.

Owner:杨善让

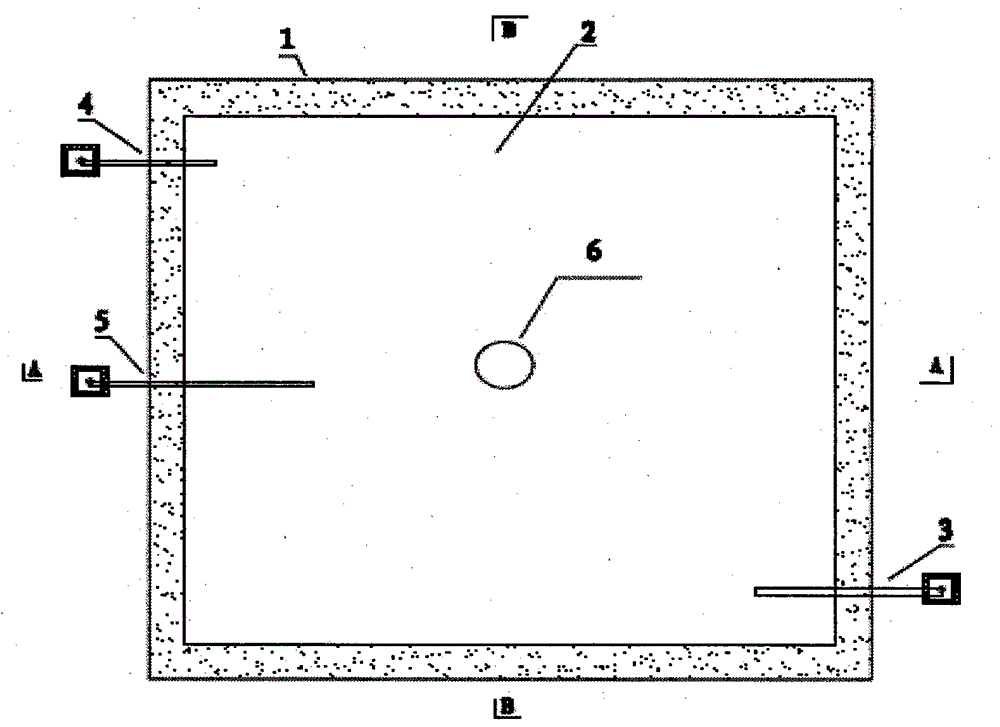

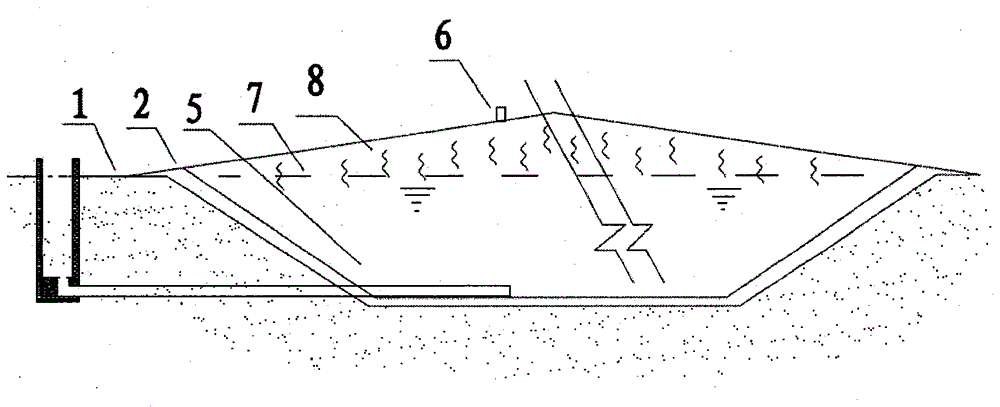

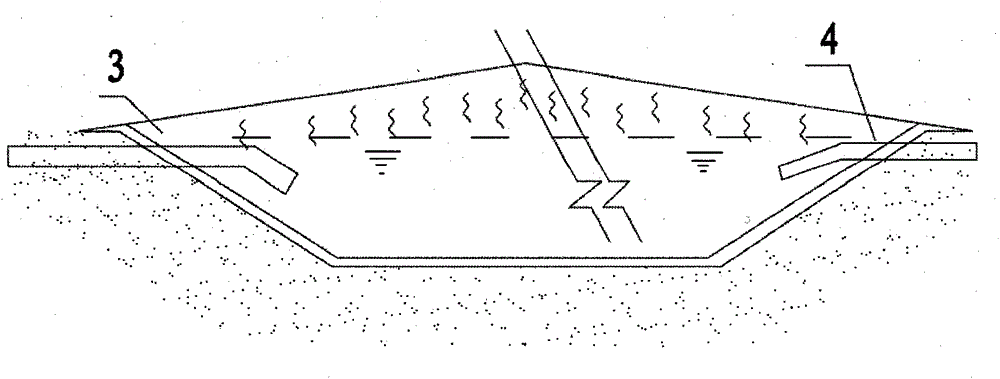

Black membrane biogas digester

InactiveCN104004647AReduce construction costsEasy constructionApparatus sterilizationGas production bioreactorsSewageFermentation

The invention relates to a black methane biogas digester. The black methane biogas digester is an anaerobic fermentation pool. The seepage and leakage resistance of an HDPE membrane is used, an HDPE impermeable membrane is laid in a dug earth pit, a water outlet, a residue pumping pipe and a biogas collecting pipe are arranged in the pool according to anaerobic fermentation process requirements, the upper mouth of the earth pit is covered with the HDPE impervious membrane in order to seal the earth pit, and peripheral anchoring trenches are fixed to form an integral anaerobic fermentation space. Pretreated aquaculture wastewater enters the sealed space and is fermented to produce biogas, so the original high construction cost problem of the biogas digester is solved.

Owner:方青海

Method for fermenting ammonia pre-treated wheat stalks to produce methane

ActiveCN102399825AIncrease profitAddressing inefficiencies in fermentationWaste based fuelFermentationAmmoniaFermentation

The invention discloses a method for fermenting ammonia pre-treated wheat stalks to produce methane in the technical field of agricultural production. The methane is prepared by pre-treating wheat stalks and carrying out complete mixed anaerobic fermentation on the pre-treated wheat stalks. According to the invention, the methane is high efficiently and stably prepared by using the wheat stalks. The method for fermenting ammonia pre-treated wheat stalks to produce methane, disclosed by the invention, has the characteristics of high raw material utilization rate, stability in gas production, large gas producing quantity and uneasiness for scum crusting in the fermenting process; and recycling, energy and harmlessness of the wheat stalks are realized.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing methane by carrying out co-digestion on pig manure and tea-oil tree shell

InactiveCN104017621AHigh activityIncrease profitGaseous fuelsWaste based fuelCo digestionBiotechnology

The invention relates to a method for producing methane by carrying out co-digestion on pig manure and tea-oil tree shell. The method for producing the methane by carrying out co-digestion on the pig manure and tea-oil tree shell concretely comprises the steps of mixing the tea-oil tree shell serving as a raw material with the pig manure in different proportions in a controllable constant temperature anaerobic stainless steel fermentation tank at the high temperature of 50 DEG C in a semi-continuous anaerobic fermentation way, and then carrying out co-digestion, thereby producing the methane. Compared with the pure pig manure fermentation, the method for producing the methane by carrying out the co-digestion on the pig manure and the tea-oil tree shell has the advantages that raw materials of the methane can be enriched, the problem of supply of the raw materials of the methane can be alleviated, popularization and application of the methane is promoted, and additional use value of tea-oil tree fruits is increased.

Owner:NANCHANG UNIV

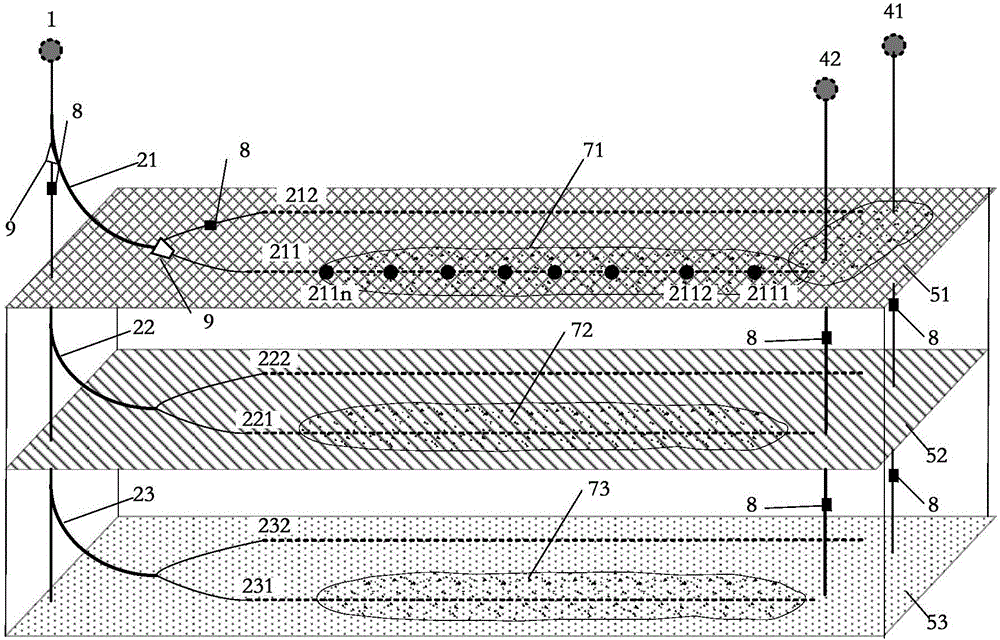

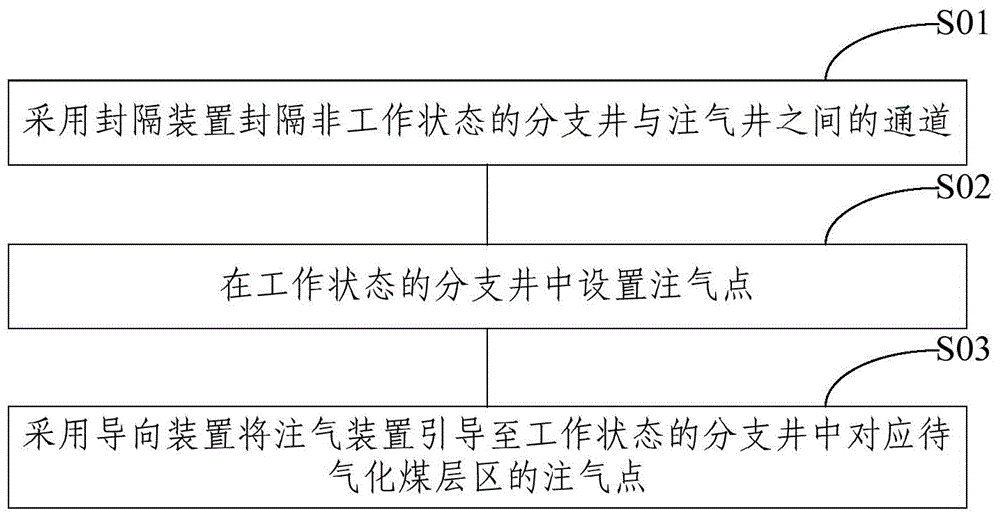

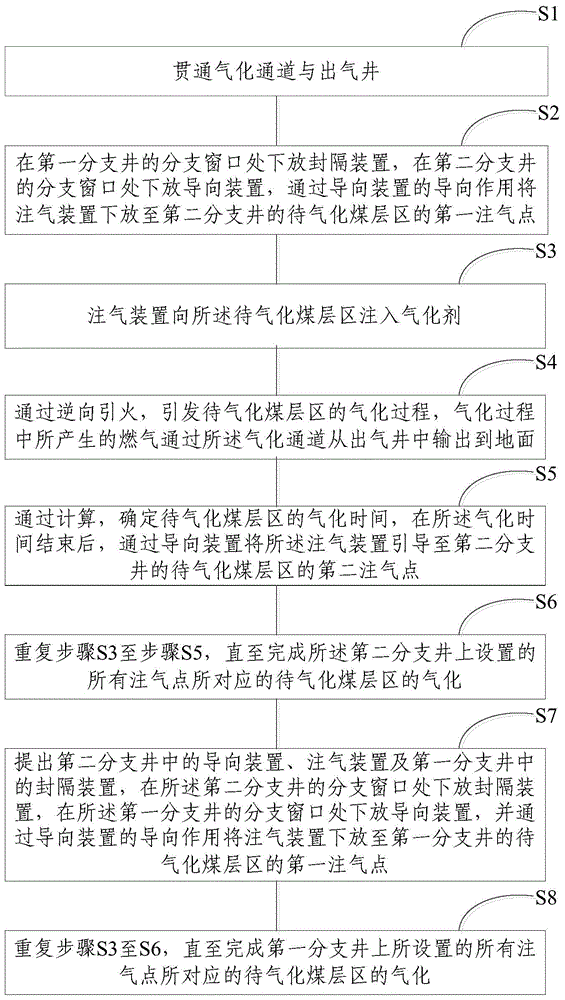

Gasification method and gasification furnace of coal seams based on branch wells

ActiveCN104695933ACalorific value stableImprove recovery rateConstructionsCoal gasificationCoal miningInjection well

The invention discloses a gasification method and gasification furnace of coal seams based on branch wells, and aims to solve the problems that a gasification technique of coal seams is high in cost and low in recovery ratio in the prior art. The gasification method comprises the following steps: after finishing drilling construction, enabling gasification channels to be run-through, respectively downwards placing packers or guidance devices in different branch wells, downwards placing gas injecting devices in corresponding branch wells through the guidance devices, injecting a gasifying agent, confirming the gasifying time of coal seam regions to be gasified through calculation, and completing the gasifying process of the coal seam regions to be gasified; replacing the packers or the guidance devices in the branch wells, completing the gasifying process of the coal seam regions to be gasified of all branch wells, and outputting generated fuel gas to the ground through gas exhaust wells. Through the adoption of the gasification method disclosed by the invention, the fixed point quantitative controllable injection of the gasifying agent is realized, the process of gas generation is stable, the demands of the deep processing of fuel gas are satisfied, the gasification coal mining output and the recovery ratio of single well are effectively increased, besides, the service life of each gas injection well is prolonged, the cost of building furnaces and drilling is reduced, and the cost of ground construction and operation is reduced.

Owner:ENN SCI & TECH DEV

Method for improving characteristics of marsh gas produced through anaerobic fermentation of chicken manure

InactiveCN107935344AEasy to operateImprove controllabilityBiological sludge treatmentProduction rateResource utilization

The invention discloses a method for improving the characteristics of marsh gas produced through anaerobic fermentation of chicken manure. The production of marsh gas is promoted through anaerobic fermentation of chicken manure by taking zeolite as an external source additive. According to the method, efficient and stable production of marsh gas by using chicken manure is realized, the method hasthe characteristics of large fermentation gas production rate, stable gas production and high content of methane in the produced gas, the problem that the system is easy to collapse, which is caused by ammonia nitrogen inhibition in the anaerobic digestion process of chicken manure, is solved, and theoretical foundation and data support are provided for energy and resource utilization of chicken manure.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing marsh gas by pretreating rice straws with acid

InactiveCN102154374BImprove efficiencyIncrease profitWaste based fuelFermentationSlagEnergy regeneration

The invention relates to a method for preparing marsh gas by pretreating rice straws with acid, belonging to the technical field of agricultural production. In the method, marsh gas is prepared by pretreating rice straws with acid and performing completely mixed anaerobic fermentation. By adopting the method, efficient and stable preparation of marsh gas is realized by using rice straws. The method has the characteristics of high raw material utilization ratio, stable gas production, high gas yield, difficult occurrence of floating slag incrustation phenomenon in the fermenting process and realization of resource, energy regeneration and harmless treatment of rice straws.

Owner:SHANGHAI JIAO TONG UNIV

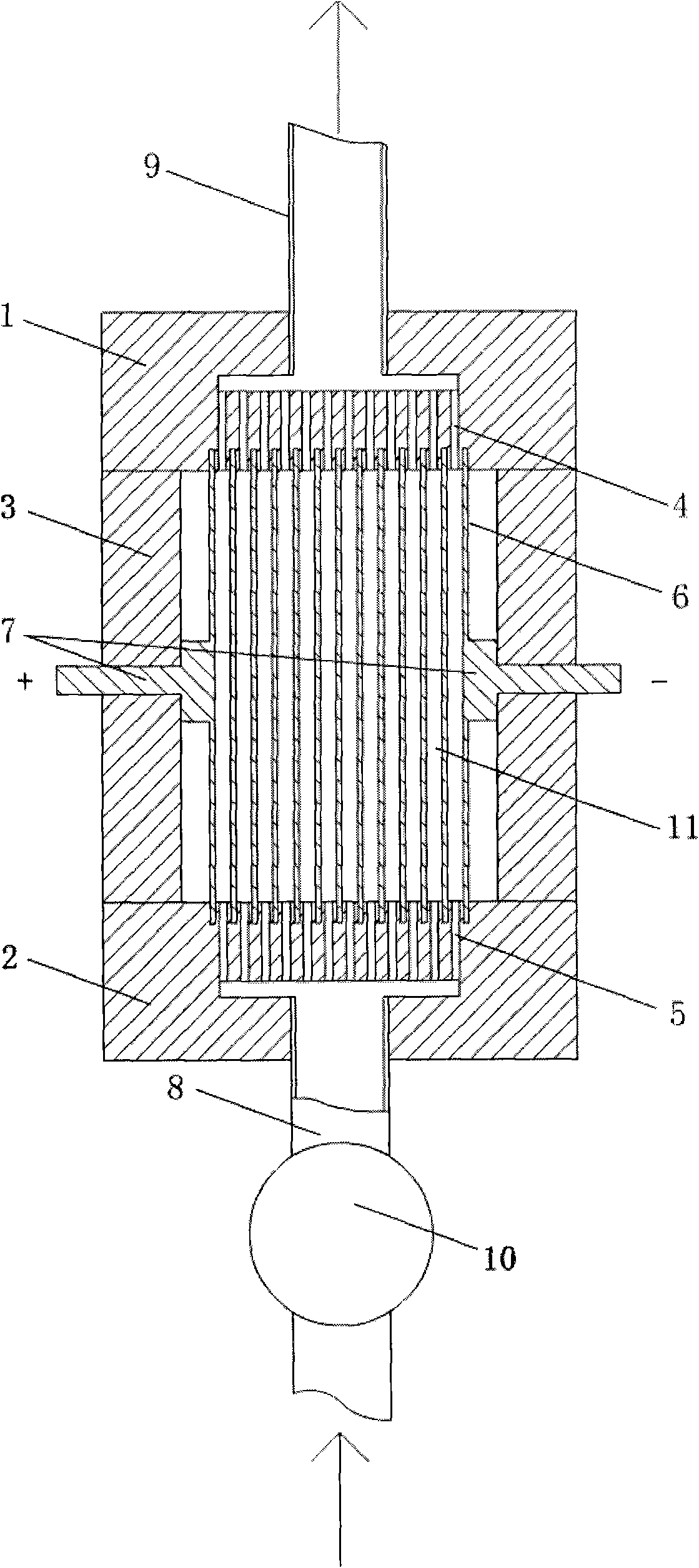

Oxyhydrogen electrolytic cell with high efficiency

InactiveCN101550553AOvercome the drawbacks affecting gas productionQuality improvementElectrolysis componentsLongest DiameterMetal electrodes

The present invention relates to an oxyhydrogen electrolytic cell with high efficiency which includes a housing, a subbase, an upper cover, N+1 metal electrode plates, an electrolysing solution ingress pipe, an electrolysing solution and gas eduction tube, N*M upper cover manifold assembly, N*M subbase manifold assembly, two electrode connection bolts, two electrode connection bolts are installed on the housing, the subbase is equipped with the electrolysing solution ingress pipe connecting with the subbase manifold assembly, the upper cover is equipped with the electrolysing solution and gas eduction tube connecting with the upper cover manifold assembly, four edges of N+1 metal electrode plates are beset in the upper cover, the housing and the subbase with same interval, an electrolysing small chamber communicates with the upper cover manifold assembly and the bottom manifold assembly distributed evenly, the first and the N+1 th electrode plate connects with a positive pole and a cathode pole through two electrode connection bolts respectively. The manifold assembly has little and relative long diameter, each metal electrode plate generates little side road parasitic current through the electrolysing solution in the manifold assembly, accordingly, reduces consumption and increases electrolytic efficiency.

Owner:武汉微氢科技有限公司

Ammonia-biological joint treatment method for fermenting wheat straws to produce biogas

ActiveCN102586335BEasy to operateSolve the problem of low fermentation efficiencyWaste based fuelFermentationBiotechnologyBiogas production

The invention discloses an ammonia-biological joint treatment method for fermenting wheat straws to produce biogas, in the technical field of agricultural production. After being sequentially pretreated by ammonia and biologically, the wheat straws undergo complete mixing type anaerobic fermentation to produce the biogas. The method utilizes the wheat straws to efficiently and stably produce the biogas. The method has the characteristics of short fermentation period, stable biogas production, high biogas output and high methane content in the produced biogas, solves the problem that wheat straw waste is difficult to be anaerobically digested to produce the biogas, and provides a feasible reference for the utilization of the wheat straws as a resource and energy.

Owner:SHANGHAI JIAO TONG UNIV

Process for producing biogas through livestock and poultry solid excrements

InactiveCN107857451AImprove fertilizer efficiencyEfficient use ofSludge treatment by de-watering/drying/thickeningWater treatment parameter controlBiotechnologyFeces

The invention relates to a process for producing biogas through livestock and poultry solid excrements, and belongs to the technical field of livestock and poultry breeding. The process includes the following steps of firstly, preprocessing the livestock and poultry solid excrements; secondly, conducting anaerobic biological treatment, wherein a fermentation auxiliary material is prepared, fermentation fungus liquid is prepared, the livestock and poultry solid excrements and the fermentation auxiliary material are sufficiently mixed to prepare a mixed material, the mixed material is put in a biogas digester, the fermentation fungus liquid is prayed in the mixed material, anaerobic digestion is conducted, generated biogas is collected in a storage cylinder, biogas slurry and biogas residuesare further processed and can be used for greening and applying. The process is simple in process, low in cost, rapid in fermentation speed and uniform and stable in gas generation, nutrients lost infermentation are few, the obtained organic fertilizer is high in fertilizer efficiency and convenient to apply, and the pollution-free ecological healthy livestock and poultry breeding mode is realized.

Owner:山东绿福地生物科技有限公司

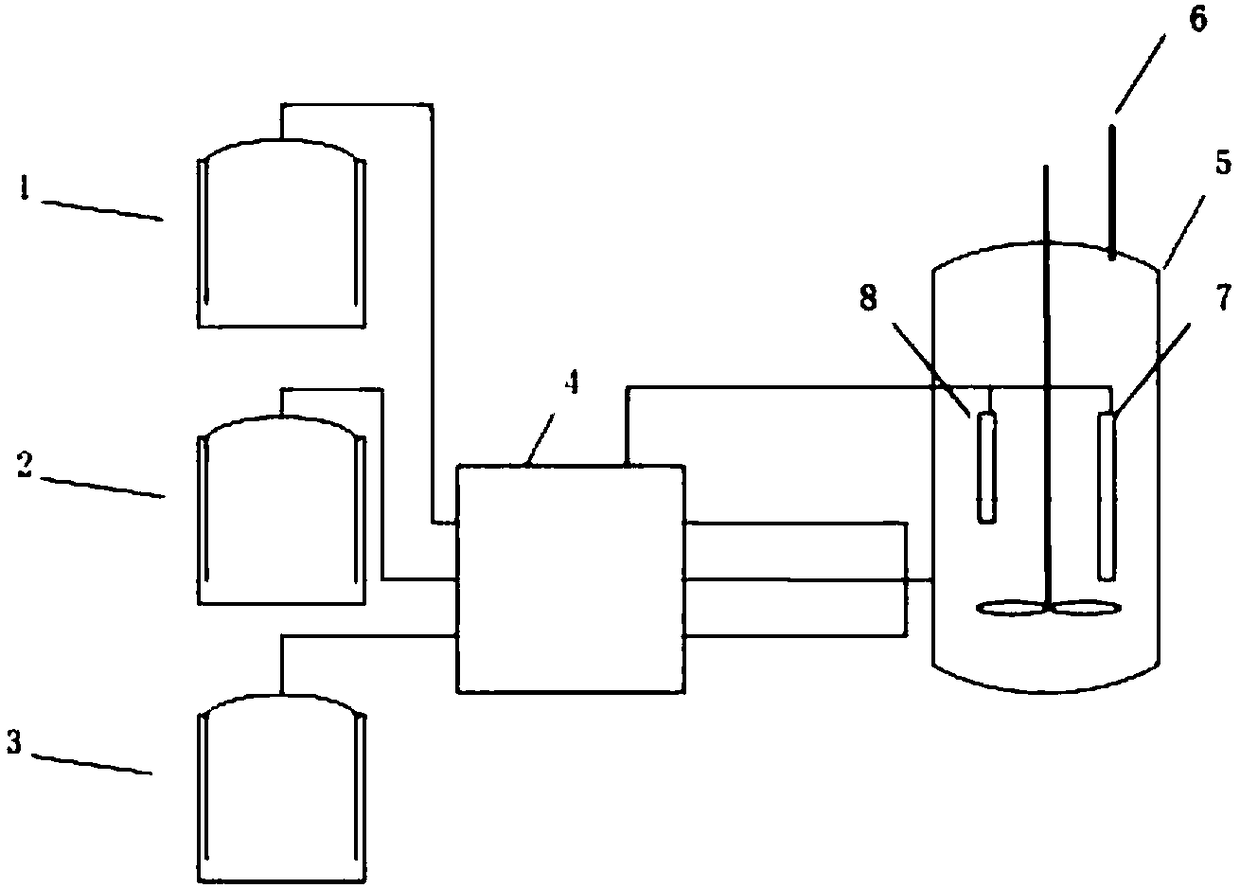

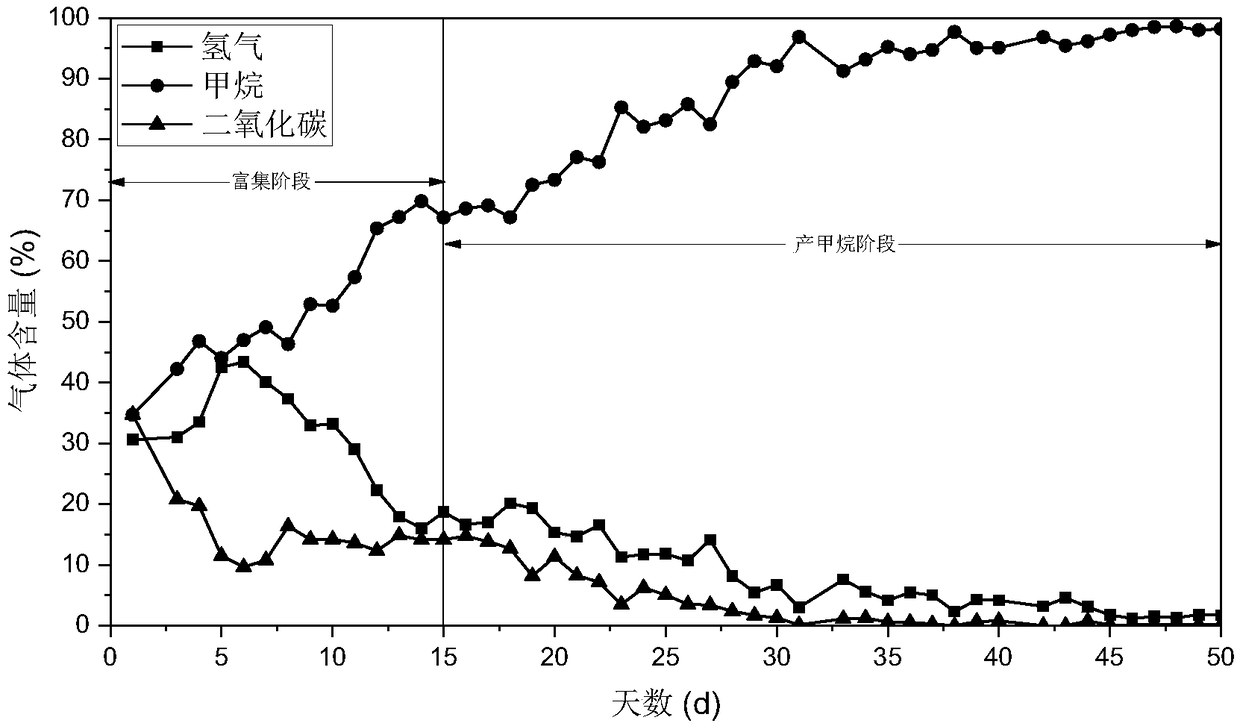

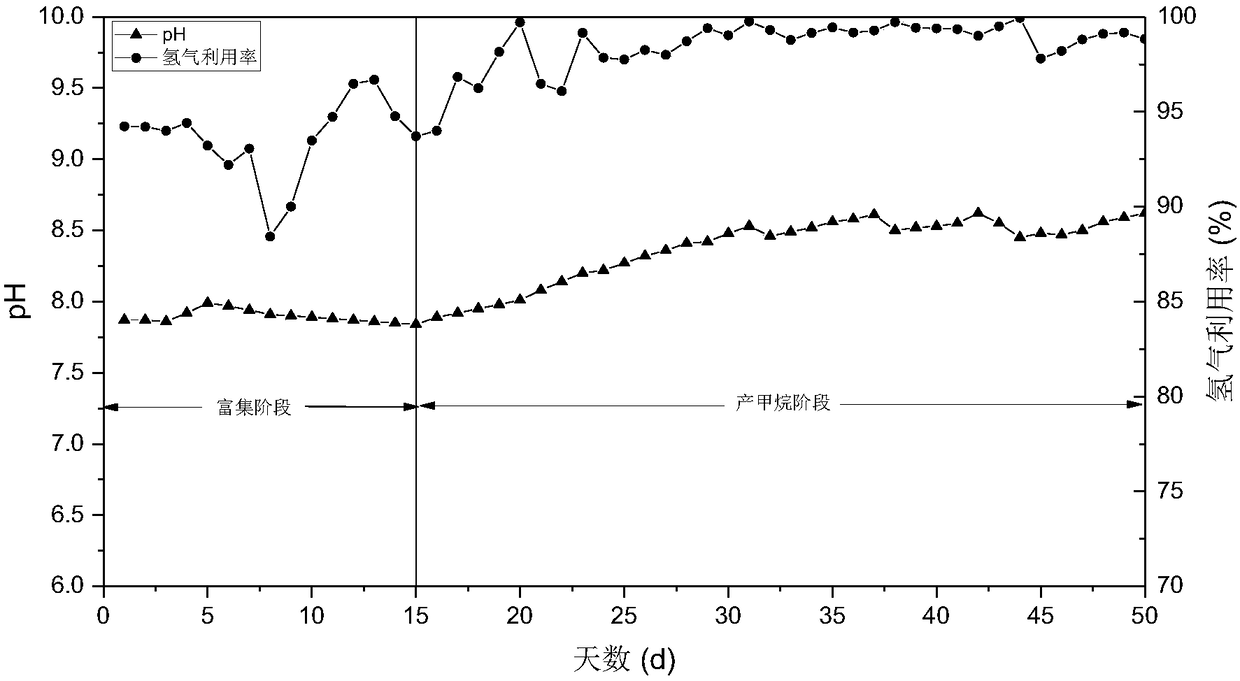

Method for simple production of high-quality biological methane

InactiveCN108265081AHigh purityPracticalMicroorganism based processesWaste based fuelHydrogenMethane production

The invention provides a method for production of high-quality biological methane by biotransformation. The method includes the following steps: firstly, hydrogen trophic methanogenic archaea is enriched in a reactor to show a good hydrogen-eating and methane-production capacity; and on the basis, the reactor is operated by a device console, so that the device can prepare the high-quality biological methane under conditions of only controlling the device gas intake quantity, gas intake ratio and rotating speed at medium temperature. Any other nutrient substances or nutrient solutions do not require to be added in the process. An idea is provided for making biological methane enter natural gas infrastructure.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com