Symbolic gas detecting, regulating and controlling method for underground coal gasification

An underground gasification and gas technology, which is applied in the fields of measurement, production of fluids, and earthwork drilling, can solve the problems of low gas calorific value, short service time, unstable gas production, etc., and achieve high gas calorific value and long service time. , Combustible components and stable effect of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

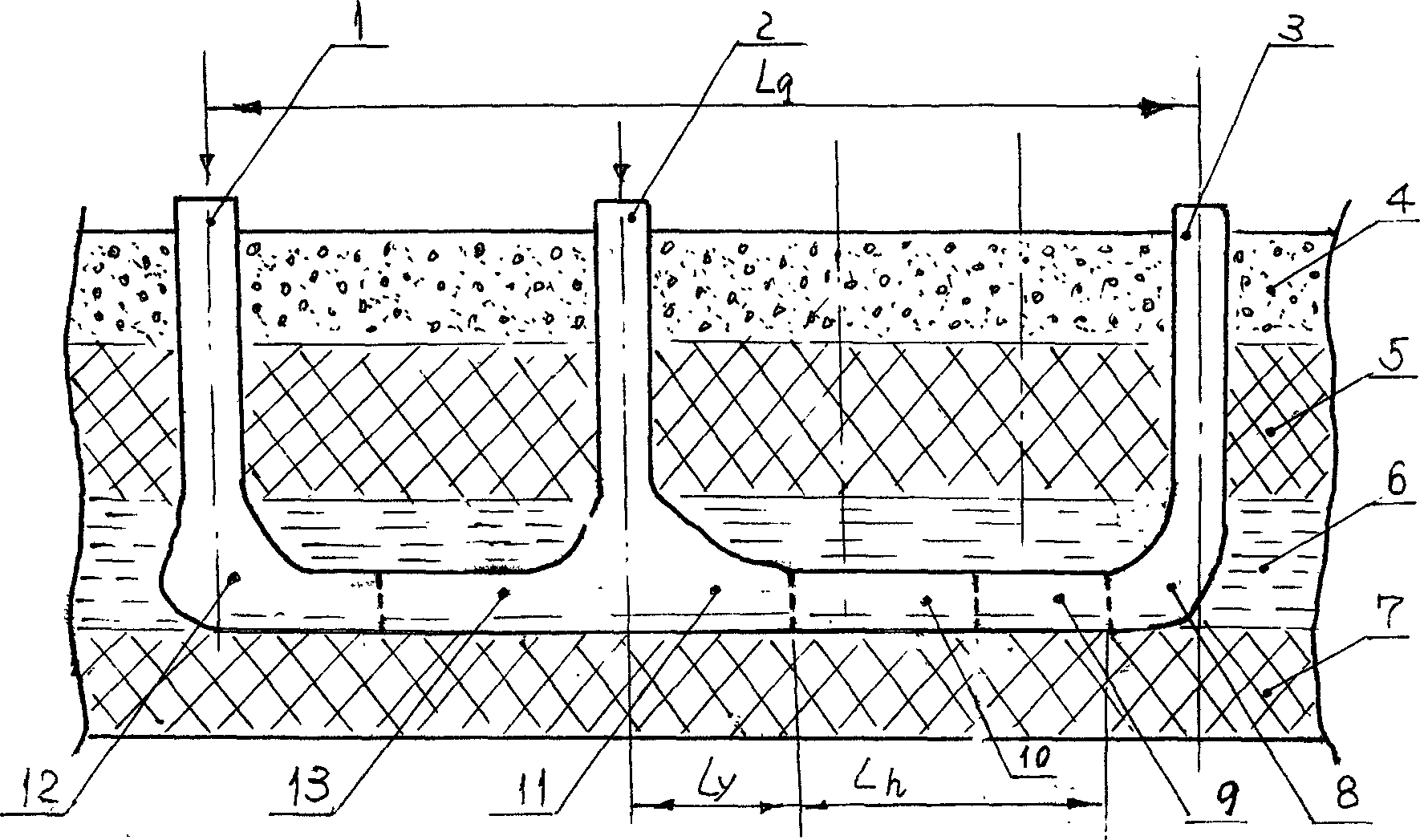

[0027] Refer to attached figure 1 , an underground coal gasification system consisting of oxidant inlet borehole 1, gas outlet borehole 3, rock and soil cover layer 4, roof and floor rock layers 5, 7, and underground coal seam 6, which is characterized in that the thickness of the underground coal seam 6 and inclination angle to ensure the continuous and stable gasification space for underground coal gasification, determine the length L of the gasification channel 13 in the underground coal gasification system q :

[0028] L q ≥ L y +L h +V s t

[0029] In the formula: L y - regulate the length of the oxidation zone, m;

[0030] L h - regulate the length of the reduction zone, m;

[0031] V s -Propelling speed of the burning face, m / d;

[0032] t-gasification one-way operation time, day;

[0033] L y =16Re 0.16 d n

[0034] In the formula: Re-Reynolds number; d-fluid equivalent value;

[0035] d=2hw / (h+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com