Biomass pool and automatic slagoff method for the same

A technology of automatic slag discharge and biogas digester, which is applied in the direction of gas production bioreactor, waste fuel, etc. It can solve the problems of the difficulty of cleaning the crusted slag, the easy leakage of the top cover, and the difficulty of breaking, etc. Discharging, conducive to heat preservation, the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

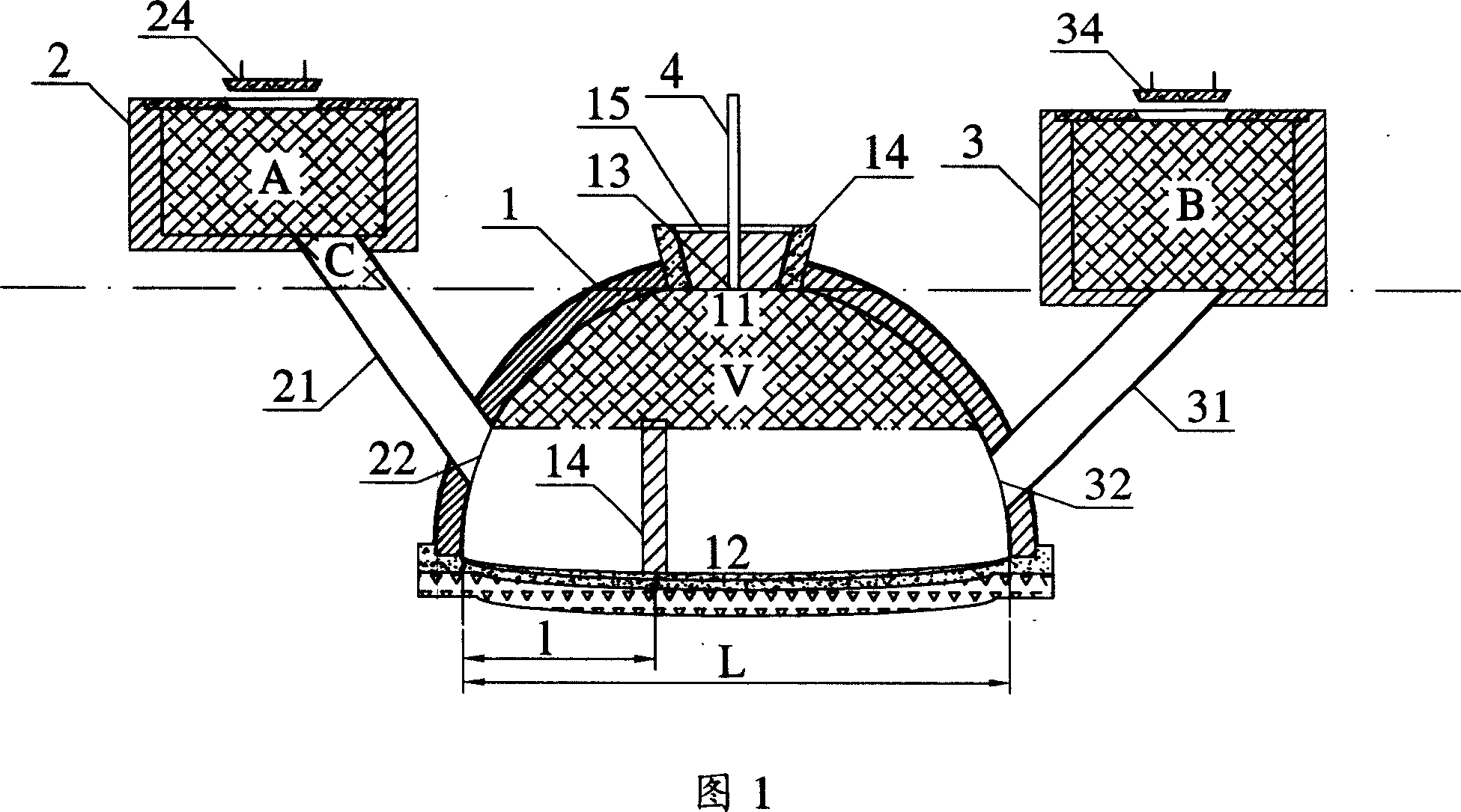

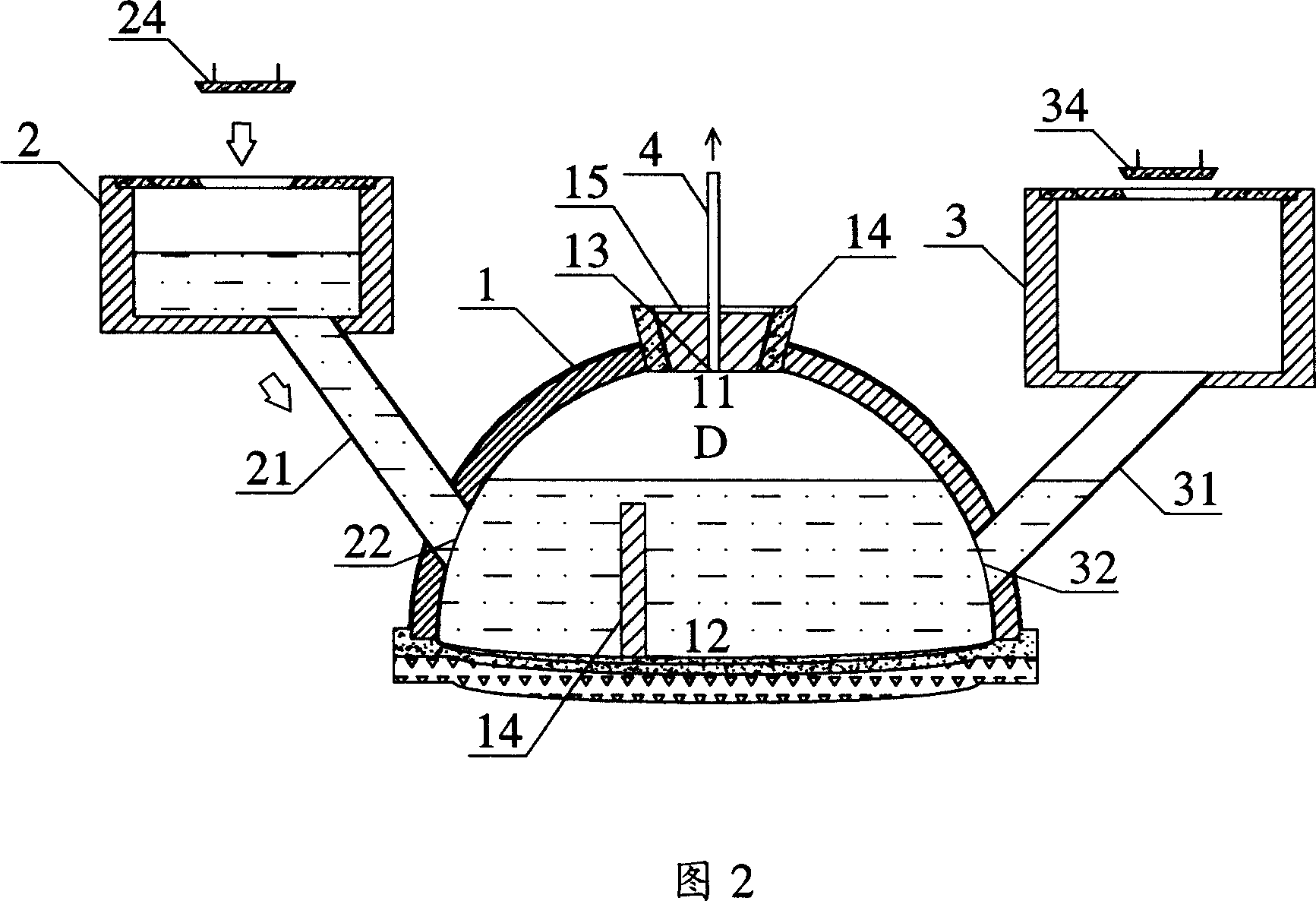

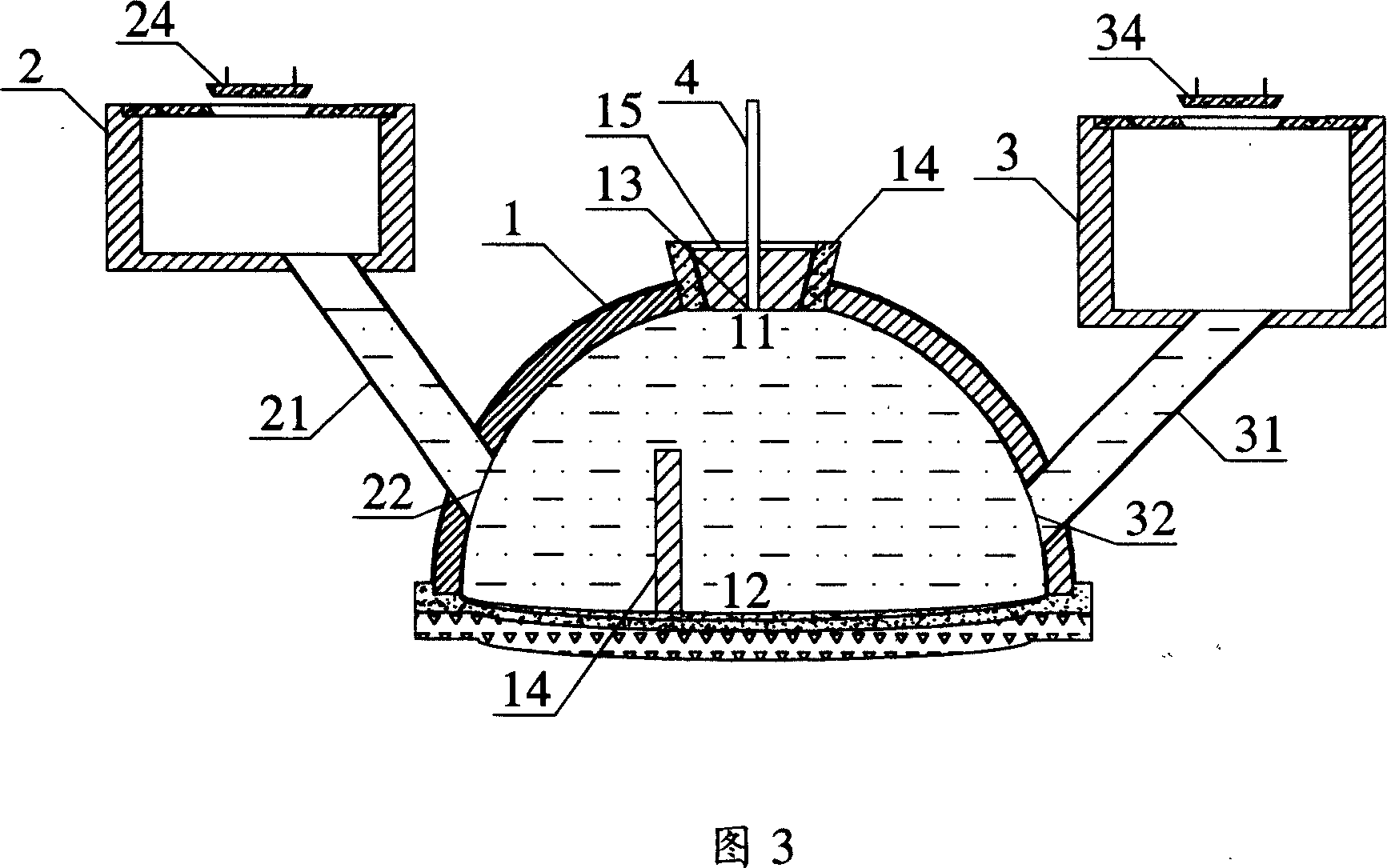

[0076] A kind of biogas digester as shown in Figure 1, comprises fermentation tank 1, feed tank 2 and discharge tank 3, feed tank 2 and discharge tank 3 are connected with fermentation tank 1 through feed pipe 21 and discharge pipe 31 respectively Connected, the fermentation tank 1 is hemispherical. In order to enable the directional flow of the fermentation feed liquid, the feed tank 2 of this embodiment is slightly higher than the discharge tank 3, the bottom of the discharge tank 3 is equal to the top 11 of the fermentation tank, and the mouth 22 of the feed pipe on the fermentation tank 1 is higher At the nozzle 32 of the discharge pipe. Under the action of hydraulic pressure, it can ensure that the fermentation feed liquid flows from the feed tank 2 to the discharge tank 3 through the fermentation tank 1 . The feed pool 2 and the discharge pool 3 are respectively provided with pool covers 21 and 31 for feeding and slag discharge. The top 11 of the fermentation tank is p...

Embodiment 2

[0083] As shown in Figure 8, the basic structure of this embodiment is the same as that of Embodiment 1, and the main structural difference is that this embodiment sets a feed port 23 and an overflow port 33 on the top side of the feed tank 2 and the discharge tank 3 respectively. , the position of the feed port 23 is slightly higher than the overflow port 33, the volume from the feed port 23 to the bottom of the pool in the feed pool 2 is A', and the volume from the overflow port 33 to the bottom of the pool in the discharge pool 3 is B' , The volume V from the upper end of the feed pipe mouth 22 to the inside of the top 11 of the fermentation tank in the fermentation tank 1 is: V=A+B+C. Also due to the problem of construction accuracy, there may be a certain error, but it should not be too large, generally controlled within 5%. The relationship between the distance l between the retaining wall 14 and the edge of the fermentation tank bottom 12 and the width L of the fermenta...

Embodiment 3

[0086]For example, there is a certain accuracy error when building a biogas digester, as shown in Figure 11. There is a certain height difference Δh between the bottom of the discharge tank 3 and the top 11 of the fermentation tank, so that in the process of feeding, when the feed liquid overflows from the bottom of the discharge tank 3, there is still a gap above the feed liquid in the fermentation tank 1. Small air chamber E. The oxygen in the air chamber E can make the upper layer of the feed liquid slagging, forming a slagging layer 52, which affects the efficiency of biogas generation. However, during the use of the present invention, the volume of the biogas chamber is constantly changing, and new feed liquid is continuously replenished, so the volume of the biogas chamber can be changed within the range of 0-V. When the dynamic air chamber is running automatically, the fermented matter in the tank is automatically floated and stirred, which can easily break the slaggin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com