An electroosmotic belt press sludge dewatering equipment

A technology of sludge dehydration and electroosmosis, applied in electrochemical sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as poor sludge dehydration effect, achieve easy replacement and improve efficiency , Free drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

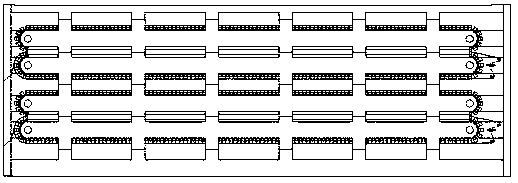

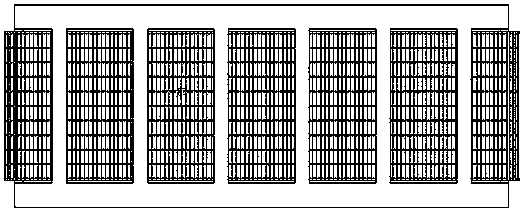

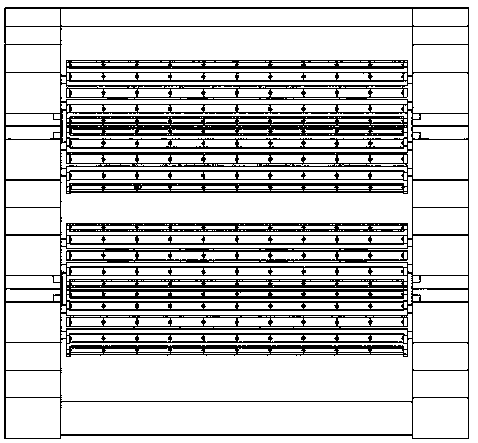

[0030] Example 1 as Figure 1-7 As shown, a kind of electroosmotic belt press sludge dewatering equipment is a daily treatment of 50 tons of 80% sludge sludge dewatering device, including a top frame 15, a base 16 and two dewatering units, and two A dehydration unit, wherein the dehydration unit includes frame 1, upper press belt 2, lower press belt 3, guide rail 4, transmission shaft 6, single-sided toothed synchronous belt 7, driving structure 8, tensioning device 9, filter belt 10, DC The power supply 11, the support wheel 12, the cooling and dehumidification isolation air duct 13 and the sludge discharge water channel 14 are inserted into the guide rail 4 in the installation groove of the frame 1, and the frame 1, the top frame 15, and the base 16 are all resin, Fiber-reinforced or clad metal-reinforced composite materials, frame 1 is a multi-layer module of horizontal long composite material structure, which is convenient for capacity expansion and maintenance. The guide...

Embodiment 2

[0035] This embodiment is an electro-osmosis belt press sludge dewatering equipment for daily treatment of 75 tons of 80% sludge. Its structural parameters: length and width are exactly the same as those in Example 1, and only one dehydration unit is added to the height.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com