Apparatus for handling fine bulk material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

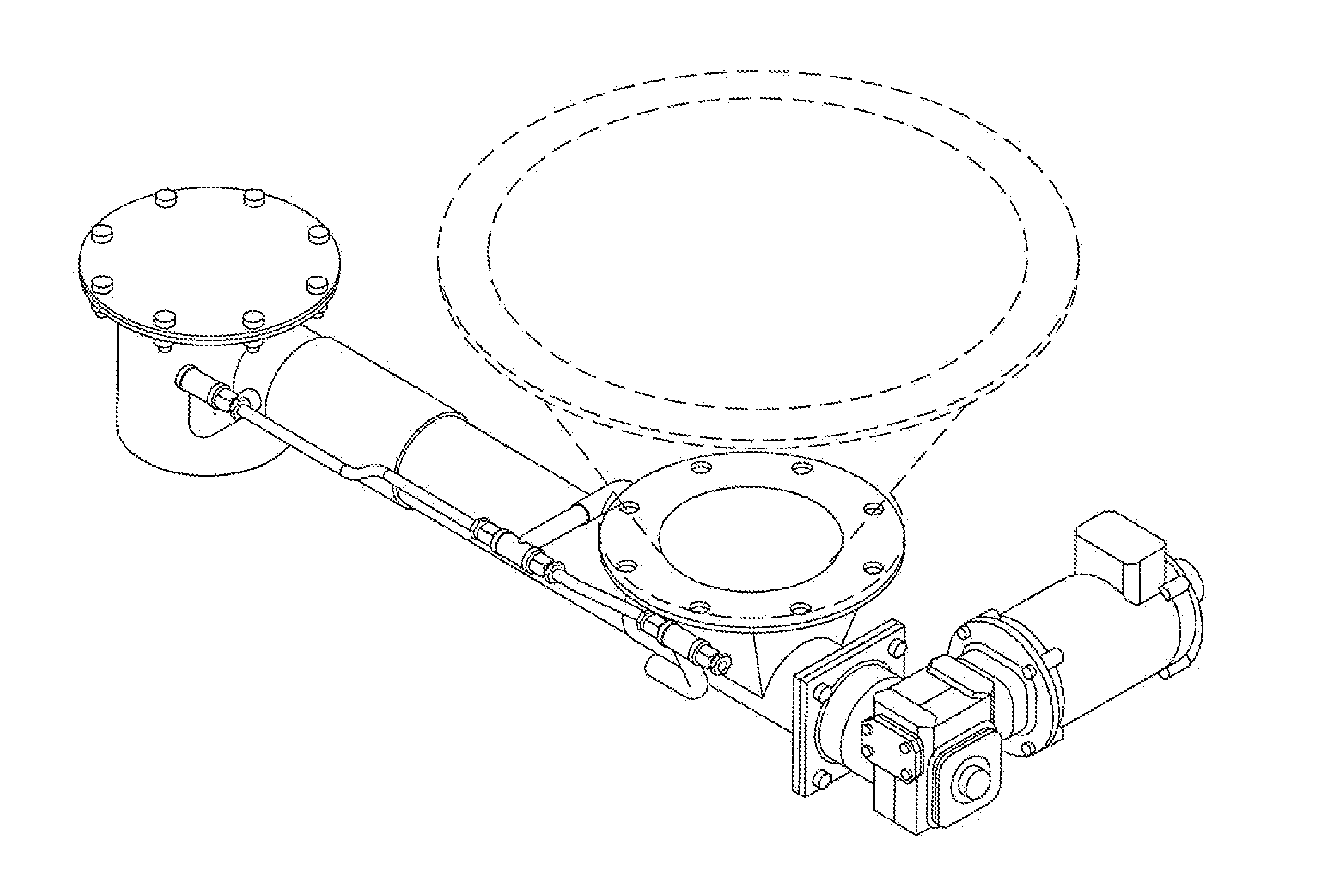

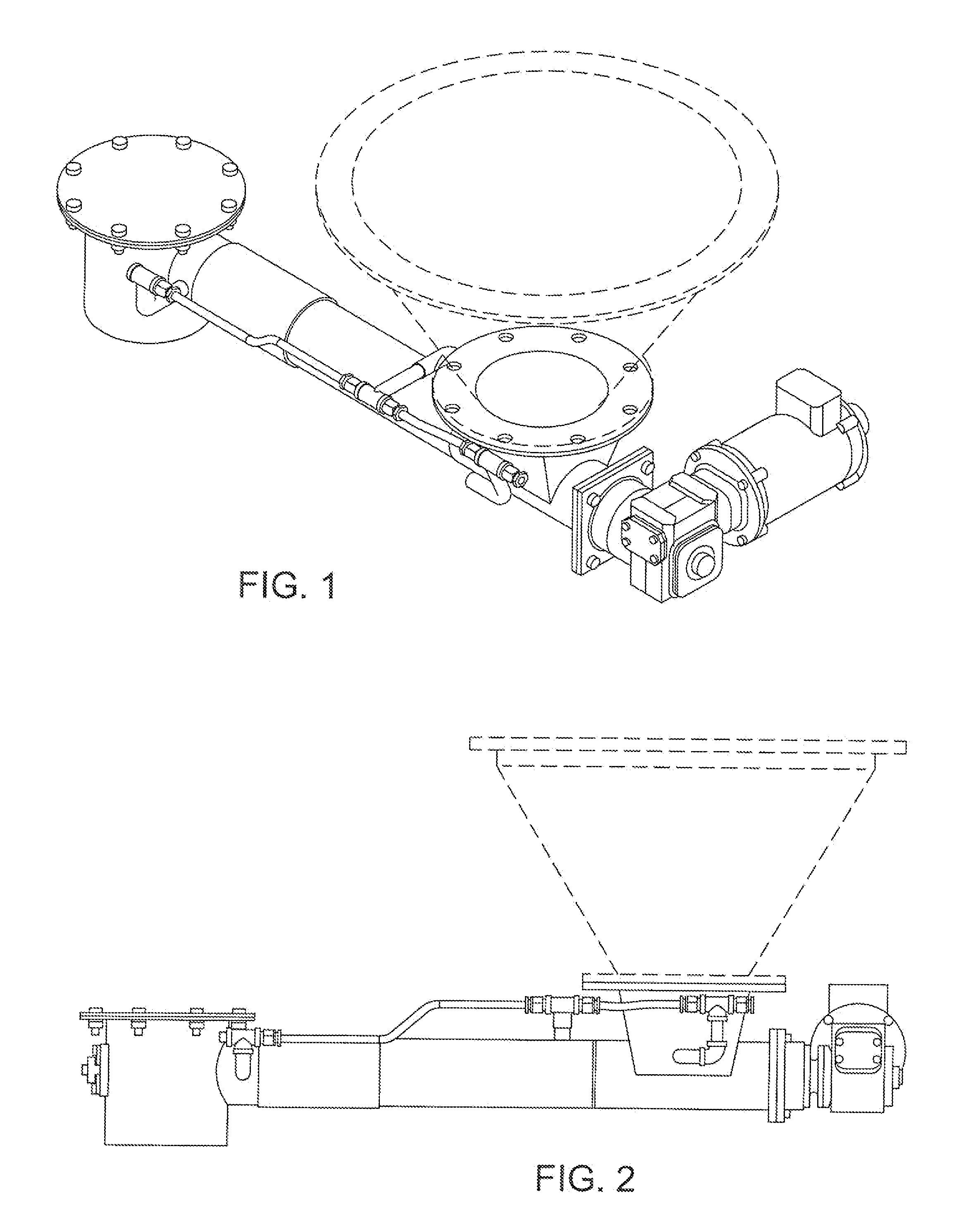

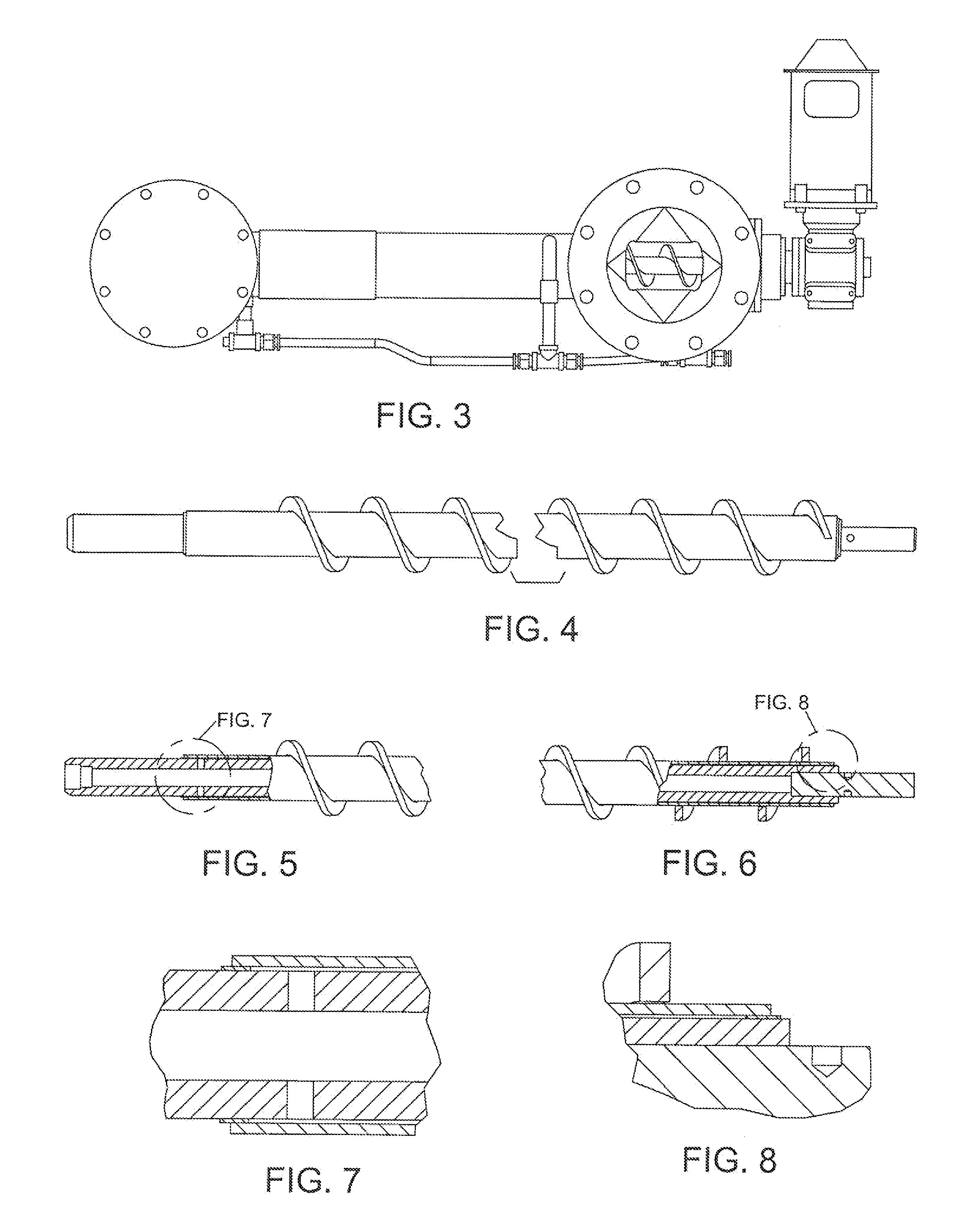

[0014]Referring to the drawings, there is illustrated an embodiment of the invention, generally including an assembly 10 for conveying a fine bulk material gravity fed from a vessel 11 and discharged into a conduit 12. Assembly 10 includes an inner, tubular conduit 13 formed of an impermeable material, an intermediate tubular conduit 14 formed of a permeable material encompassing, spaced from and disposed coaxially relative to inner conduit 13 and an outer tubular conduit 15 also formed of an impermeable material encompassing, spaced from and also disposed axially relative to inner conduit 13.

[0015]Inner tubular conduit 13 includes an axially disposed fluid passageway 16, having one end as shown in FIG. 5 extending through an opening in a side of conduit 12 and journalled in a mounting provided on an opposite side of conduit 12, and an opposite end as shown in FIG. 6, provided with a stub shaft portion 18 having one end thereof extending into and closing an end of passageway 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com