Intermittent electro-osmotic belt squeeze sludge dewatering apparatus

A technology of sludge dehydration and electroosmosis, applied in electrochemical sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem that sludge cannot meet the sludge treatment standards, and improve dehydration efficiency , easy to replace, no drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

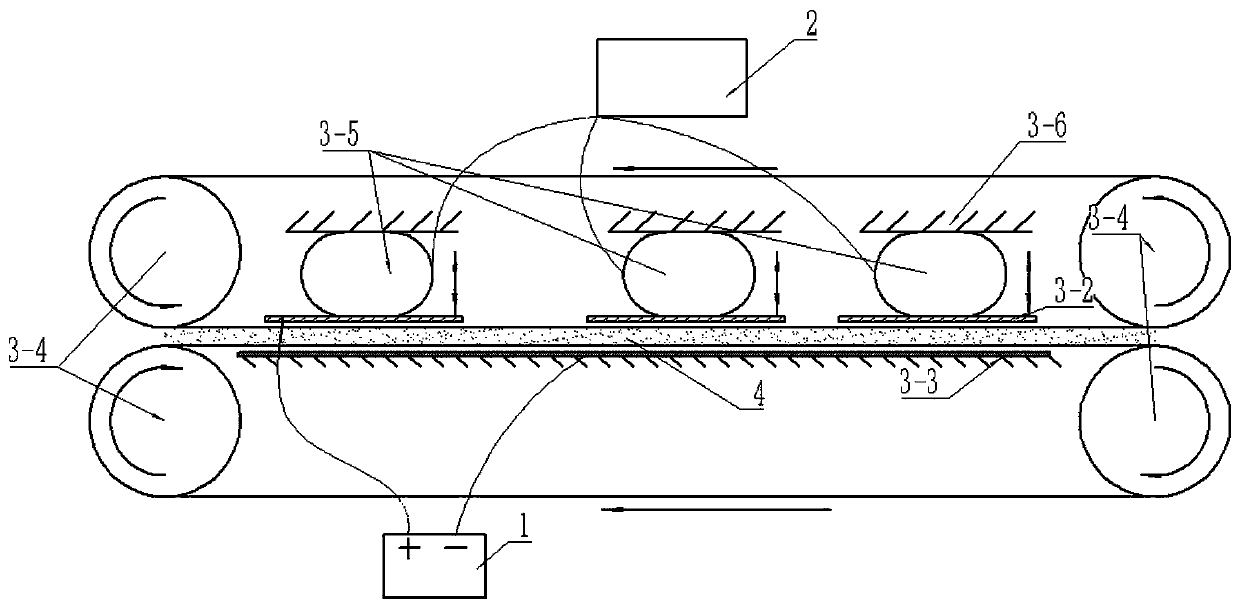

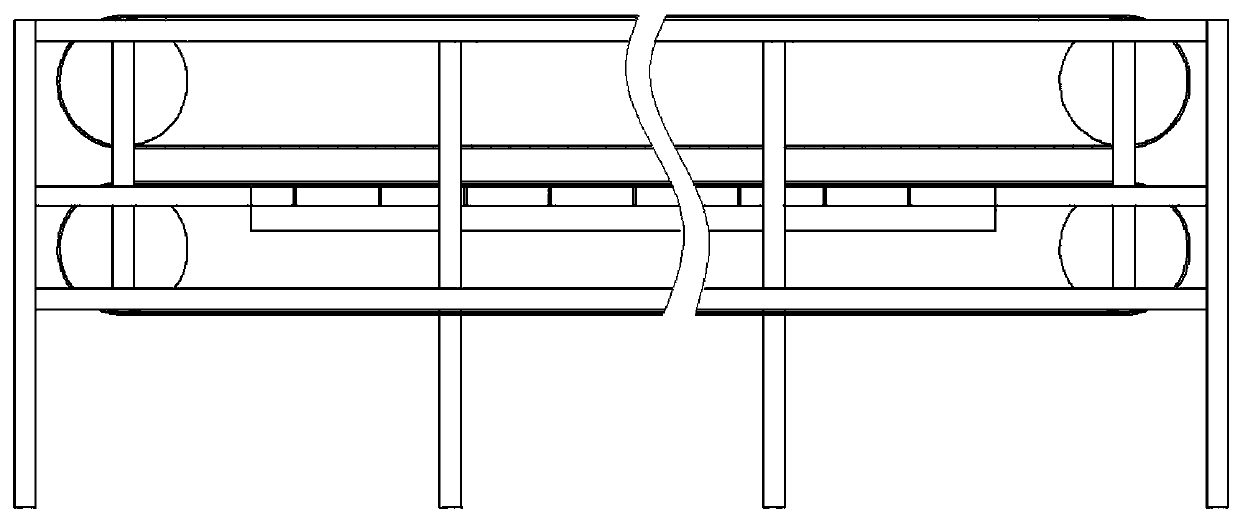

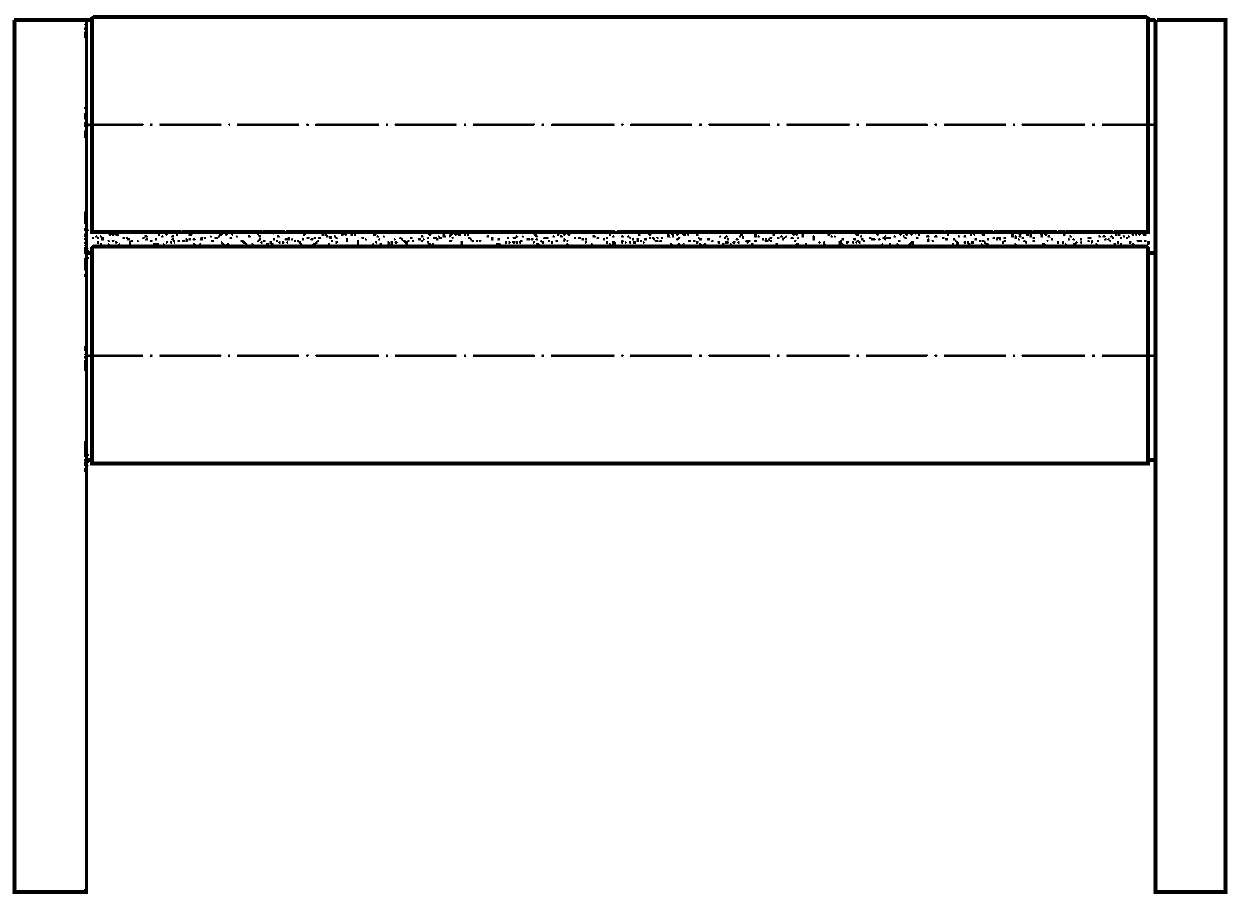

[0029] Embodiment 1, daily processing 50 tons of 80% sludge sludge dewatering device, such as Figure 1-6 As shown, an intermittent electro-osmotic belt press sludge dewatering equipment, which includes a power supply (1), an air compressor (2) and a dehydration unit (3), wherein the dehydration unit (3) is the main component, including the frame (3-1), upper electrode plate (3-2), lower electrode plate (3-3), drive shaft (3-4), air bag (3-5), air bag support seat (3-6), filter belt (3-7) and water tank (3-8); it is characterized in that: the drive shaft (3-4) is made of a material with a high friction coefficient relative to the filter belt (3-7), and the drive shaft (3-4) is fixed At both ends of the frame (3-1), the filter belt (3-7) is driven to move around the frame (3-1);

[0030] The upper electrode plate (3-2) has a plurality of upper electrode modules (3-2-1) arranged at intervals in the longitudinal direction, and the upper electrode modules (3-2-1) are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com