Vertical continuous anaerobic dry fermentation method

A kind of technology of anaerobic fermentation and anaerobic fermenter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

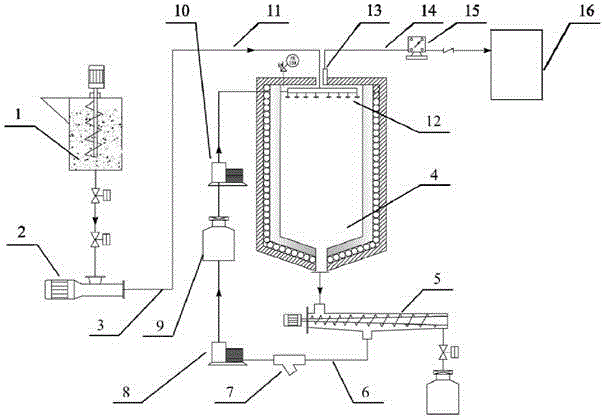

[0024] Refer to the attached figure 1 The vertical continuous anaerobic dry fermentation device of the present invention will be described in detail.

[0025] like figure 1 As shown, the vertical continuous anaerobic dry fermentation method and device of the present invention include a homogeneous tank (1), a screw pump (2), a feed pipeline (3), an anaerobic fermentation tank (4) connected in the order of feeding ) and screw discharge machine (5), biogas slurry pipeline (6), Y-type filter (7), biogas slurry pump (8), biogas slurry buffer tank (9), spray pump (10), spray Pipe (11), sprinkler head (12), biogas outlet (13), biogas pipe (14), biogas flow meter (15), biogas cabinet (16).

[0026] Yellow stalks are used as raw materials, and biogas residues after fermentation of cow dung are used as inoculum. Firstly, the yellow stalks are filled into the homogenization tank (1). Start the screw discharger (5), 1 / 3 of the biogas residue after solid-liquid separation is added int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com