Pipeline cut-off device and method for realizing underground coal gasification mobile gas injection

An underground gasification and cut-off device technology, which is applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problems of complex structure, poor sealing, and difficulty in popping off the gas injection pipeline, and achieves sensitive and reliable response and convenient installation , the effect of continuous gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

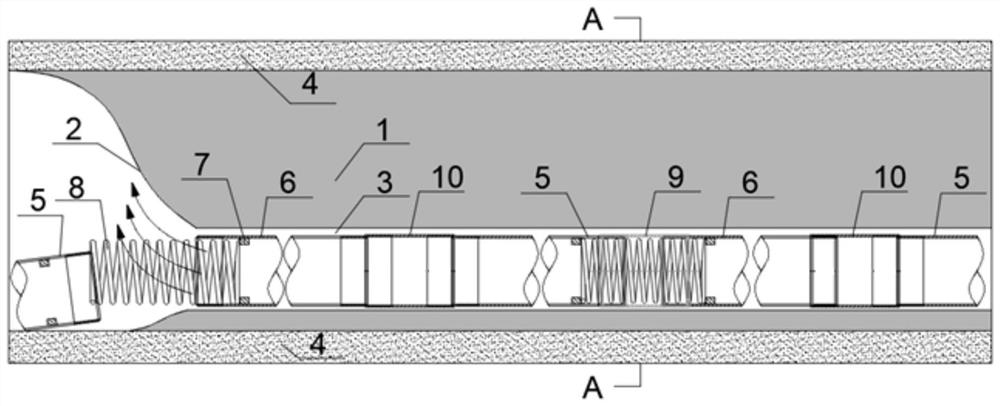

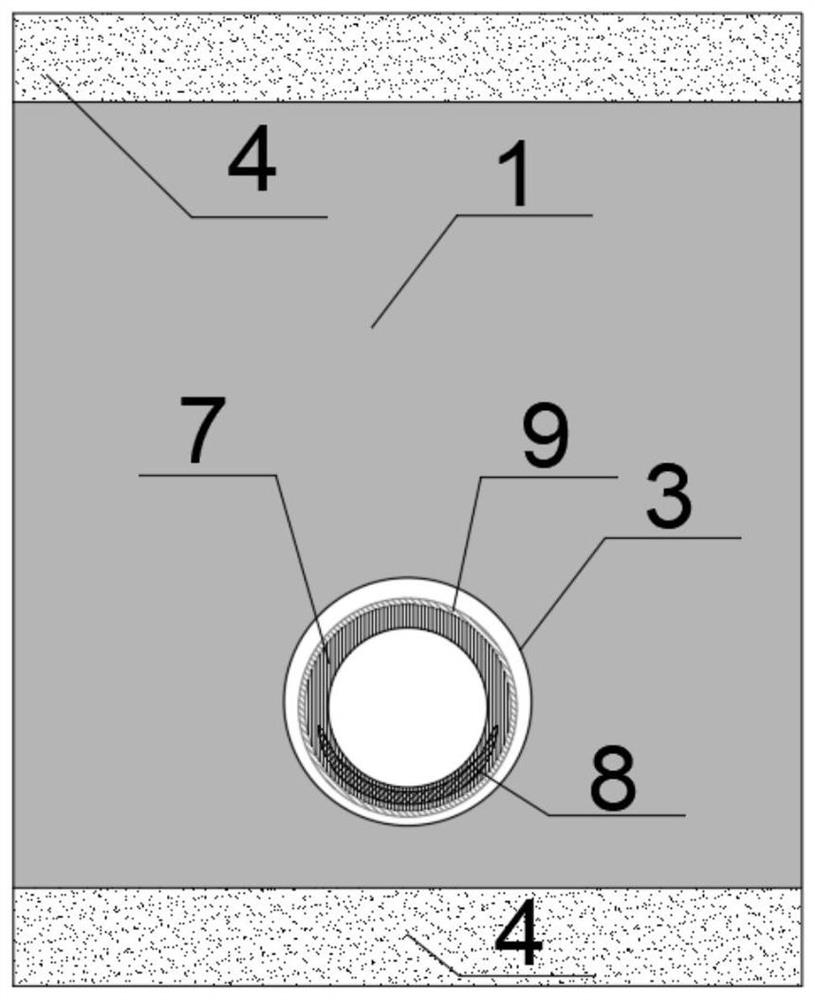

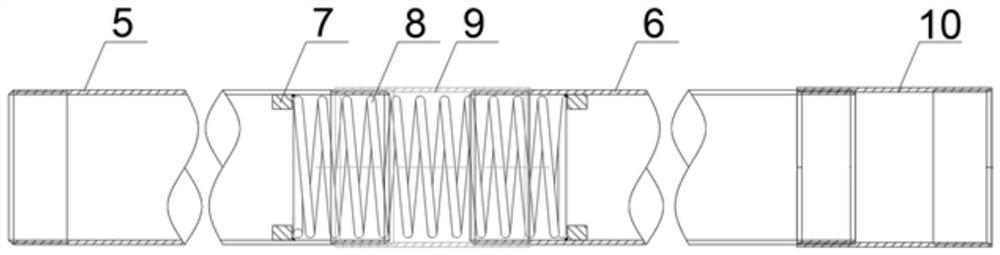

[0037] A pipeline cutting device for realizing mobile gas injection of underground coal gasification, such as Figure 1-4 As shown, it is used in conjunction with the gas injection hole 3 reserved at the bottom of the coal seam 1 between the top and bottom plates of the coal seam 4. The diameter of the gas injection hole 3 is 200mm, including several gas injection pipes located in the gas injection hole 3. Section 5 and 6 (gas injection pipe section-1 and gas injection pipe section-2) are connected to form a gas delivery pipe, the diameter of the gas delivery pipe is 140mm, each adjacent two gas injection pipe sections is a group of gas injection pipes, between each group of gas injection pipes It is fixedly connected by the connecting ring 10, and the two gas injection pipe sections of each group are connected by the cutting device body. On the inner wall of the gas injection pipe section on the left and right sides, a high temperature resistant spring 8 in a compressed state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com