Method for simple production of high-quality biological methane

A biological methane and anaerobic biological technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of limiting the rate of biogas production and taking a long time to achieve stable gas production process and strong practicality. , the effect of rational use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

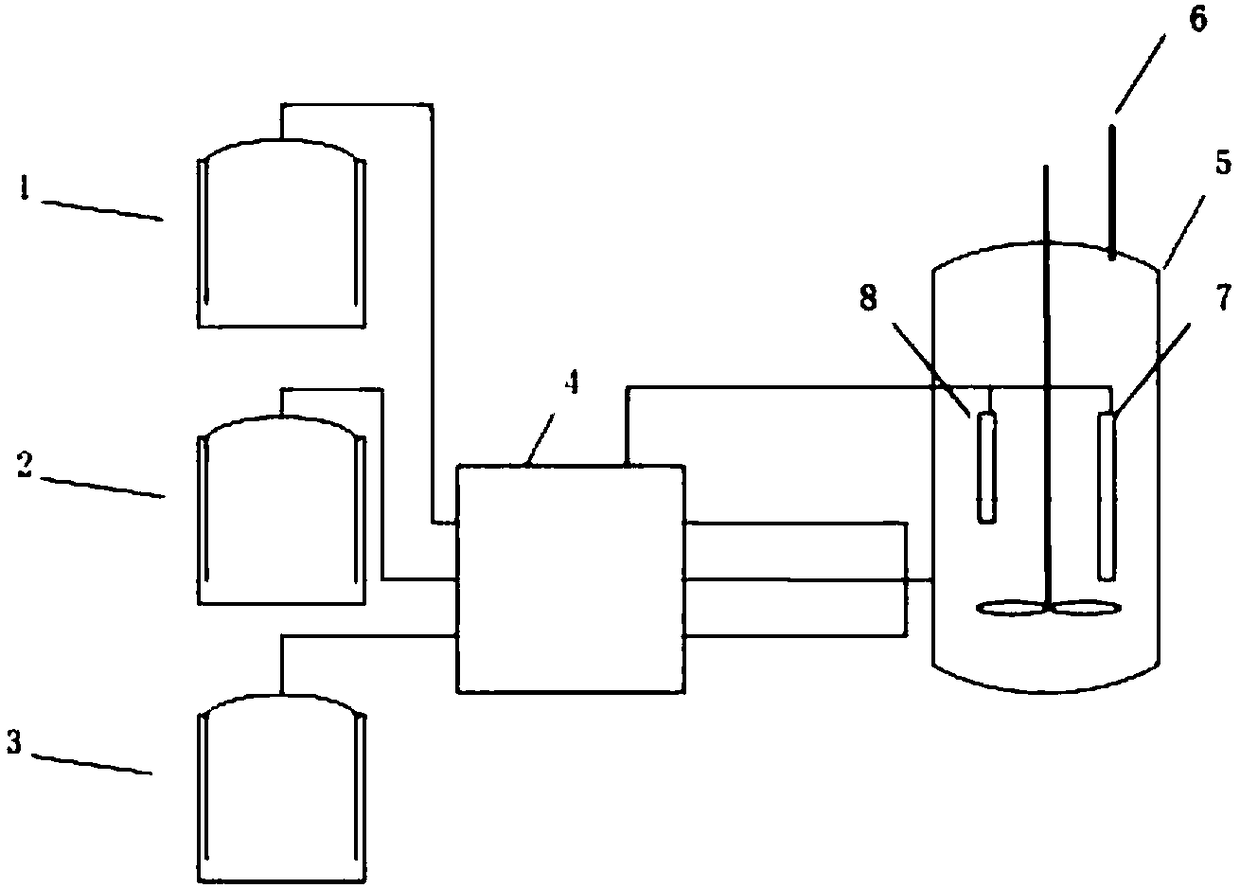

[0043] (1) Activation of methanogenic archaea: In this example, the selected inoculum comes from a waste treatment plant in Changping District, Beijing. The measurement indicators are: TS is 6.23%±0.05, VS is 2.01%±0.03, and pH is 8.24±0.03 , The content of ammonia nitrogen is 4.4±0.4g / L. Add 3.5L biogas slurry containing inoculum to the CSTR reactor 5 with a volume of 6.5L, set the temperature (37°C) and the initial rotation speed (200rpm), and fill the CSTR reactor 5 with N through the console 4 2The air in the replacement device is filled at a rate of 2ml / min and the filling time is 24 hours to ensure a strict anaerobic environment. After the air is replaced, add 2.00g of microcrystalline cellulose as an activation substance and activate for 2-3 days. After the device no longer produces methane, the activation of methanogenic archaea is completed.

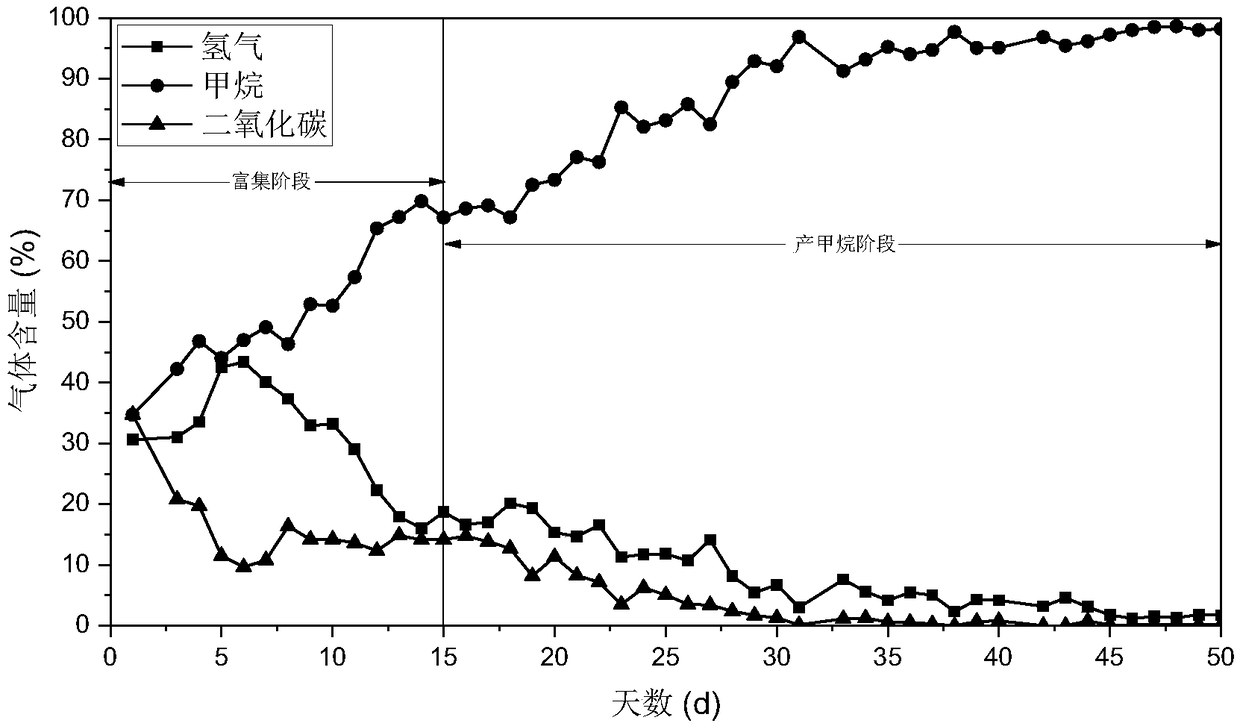

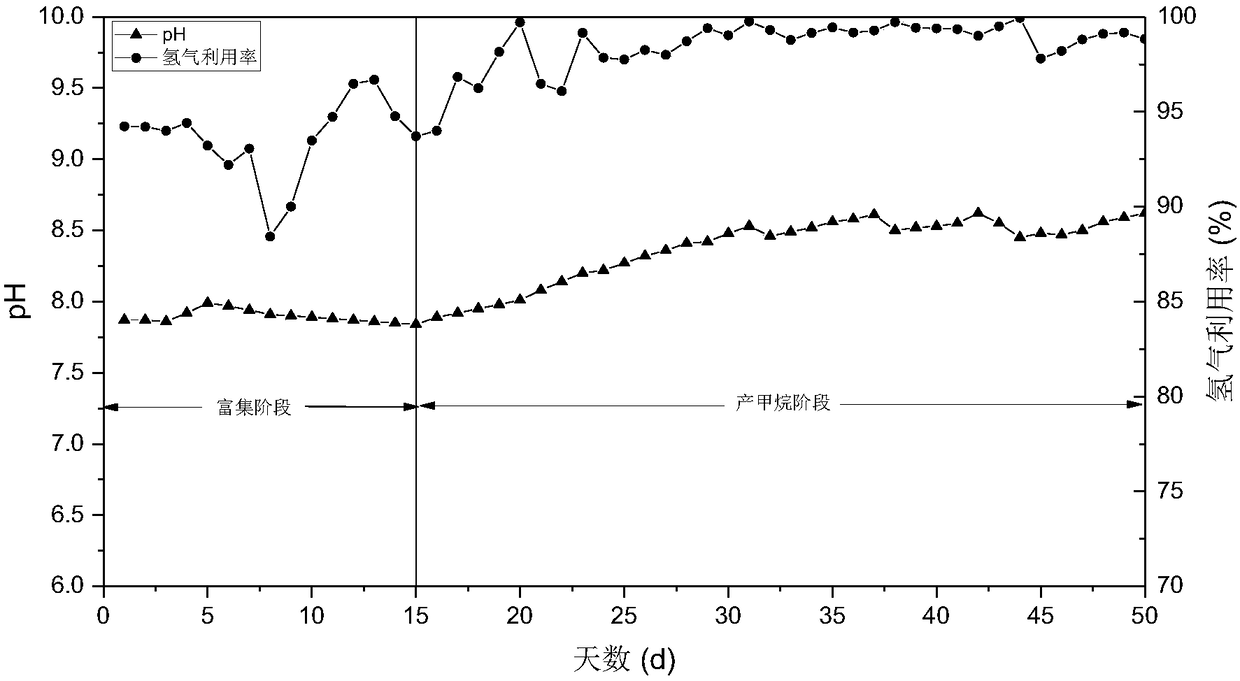

[0044] (2) Enrichment of hydrogenotrophic methanogenic archaea: after the activation of methanogenic archaea, the device no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com