Fire-extinguishing device capable of continuously generating carbon dioxide

A fire extinguishing device, CO2 technology, applied in fire rescue and other directions, can solve the problems of operational safety, stability, difficult to grasp, equipment pressure measures, insufficient anti-corrosion measures, and the continuity of gas production cannot be guaranteed. Good maneuverability and reduced weight of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

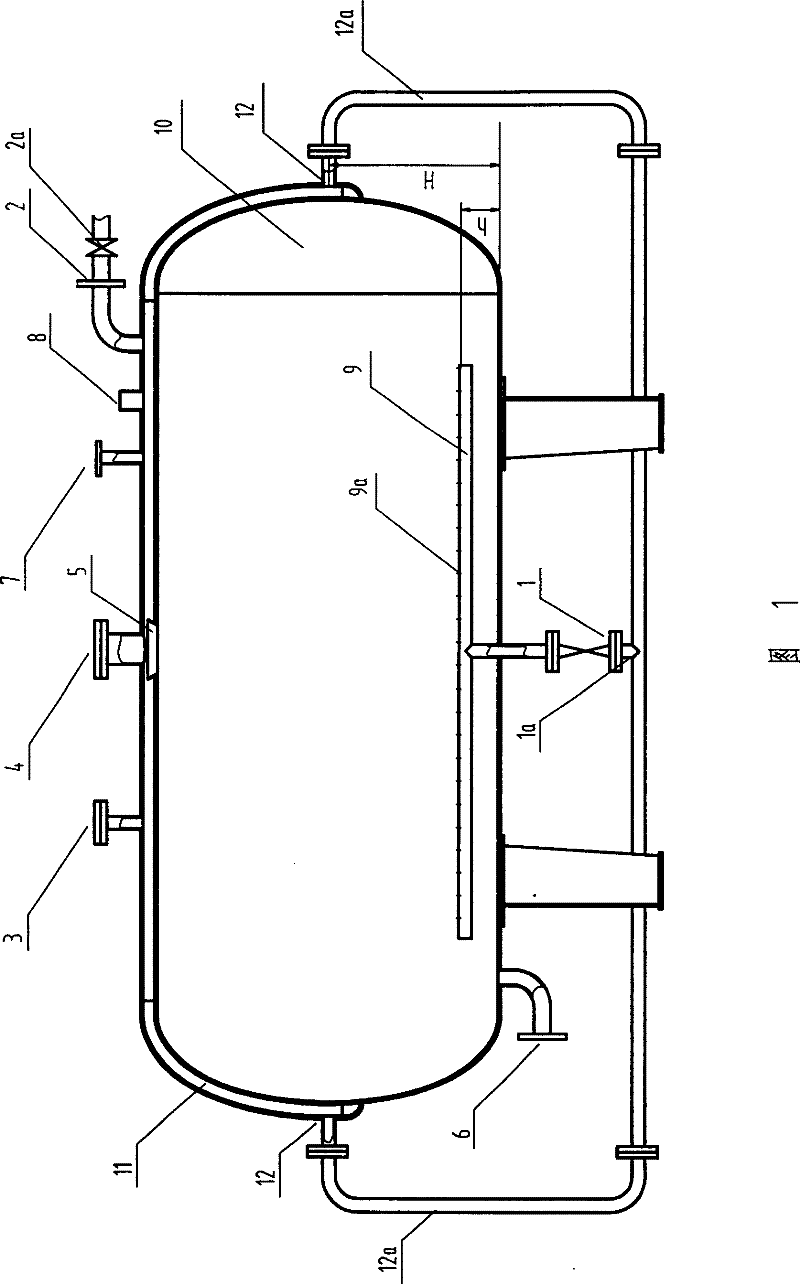

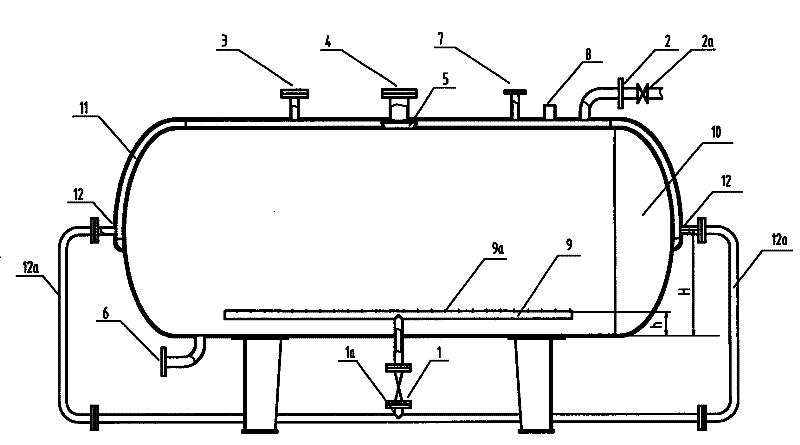

[0033] Further illustrate concrete feature and technical means of the present invention below in conjunction with accompanying drawing,

[0034] The continuous production of CO provided by the present invention 2 Gas installations include:

[0035]A carbon dioxide generation tank 10 is provided with an ammonium bicarbonate feed port on the upper top tank wall of the tank body of the tank, and a funnel device 5 is provided on the feed port, and it is provided with a higher than the feed port around the feed port. The side wall of the outer surface of the tank wall forms a funnel, and a feed hole and a drain hole are opened on the lower bottom tank wall of the tank, and a sulfuric acid feed pipe 1a is sealingly inserted in the feed hole, and on the feed pipe A valve 1 is provided, and a distributing pipe 9 is sealedly connected to the end of the feed pipe extending into the tank. Several distributing holes 9a are arranged on the pipe wall of the distributing pipe 9, and the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com