Patents

Literature

37results about How to "Easy to push down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

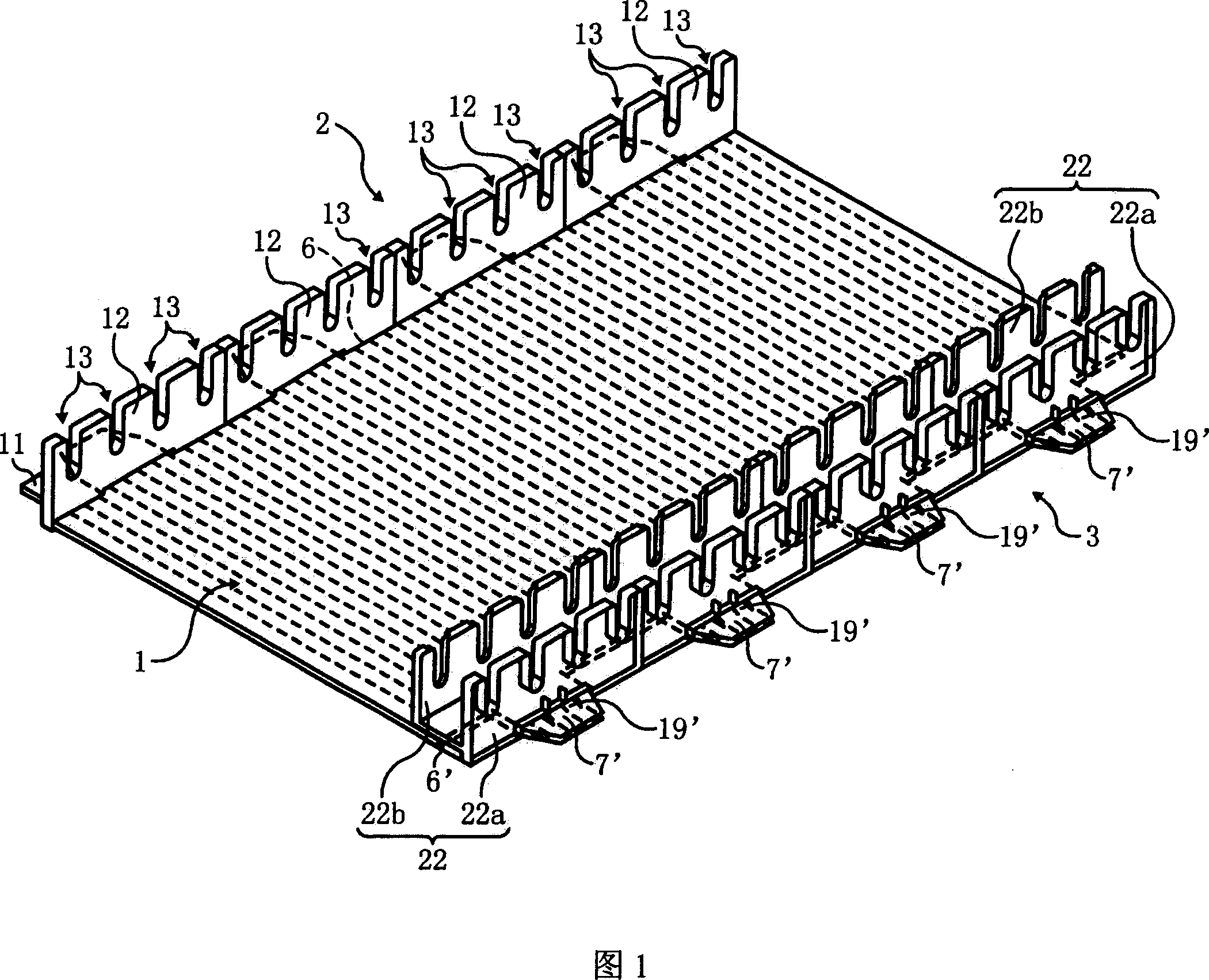

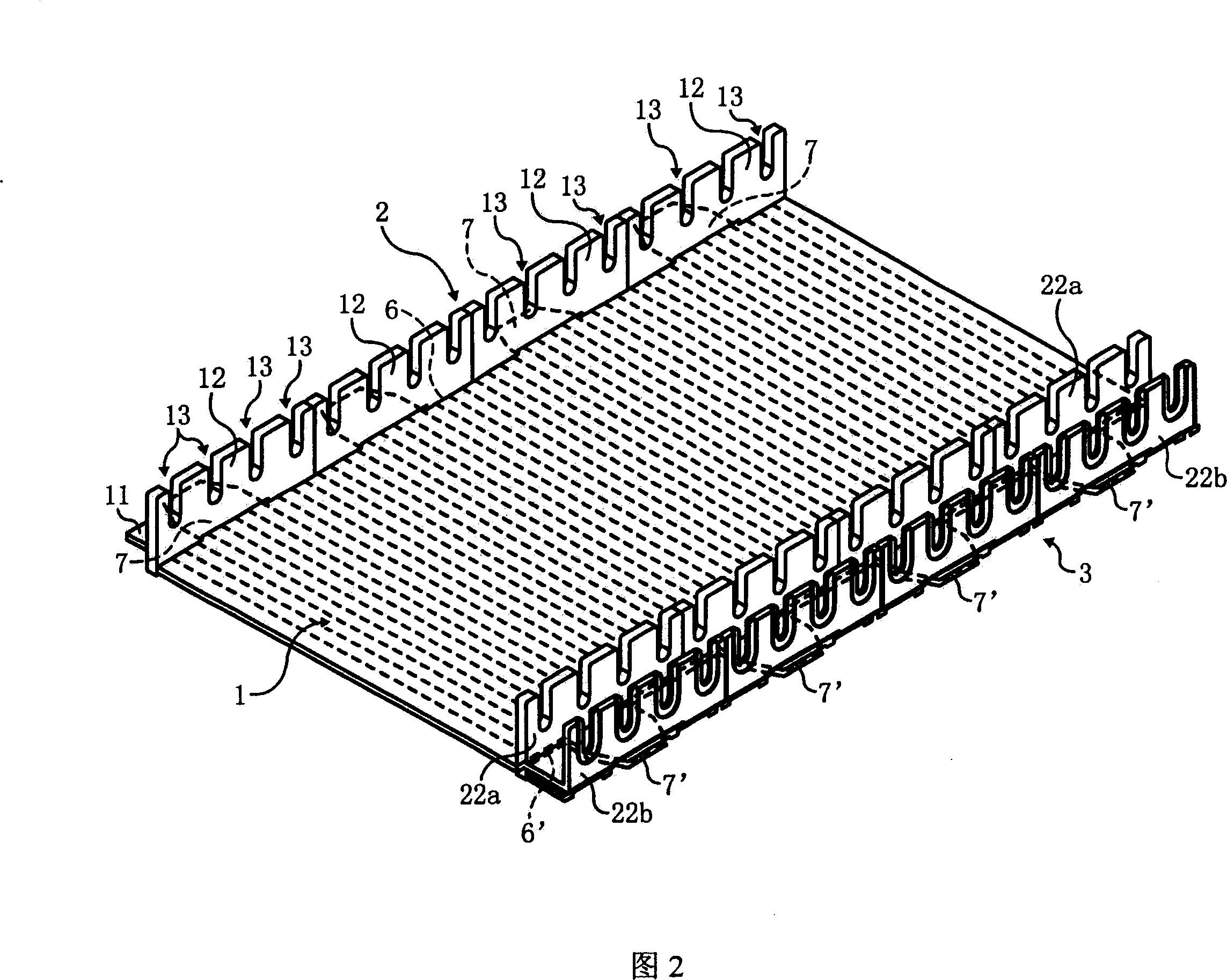

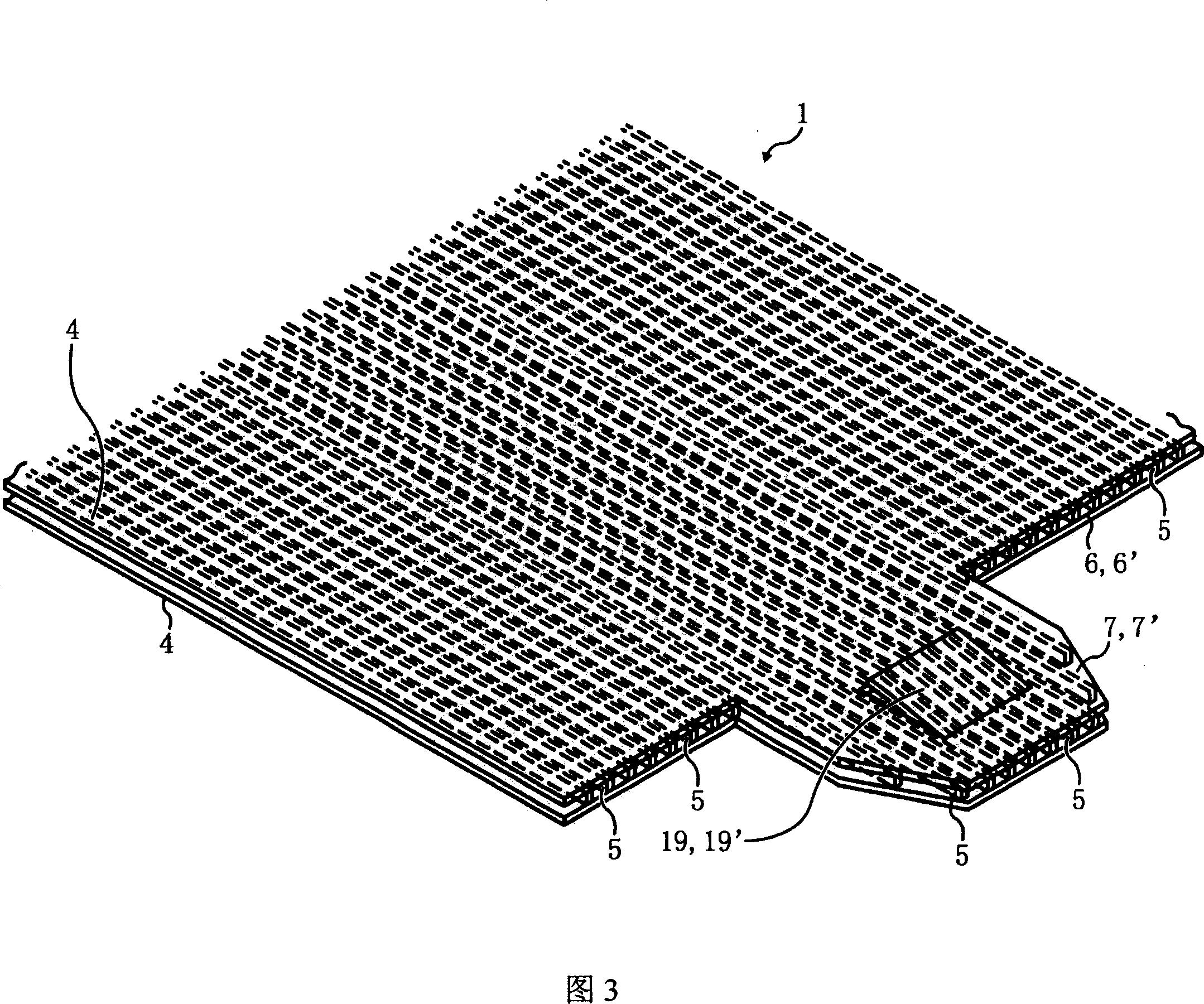

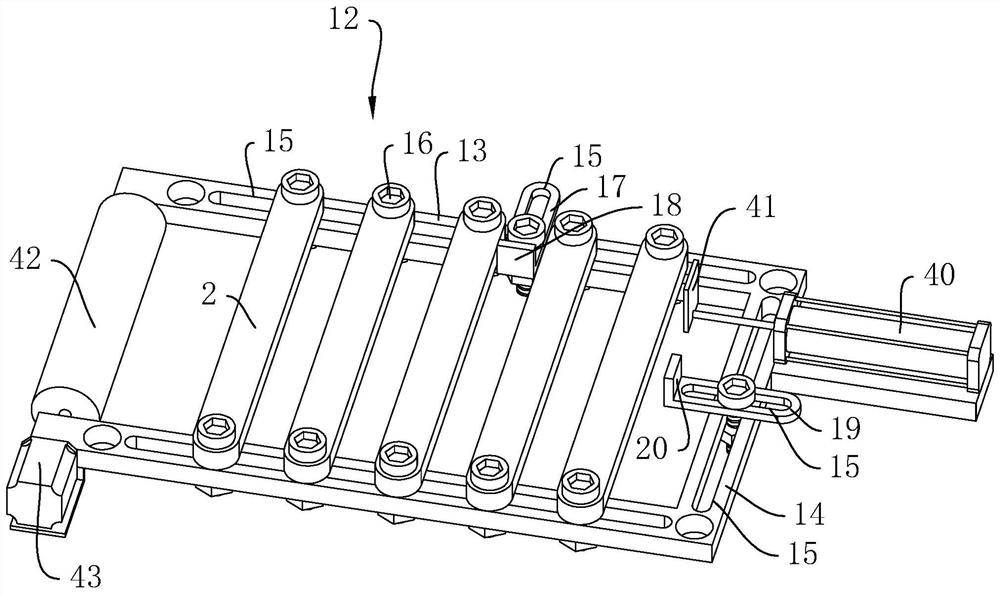

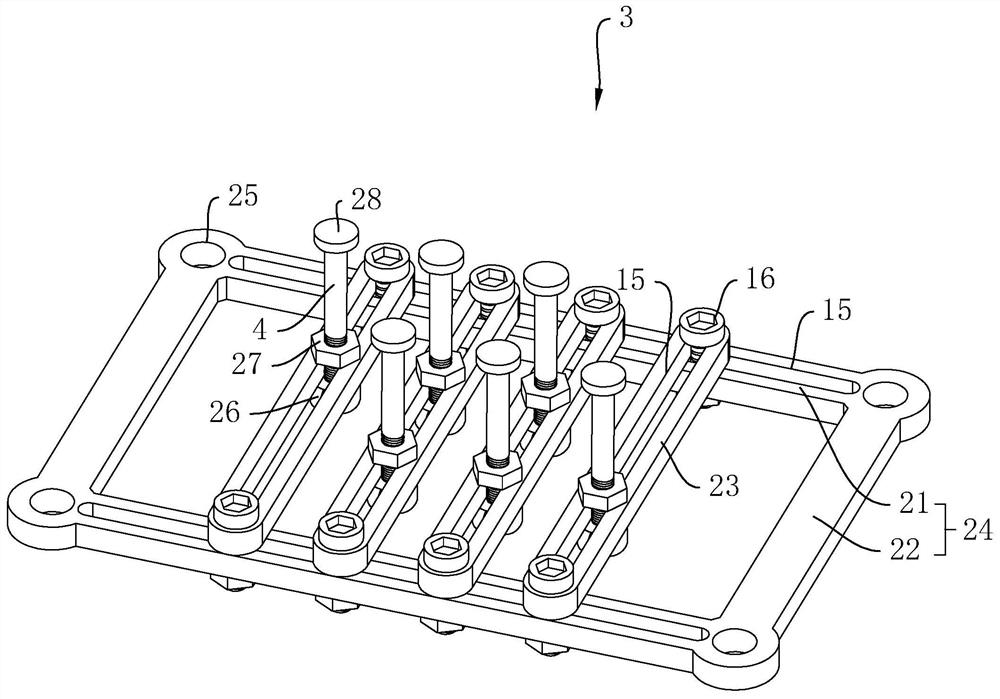

Assembly for transportation and transportation method using same

InactiveCN1927664APrevent jumpingSuitable for generalizationRigid containersInternal fittingsMechanical engineering

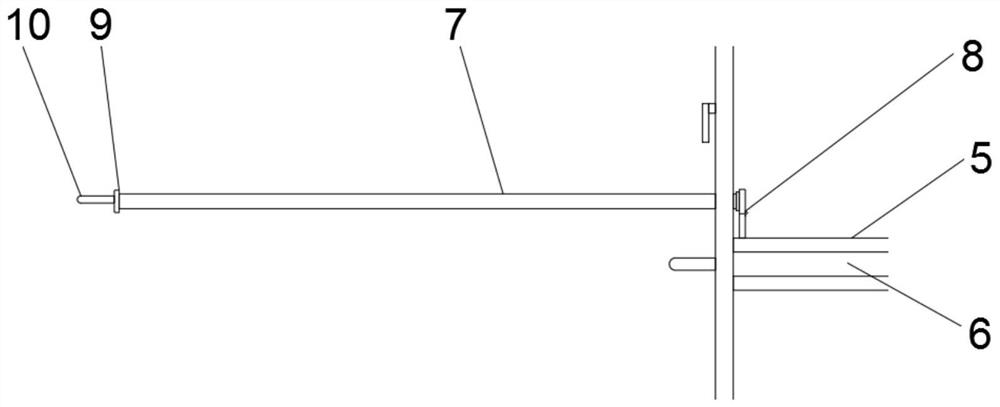

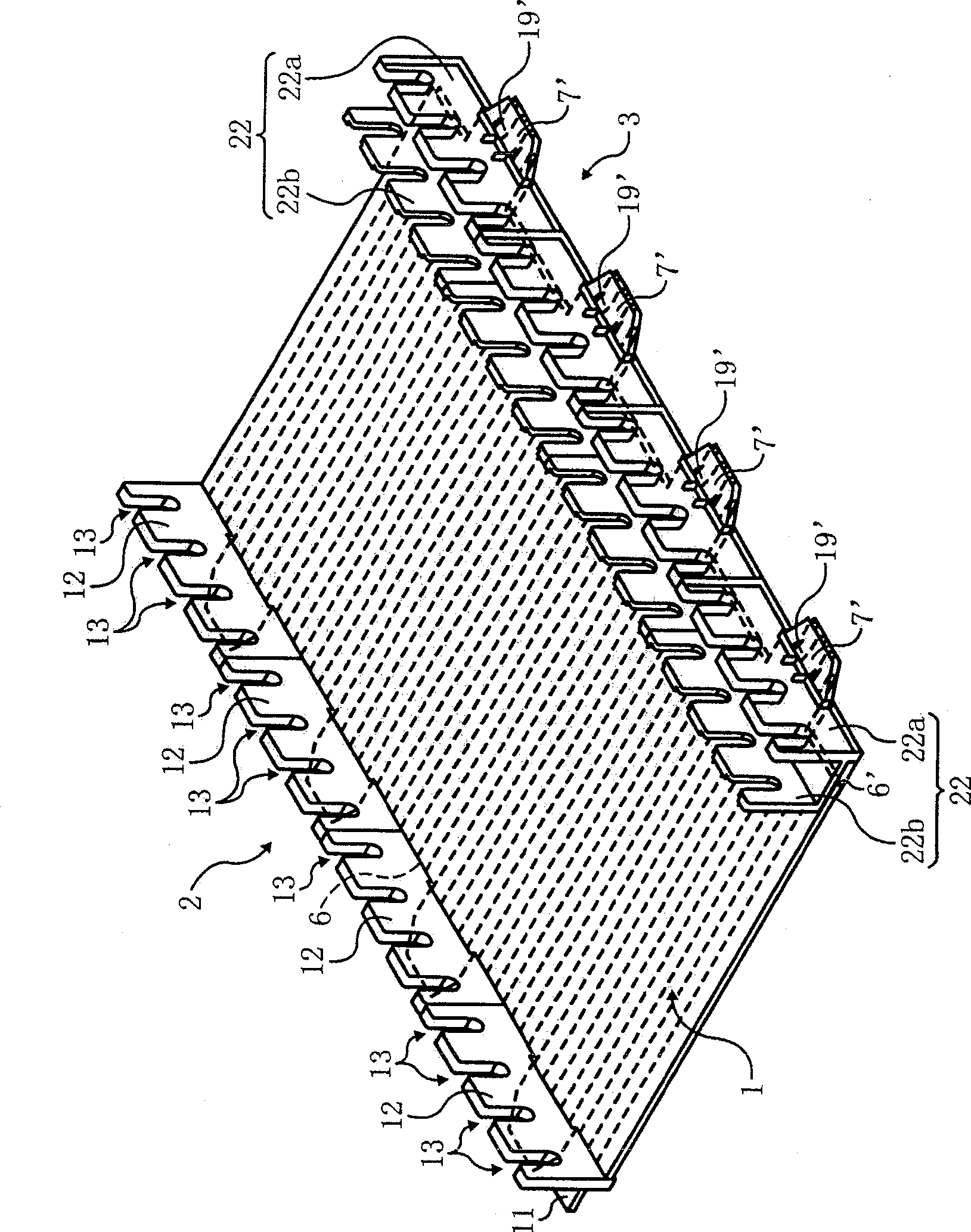

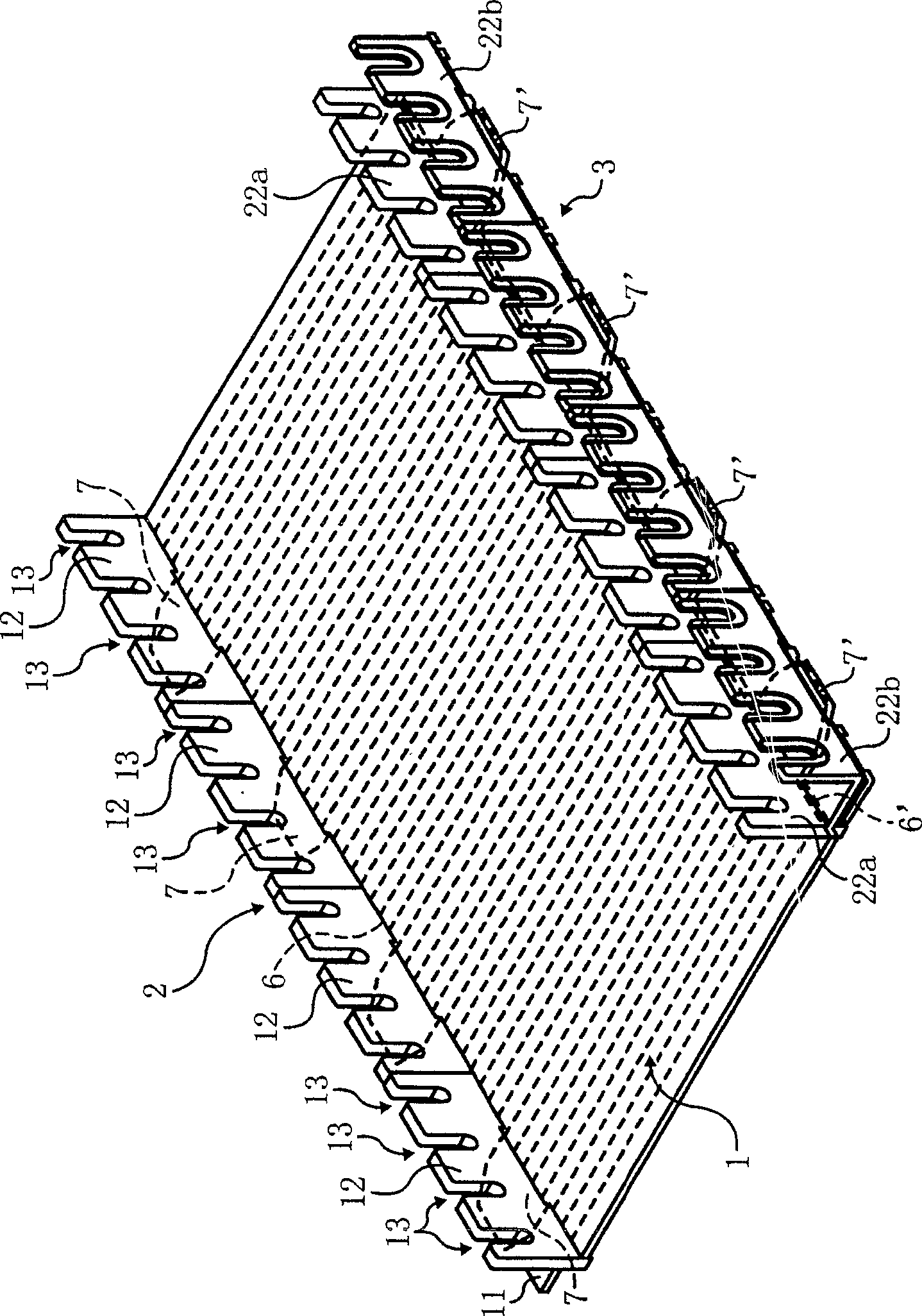

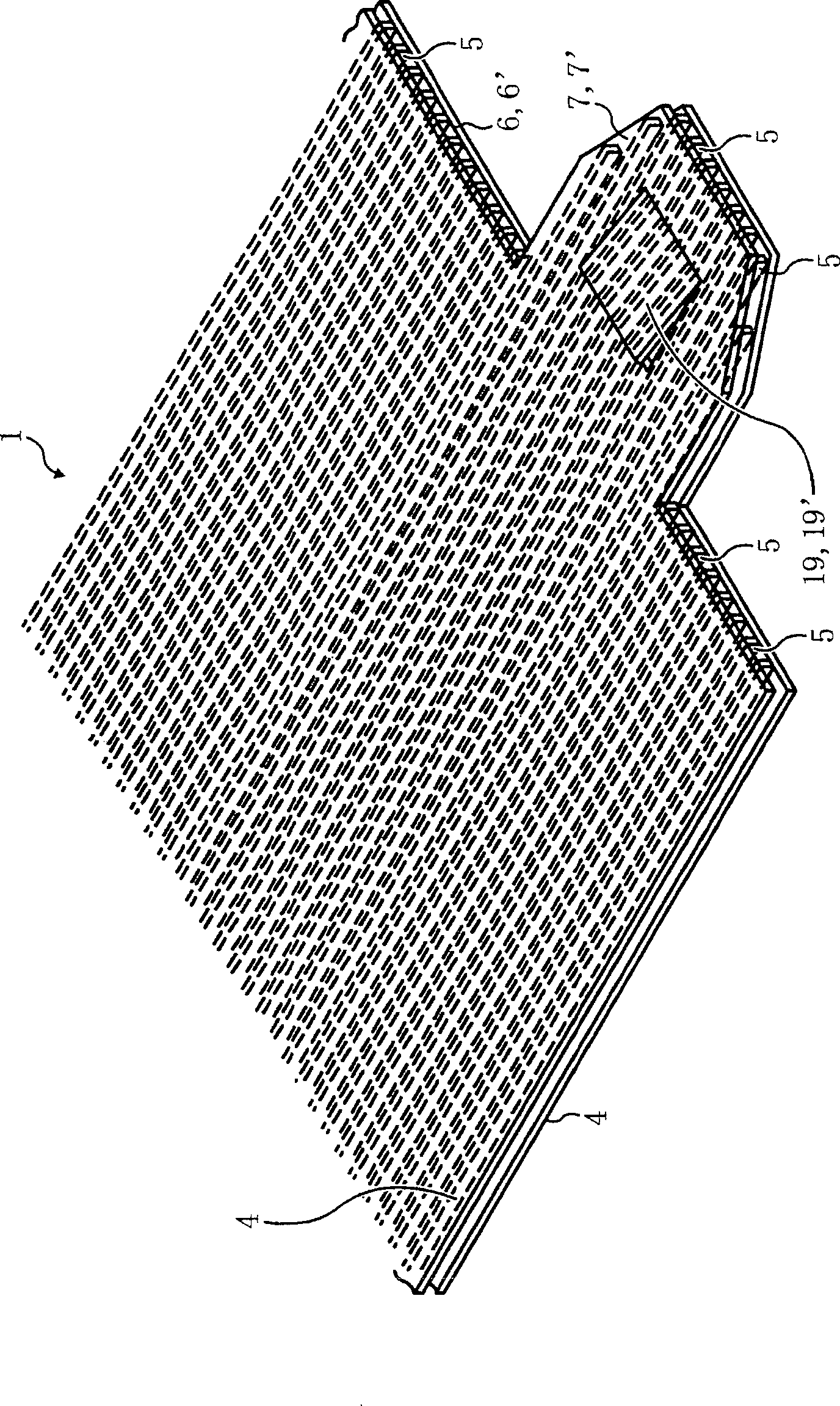

The invention provides an assembly for transport which can hold cylindrical members having different lengths without performing the replacement of componentry. This assembly for transport comprises a rectangular base body (1), and divided holders (2, 3). In this case, the rectangular base body (1) has inserted holding plate sections (7, 7') which are formed along both edge sections being in parallel with each other while keeping an interval, and are formed in the direction being orthogonal to both edge sections. The divided holders are detachably fitted on the inserted holding plate sections, are arranged along both edge sections being in parallel with each other of the rectangular base body (1), and on which long-shaped cylindrical members (M1, M2) are bridged. The divided holder (2) which is arranged along one edge section of the rectangular base body, and the divided holder (3) which is arranged along the other edge section of the rectangular bas body have a standing plate section (12). In this case, the standing plate sections (12) extend in the standing direction to the rectangular base body, and hold both end sections of the cylindrical members while cooperating with each other. The standing plate section (22) of the divided holder (3) can hold the cylindrical member having a different length by changing the inserting direction to the inserted holding plate section (7').

Owner:RICOH KK

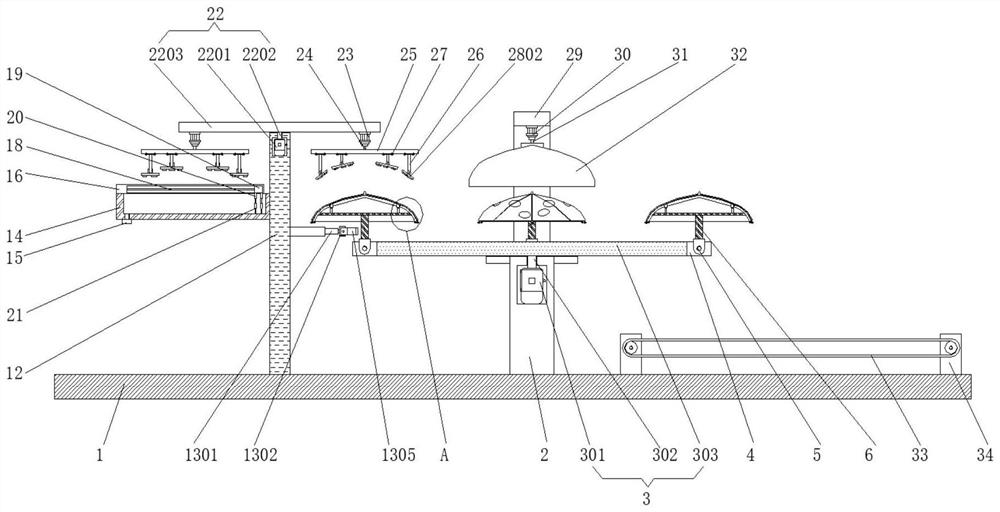

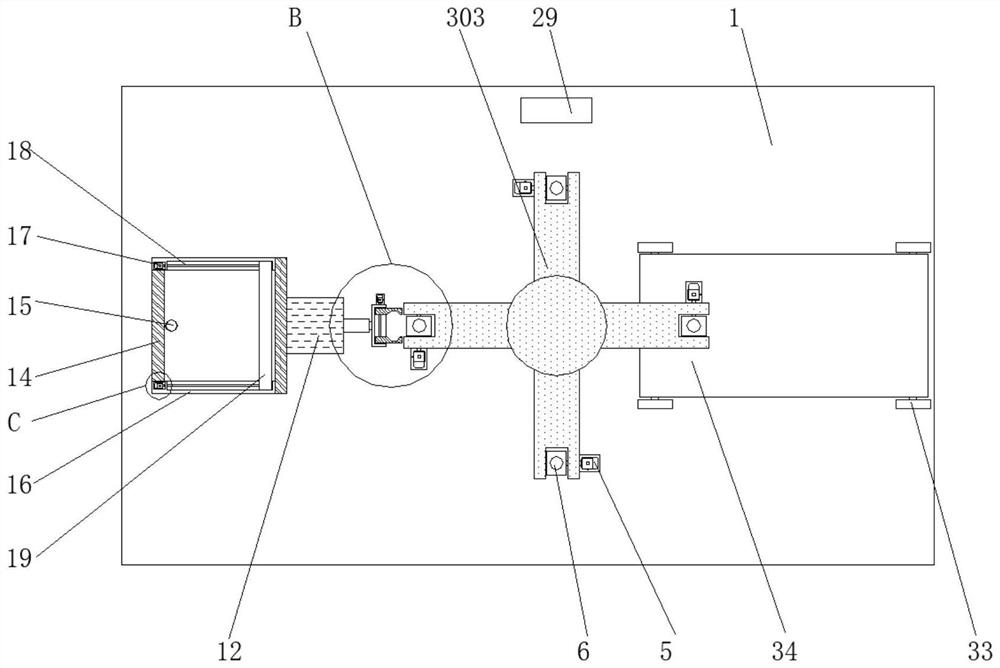

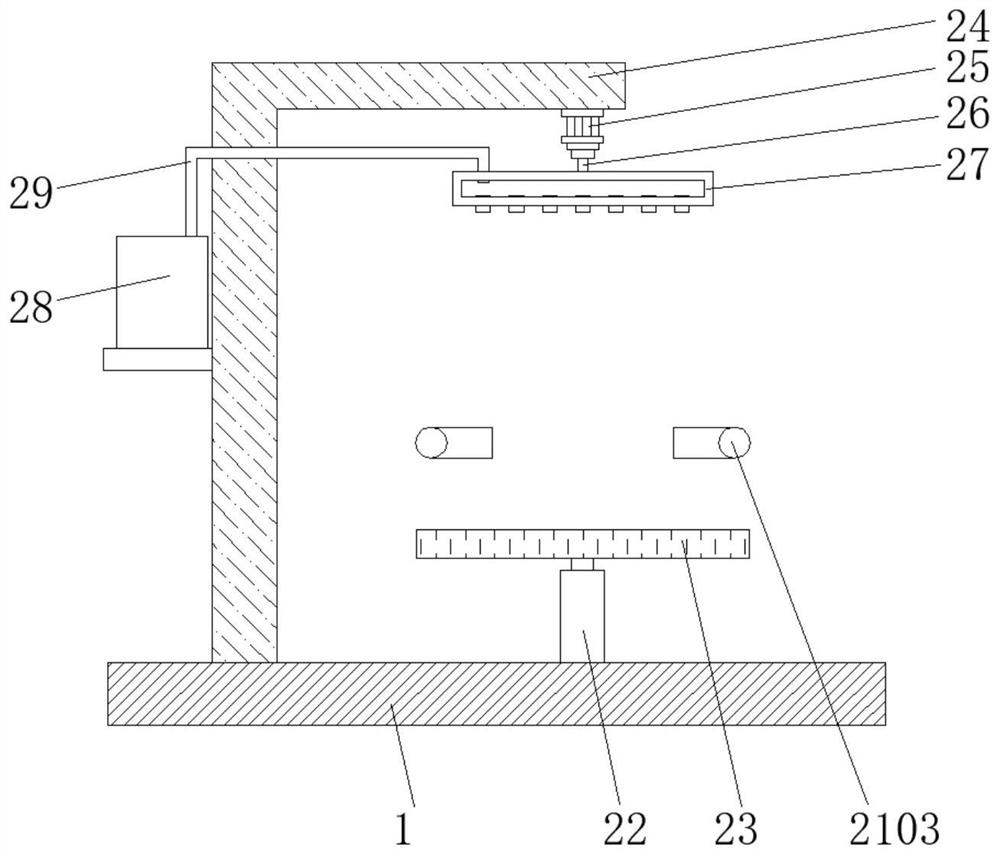

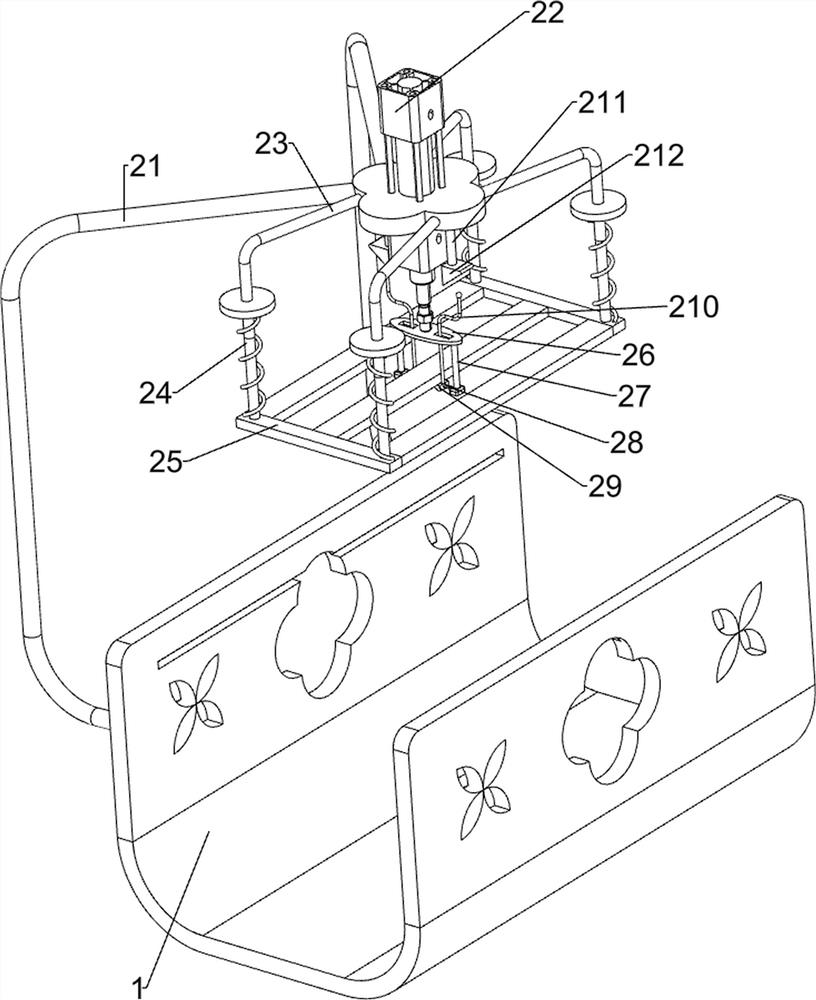

Coating method and coating device applied to umbrella cover colorful coatings

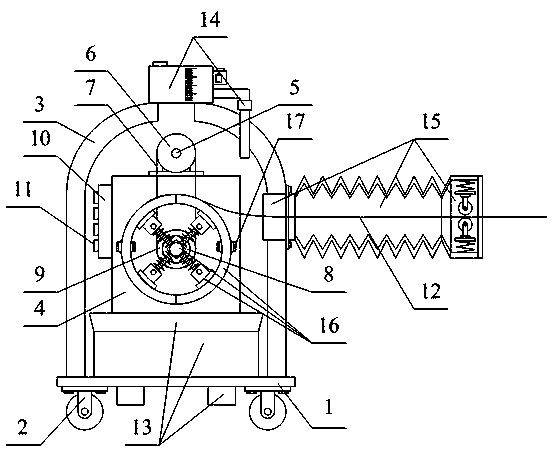

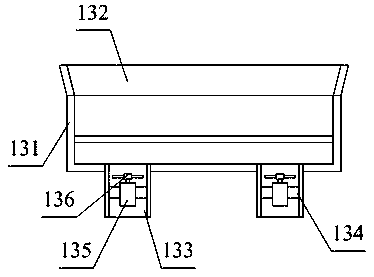

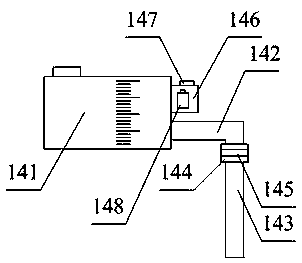

ActiveCN113171949AContinuous and efficient operationGuaranteed uniformityPretreated surfacesCoatingsStructural engineeringDip-coating

The invention discloses a coating method and a coating device applied to umbrella cover colorful coatings. The coating device comprises a rotating mechanism, a jacking mechanism, a locking mechanism, a clamping and fixing mechanism, a switching mechanism, a coating mechanism and a bearing frame, wherein a second sliding channel is fixed on the top of a material storage box; the switching mechanism is arranged at the top of a second support frame; the coating mechanism is arranged at the bottom of a mounting frame; the bottom of the bearing frame is fixed on the rear side of the middle of the upper end surface of a base; and a fixed frame is fixed on the right side of the upper end surface of the base. According to the coating method and the coating device applied to the umbrella cover colorful coatings, a whole piece of spliced and sewn umbrella cloth is placed on a supporting shed on the top of a rotating frame on the front side of the upper end surface of a rotary table, then the umbrella cloth can be locked through the corresponding locking mechanism, and then the rotary table rotates clockwise by 45 degrees; after a coating plate is used for dipping coating in the material storage box, a rotating plate horizontally rotates by 180 degrees; after the angle of the coating plate is adjusted, the coating plate moves downwards, so that the surface of the umbrella cloth is conveniently coated with the coating.

Owner:东阳市好旺伞业有限公司

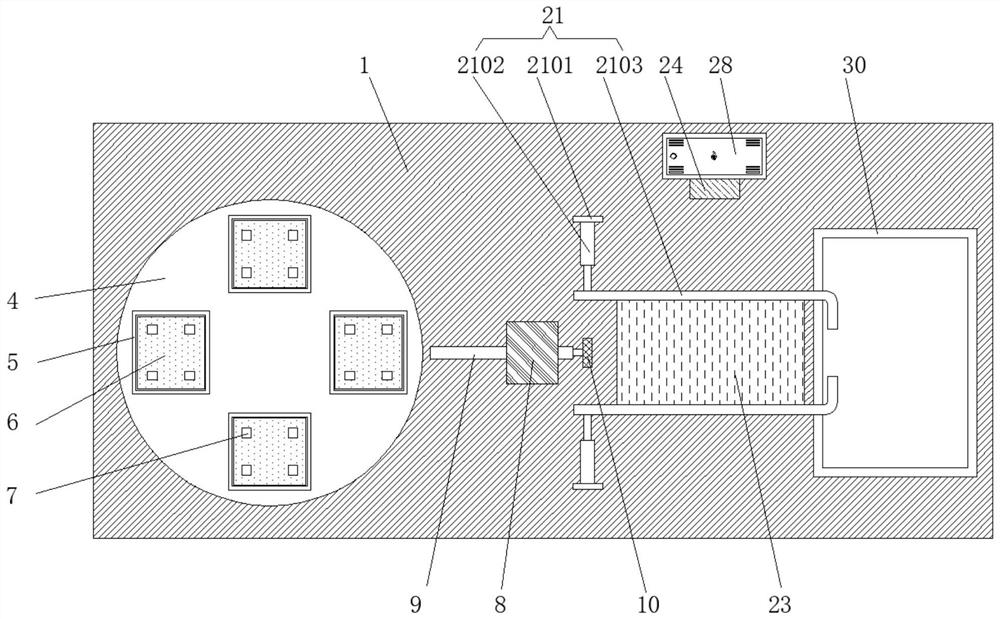

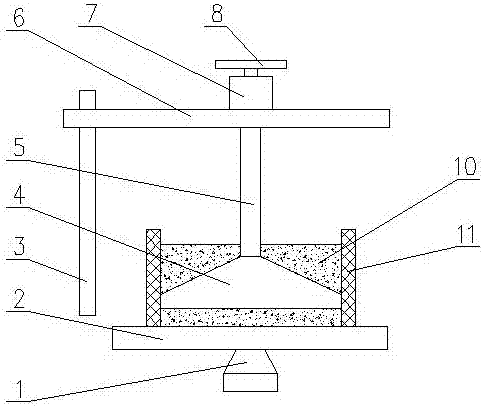

Rotary dicing device capable of positioning yellow rice cake

The invention discloses a rotary and positionable yellow cake cutting device, which comprises a workbench (1), a blade (2), and a positioning pole (6), and is characterized in that a support frame ( 5), the support frame (5) is connected with a positioning support rod (6), and the positioning support rod (6) is equipped with a blade (2) that can be lifted up and down through the knife rod, and the knife rod is divided into a positioning section (4) and a rotating section (3), the positioning section (4) is movably matched with the positioning pole (6), the rotating section (3) is rotatably matched with the positioning pole (6), and the upper part of the positioning section (4) is connected with The stop block (7), the stop block (7) is placed on the positioning pole (6), the blade (2) is connected to the lower part of the rotating section (3), and the positioning pole (6) is provided with a rectangular chute ( 9). The invention is convenient and adjustable, highly efficient and feasible, simple in structure, high in quality and reliable, and is suitable for popularization and use of cutting yellow cakes in the vertical direction.

Owner:WENGAN RENJIUMEI FOOD

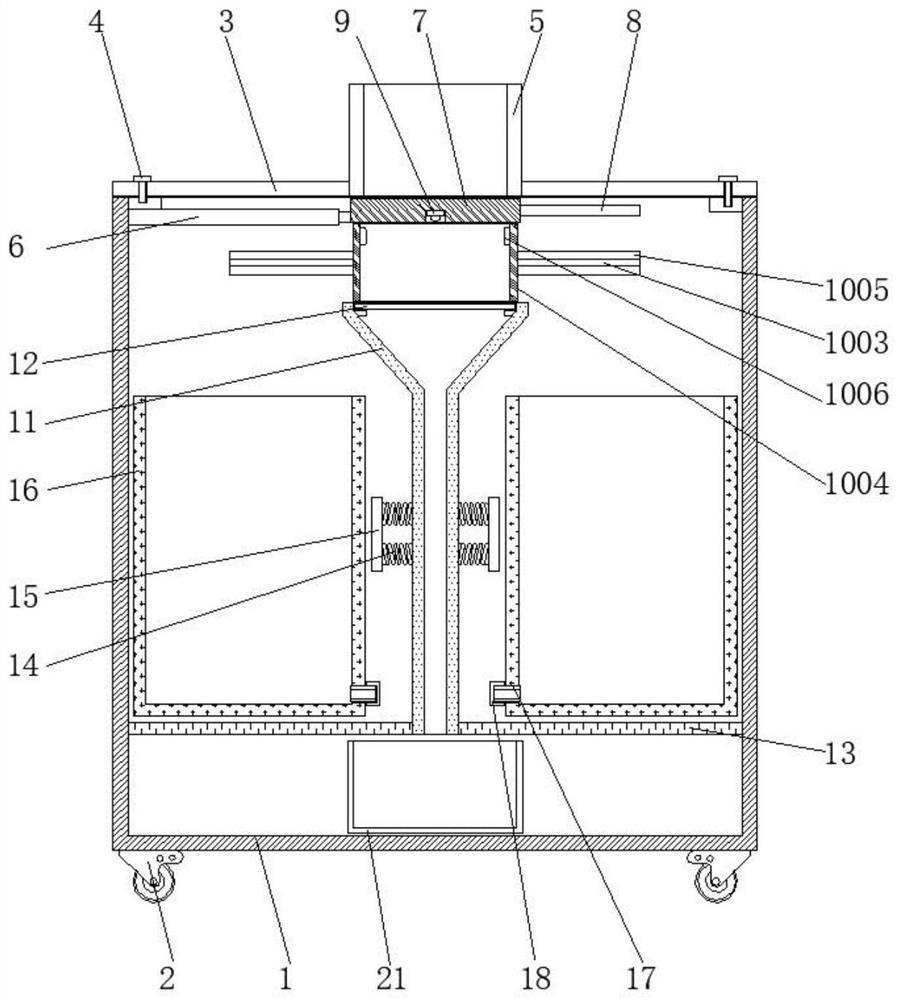

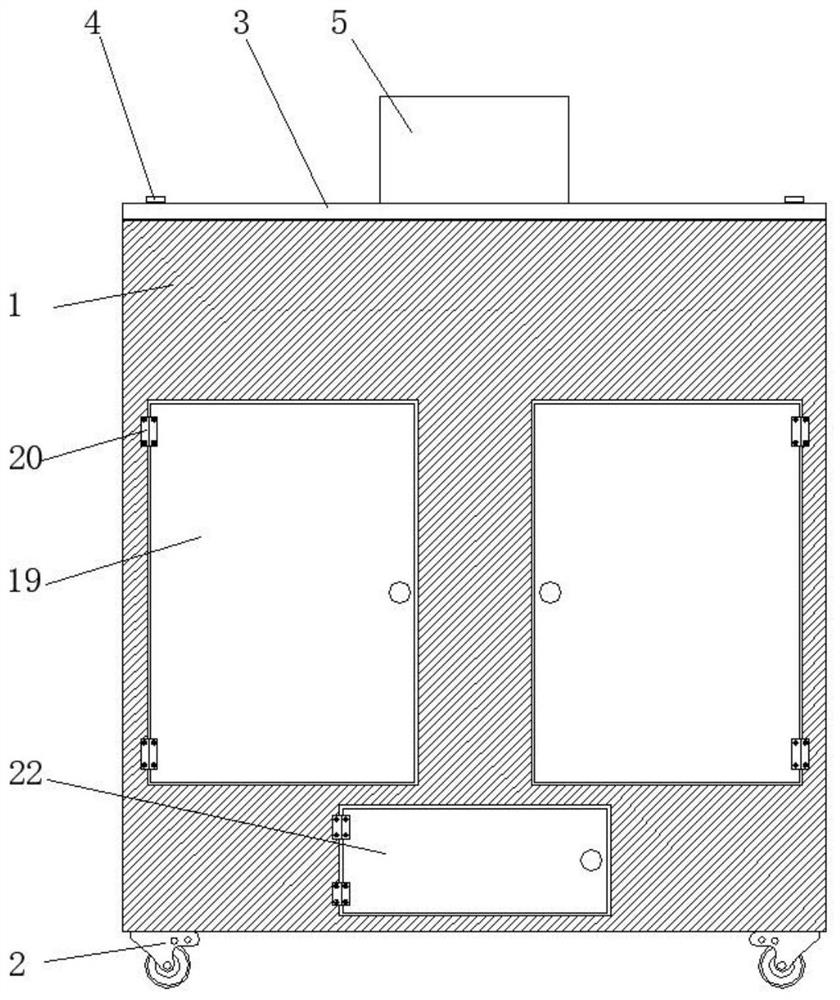

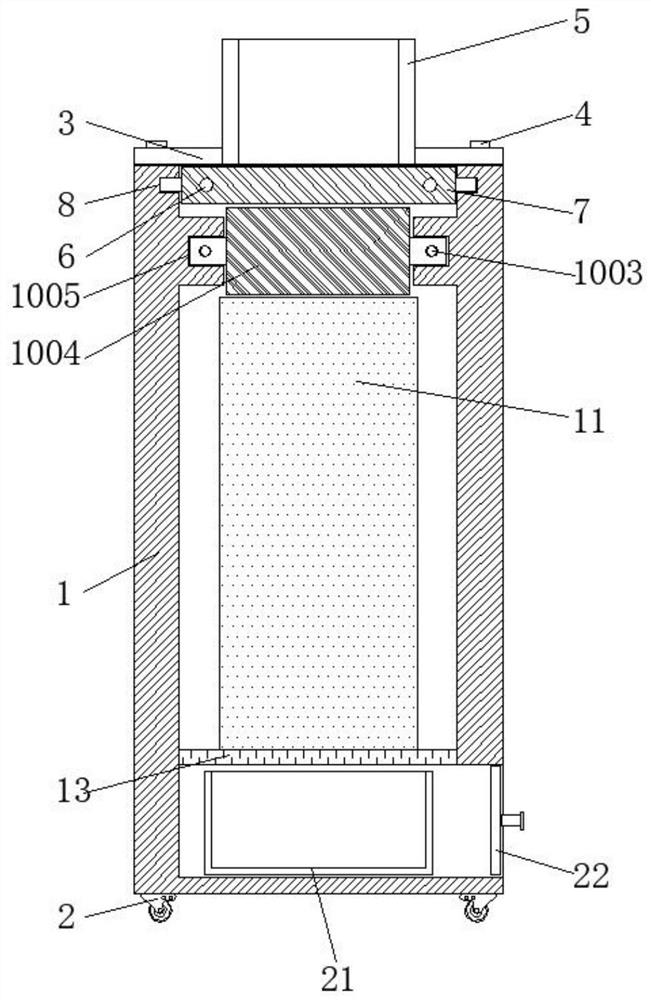

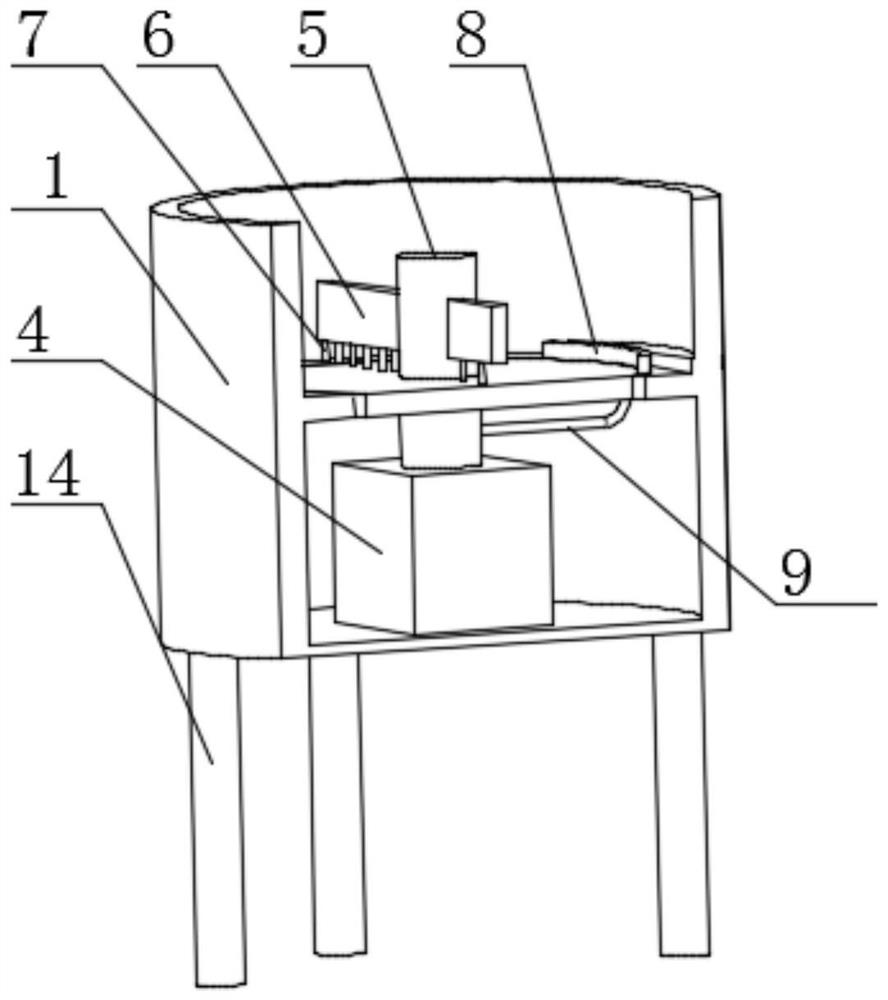

Machine-vision-based kitchen garbage classification method and equipment

InactiveCN113184406AEasy to control opening and closingEasy to push downRefuse receptaclesComputer hardwareMachine vision

The invention discloses a machine-vision-based kitchen garbage classification method and equipment. The machine-vision-based kitchen garbage classification equipment comprises a bearing box and a garbage classification auxiliary mechanism, wherein a draining plate is put in the top of a drainage channel, garbage cans are arranged at the outer sides of abutting plates, first box doors are arranged at the front sides of the garbage cans, a collecting box is arranged at the lower side of the drainage channel, and a second box door is arranged at the front side of the collecting box. According to the machine-vision-based kitchen garbage classification method and equipment, a baffle can move in leftward and rightward directions under the telescopic action of an electric telescopic rod, opening and closing of a feeding channel are conveniently controlled, garbage can be thrown into the feeding channel after the feeding channel is opened, the feeding channel is closed after the garbage enters a guiding channel, at the moment, a visual detection probe can detect the types of the garbage, then the guiding channel can selectively slide in a leftward or rightward direction according to detection results, and the garbage can be conveniently pushed into the corresponding garbage cans, so that an automatic classification effect is achieved.

Owner:徐州木牛流马机器人科技有限公司

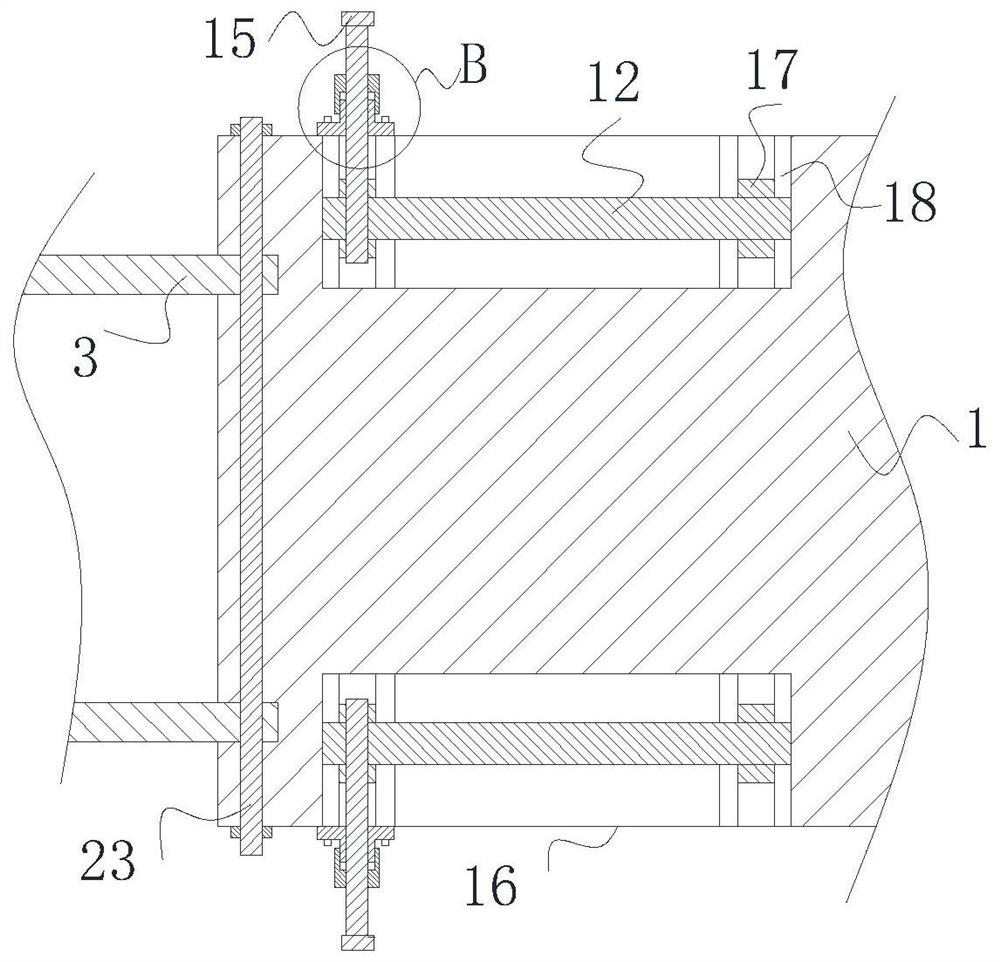

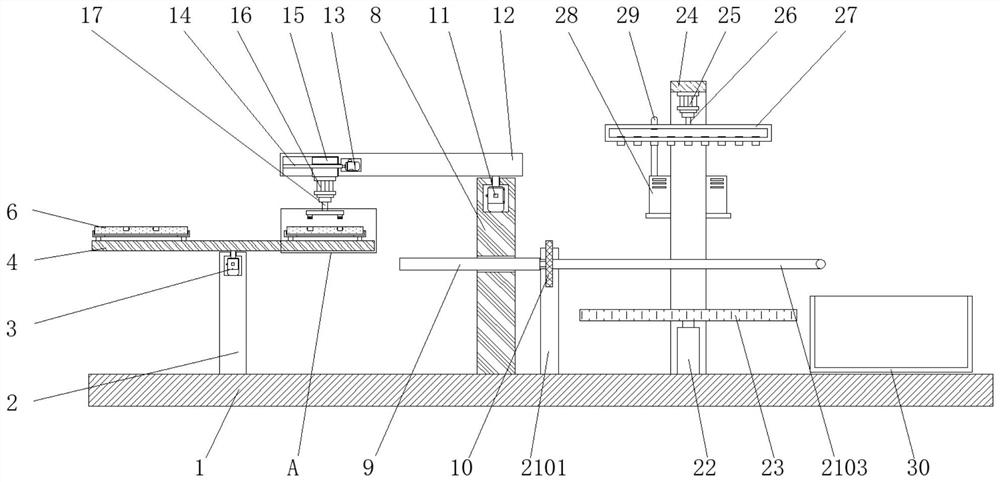

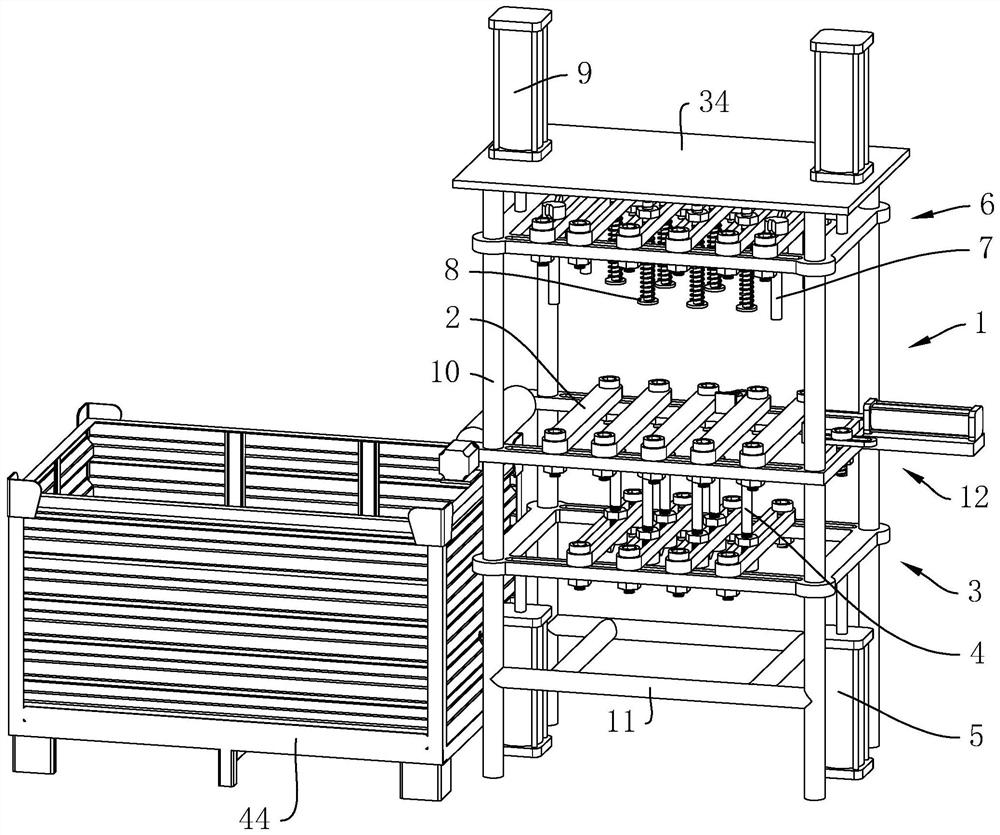

Automatic garbage distributing device

PendingCN113120467ALower feeding heightStable deliveryConveyorsRefuse receptaclesSoftware engineeringControl cell

The invention discloses an automatic garbage distributing device, and relates to the technical field of garbage classification. The problem that garbage is identified by people in the prior art is solved. The automatic garbage distributing device comprises a conveying unit, an identification unit, a pushing unit and a control unit, and the conveying unit is used for conveying input garbage to a corresponding garbage frame; the identification unit is used for identifying the type of the thrown garbage and transmitting a signal to the control unit; the pushing unit is used for pushing out the garbage on the conveying unit; and the control unit is used for receiving a signal of the identification unit. The garbage is thrown in through a throwing opening, after the garbage type is identified through the identification unit, the identification unit feeds back a garbage type signal to the control unit, after the control unit receives and processes the signal, the conveying unit is controlled to convey the garbage to a set position and then stops, the control unit controls the pushing unit to push out the garbage on the conveying unit, then the pushing unit returns to the initial position, the conveying unit is started again, the identification unit identifies the next piece of garbage again, working circulation is carried out, and garbage distribution is completed.

Owner:绵阳聚贤自动化设备有限公司

Sewage filtering and recycling device convenient to use

InactiveCN112892028AReasonable designGood practical effectStationary filtering element filtersSewageDrainage tubes

The invention discloses a convenient-to-use sewage filtering and recycling device, and the device comprises a mounting pipe; a water inlet pipe and a water outlet pipe are mounted on the mounting pipe; a sealing top cover is detachably mounted at the top end of the mounting pipe, a plurality of fixing rods are uniformly and fixedly mounted on the bottom wall of the sealing top cover, and a mounting frame is jointly and fixedly mounted at the bottom ends of the fixing rods; a metal filter screen is fixedly mounted on the inner side wall of the mounting frame, the water inlet pipe and the water outlet pipe are located at the bottom end and the top end of the metal filter screen respectively, an air cylinder is fixedly mounted on the top wall of the sealing top cover, and a piston rod is fixedly mounted at the output end of the air cylinder. Sewage is pumped into a mounting pipe, filtered impurities can be accumulated at the bottom end of a metal filter screen, an air cylinder is started to drive a piston rod to drive a mounting plate, and after a mounting rod and a conical blocking block move downwards, the impurities accumulated at the bottom end of the metal filter screen can be discharged from the bottom end of the mounting pipe; therefore, substances such as filtered residues can be conveniently cleaned or recycled, the design is reasonable, and the practical effect is good.

Owner:唐伟光

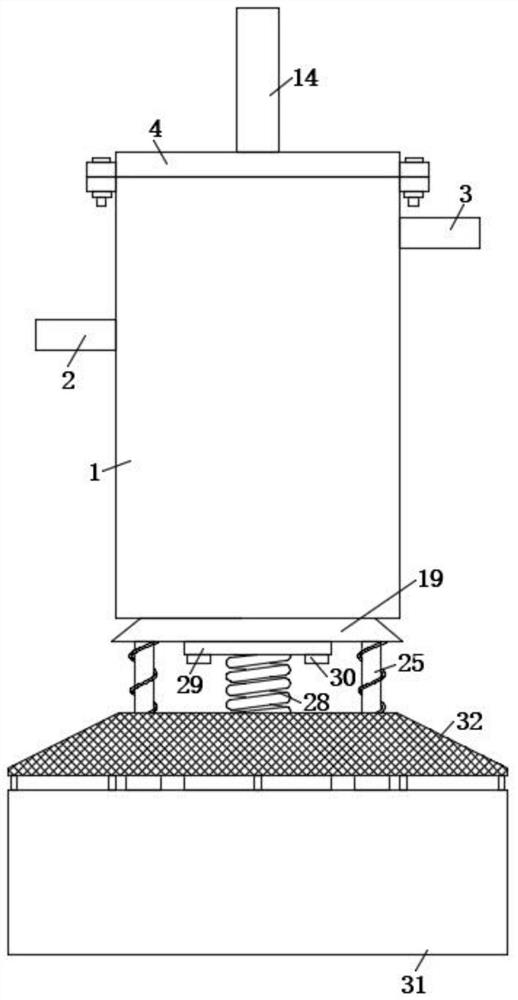

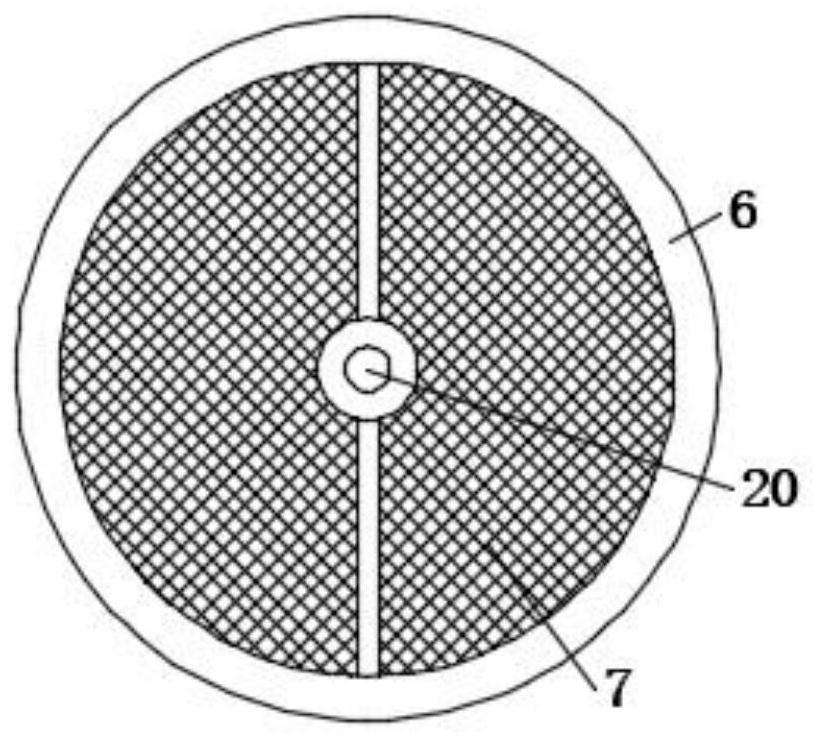

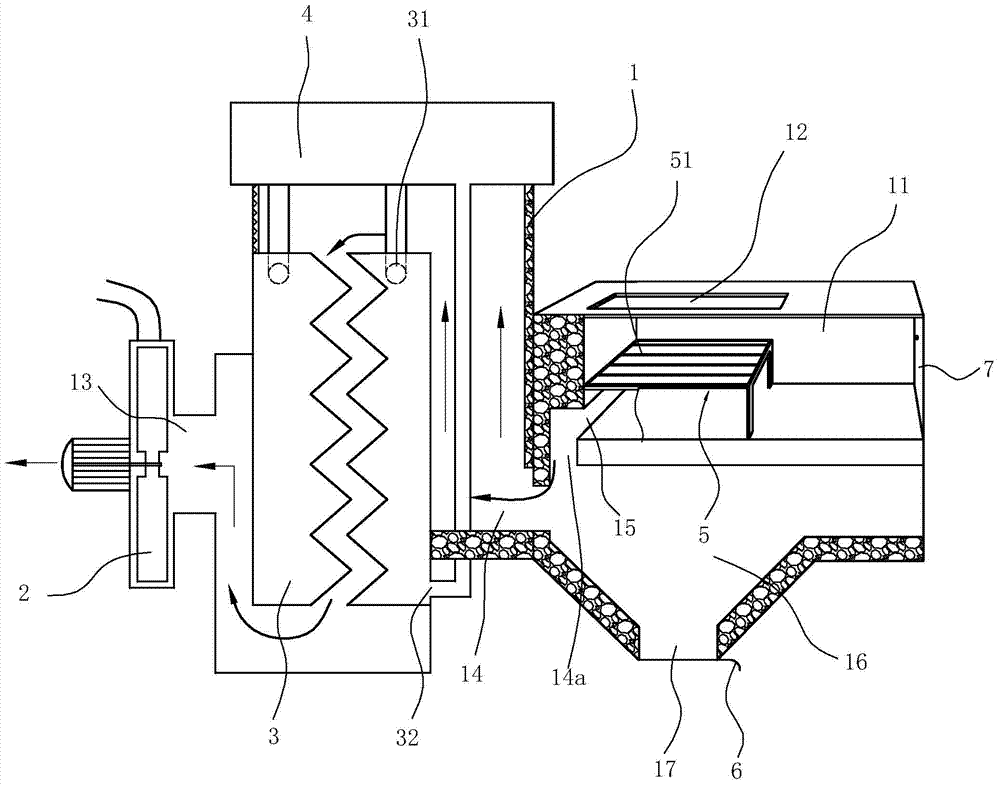

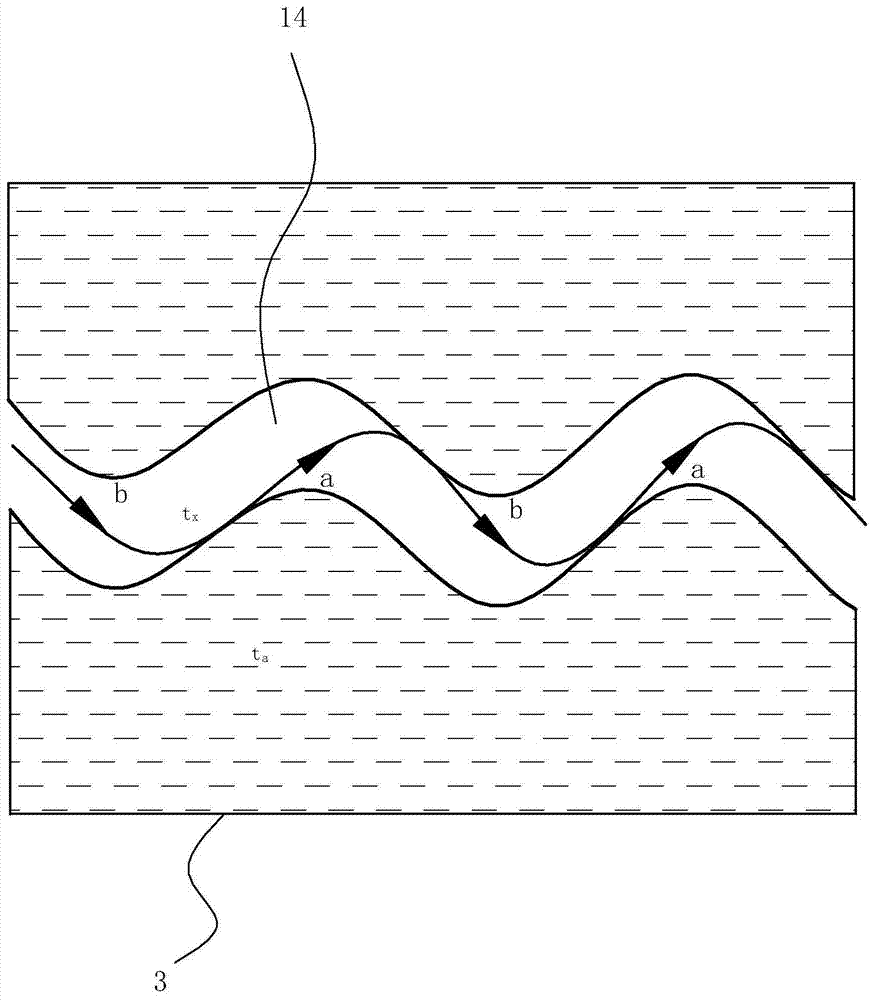

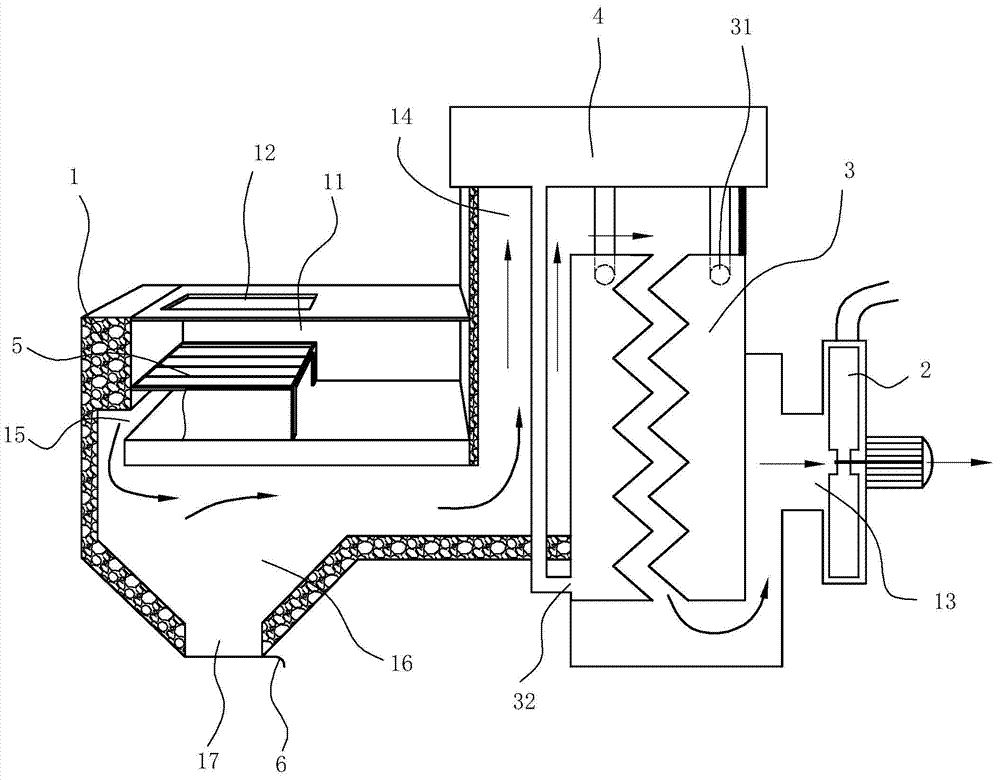

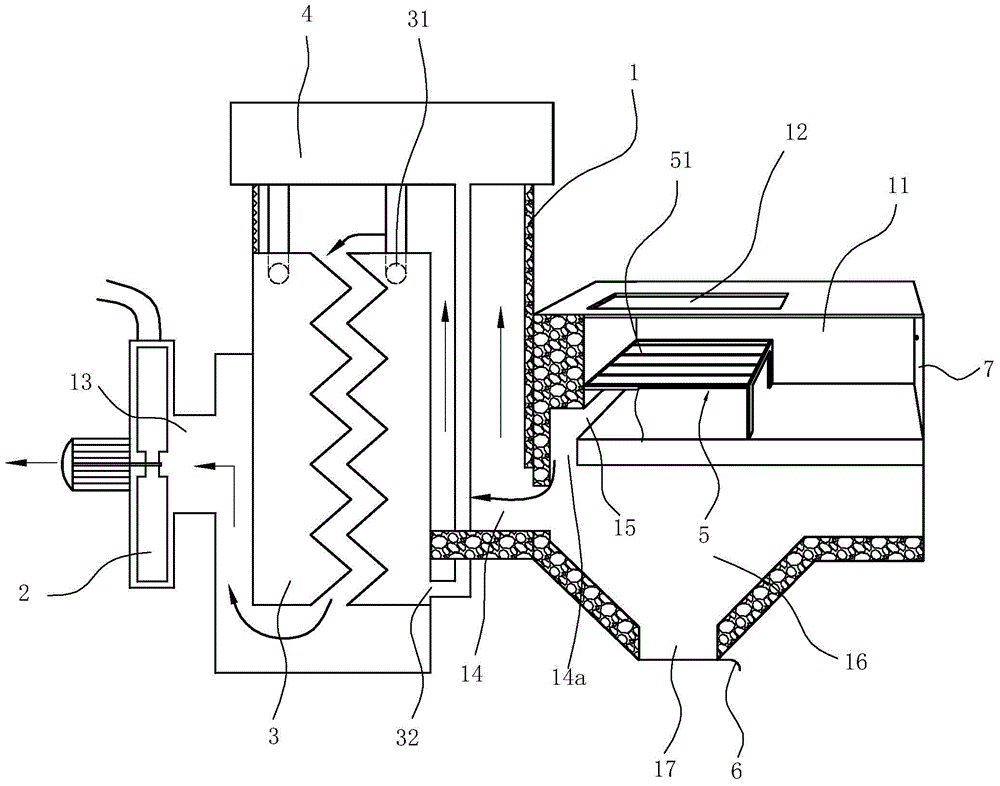

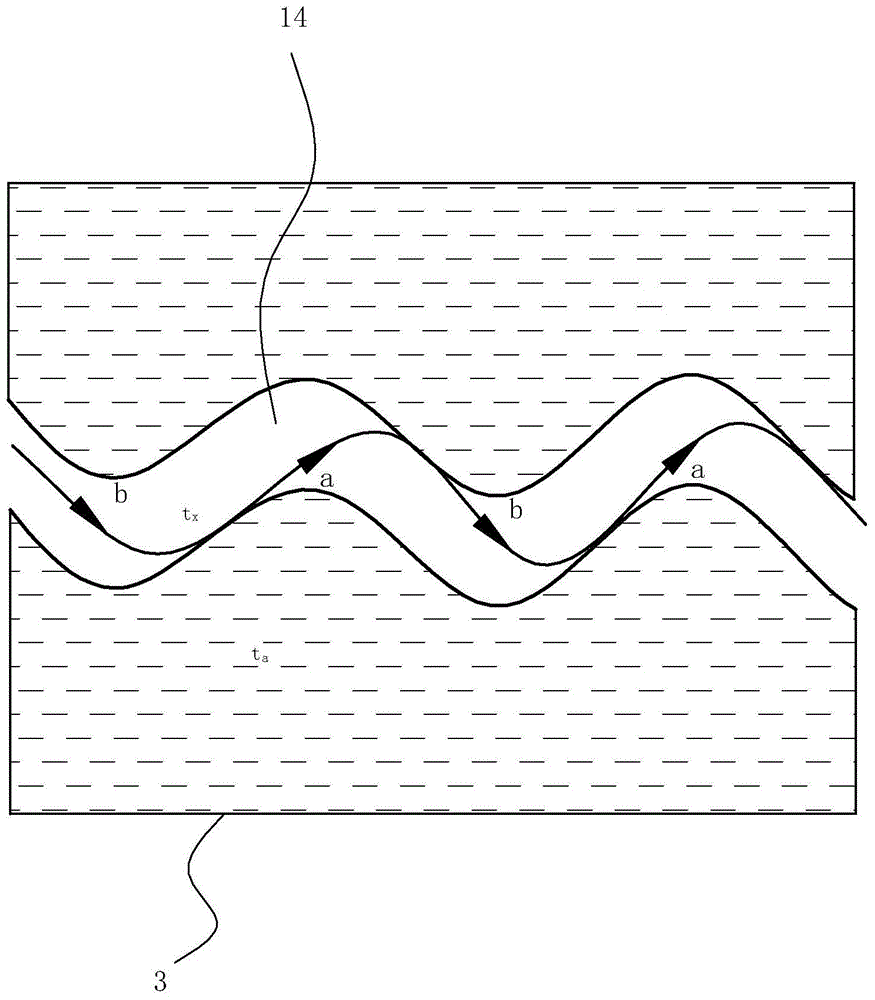

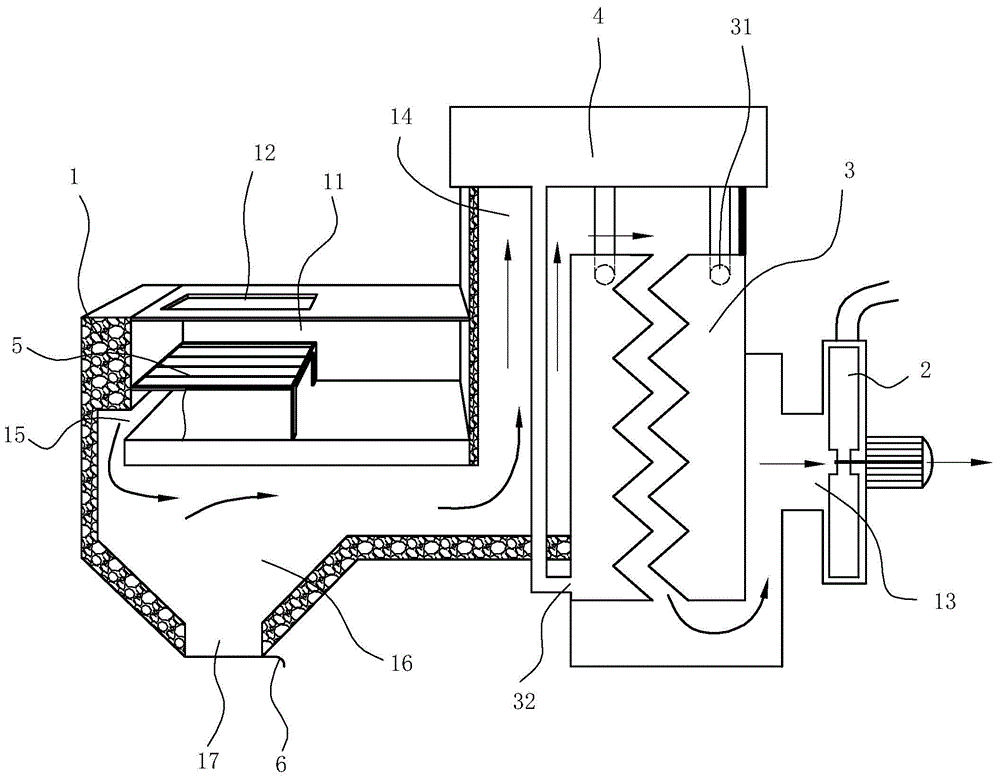

Incinerator

ActiveCN103528096AStable combustionBurn completelyDomestic stoves or rangesLighting and heating apparatusFirewoodCombustion chamber

The invention relates to an incinerator. The incinerator comprises an incinerator body, a combustion chamber arranged in the incinerator body, a feed port communicated with the combustion chamber, and an exhaust port provided with an exhaust blower, wherein an exhaust channel which exchanges heat with a heated body is arranged in the portion, between the exhaust port and the combustion chamber, inside the incinerator body. The incinerator is characterized in that the feed port is an air inlet and located above the combustion chamber, the lower portion of the combustion chamber is provided with a smoke discharge port communicated with the exhaust channel, meanwhile, a combustion bed which covers the smoke discharge port is placed at the bottom of the combustion chamber, the upper surface of the combustion bet is design into a grid, vent holes which are communicated with the smoke discharge port are formed in two side faces, corresponding to the smoke discharge port, of the combustion bed respectively, other side faces of the combustion bed are closed, and therefore a combustion area above the grid and a smoke and dust discharge area below the grid are formed in the combustion chamber. By the adoption of the structure, the incinerator has the advantages that full combustion can be achieved, no black smoke is produced, firewood can be conveniently added, combustion is stable and controllable, and the smoke can be smoothly discharged.

Owner:宁波科莱尔节能科技股份有限公司

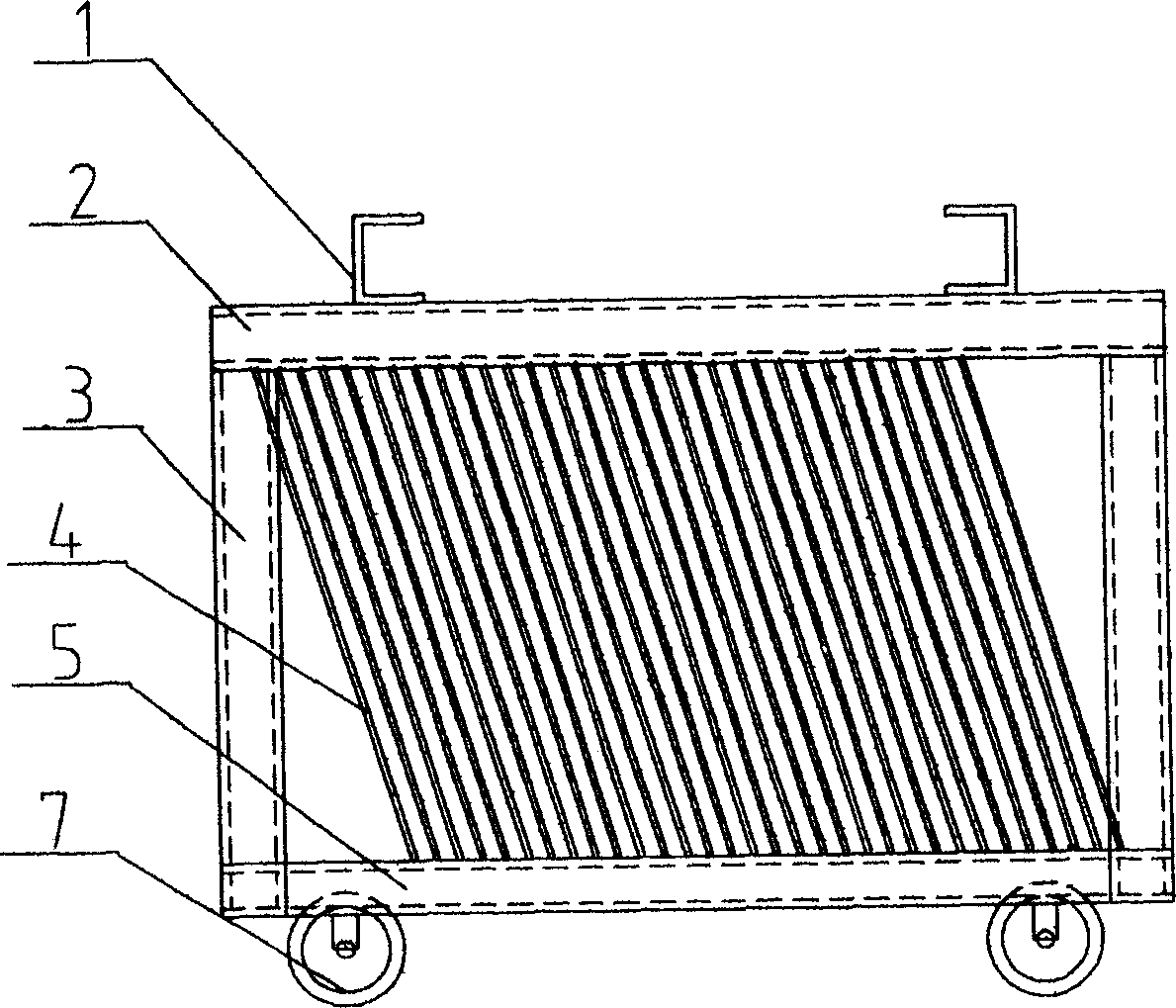

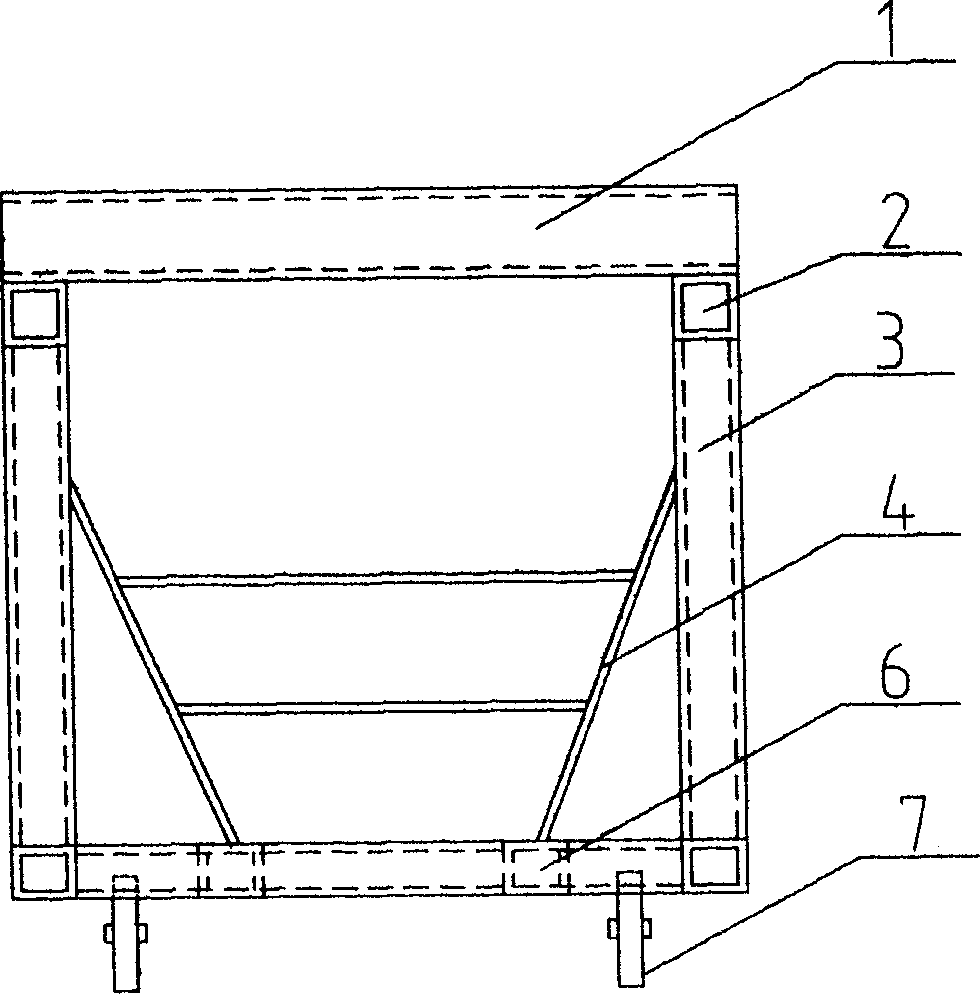

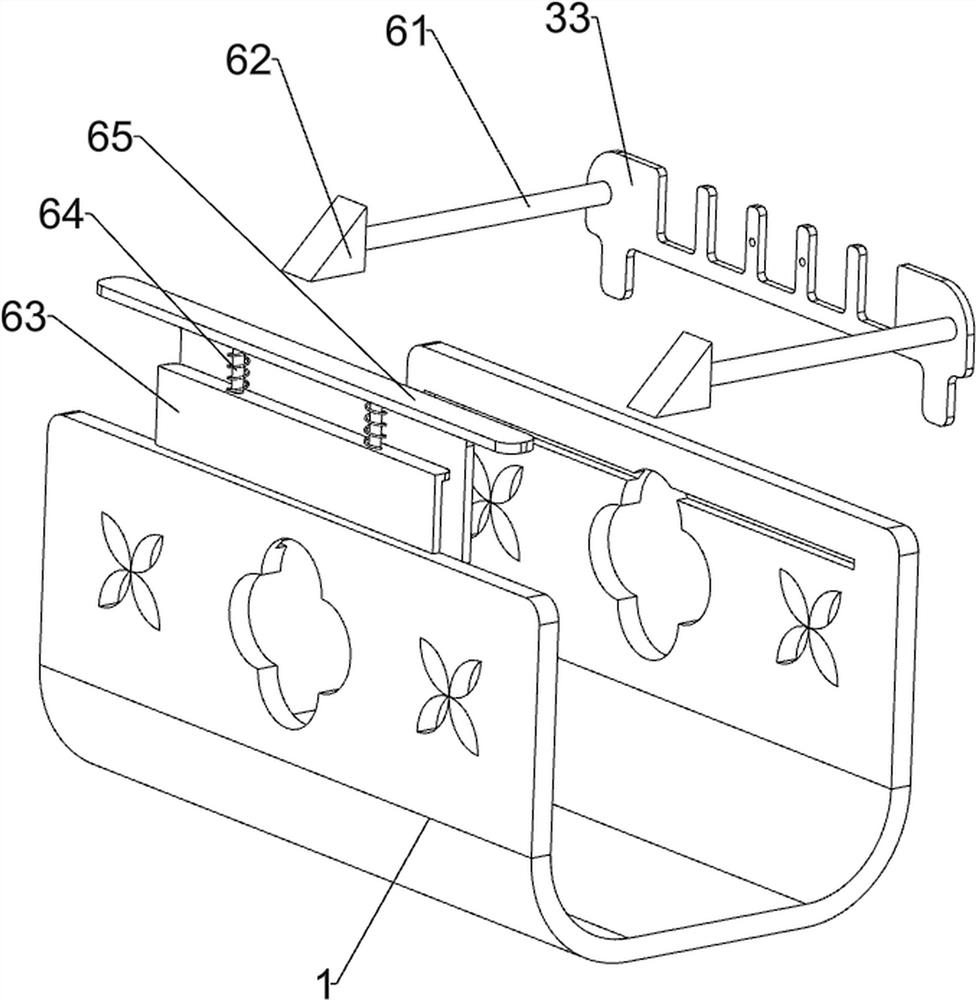

Circular protection plate type shelf vehicle for airing varnish

The invention provides a circle protective plate paint-good movable bracket, belonging to the good bracket, which comprises: a six-surface frame and an inner retainer. It is characterized in that: the upper frame has two support beams; the bottom frame has two support rods; the retainer is inclined arranged between the upper frame and the support rod; the upper end of retainer is connected to the upper frame while the lower end is connected to the support rod; and a rolling wheel is under the bottom frame. When airing the paint, the circle protective plate is inserted into the retainer with one-to-one; the circle protective plate is above two support rods, while its back contacts the retainer to form a incline surface. The invention has the advantages that: the inserting and getting are easily; the bracket can be moved flexibly; the light is uniform, and the airing time can be shortened. In addition, several brackets can be layered to air paint-goods, with less occupied area.

Owner:安徽马钢和菱实业有限公司

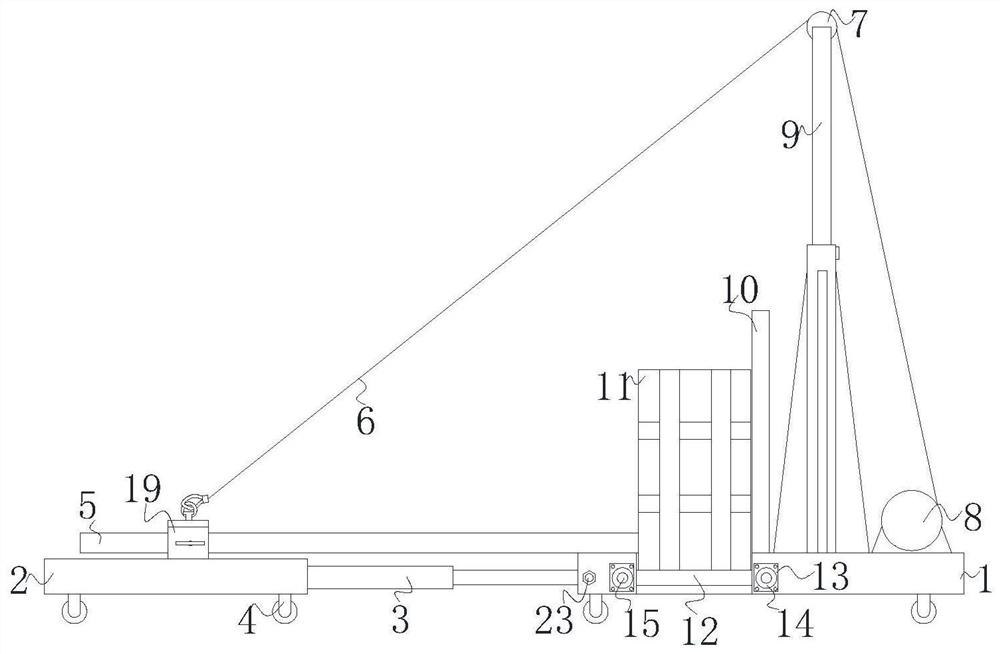

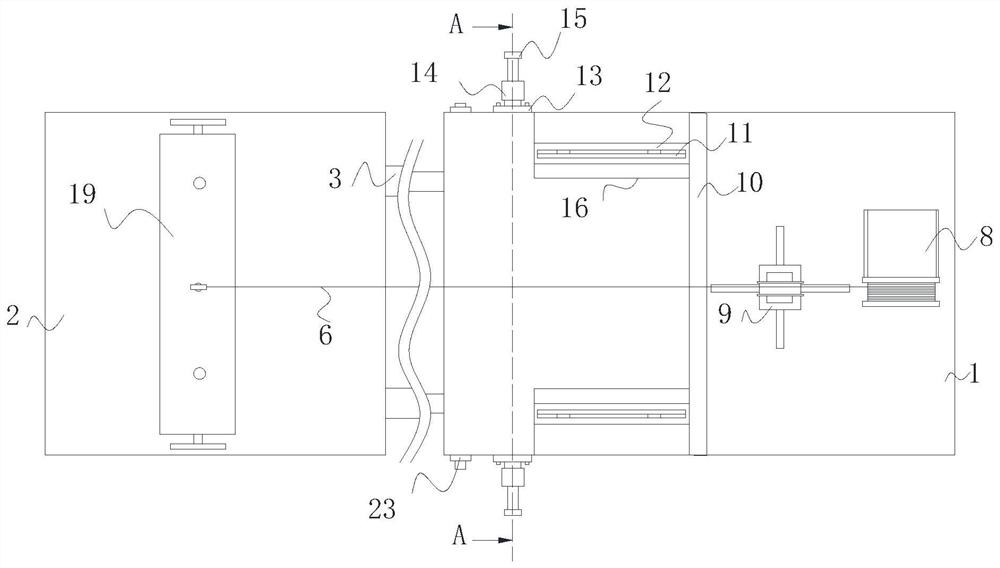

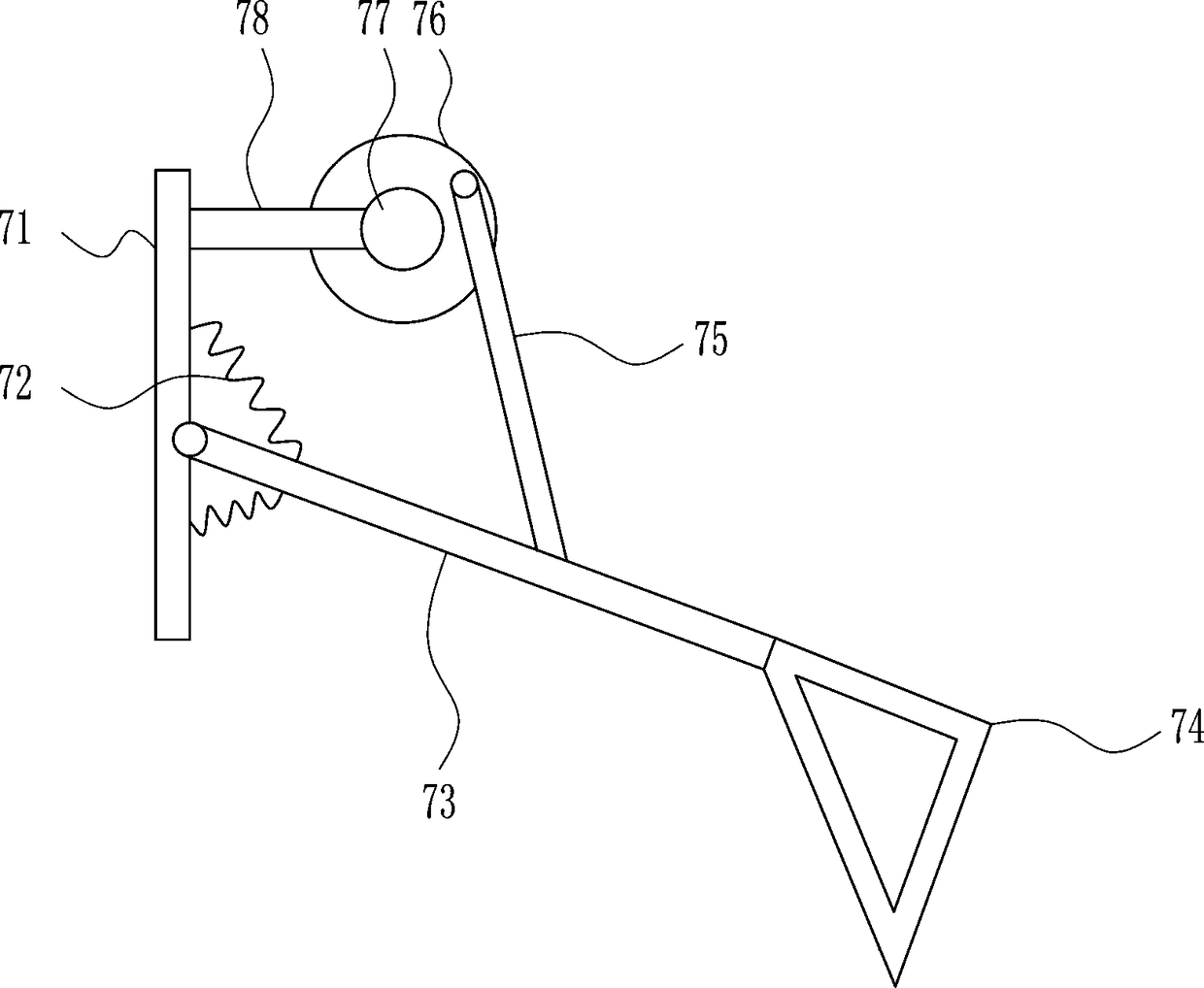

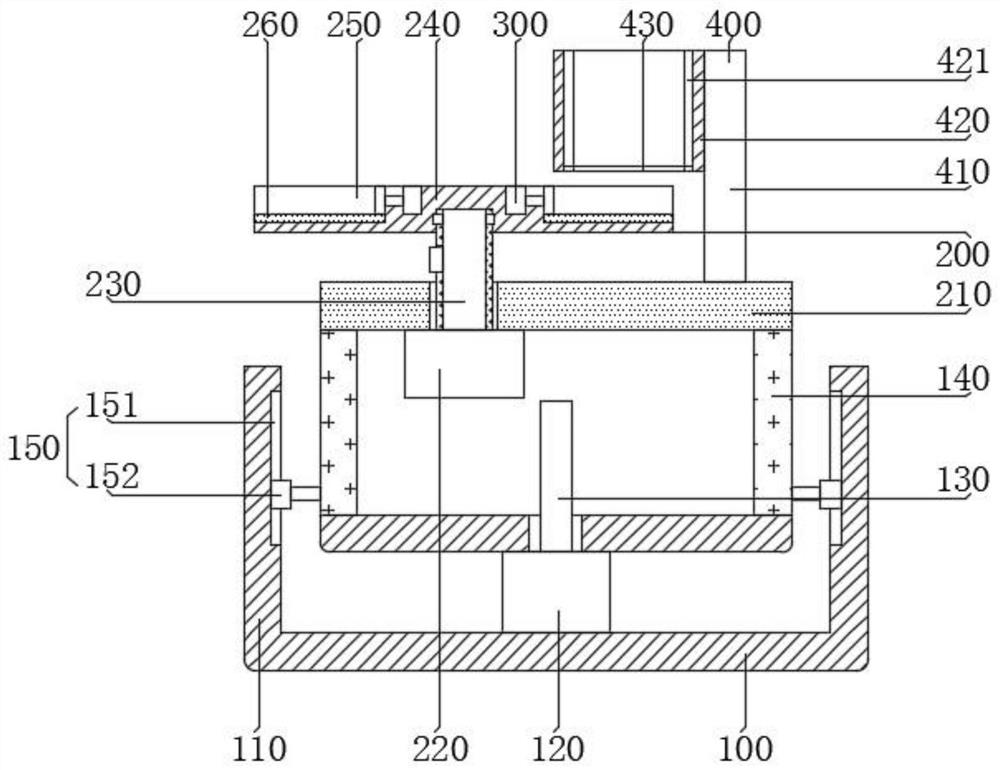

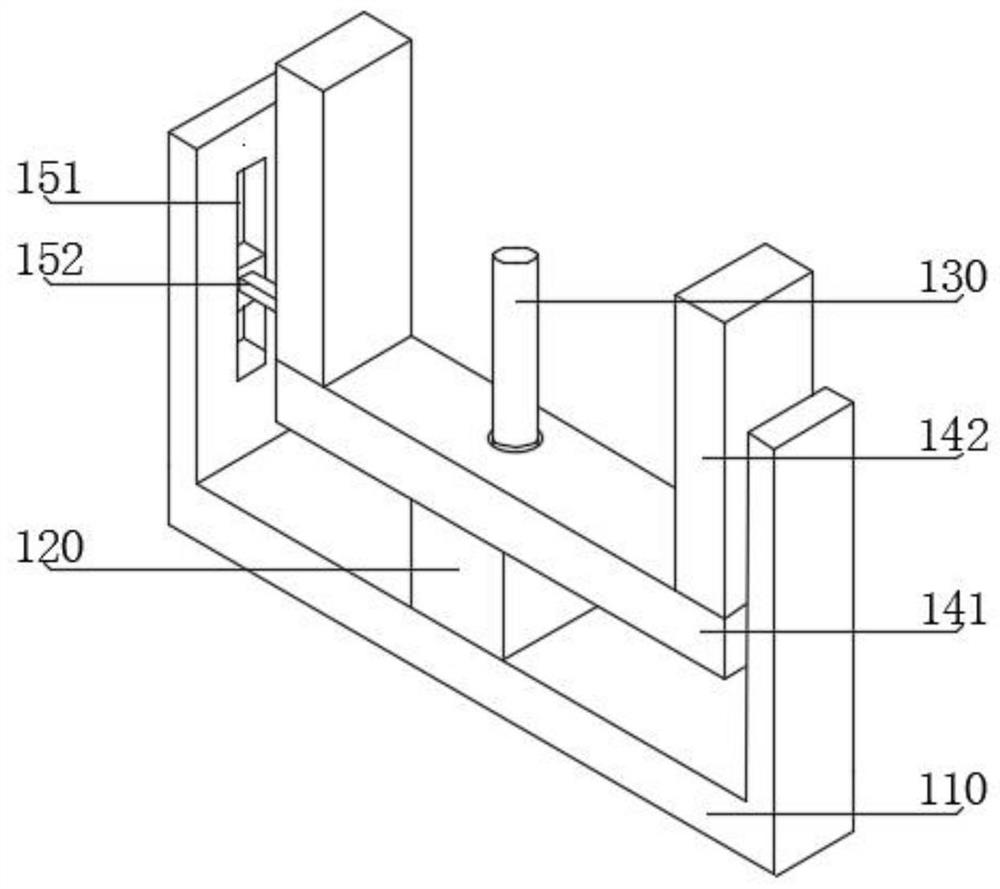

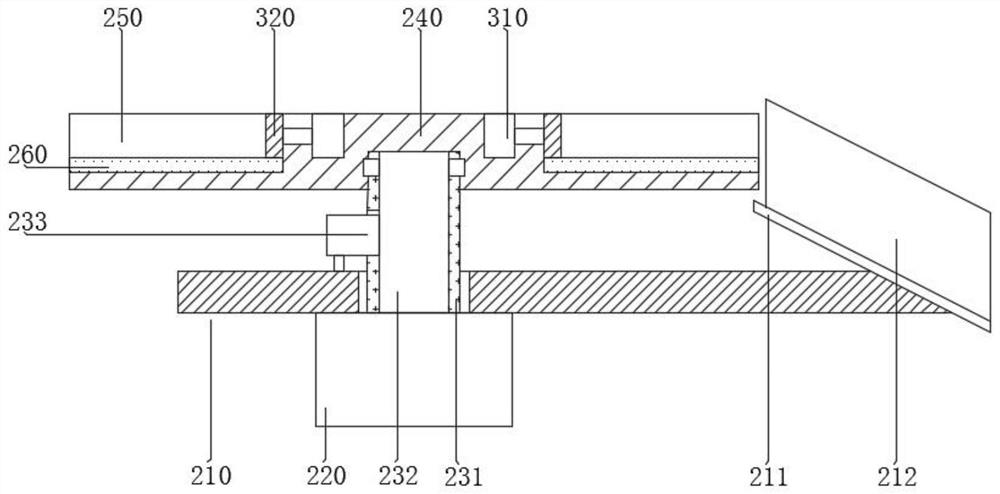

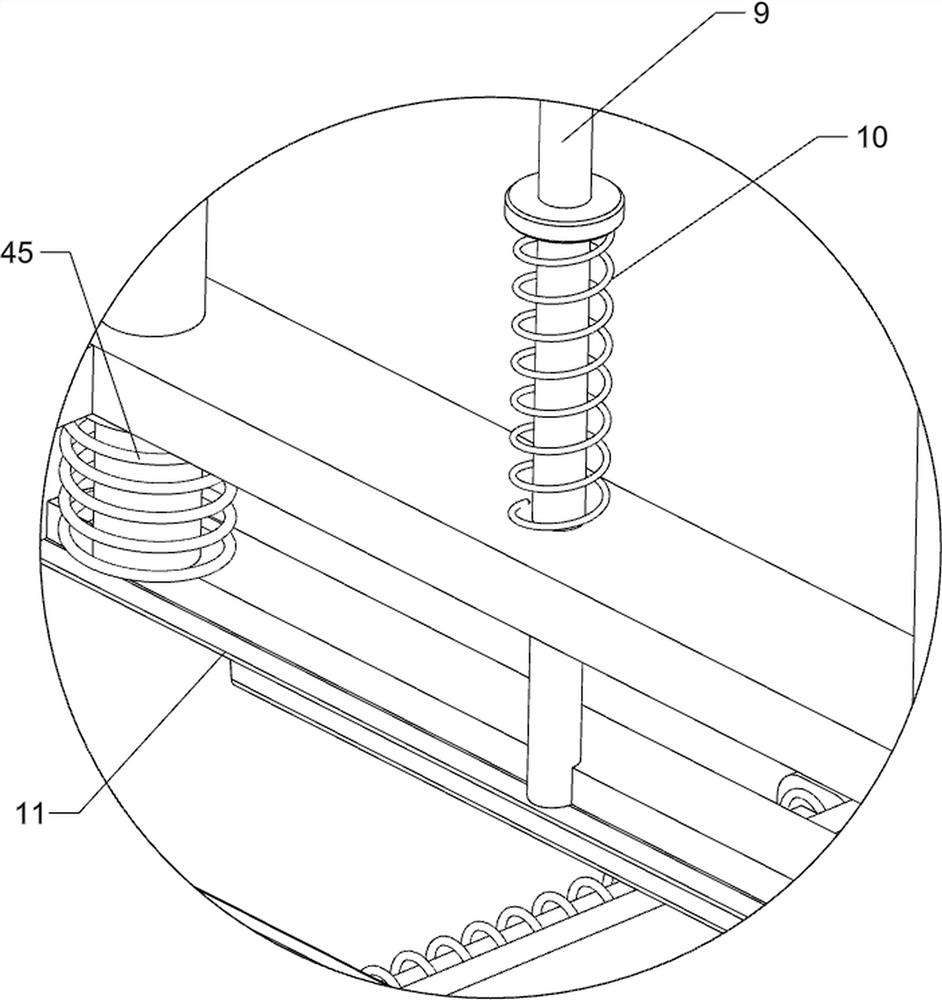

Fabricated building installation equipment

ActiveCN113503043AEasy to slide downReduce labor burdenBuilding material handlingArchitectural engineeringMechanical engineering

The invention belongs to the field of fabricated buildings, particularly relates to structural improvement of fabricated building installation equipment, and particularly provides fabricated building installation equipment. The fabricated building installation equipment comprises a supporting base used for containing a wallboard, a driving device is arranged on the supporting base, the output end of the driving device is connected with one end of a connecting rope, the other end of the connecting rope is connected with the position, close to the end, of the wallboard through a clamping assembly, the connecting rope is arranged above the wallboard and is obliquely arranged, the driving device is arranged on the side, away from the clamping assembly, of the wallboard, and the driving device is used for pulling the connecting rope so that the wallboard can rotate to be upright. A baffle is arranged between the driving device and the wallboard and used for abutting against the end, away from the clamping assembly, of the wallboard when the wallboard rotates, and the beneficial effect of effectively reducing the labor burden of construction workers is achieved.

Owner:同合智造(哈尔滨)科技有限责任公司

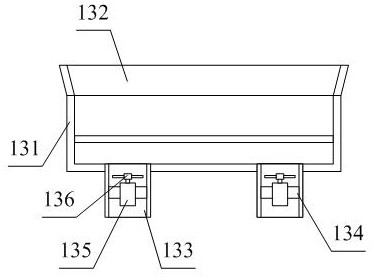

Bulk food packaging feeding device

The invention discloses a bulk food packaging feeding device. The bulk food packaging feeding device comprises a machine body, a material receiving box, a motor shield and a transport belt. Supportingcolumns are welded on the lower portion of the machine body, and a feeding inlet is formed in the top end of the machine body. Two fixing bearings are welded in the machine body, and supporting wheels are rotatably mounted outside the fixing bearings. A connecting fixing plate is welded at both ends of the fixing bearings, and a driving wheel is rotatably mounted at the end, outside the fixing bearings, of the connecting fixing plate. The motor shield is welded at the end, near the driving wheel, of the connecting fixing plate, and a motor is fixed into the motor shield through a motor fixingbracket in a welded mode. A motor output wheel and the driving wheel are connected through a transmission belt in a transmission mode, and a driven wheel is connected to the driving wheel through thetransport belt in a transmission mode. Quantitative boxes are connected and fixed to the surface of the transport belt through rubber fixing blocks. The bulk food packaging feeding device has the advantage that a certain amount of bulk food can be picked up according to the capacity of the quantitative boxes.

Owner:海宁市立派商贸有限公司

Winding and storage device for producing chemical fibers

The invention provides a winding and storage device for producing chemical fibers. The winding and storage device comprises a base plate, moving wheels, protection plates, an outer shell, a first motor, a driving pulley, a connecting belt, an insertion connection bearing, a driven pulley, a power distribution box, keys, the chemical fibers, a collection box structure, a mist spray box structure, aconnecting pipe structure, a containing wheel structure and a push plate structure. The moving wheels are welded to the left side and the right side of the lower surface of the base plate correspondingly. The protection plates are welded to the front portions of the left side and the right side of the upper surface of the base plate correspondingly. The outer shell is welded to the middle of therear portion of the upper surface of the base plate. The first motor is mounted in the middle of the upper surface of the base plate through bolts. Meanwhile, the driving pulley is mounted on an output shaft of the first motor. The winding and storage device has the beneficial effects that by means of the collection box structure, the chemical fibers falling off the winding and storage device canbe collected, and the problem that excessive chemical fibers are wasted can be further avoided conveniently.

Owner:苏州科知律信息科技有限公司

Drilling device for brake pads

InactiveCN106964811BFast collection and processingEasy to collect and processWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:YANCHENG LICHENG AUTO PARTS CO LTD

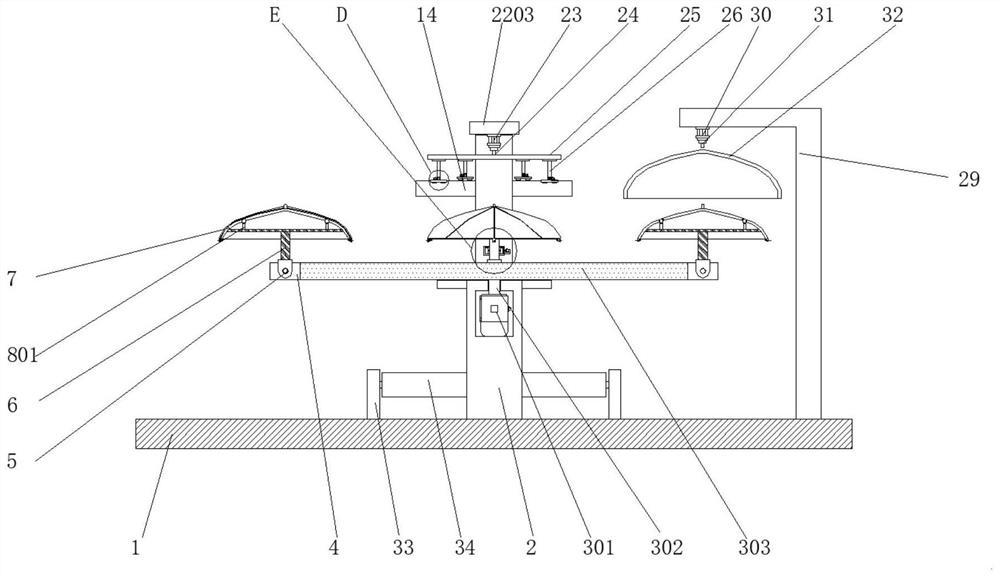

Garment processing printing equipment with flattening function

PendingCN113858787APlay a role in taking overEasy to collectRotary pressesOther printing apparatusHydraulic cylinderEngineering

The invention discloses garment processing printing equipment with a flattening function. The garment processing printing equipment comprises a base, a second motor, a rotating frame, a flattening mechanism, an electric telescopic column, a bearing frame and a collecting box, a second support is fixed to the middle of the upper end face of the base, the rotating frame is rotationally connected to the top of the second support, and a first hydraulic cylinder is fixed to the bottom of a sliding block; and the flattening mechanism comprises a third support, a third electric telescopic rod and pull supporting rods, the third support is fixed to the base, the inner side of the third support is connected with the pull supporting rods through the third electric telescopic rod, and the electric telescopic column and the bearing frame are fixed to the other side of the upper end face of the base. A second hydraulic cylinder is fixed to the inner top of the bearing frame, and an air heater is fixed to the rear side of the bearing frame. According to the garment processing printing equipment with the flattening function, after the outer sides of the pull supporting rods are sleeved with clothes, the two pull supporting rods are far away from each other, so that the clothes are conveniently pulled, supported and flattened, and the clothes are smoother.

Owner:建湖县利达制衣有限公司

Chemical plant sewage pool decontamination device

The invention discloses a chemical plant sewage pool decontamination device which comprises a sewage pool, a carrying plate is installed in the sewage pool in a lifting mode, the carrying plate is tightly attached to the bottom wall of the inner side of the sewage pool, the carrying plate makes contact with the inner side wall of the sewage pool, a plurality of installation rods are connected to the top walls of the two sides of the carrying plate, and the top ends of the installation rods extend to the upper side of the sewage pool. A lifting plate is fixedly mounted at the top ends of the mounting rods located on each same side, first servo motors are fixedly mounted on the outer side walls of the two sides of the sewage pool, and lead screws are fixedly mounted at the output ends of the two first servo motors. A sludge scraping device matched with the carrying plate is arranged on one side of the sewage pool, after the carrying plate cleans impurities such as sludge in the sewage pool to the top end of the sewage pool, a second servo motor is started to drive a sludge scraping plate to move in the horizontal direction, the impurities such as the sludge on the carrying plate can be conveniently pushed down, manual cleaning is not needed, operation is convenient, the manual labor intensity is small, and the cleaning speed is greatly improved.

Owner:JIANGSU OCEAN UNIV

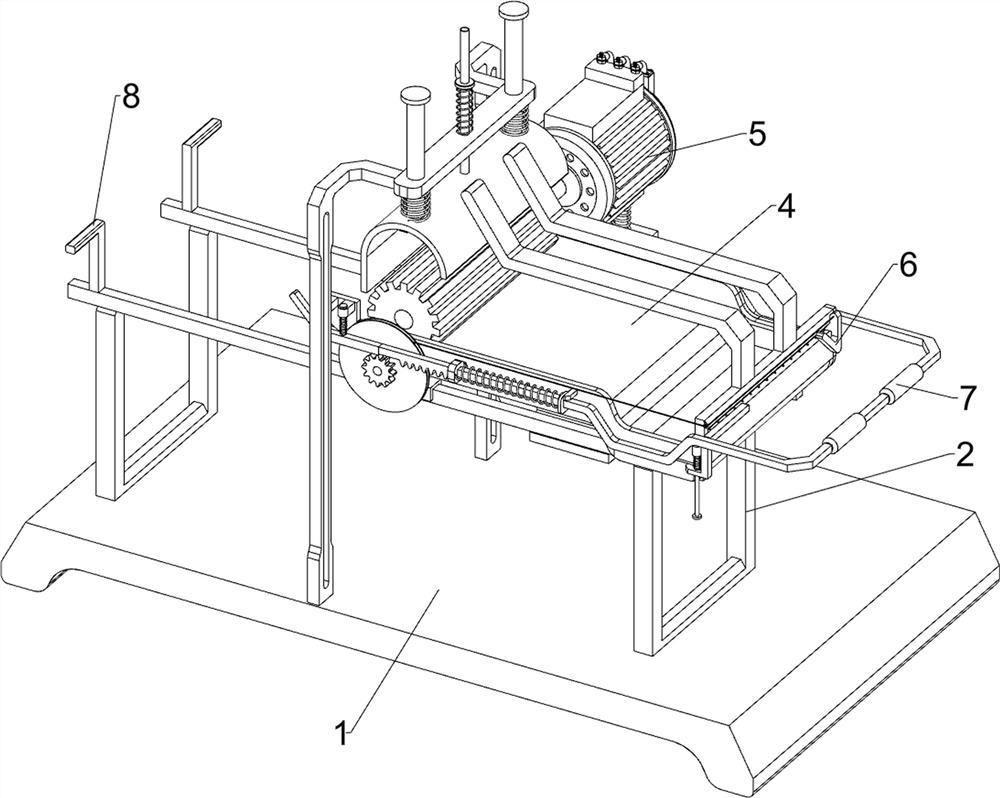

Energy-saving and environment-friendly water bottle cutting and packaging device

The energy-saving and environment-friendly water bottle cutting and packaging device comprises a base, an n-shaped plate, a fixing plate, a discharging hopper, a rotating shaft, a driving motor, a cutting knife, a gear, a reset mechanism and a rotating mechanism, the n-shaped plate is fixedly connected to one side of the base, the fixing plate is fixedly connected between the two sides of the n-shaped plate, and the discharging hopper is fixedly connected to the middle of the fixing plate in a penetrating mode. A water bottle is clamped on a rotating mechanism, a driving motor is started, a cutting knife rotates, then the rotating mechanism is started to drive the water bottle to rotate, a reset mechanism is pulled to move downwards, the reset mechanism moves downwards to drive the rotating mechanism to move downwards, and the rotating mechanism moves downwards to drive the water bottle to move into a discharging hopper to make contact with the cutting knife. And the cutting knife rotates to cut the water bottle, so that the water bottle does not need to be cut manually, labor is saved, and hands can be prevented from being cut.

Owner:张鑫州

Unloading device for production of numerically controlled electromechanical equipment and method of use thereof

ActiveCN111922364BProblems affecting processing qualityReduce in quantityMetal working apparatusElectric machineDrive shaft

The invention discloses an unloading device for the production of numerically controlled electromechanical equipment, which includes a lifting assembly, a rotating assembly, a pushing assembly and a feeding assembly. The assembly includes a support plate, a rotating motor, a drive shaft and a turntable, the pushing assembly includes an electric push rod and a pushing plate, the feeding assembly includes a connecting frame and a storage box, the feeding assembly includes a connecting frame and a storage box, and the connecting frame is installed on the top of the support plate. The invention also discloses the use method of the unloading device. The invention can replace the manual loading and unloading operation of the parts, effectively reduce the labor workload of the staff, not only meet the production requirements, but also prevent the staff from causing serious damage to the staff due to repeated manual loading and unloading actions. Large damage can avoid the problem that shaft parts are easily misaligned due to worker fatigue and affect the processing quality of parts, and can effectively reduce the number of defective products, thereby improving production efficiency and product quality.

Owner:深圳市正源智能刀模设备有限公司

Novel instant noodle block grabbing device

The invention discloses a novel instant noodle block grabbing device. The novel instant noodle block grabbing device comprises a frame, a panel, a noodle grabbing mechanism and a cam, wherein the noodle grabbing mechanism comprises a first noodle jaw, a second noodle jaw, a first fixed plate, a second fixed plate, a noodle pushing plate, a first slide rod, a second slide rod, a connecting rod and a transmission rod; the first noodle jaw and the second noodle jaw are respectively fixed on the first fixed plate and the second fixed plate; the first fixed plate is hinged with the second fixed plate; a first end of the connecting rod is fixedly connected with the noodle pushing plate after penetrating through the first fixed plate and the second fixed plate; a second end of the connecting rod is fixedly connected with the transmission rod; a first end of the first slide rod and a first end of the second slide rod are fixedly connected to the connecting rod; a second end of the first slide rod and a second end of the second slide rod are slidingly connected with the first fixed plate and the second fixed plate; and a guide part fitting the transmission rod is formed on the cam. The device is simple in structure, convenient for operation and high in automation degree, saves the labor cost, and improves the working efficiency.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

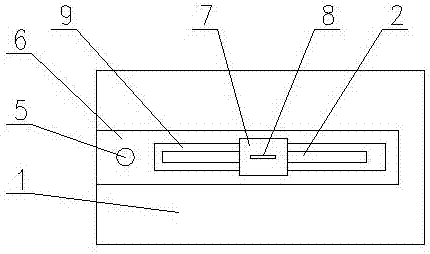

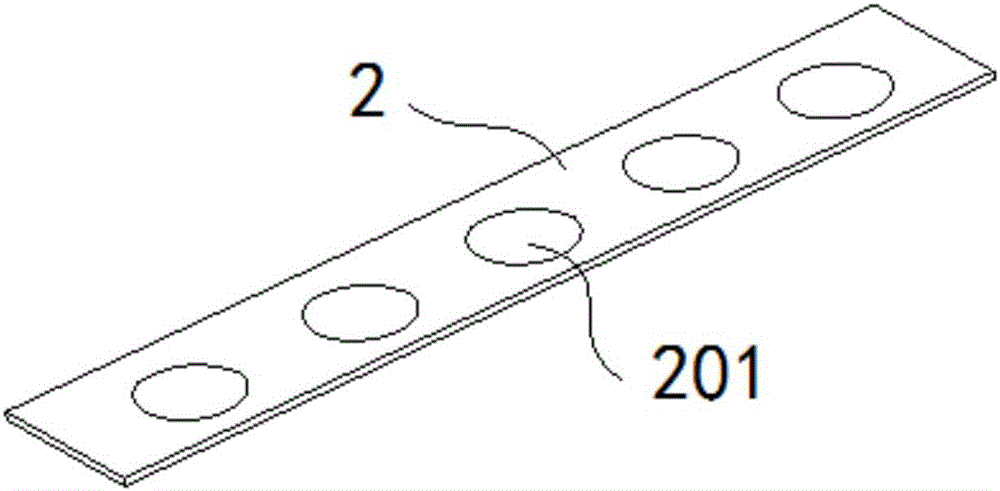

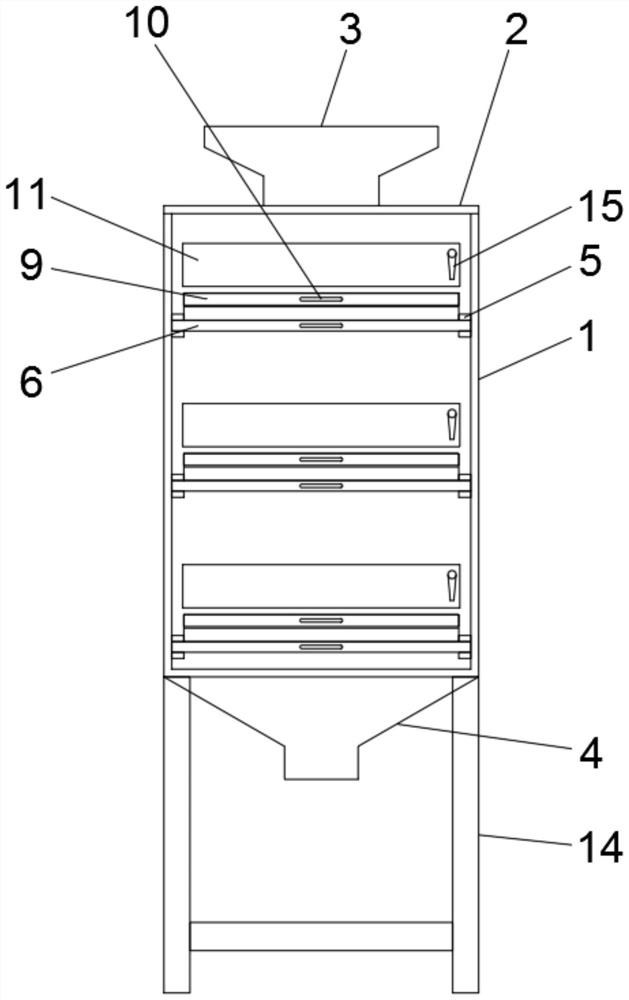

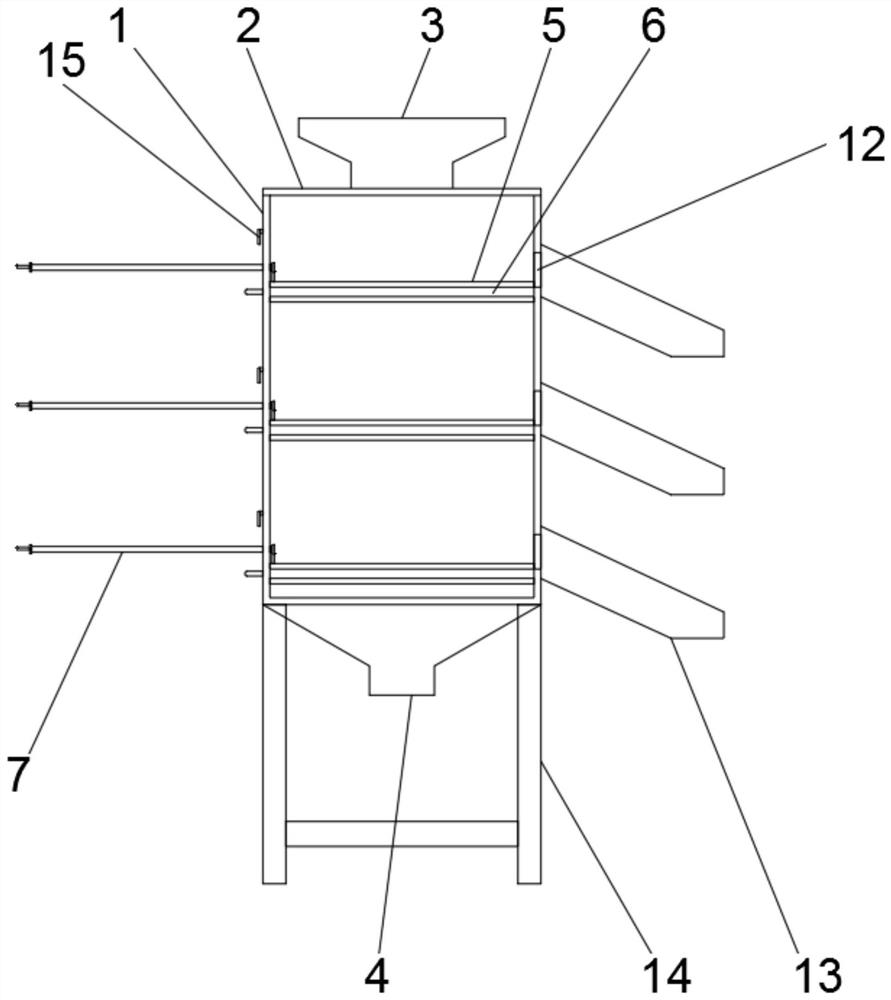

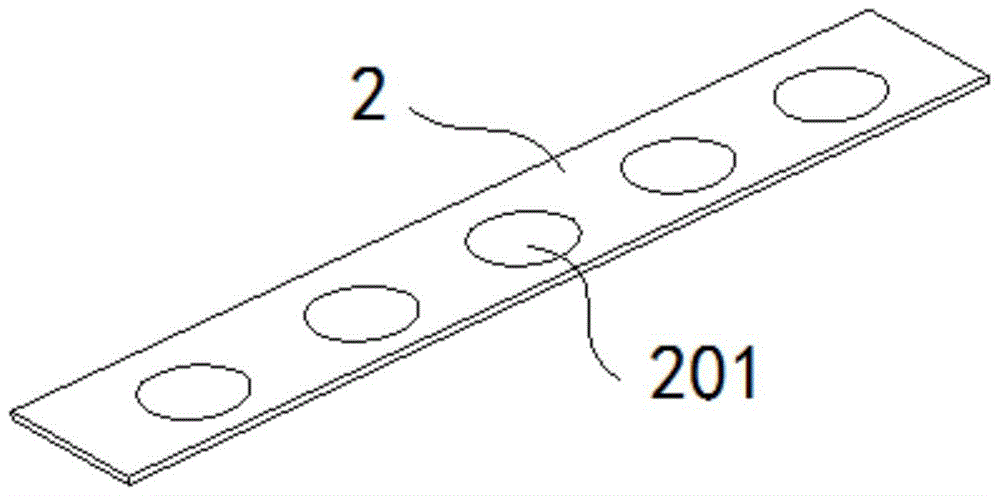

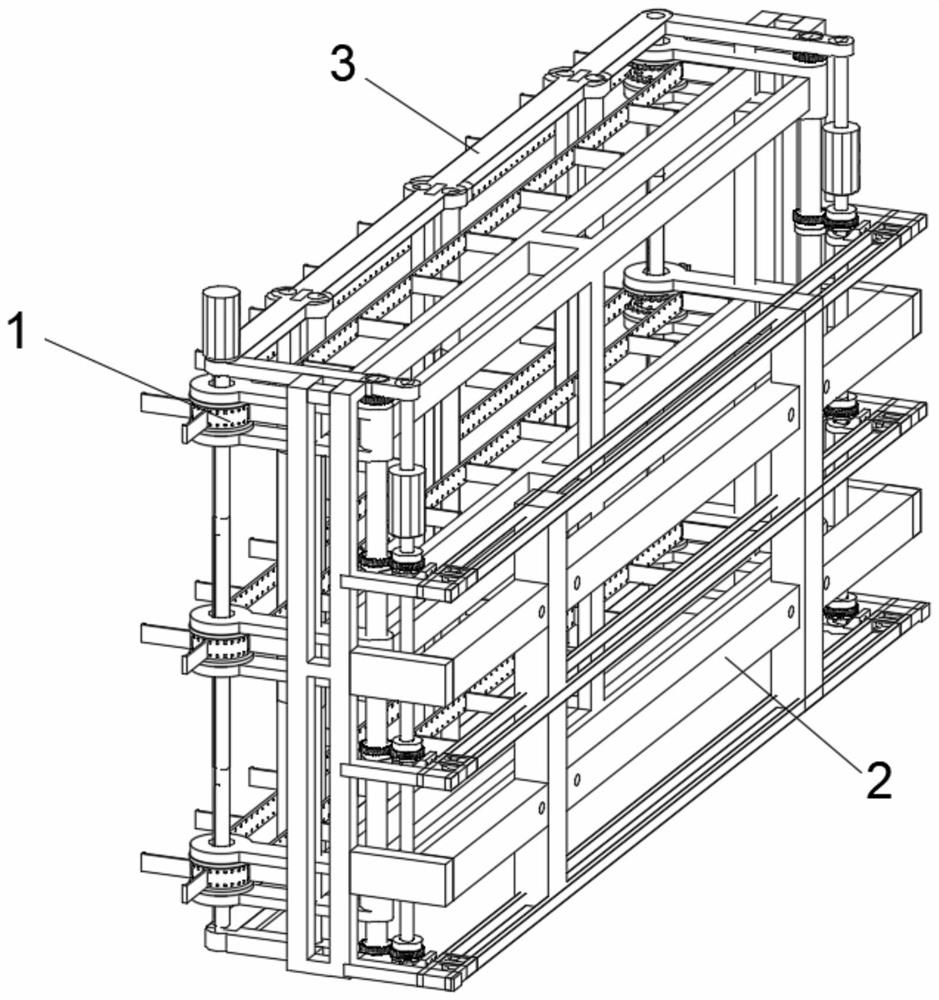

Convenient-to-mount non-ferrous metal waste screening device

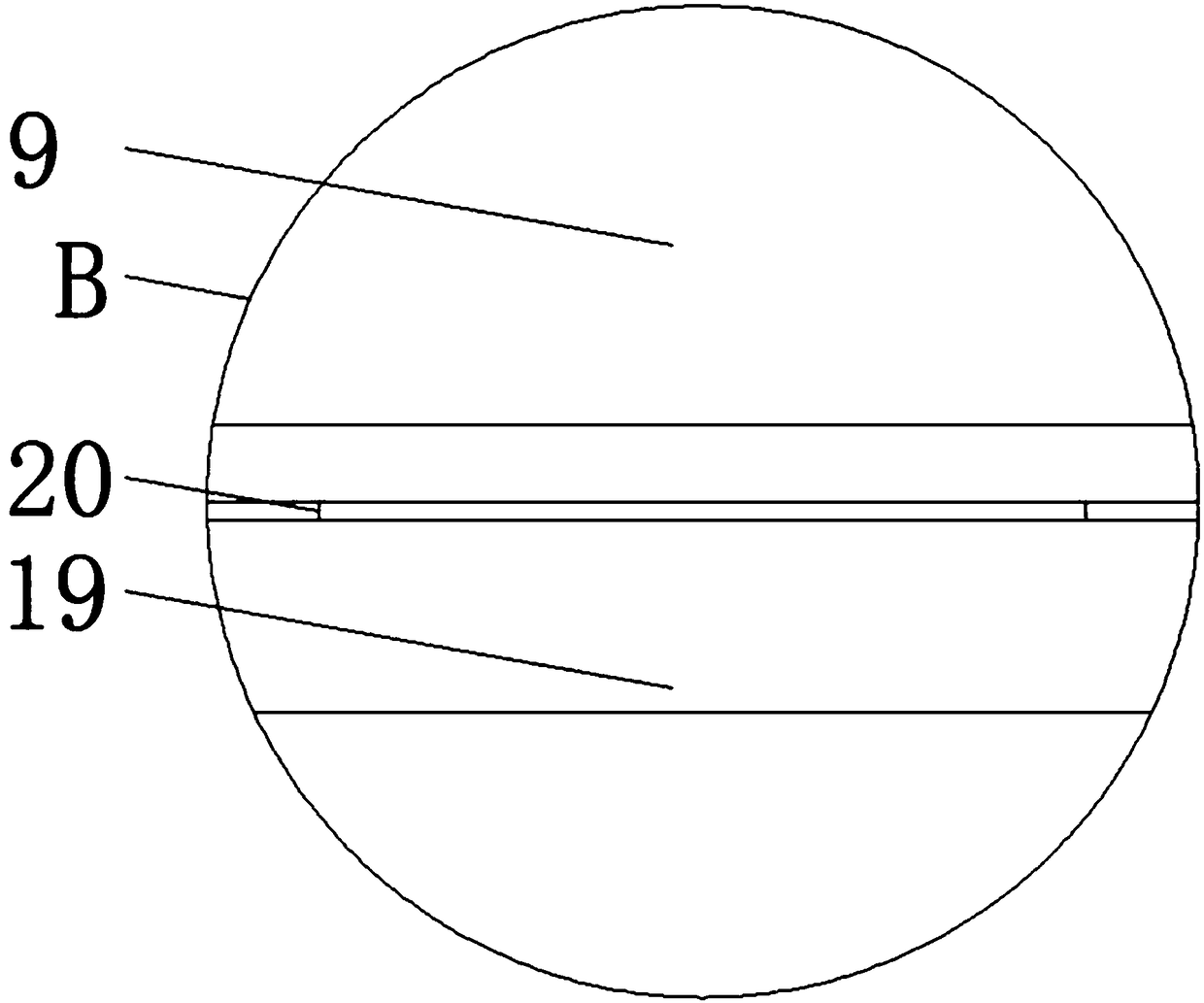

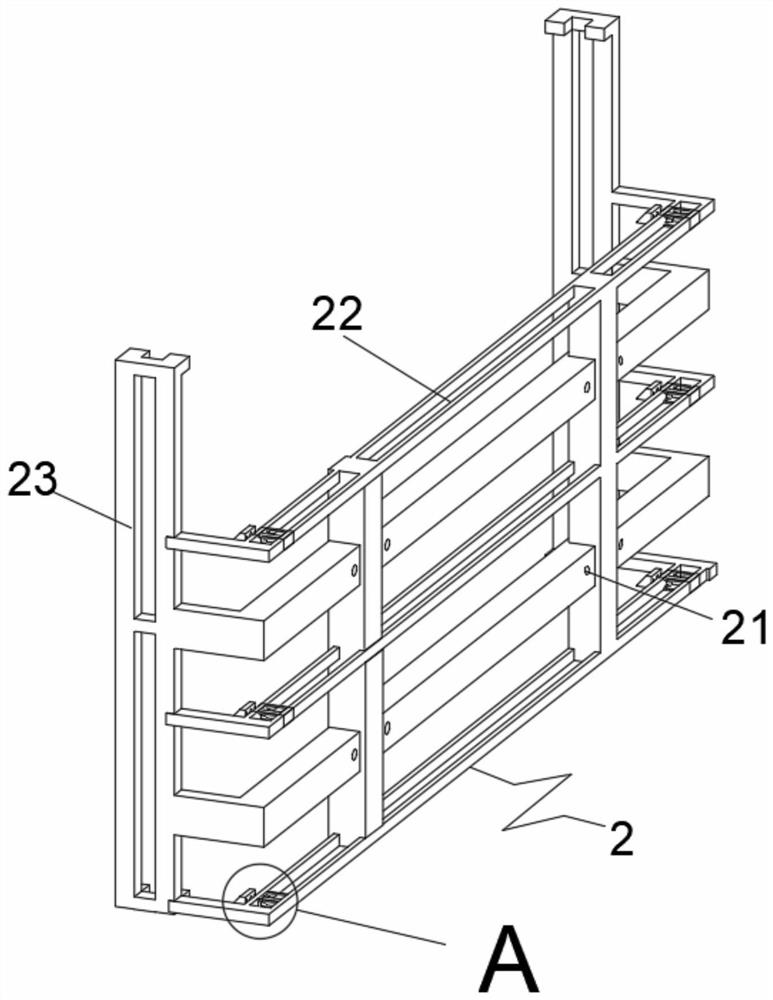

InactiveCN112371502AEasy to push downReasonable structureSievingGas current separationNonferrous metalSlide plate

The invention discloses a convenient-to-mount non-ferrous metal waste screening device. A plurality of slide rails are symmetrically arranged at the two sides inside a screening bin; through slots areformed in positions, at each pair of slide rails, on the surface of the screening bin; screening plate assemblies are inserted into the through slots in the surface of the screening bin; through holes, above the through slots, are formed in the surface of the screening bin; push rods are arranged in the through holes in a sliding mode; ends, inside the screening bin, of the push rods are equippedwith folding push plates; ends, outside the screening bin, of the push rods are equipped with connecting plates; first handles are arranged on the surfaces of the connecting plates; small doors are arranged on positions, above each layer of the through holes, on the surface of the screening bin; screening discharge holes are formed in positions, at corresponding slide rails, of the rear end surface of the screening bin; and discharge slide plates are arranged on positions, at screening discharge holes, of the surface of the rear end of the screening bin. The convenient-to-mount non-ferrous metal waste screening device is reasonable in structure, is simple and convenient in mounting way, and greatly saves assembly time; each layer of screening plate assemblies are directly inserted into the screening bin, and are in sliding connection to the slide rails at the two sides, so that replacement is convenient.

Owner:CHANGNING YANJIANG ZINC IND

Cargo handling device convenient to combine

InactiveCN111824227AEasy to combineEasy to useHand carts with multiple axesHand cart accessoriesStructural engineeringMechanical engineering

Owner:陈洁

A device that facilitates the extraction of genes from diverse organisms

ActiveCN112473804BEasy to operateEasy to collect and processBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyEngineering

The invention relates to an extraction device, in particular to a device for facilitating the extraction of diverse biological genes. The technical problem is how to design a device that can replace manual crushing of biological samples and add liquid medicine to biological samples, which is labor-saving and easy to operate for the extraction of diverse biological genes. A device that facilitates the extraction of diverse biological genes includes: a base, a guide frame is fixedly connected to one side of the base; and a support base is fixed to the middle edge of one side of the base. In the present invention, the biological sample and the medicinal liquid are put into the placing groove plate, the crushing assembly is started, and the placing groove plate is pushed to move to the left to drive the biological sample and the medicinal liquid to move to the left, and the biological sample moves to the left to contact the crushing assembly, and the crushing assembly then The biological sample is crushed and mixed with the liquid medicine, so that people do not need to manually crush the biological sample, which is labor-saving and convenient to operate.

Owner:广州市粤家科技发展有限公司

A grabbing device for instant noodles

The invention discloses a novel instant noodle block grabbing device. The novel instant noodle block grabbing device comprises a frame, a panel, a noodle grabbing mechanism and a cam, wherein the noodle grabbing mechanism comprises a first noodle jaw, a second noodle jaw, a first fixed plate, a second fixed plate, a noodle pushing plate, a first slide rod, a second slide rod, a connecting rod and a transmission rod; the first noodle jaw and the second noodle jaw are respectively fixed on the first fixed plate and the second fixed plate; the first fixed plate is hinged with the second fixed plate; a first end of the connecting rod is fixedly connected with the noodle pushing plate after penetrating through the first fixed plate and the second fixed plate; a second end of the connecting rod is fixedly connected with the transmission rod; a first end of the first slide rod and a first end of the second slide rod are fixedly connected to the connecting rod; a second end of the first slide rod and a second end of the second slide rod are slidingly connected with the first fixed plate and the second fixed plate; and a guide part fitting the transmission rod is formed on the cam. The device is simple in structure, convenient for operation and high in automation degree, saves the labor cost, and improves the working efficiency.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

A feeding device for bearing processing

The invention discloses a feeding device for bearing processing, which comprises a bearing arrangement box, the inner wall of the bearing arrangement box is rotatably connected with a rotary platform, the inner ring of the rotary platform is rotatably connected with a bearing base, and the inner bottom wall of the bearing arrangement box is fixedly connected with a servo motor , the output end of the servo motor is fixedly connected with a rotating shaft, the end of the rotating shaft away from the servo motor runs through the bearing base and extends to the top of the bearing base, and the rotating shaft is located at the axis of the bearing base, and the outer surface of the rotating shaft is fixedly connected with two A symmetrical bearing dial, the outer surface of the servo motor is fixedly connected with a connecting rod, and the end of the connecting rod away from the servo motor is fixedly connected with the bottom of the turntable, the top of the turntable is fixedly connected with a rotating partition, and the bearing arrangement box The outer surface is fixedly communicated with a machine parts box. The feeding device for bearing processing is smoothed by the brush curtain, and then pushed to solve the problems of bearing end surface wear and bearing precision reduction.

Owner:HUNAN MEIBEIDA TECH CO LTD

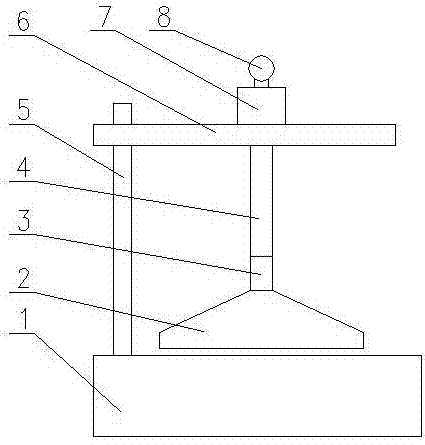

Rotary yellow rice cake stripping and slicing device

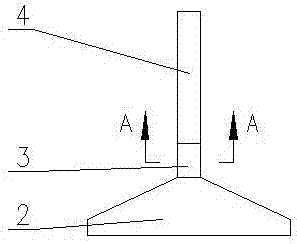

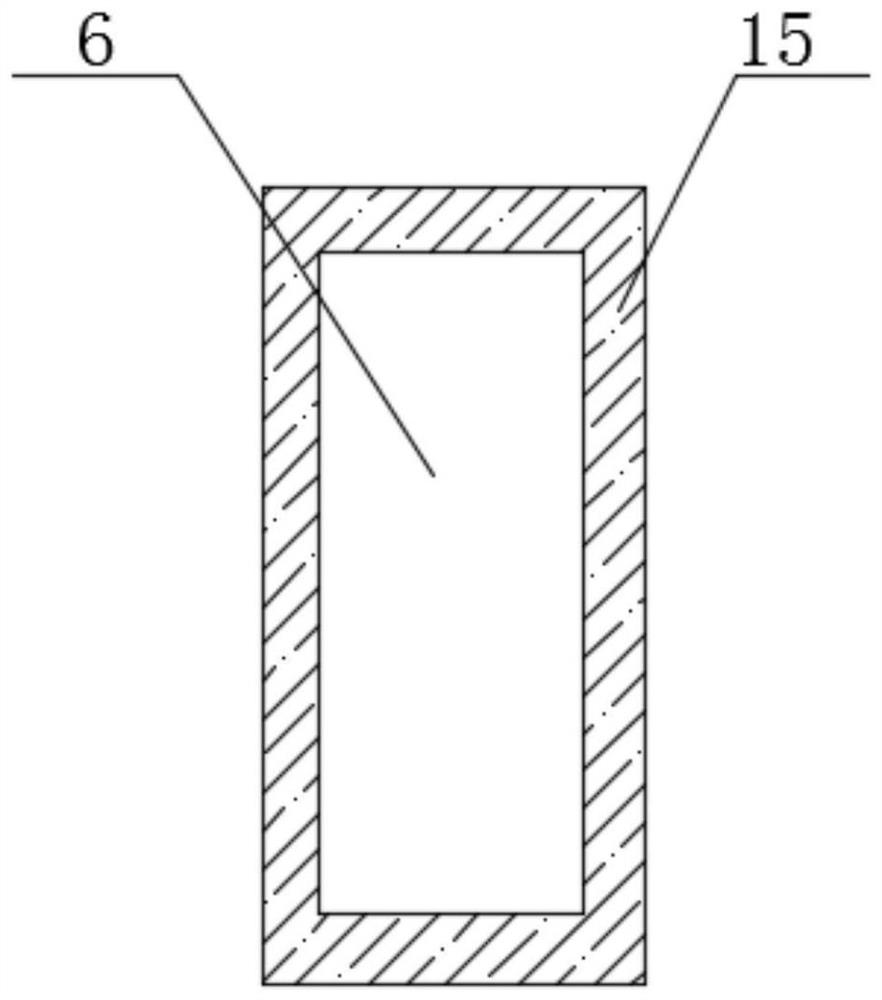

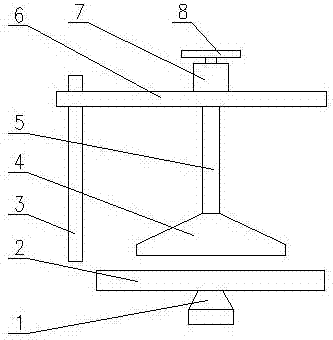

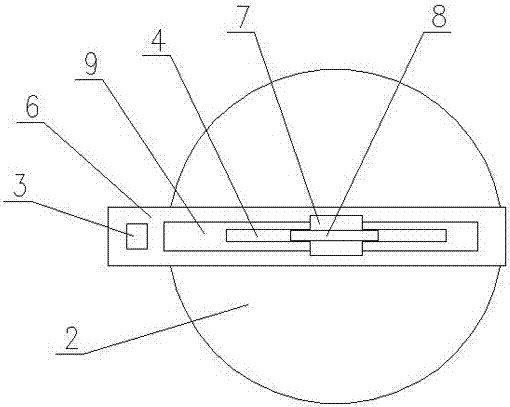

InactiveCN107053278AImprove scalabilityEasy to moveMetal working apparatusEngineeringMechanical engineering

The invention discloses a rotary yellow rice cake stripping and slicing device. The rotary yellow rice cake stripping and slicing device comprises a rotary disk (2), a blade (4) and a fulcrum bar (6) and is characterized in that the rotary disk (2) is arranged on the upper portion of a drive frame (1), a supporting frame (3) is provided with the fulcrum bar (6), the fulcrum bar (6) is located over the rotary disk (2), the blade (4) is arranged on the fulcrum bar (6) through a tool rod (5) in a lifting manner, the tool rod (5) is in movable fit with the fulcrum bar (6), the top of the tool rod (5) is connected with a check block (7), the check block (7) is arranged on the fulcrum bar (6), a rectangular sliding groove (9) is formed in the fulcrum bar (6), the tool rod (5) is a rod body matched with the sliding groove (9), the cross section of the rod body is rectangular, length scale lines are arranged on the upper surface of the fulcrum bar (6), and angle scale lines are arranged on the outer circumference of the rotary disk (2). The rotary yellow rice cake stripping and slicing device is simple in structure, high in efficiency, practical, convenient to use, reliable, high in quality, adjustable and suitable for use and popularization of yellow rice cake stripping and slicing.

Owner:WENGAN RENJIUMEI FOOD

Incinerator

ActiveCN103528096BStable combustionBurn completelyDomestic stoves or rangesLighting and heating apparatusFirewoodCombustion chamber

The invention relates to an incinerator. The incinerator comprises an incinerator body, a combustion chamber arranged in the incinerator body, a feed port communicated with the combustion chamber, and an exhaust port provided with an exhaust blower, wherein an exhaust channel which exchanges heat with a heated body is arranged in the portion, between the exhaust port and the combustion chamber, inside the incinerator body. The incinerator is characterized in that the feed port is an air inlet and located above the combustion chamber, the lower portion of the combustion chamber is provided with a smoke discharge port communicated with the exhaust channel, meanwhile, a combustion bed which covers the smoke discharge port is placed at the bottom of the combustion chamber, the upper surface of the combustion bet is design into a grid, vent holes which are communicated with the smoke discharge port are formed in two side faces, corresponding to the smoke discharge port, of the combustion bed respectively, other side faces of the combustion bed are closed, and therefore a combustion area above the grid and a smoke and dust discharge area below the grid are formed in the combustion chamber. By the adoption of the structure, the incinerator has the advantages that full combustion can be achieved, no black smoke is produced, firewood can be conveniently added, combustion is stable and controllable, and the smoke can be smoothly discharged.

Owner:宁波科莱尔节能科技股份有限公司

A winding and placing device for chemical fiber production

Owner:苏州科知律信息科技有限公司

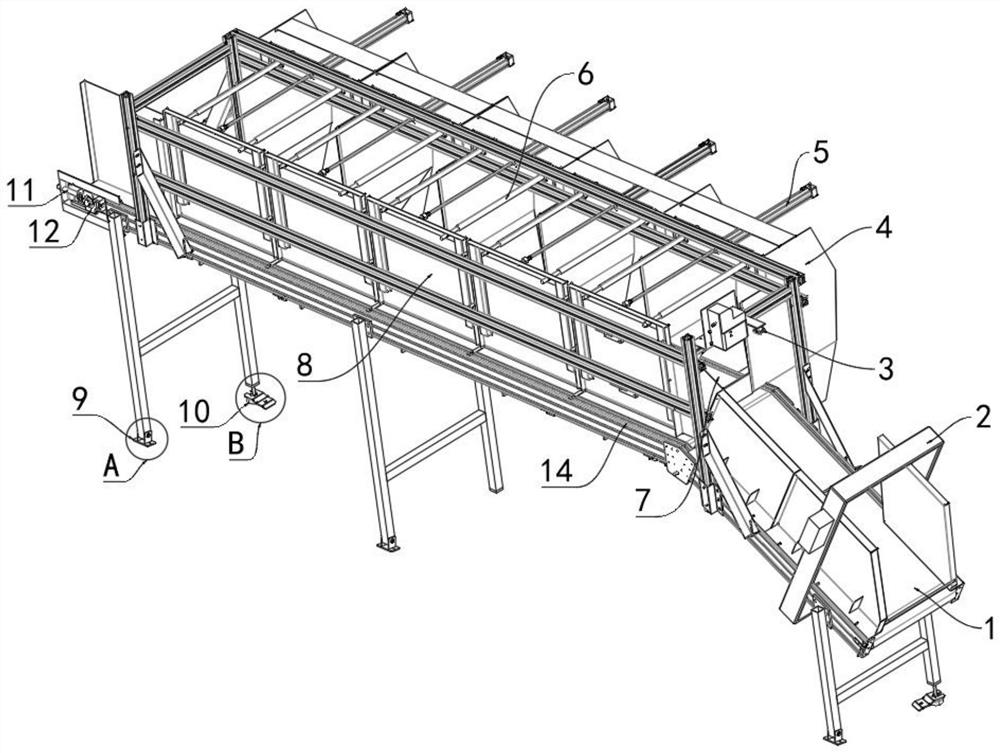

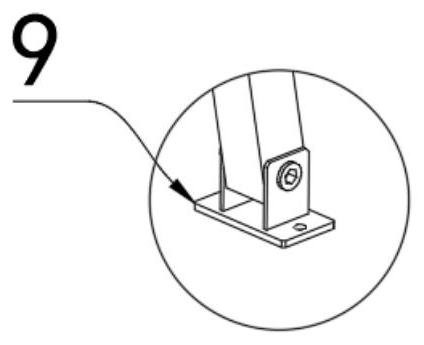

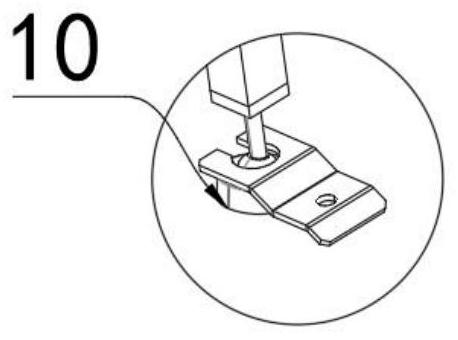

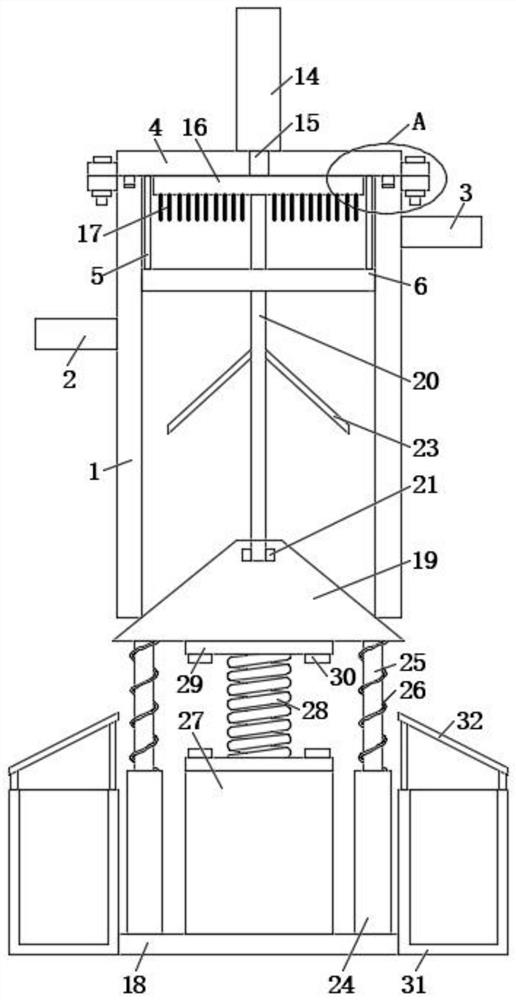

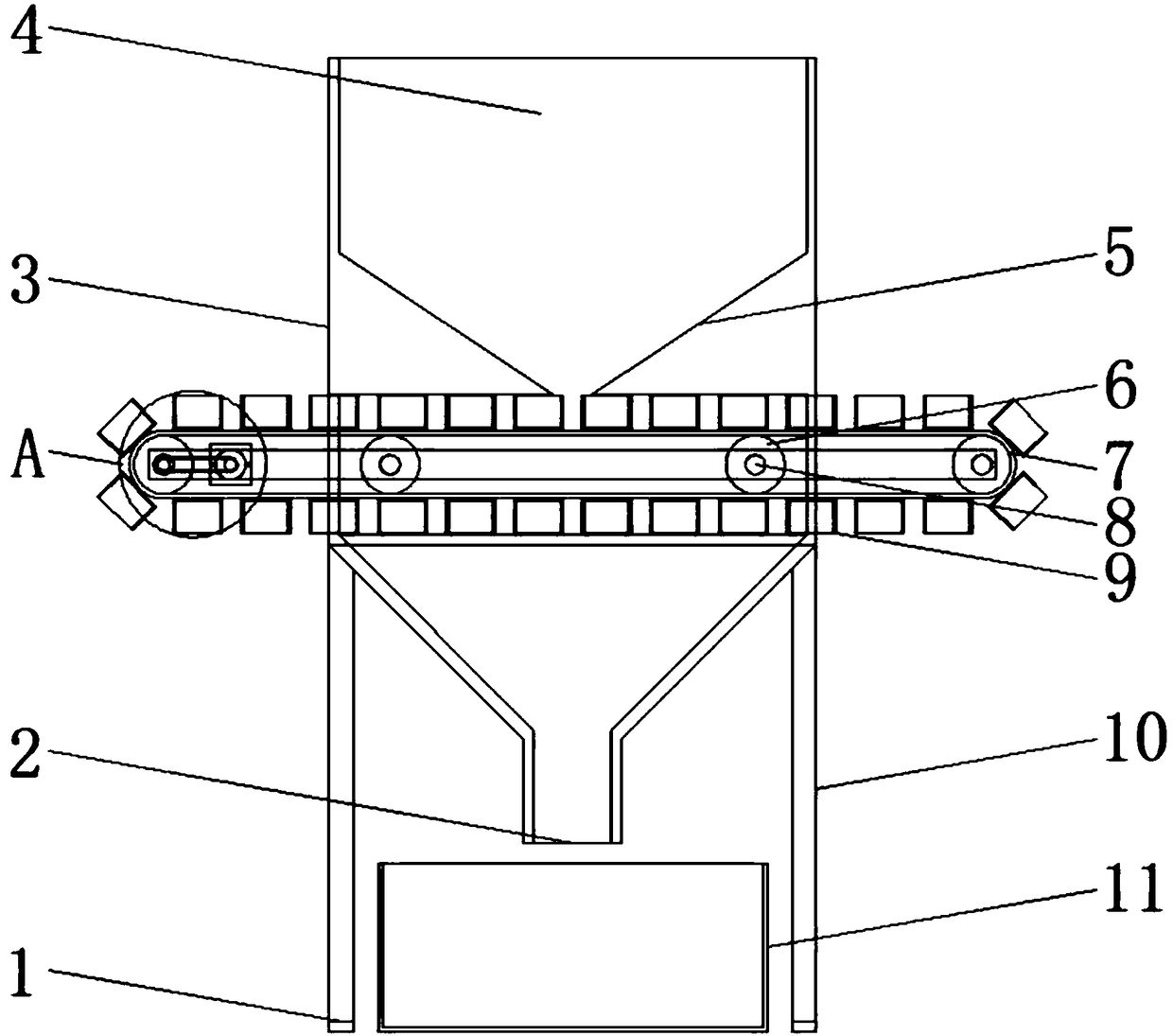

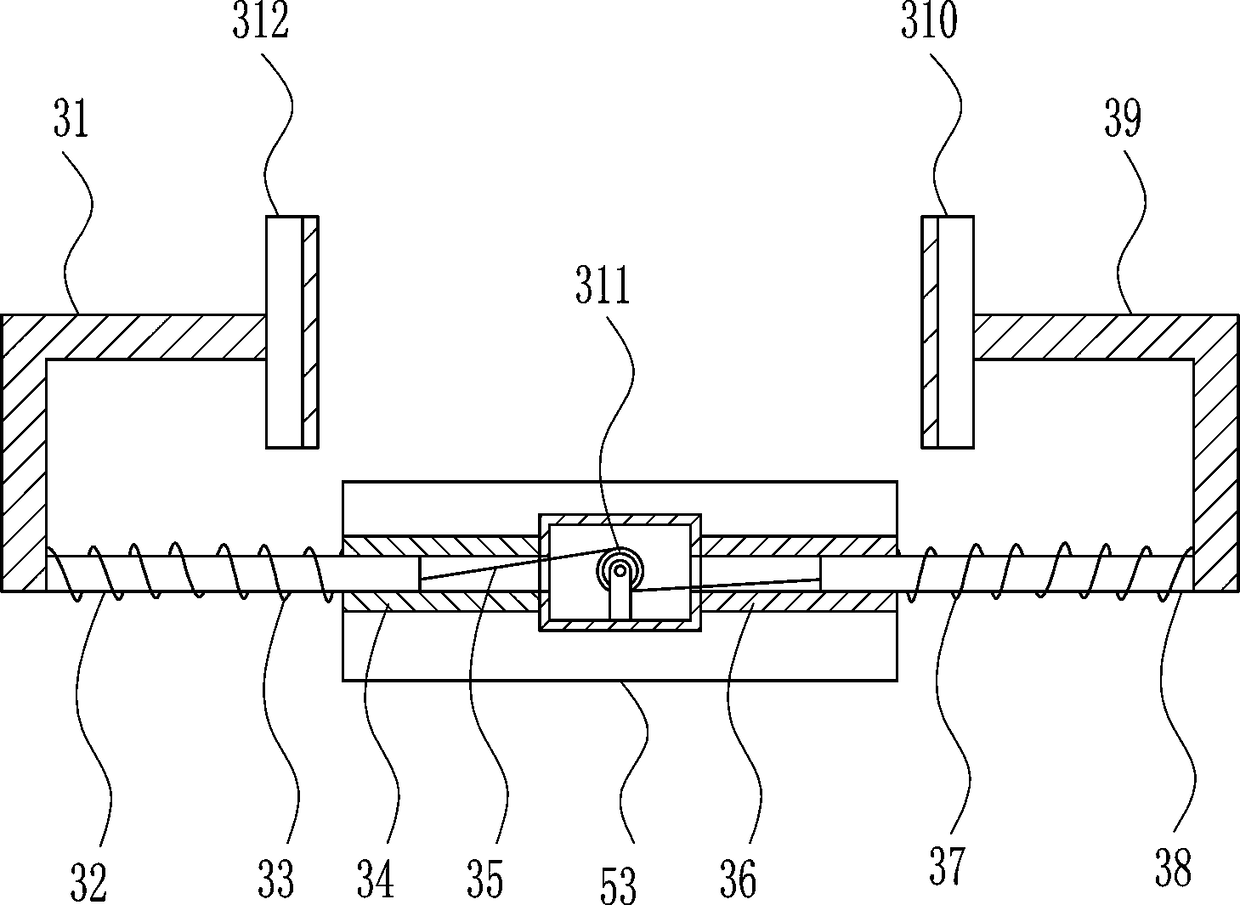

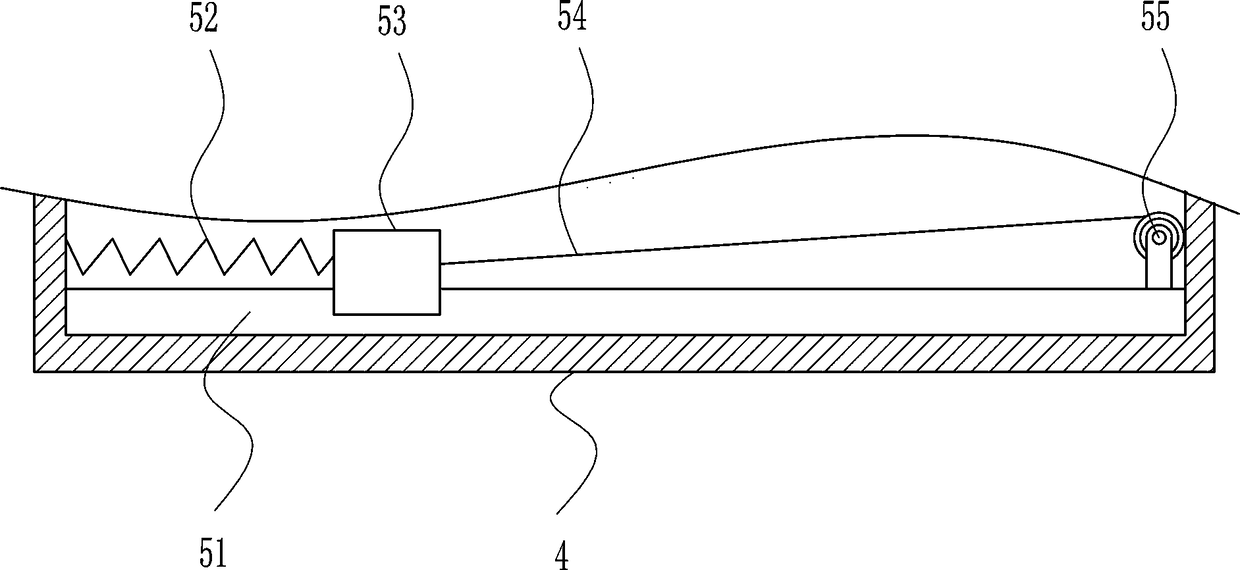

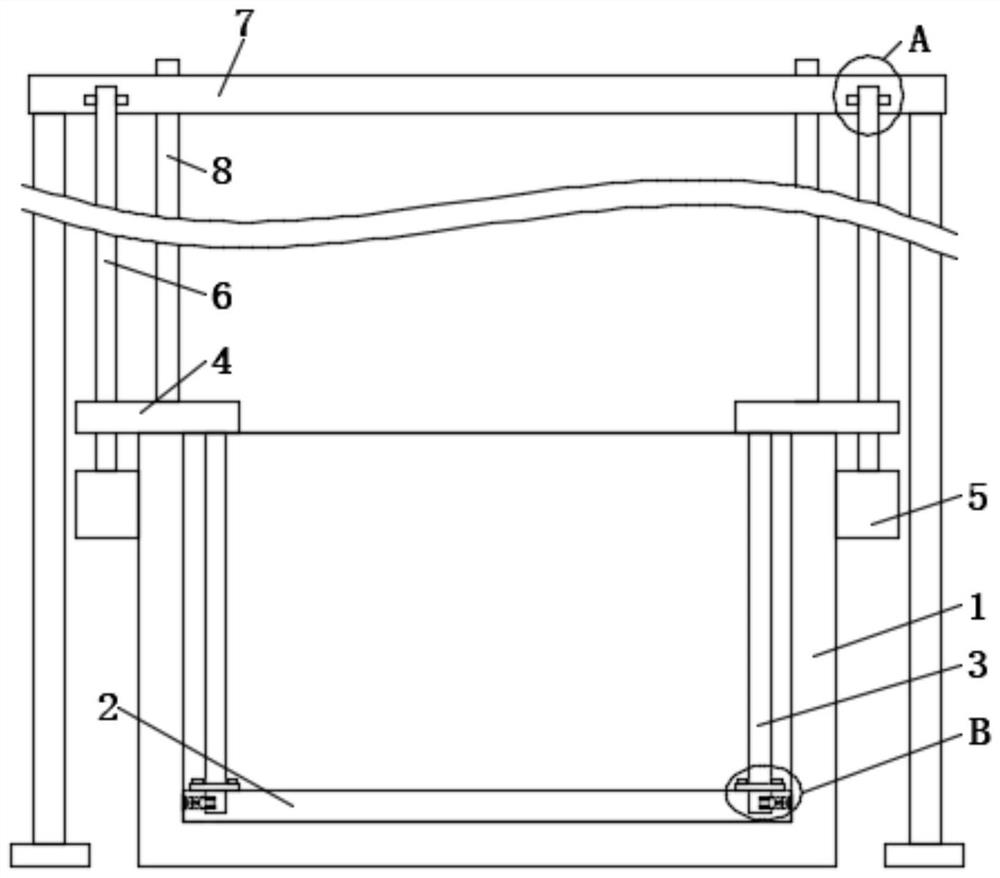

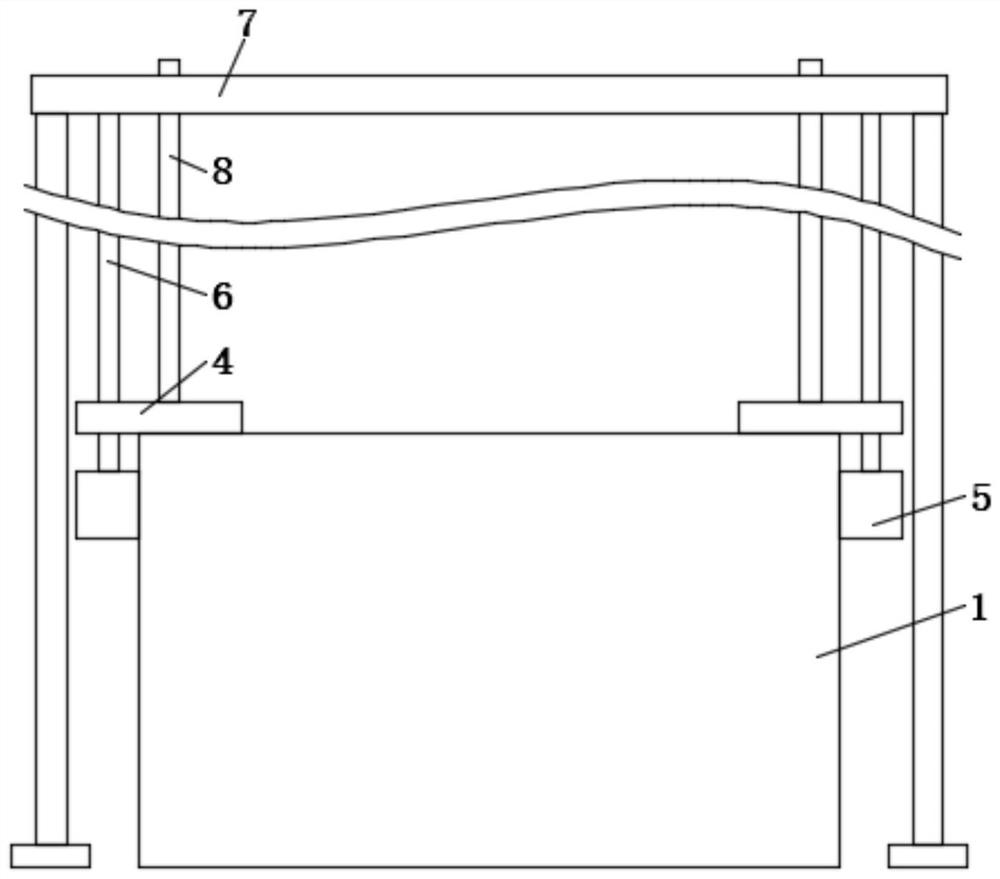

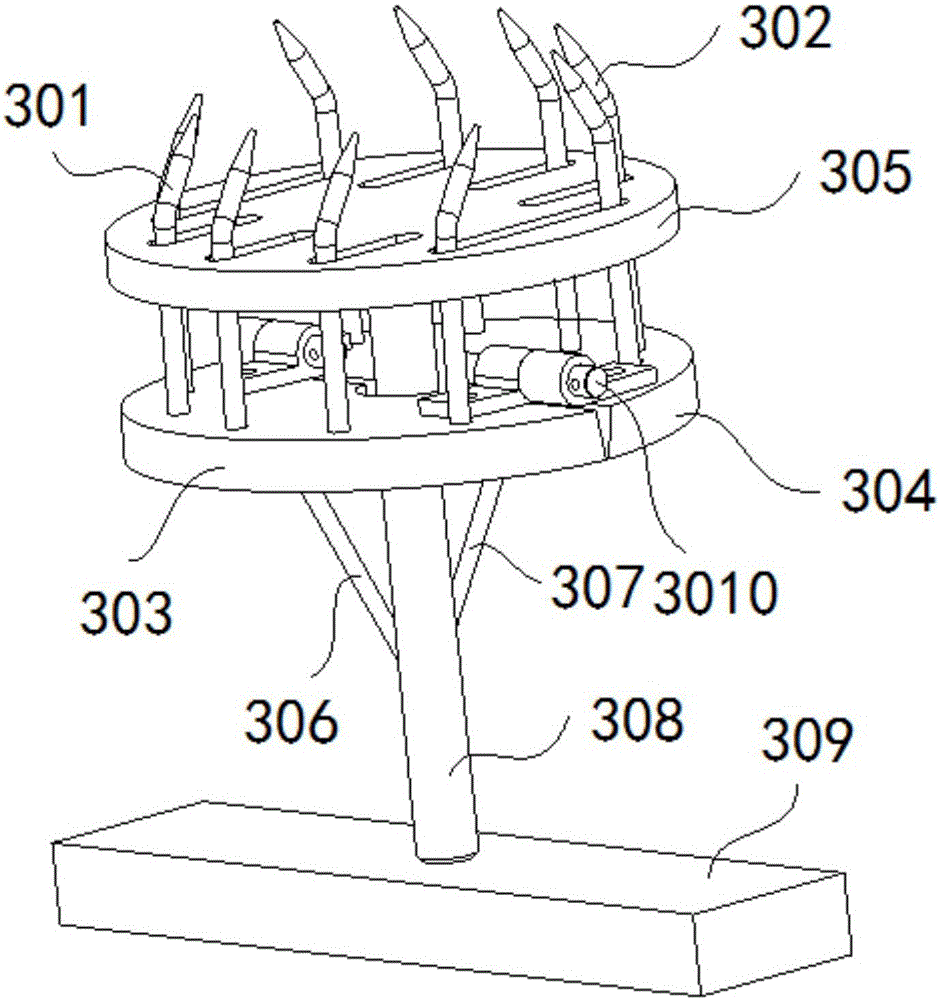

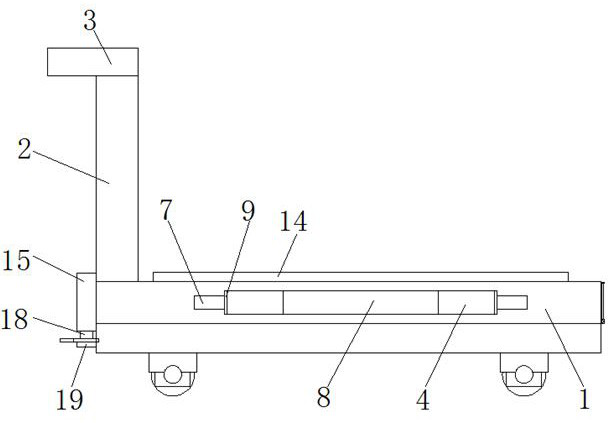

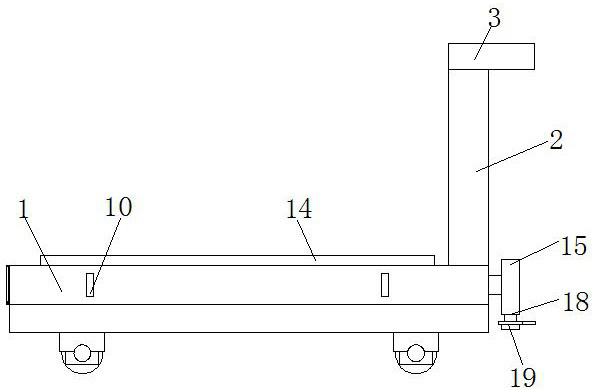

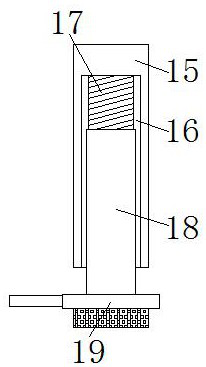

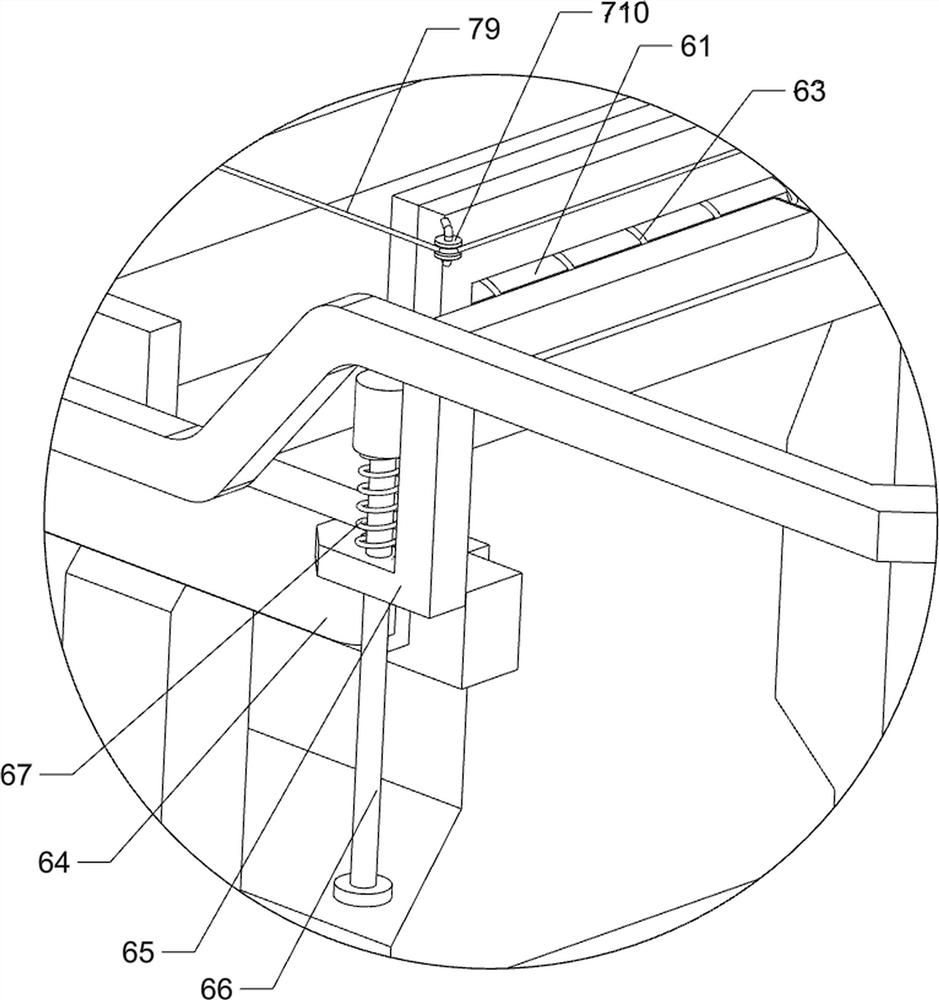

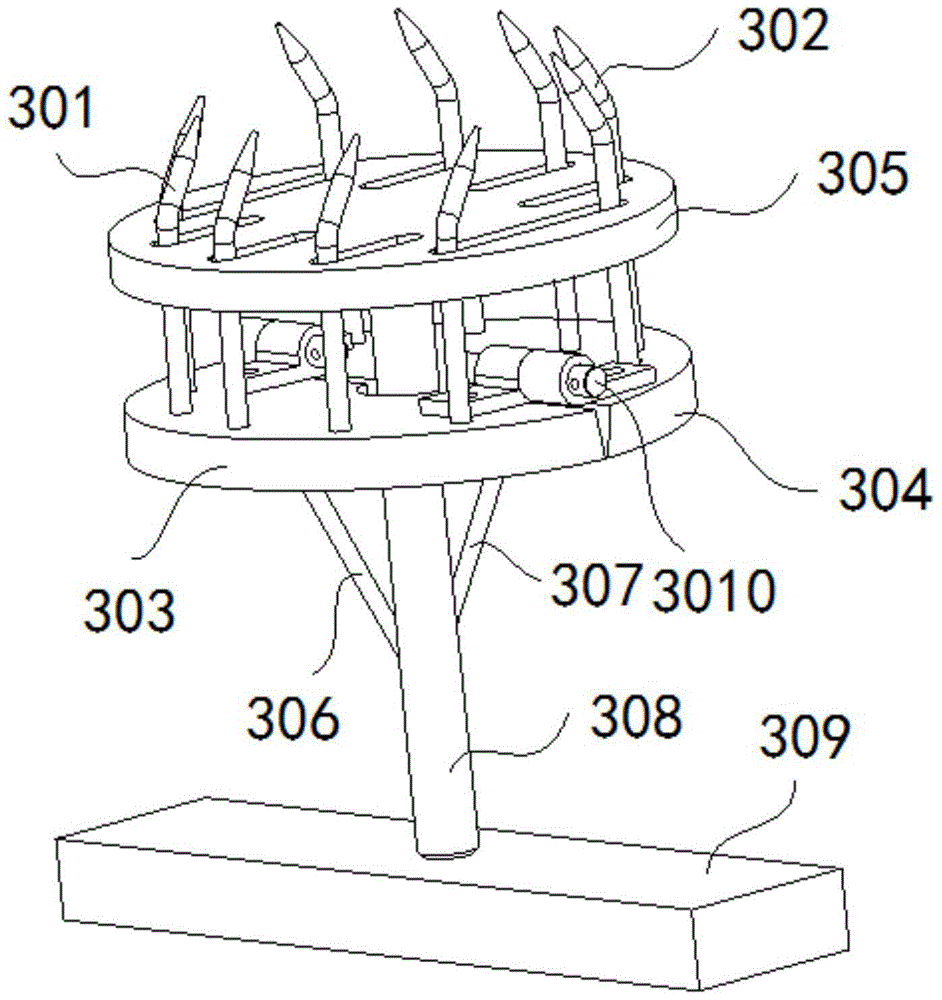

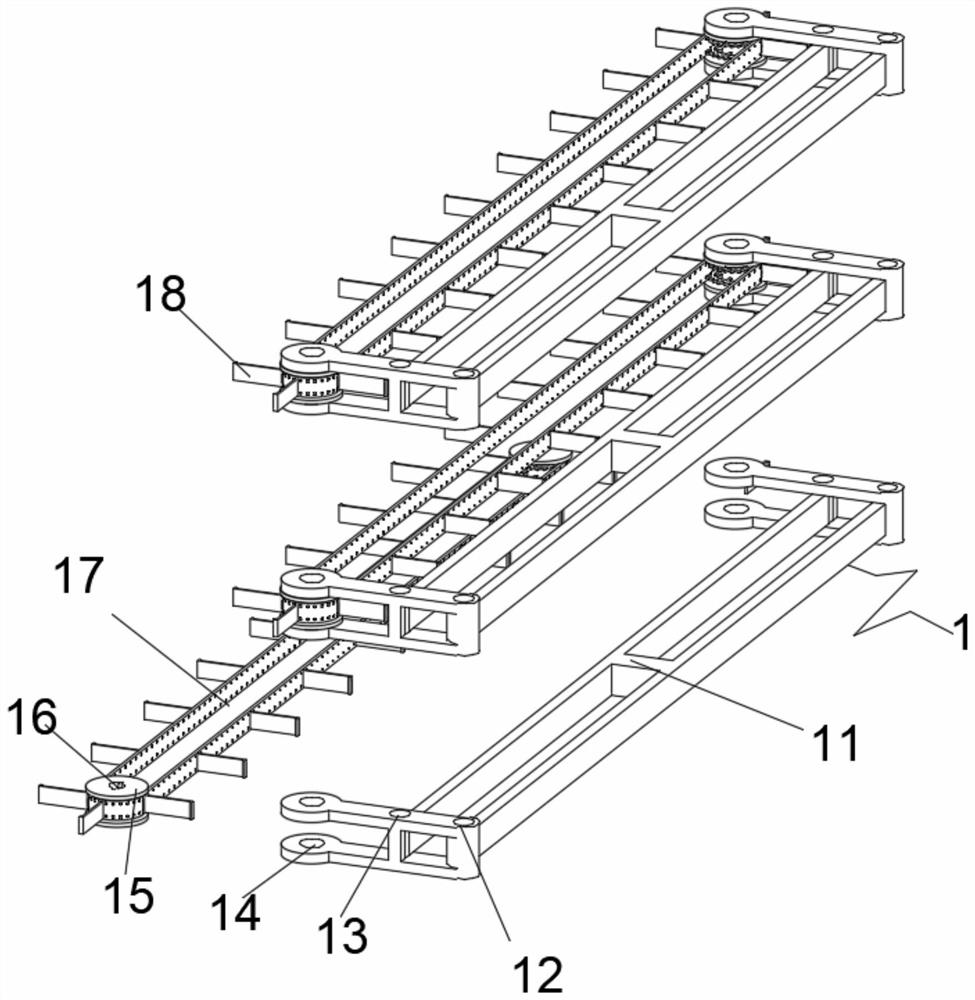

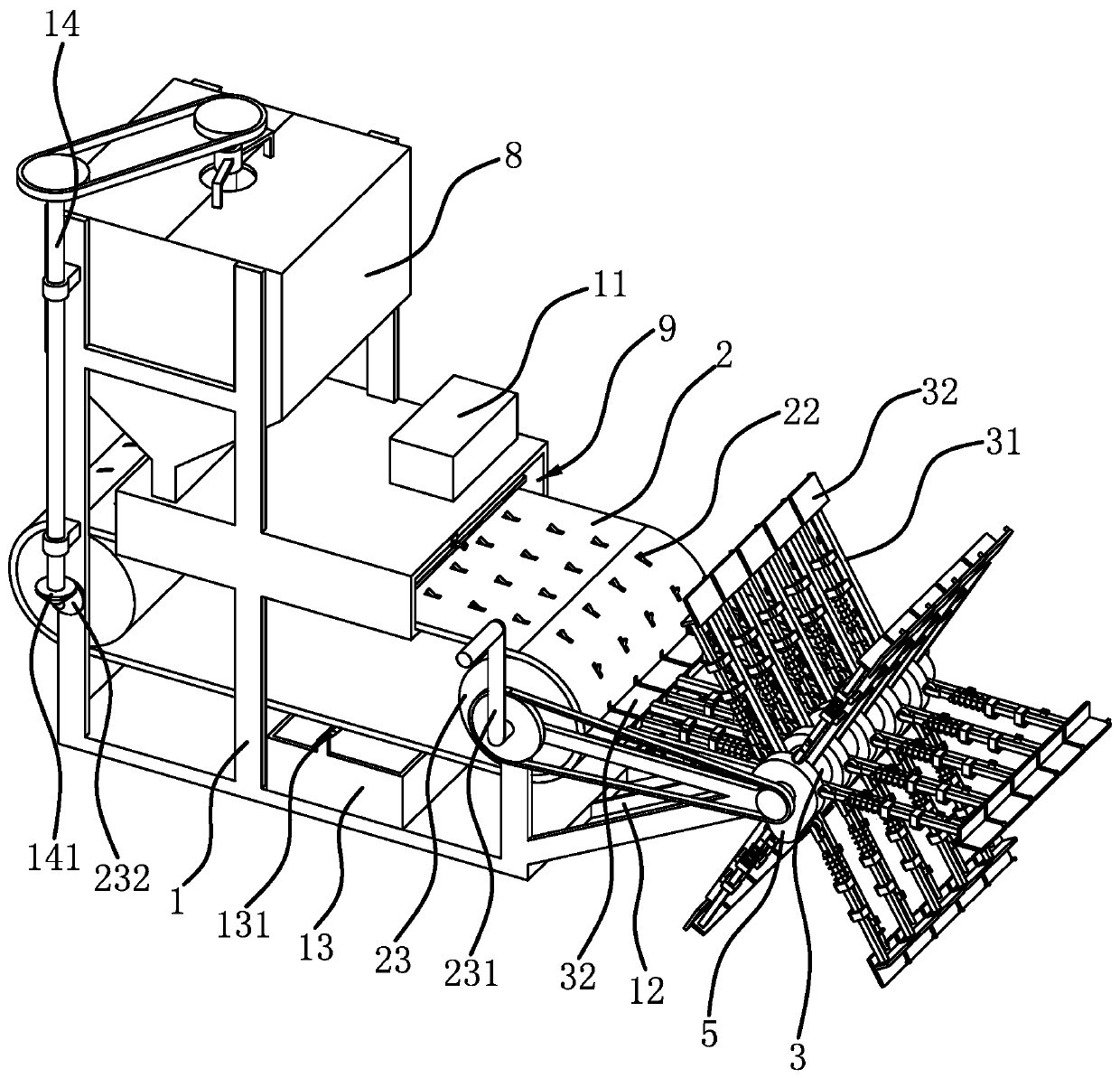

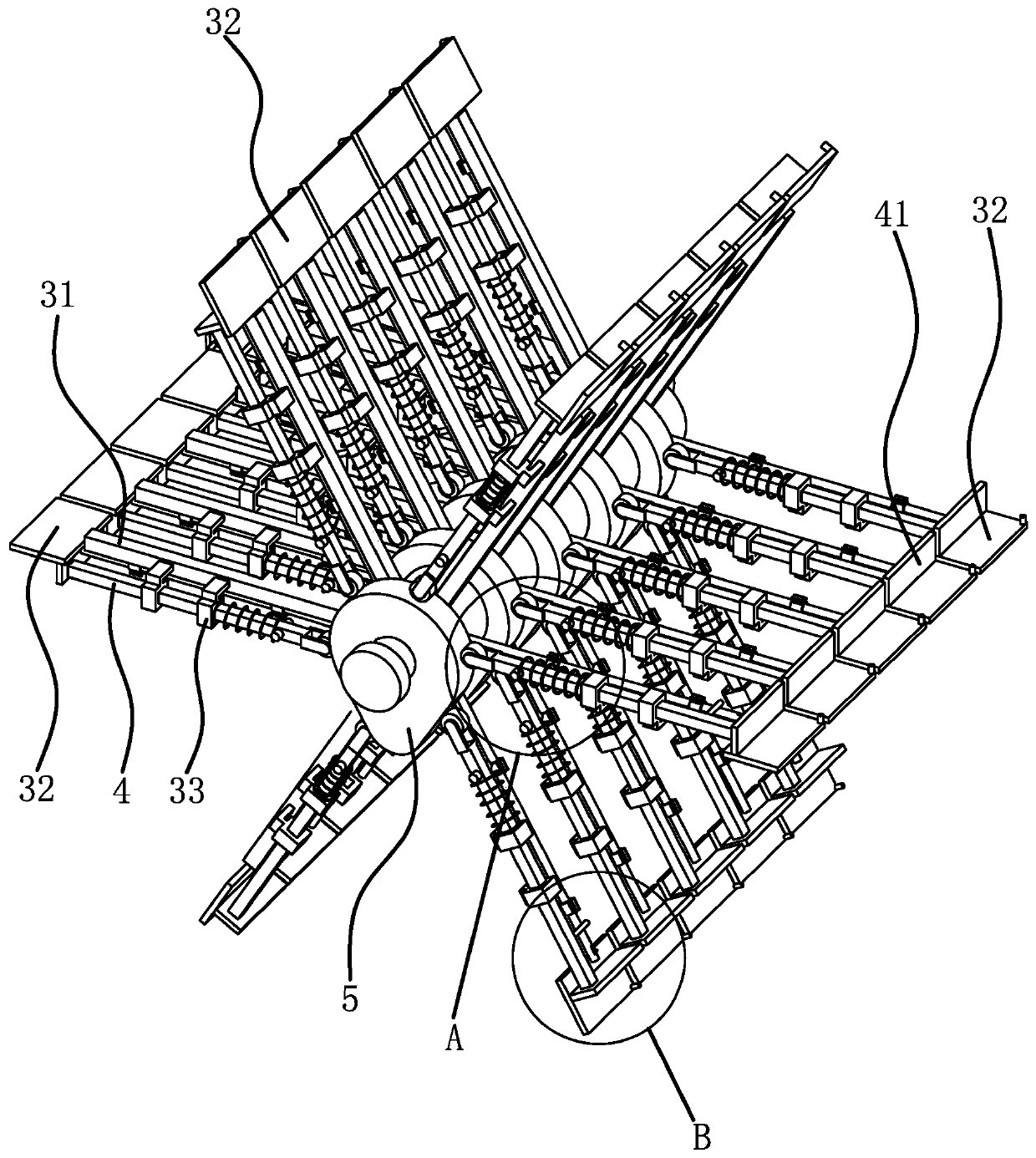

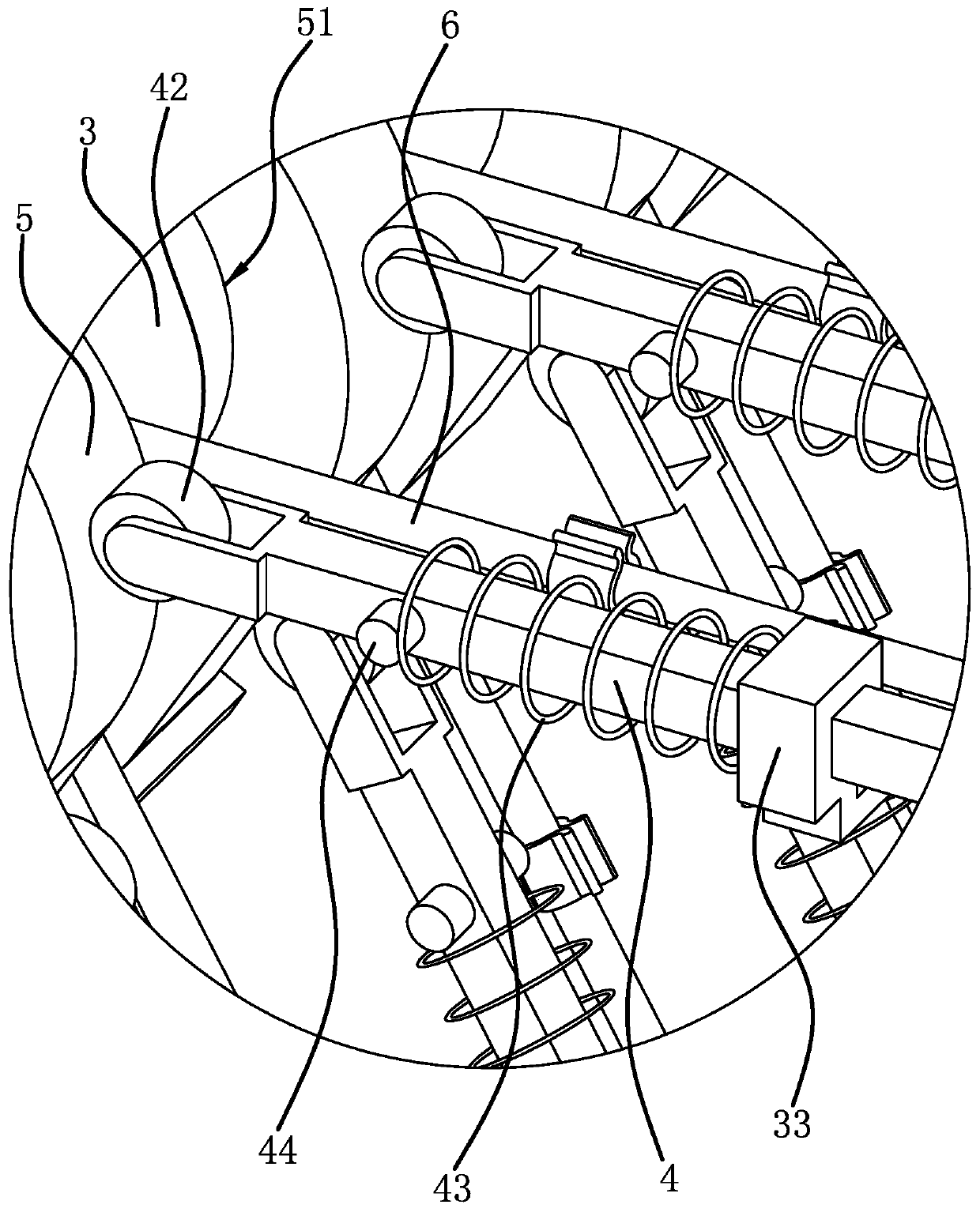

Partition push-down device for harvesting

ActiveCN112868375BEasy to push downImprove the effect of pushing downHarvestersAgricultural engineeringConveyor belt

The utility model relates to a partition and knockdown device for harvesting, which relates to the technical field of agricultural harvesting equipment. It includes a push-down device, a support frame and a drive frame, the push-down device is slidably installed inside the side of the drive frame, the support frame is welded at both ends of the side of the drive frame, and the inside of the support frame is uniformly welded with cross bars, so The two ends of the support frame are butt-welded with vertical bars, and the two sides of the center of the side of the support frame are symmetrically provided with connection holes. Threaded holes are symmetrically opened, sleeve holes are symmetrically opened through the center of the upper surface of both ends of the limit frame, and the inner rotation of the limit card slot is clamped with a toothed plate. The present invention can adjust the position of the limiting frame on the outer surface of the middle part of the driving frame, so that the height of the conveyor belt can be adapted to the height of the upright plants, thereby effectively pushing down the plants.

Owner:黑龙江省农业科学院经济作物研究所

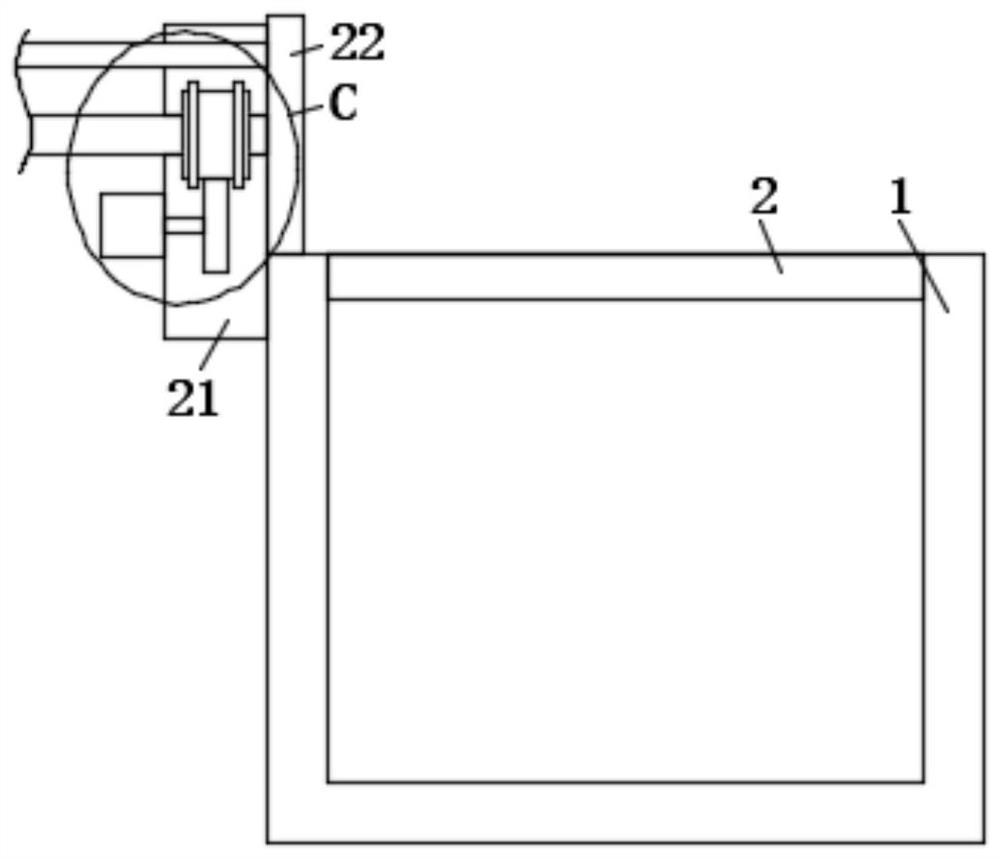

Assembly for transportation and transportation method using same

InactiveCN100542900CSuitable for generalizationEasy to replaceRigid containersInternal fittingsEngineeringMechanical engineering

The present invention provides a transport assembly capable of holding cylindrical members having different lengths without replacing constituent parts. The assembly for transportation is composed of a rectangular base (1) and split holders (2, 3). The rectangular base is formed at intervals along two sides parallel to each other. Inserting and holding plate parts (7, 7') formed by extending in opposite directions, the split holding body is detachably fitted with the inserting and holding plate parts, arranged along the two sides of the rectangular base body parallel to each other, and erecting the elongated cylindrical part ( M1, M2), the split holding body (2) arranged along one side of the rectangular base body and the split holding body (3) arranged along the other side side of the rectangular base body have a direction extending relative to the rectangular base body, and Mutually cooperate to hold the erected plate portions (12, 22) at both ends of the cylindrical member, and for the split retainer (2), change the insert retainer plate portion (7') of the split retainer (3) to the other side The insertion direction of the divided holding body (3) allows the standing plate portion (22) of the divided holding body (3) to hold cylindrical members with different lengths.

Owner:RICOH KK

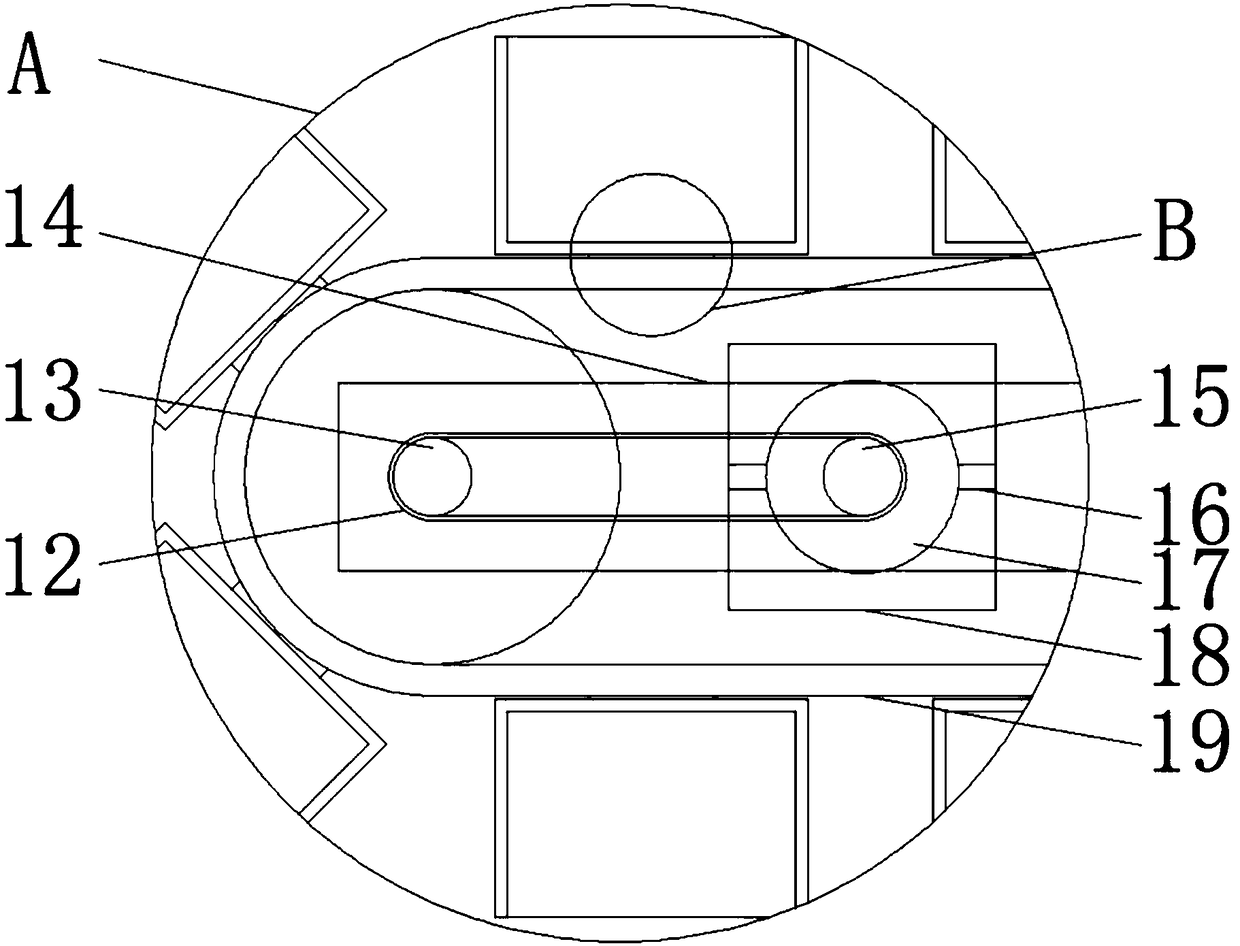

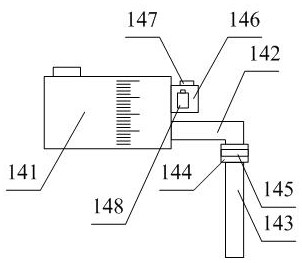

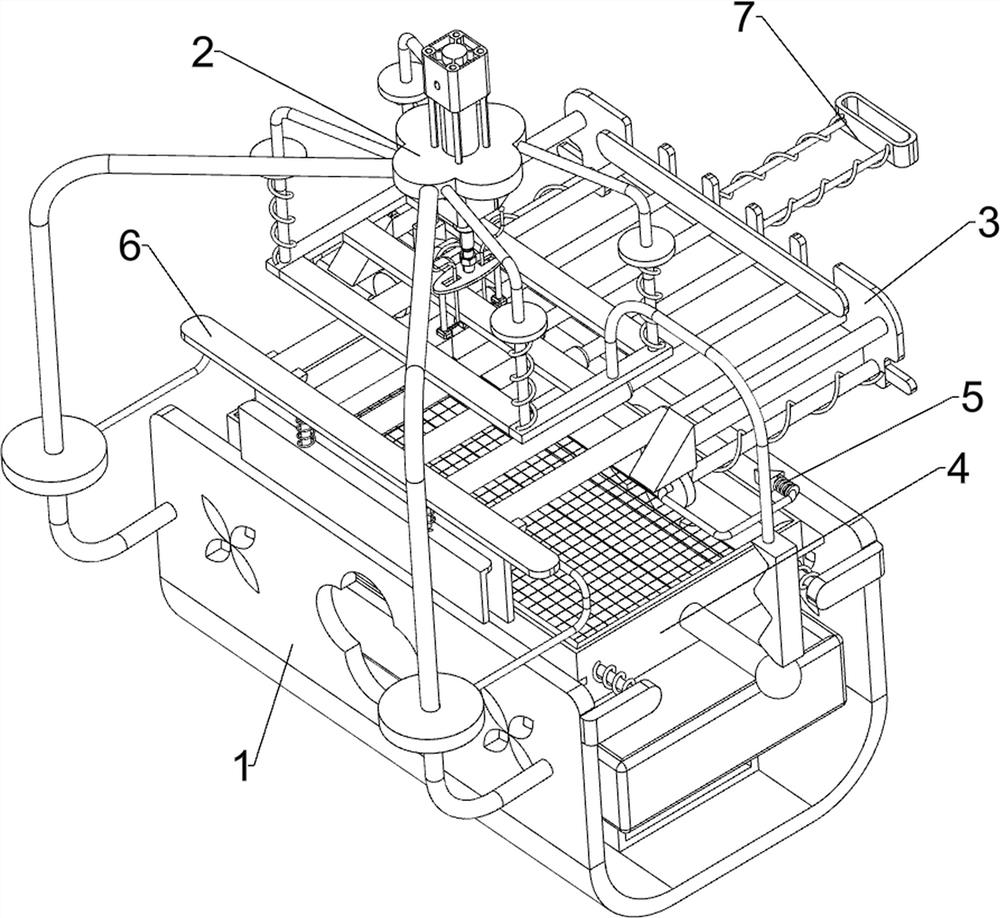

A feeding mechanism for a food processing tool

ActiveCN108433589BImprove efficiencyLarge instantaneous thrustKitchen equipmentTransmission beltAgricultural engineering

The invention provides a discharging mechanism of a food processing tool, and belongs to the technical field of mechanical equipment. The problem of low processing efficiency of existing foods such asfish balls and the like is solved. The food processing tool comprises a frame body, a transmission belt is horizontally arranged on the frame body, the discharging mechanism comprises a main shaft rotatably connected with the frame body, a plurality of groups of rod bodies are fixedly connected with the main shaft, scrapping plates are fixedly connected with the end parts of the rod bodies, pushrods are slidably connected with the side parts of the rod bodies, push sheets are fixedly connected with the end parts of the push rods, a transmission member is arranged on the frame body, water dripping pipes are fixedly connected with the rod bodies, the ends, where water comes out, of the water dripping pipes are located at the positions of the scrapping plates, valve cores capable of blocking the water dripping pipes are arranged in the water dripping pipes, and jacking members capable of driving the valve cores to start the water dripping pipes when the restoration towards the side of the main shaft of the push sheets is conducted are arranged on the push rods. The discharging mechanism of the food processing tool has higher working efficiency.

Owner:HANGZHOU FUYANG FUSHIDE FOOD CO LTD

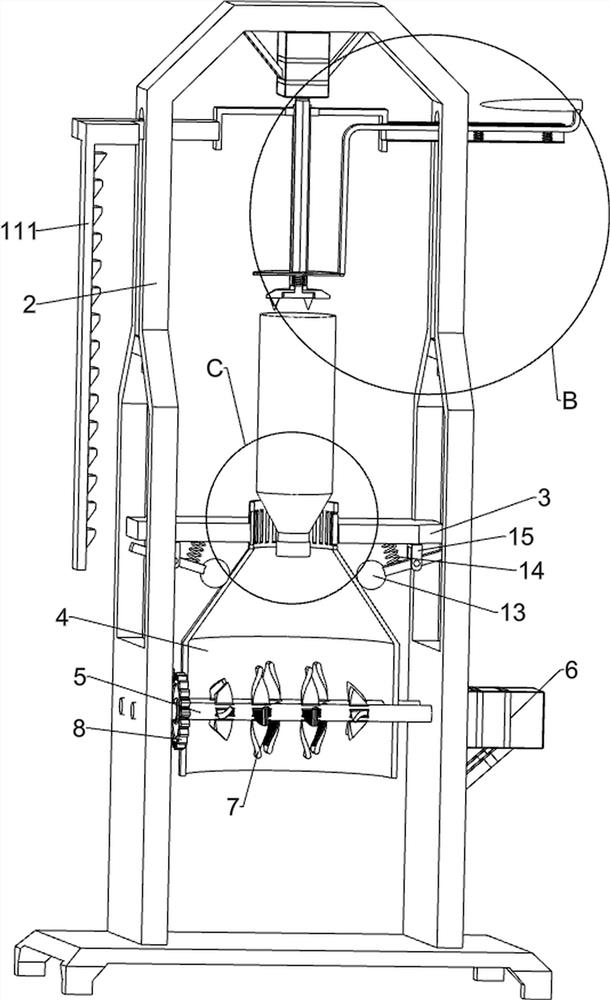

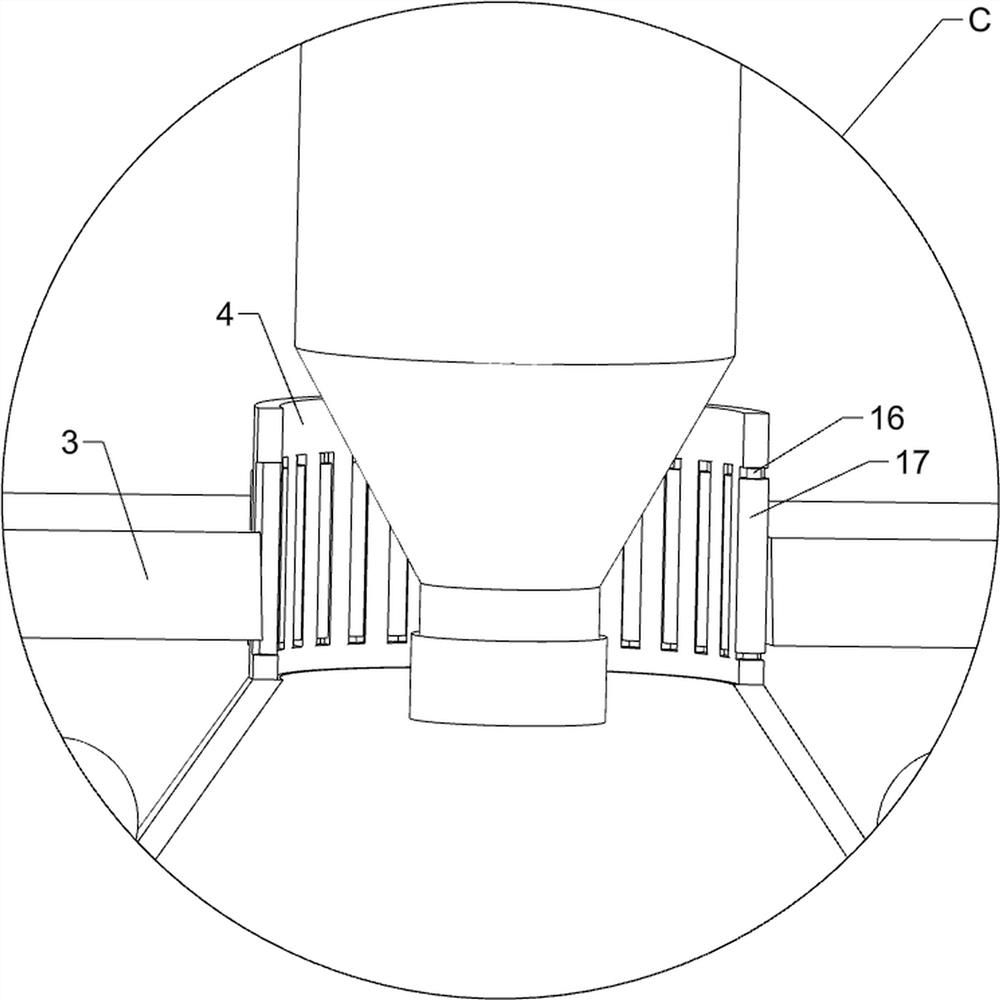

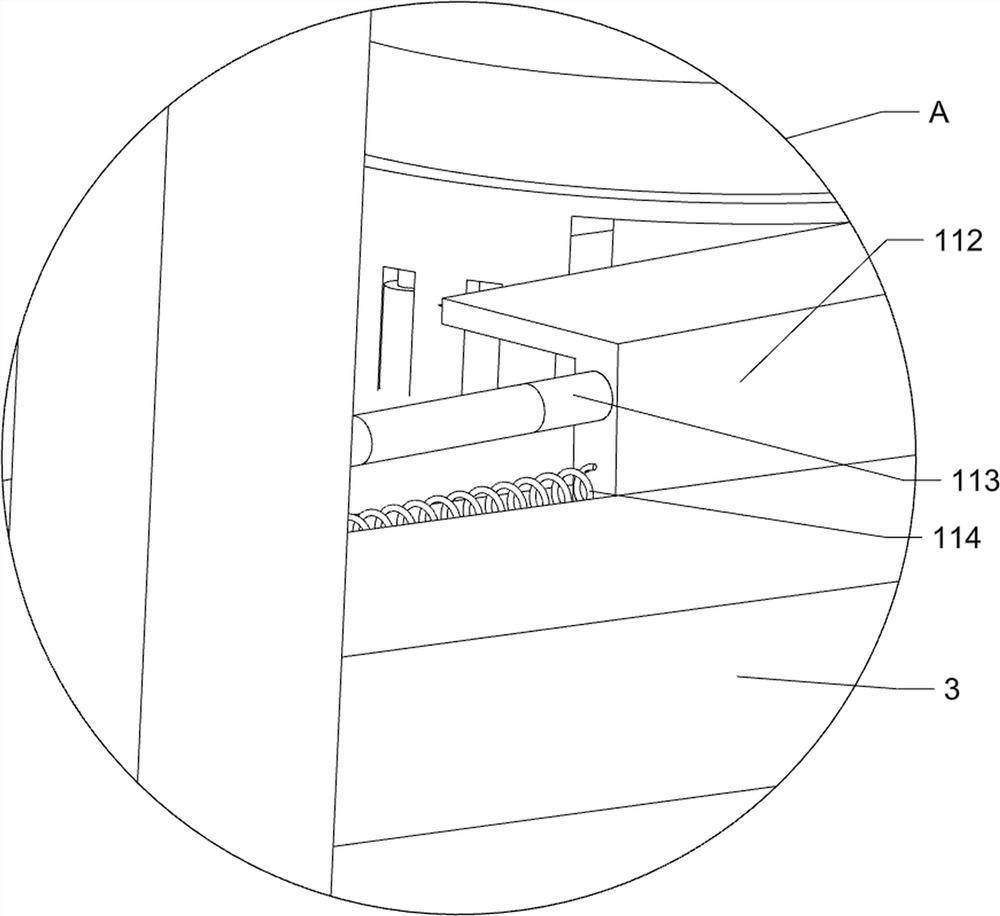

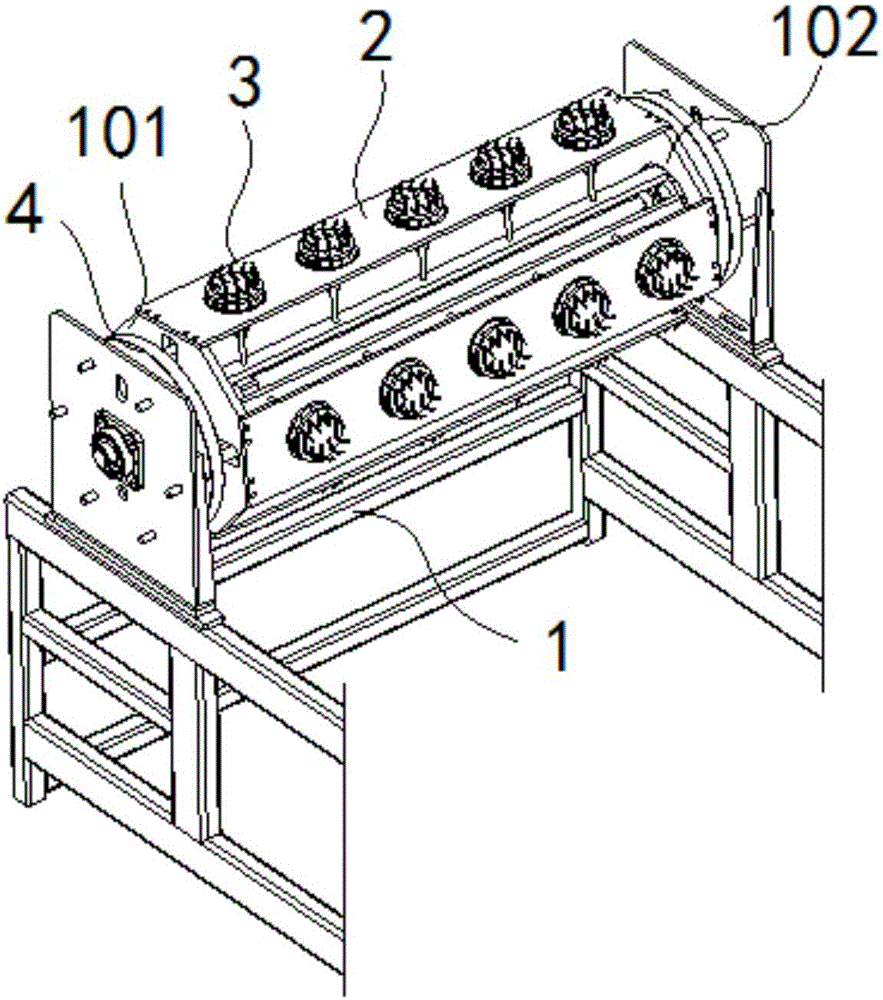

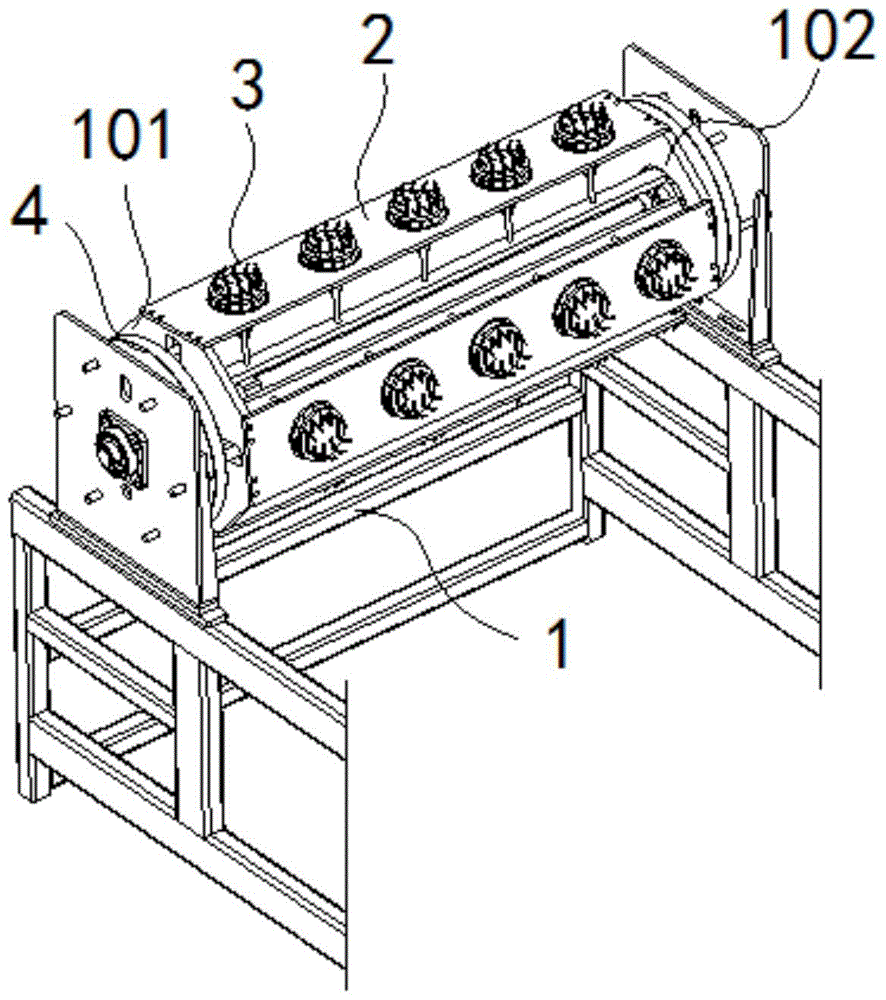

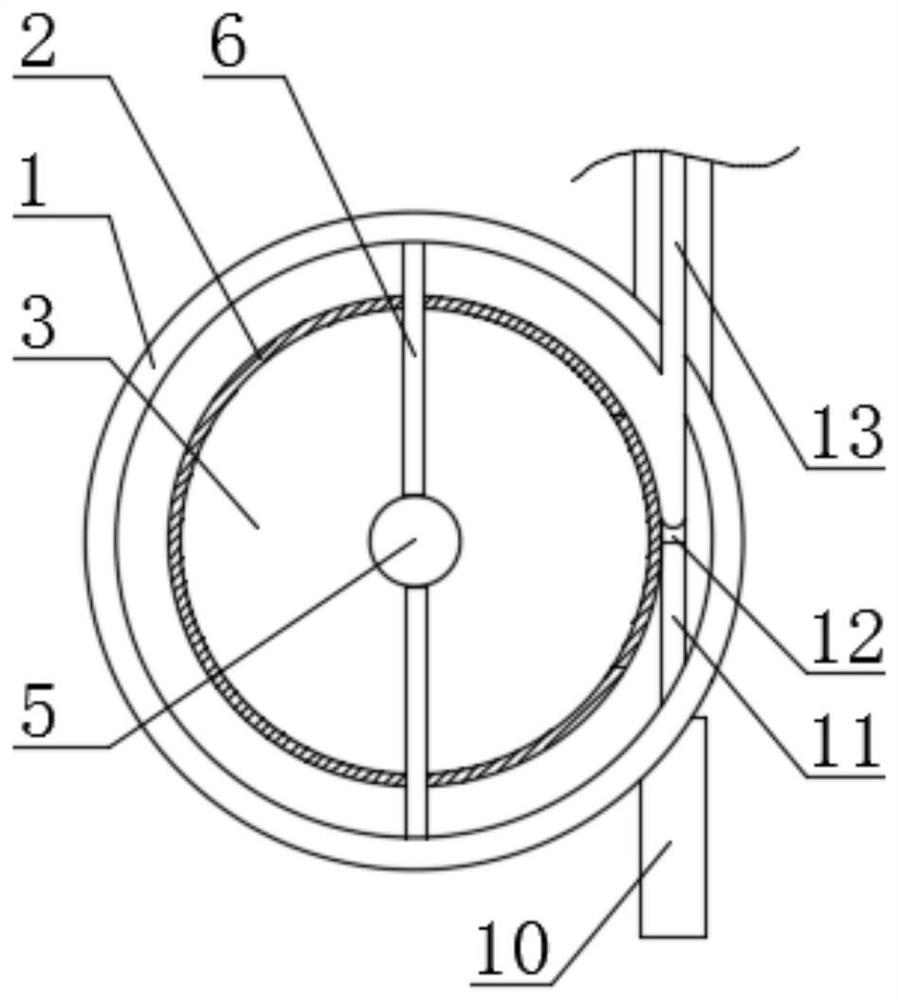

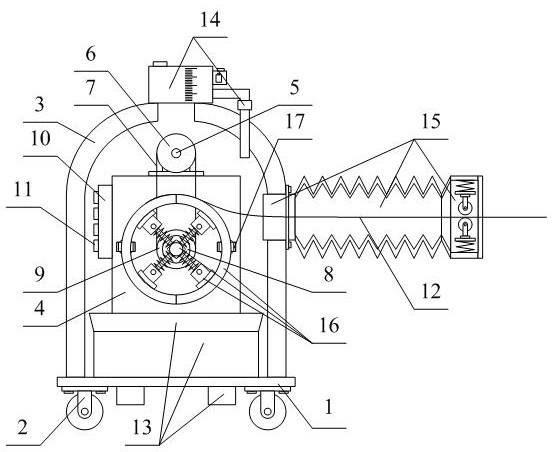

Sesame batch threshing machine

The invention relates to a batch thresher, in particular to a sesame batch threshing machine. The sesame batch threshing machine can screen threshed sesame, is convenient to operate and can automatically beat sesame stalks. The sesame batch threshing machine comprises a base, a feeding mechanism and a screening mechanism, wherein a flapping mechanism is arranged on the base, the feeding mechanism is arranged on the flapping mechanism, and the screening mechanism is arranged on the base. According to the sesame batch threshing machine, sesame stalks are placed through the feeding mechanism, then the sesame stalks are flapped under the cooperation of the flapping mechanism, so that sesame in the sesame stalks falls into the screening mechanism, and then the sesame is screened under the cooperation of the flapping mechanism and the screening mechanism.

Owner:韦红军

Waste removing machine

InactiveCN111645362AGood removal effectNot easy to fly outPaper-makingBox making operationsPaperboardMachine

The invention relates to the technical field of waste removing machines, in particular to a waste removing machine. The machine comprises a frame body, a plurality of bearing rods which are horizontally arranged on the frame body and arranged in the horizontal direction, a supporting frame which is slidably connected to the frame body in the vertical direction and located below the bearing rods, aplurality of ejector rods which are arranged at the top end of the supporting frame, pushing air cylinders which drive the supporting frame to move in the vertical direction, a fixing frame which isslidably connected to the frame body in the vertical direction and located above the bearing rods, a plurality of pressing rods which are arranged at the bottom end of the fixing frame, and fixing aircylinders which drive the fixing frame to move in the vertical direction. The machine has the effect that workers can conveniently remove excess materials on paperboards.

Owner:杭州鸿运彩印包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com