Waste removing machine

A waste removal and racking technology, which is used in container manufacturing machinery, paper/cardboard containers, and box making operations, etc., can solve the problems of reduced production efficiency, scattered packaging boxes, etc., and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings.

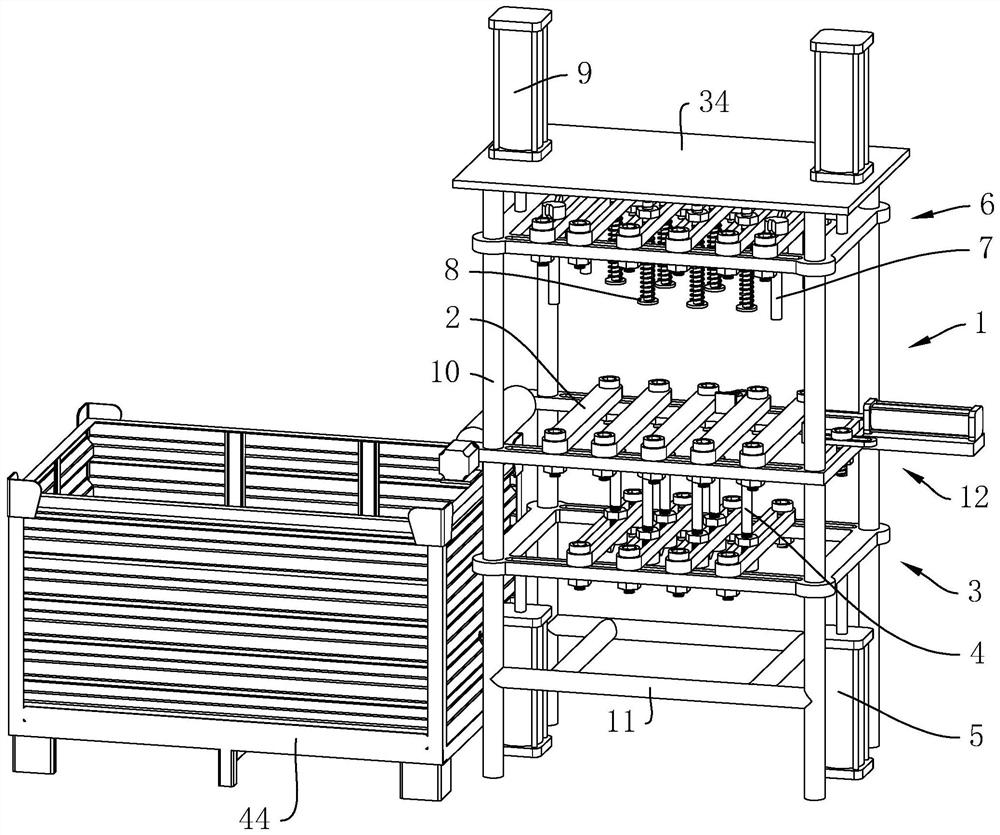

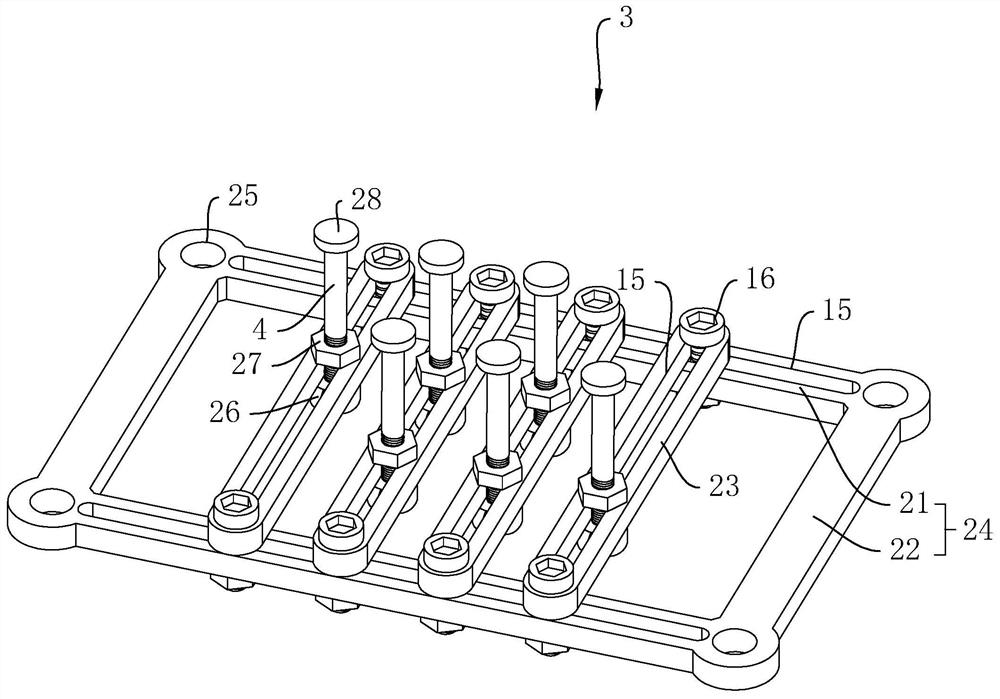

[0042] refer to figure 1 , which is a waste cleaning machine disclosed in the present invention, comprising a frame body 1, a plurality of bearing rods 2, a support frame 3, a plurality of ejector rods 4, a pushing cylinder 5, a fixing frame 6, a plurality of pressing rods 7, a plurality of Press block 8, fixed cylinder 9.

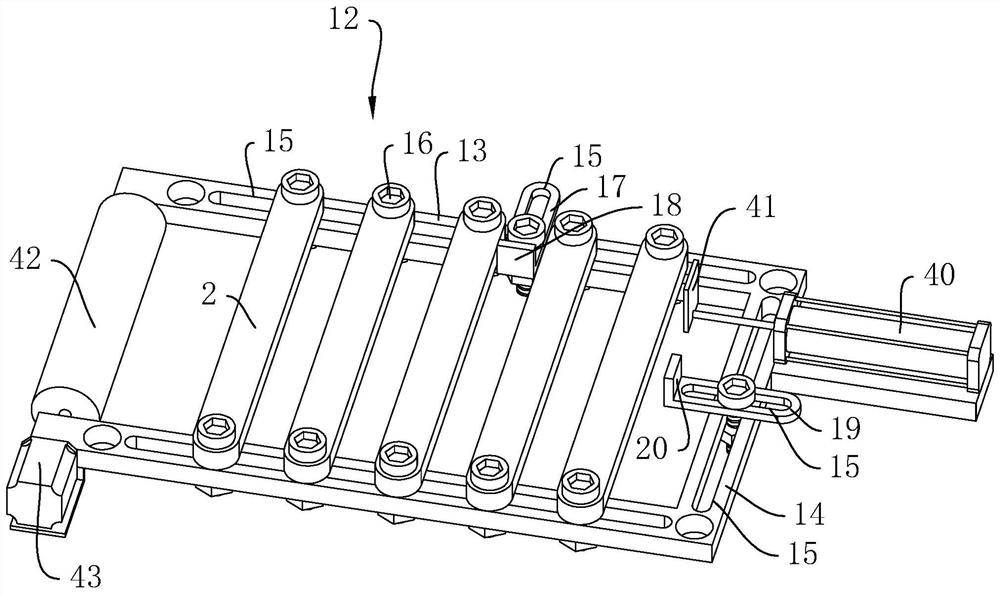

[0043] refer to figure 1 and figure 2 , the frame body 1 includes four uprights 10 and a connecting rod 11 for connecting the four uprights 10, the frame body 1 is fixedly connected to a carrier 12 at the middle position, and the carrier 12 includes two first cross bars 13 and a first A longitudinal rod 14, two first transverse rods 13 and one first longitudinal rod 14 enclose a U-shaped frame, and two first transverse rods 13 and one first longitudinal rod 14 are both provided with a vertical penetrating through rod 14. And the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com