A feeding device for bearing processing

A feeding device and bearing processing technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of bearing end face wear and reduce bearing accuracy, and achieve the effect of reducing friction, reducing impact force and preventing damage to the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

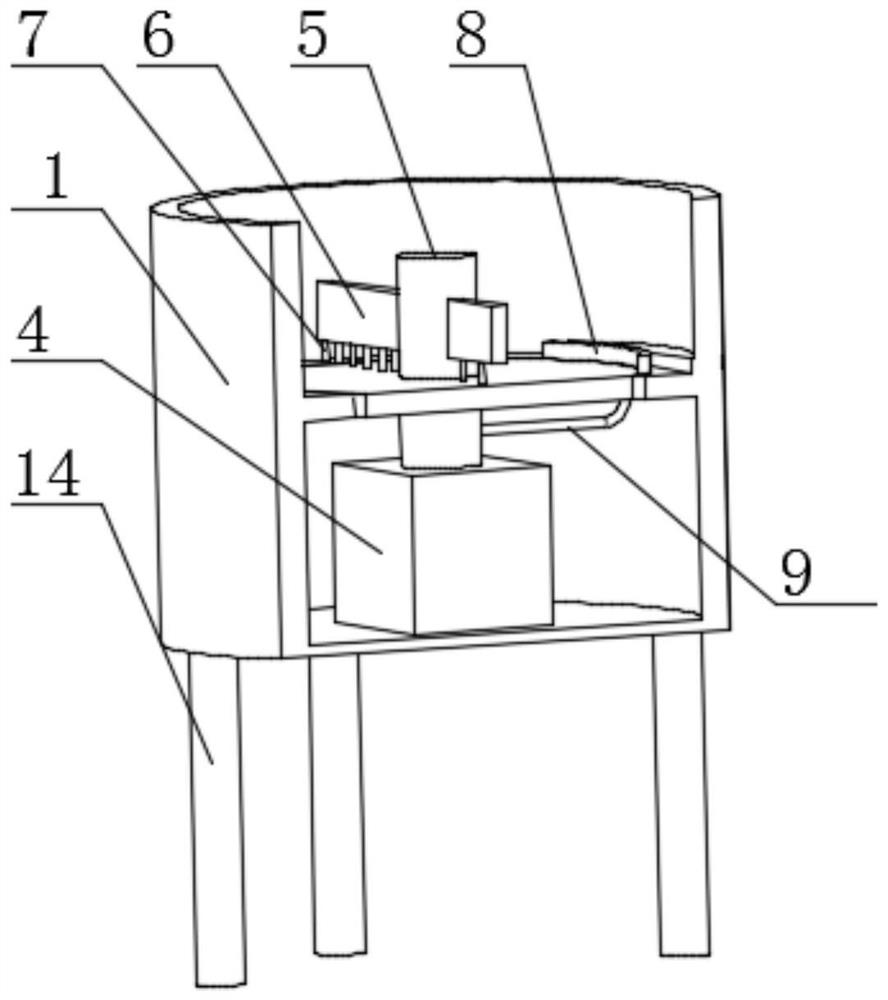

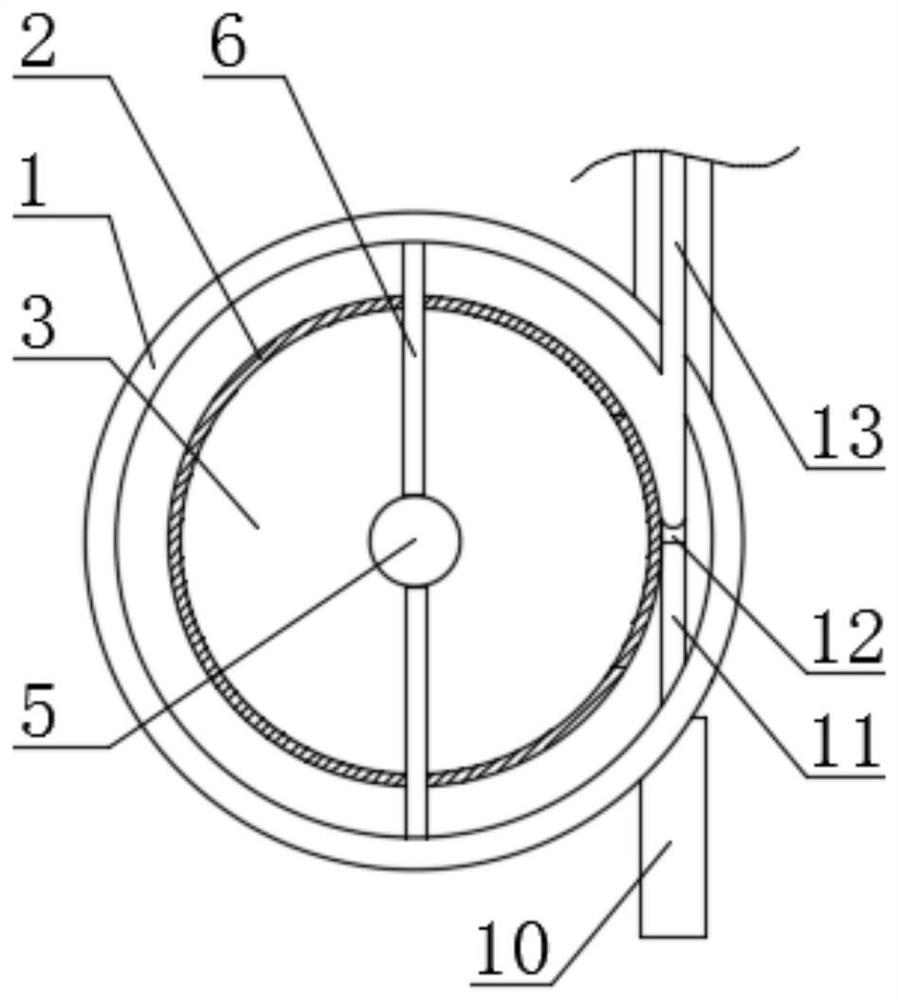

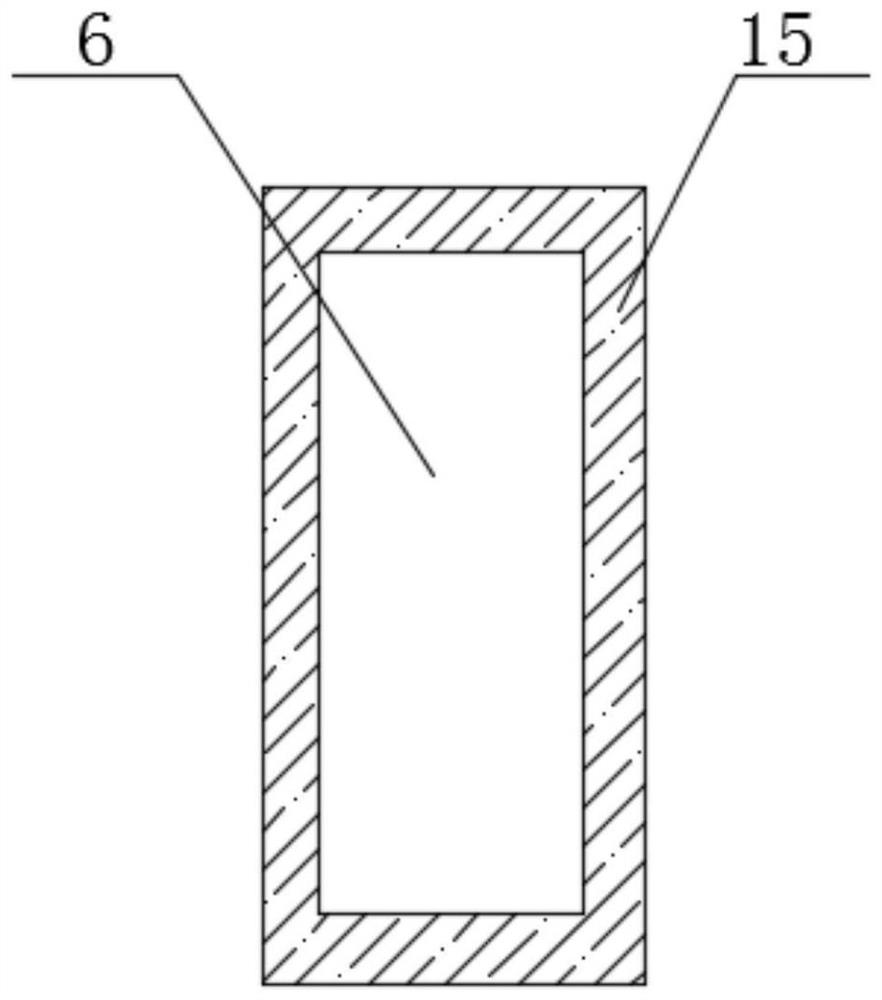

[0024]SeeFigure 1-4The present invention provides a technical solution: a feed apparatus for a bearing processing comprising a bearing arrangement tank 1, and a side of the bearing arrangement tank 1 is fixedly connected to two sets of relatively referred to a bearing box support leg 14, and each bearing box support leg 14 Located in the four corners of the bearing arrangement box 1, it is possible to prevent the bearing arrangement box 1 from contacting the ground, which can effectively prevent water or debris from damaging the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com