Circular protection plate type shelf vehicle for airing varnish

A technology of drying paint and shelves, which is applied in the field of shelves, which can solve the problems that the paint film cannot be dried, the drying speed is slowed down, and the paint film is inconvenient, so as to achieve the effects of shortening the paint drying time, uniform thickness and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

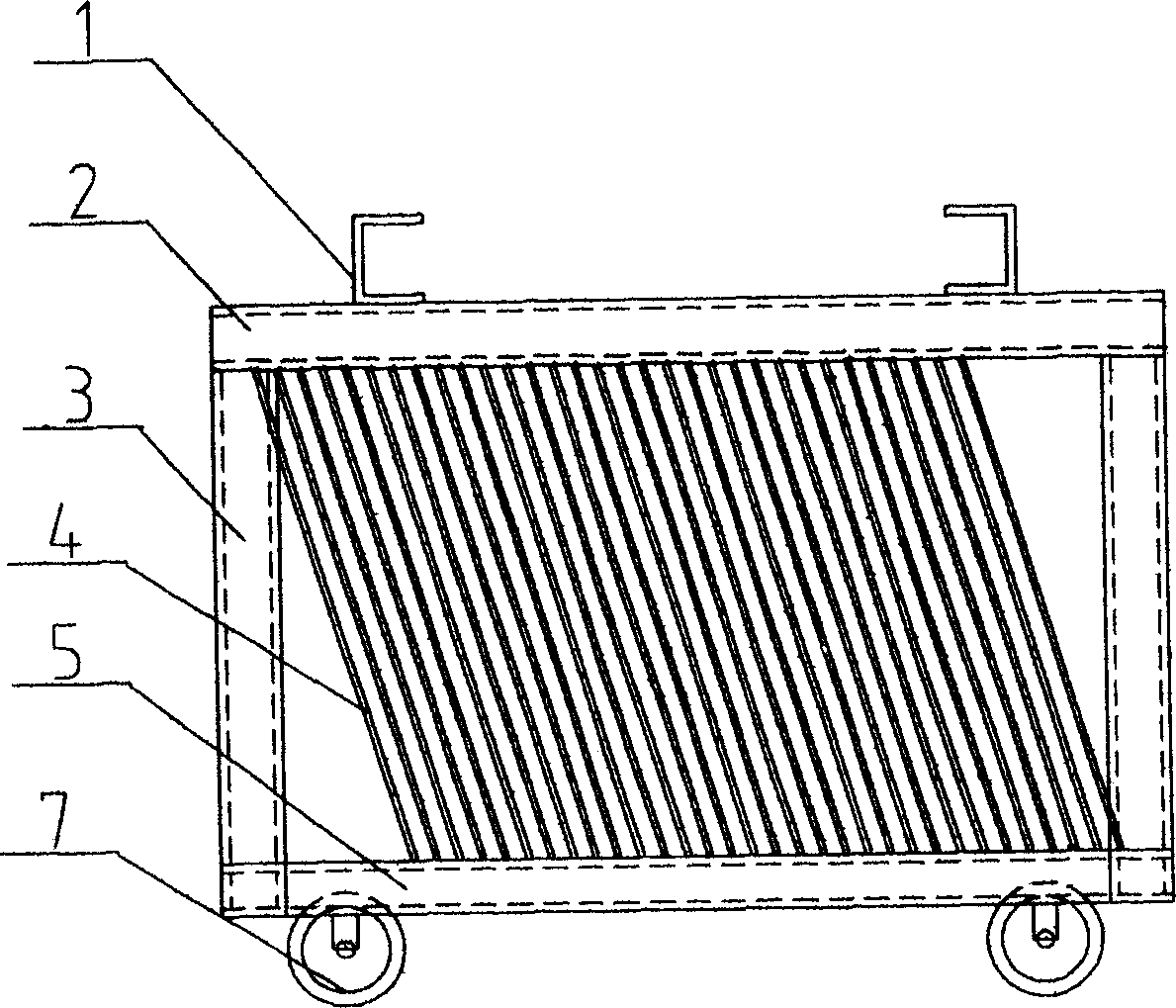

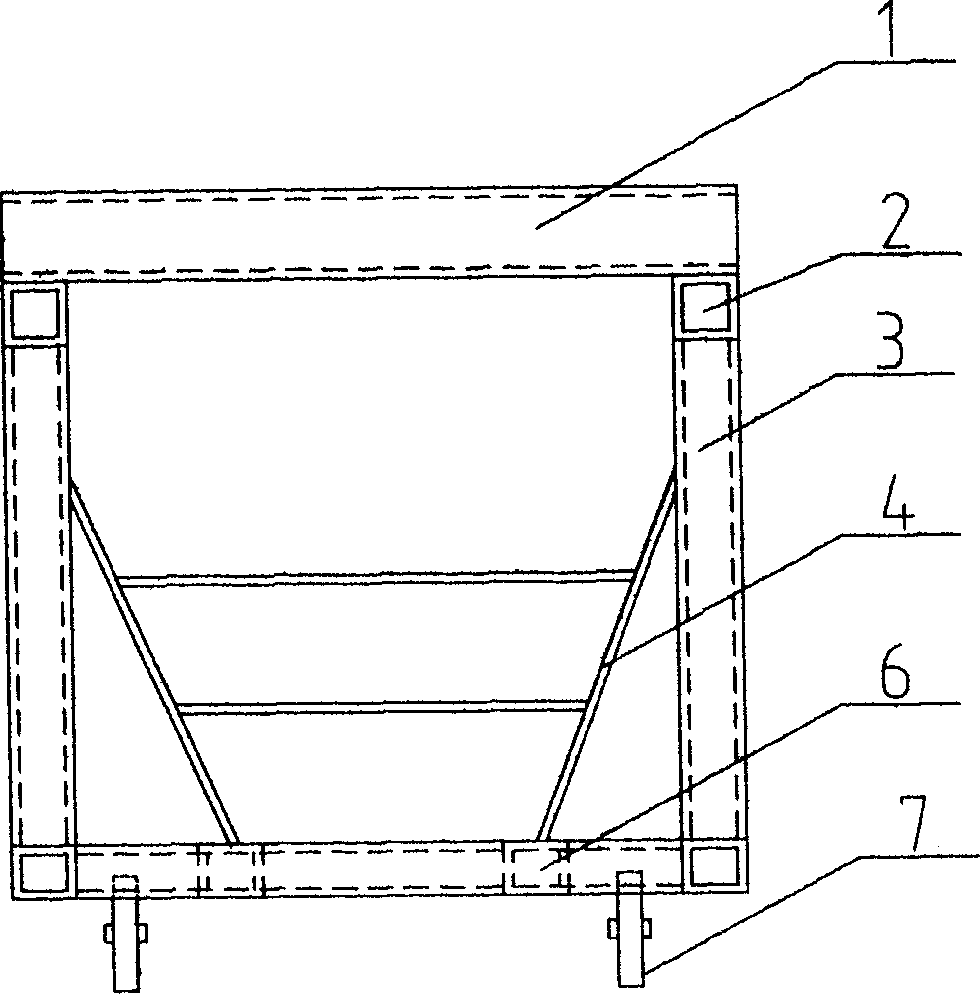

[0008] The upper frame 2, the lower frame 5 are vertically connected with the column 3, the upper frame 2 and the lower frame 5 are rectangular structures, the upper frame 2 is provided with a joist 1, and the lower frame 5 is provided with two supporting rods 6 and the lower frame 5 In the same plane, an inclined grid 4 is arranged between the upper frame 2 and the supporting rod 6, and each layer of grid 4 forms an inclined plane. The rod 6 is connected, and the bottom frame 5 is provided with a roller 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com