Assembly for transportation and transportation method using same

An assembly, one-way technology, applied in the direction of transportation and packaging, packaging, rigid containers, etc., to prevent jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

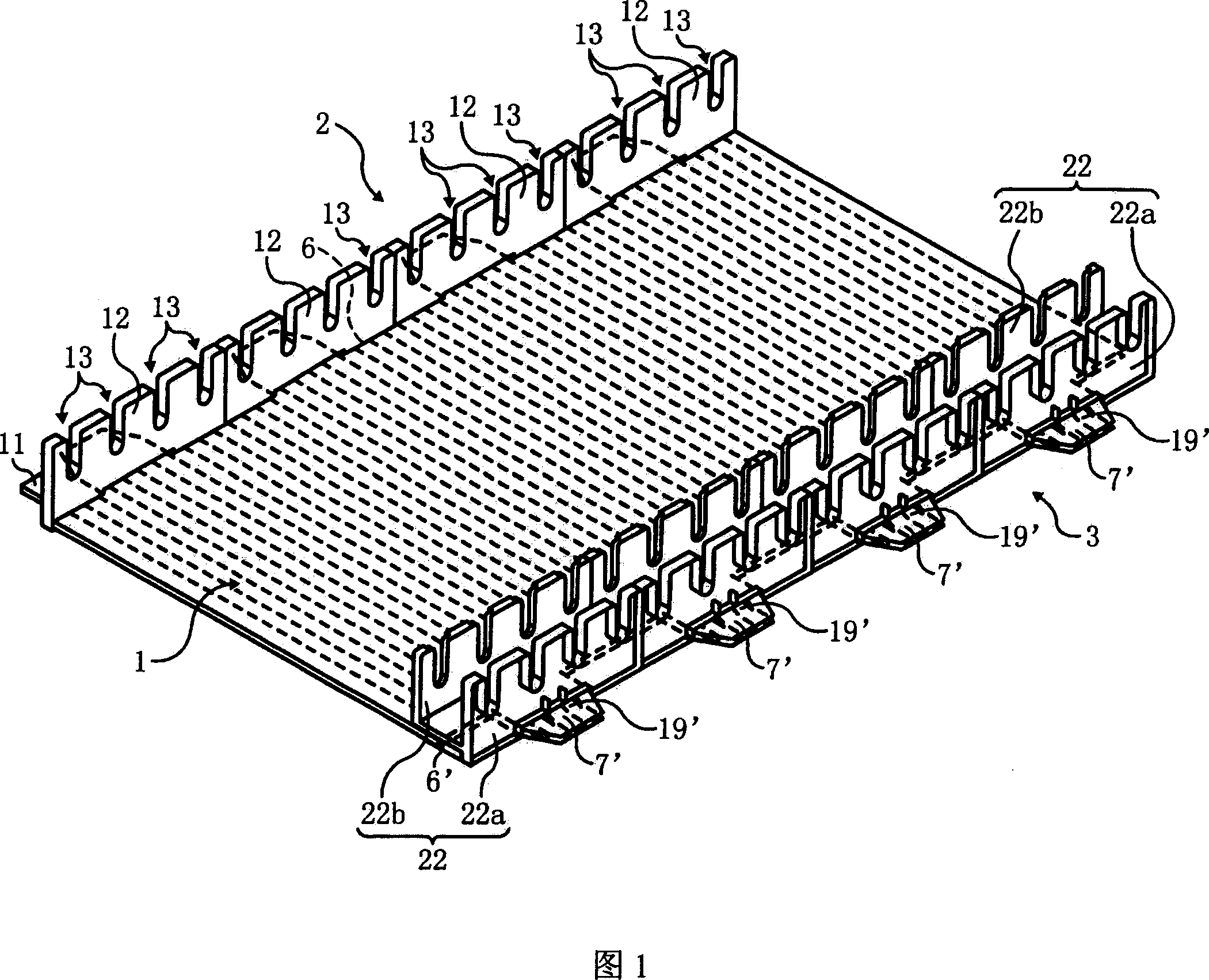

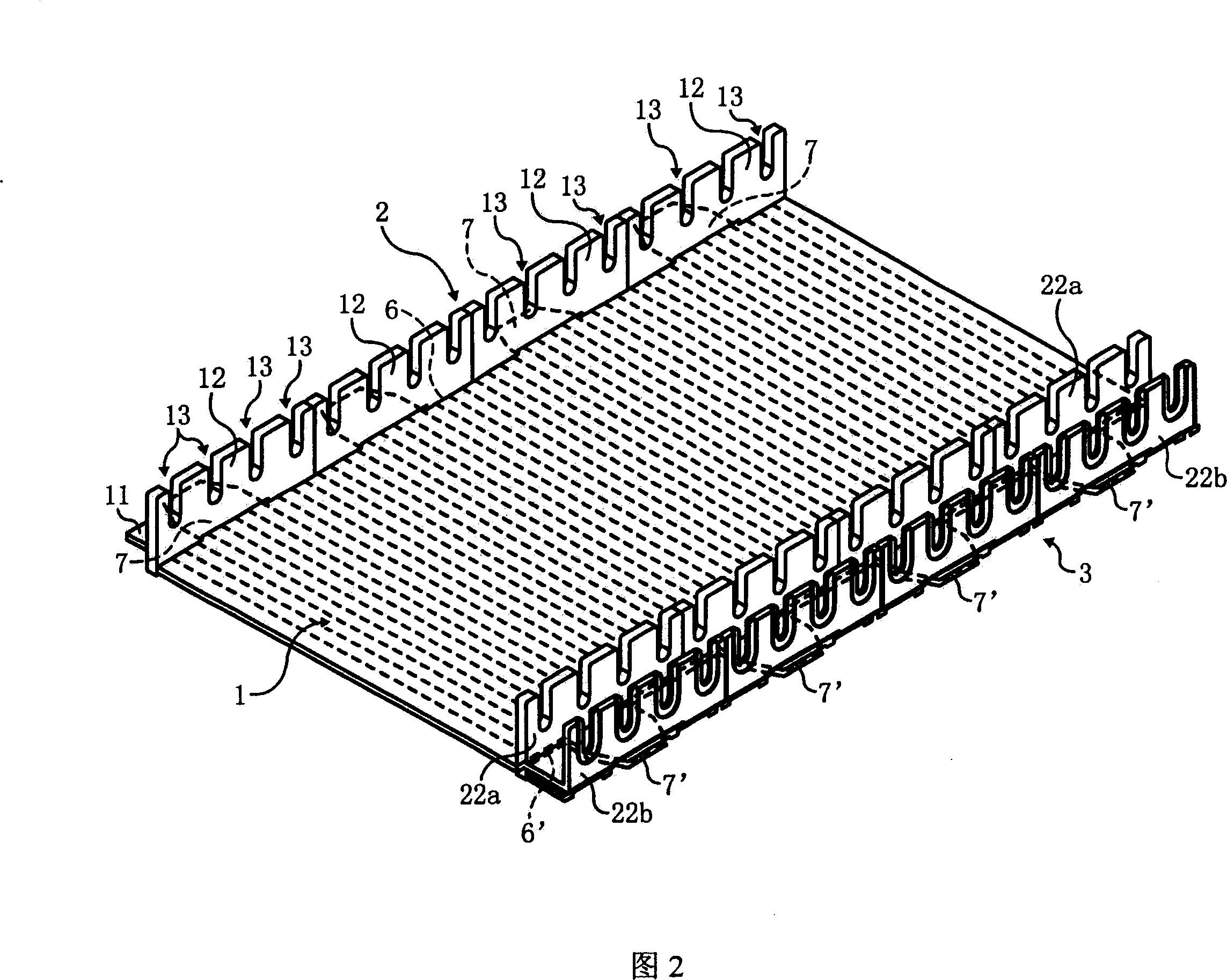

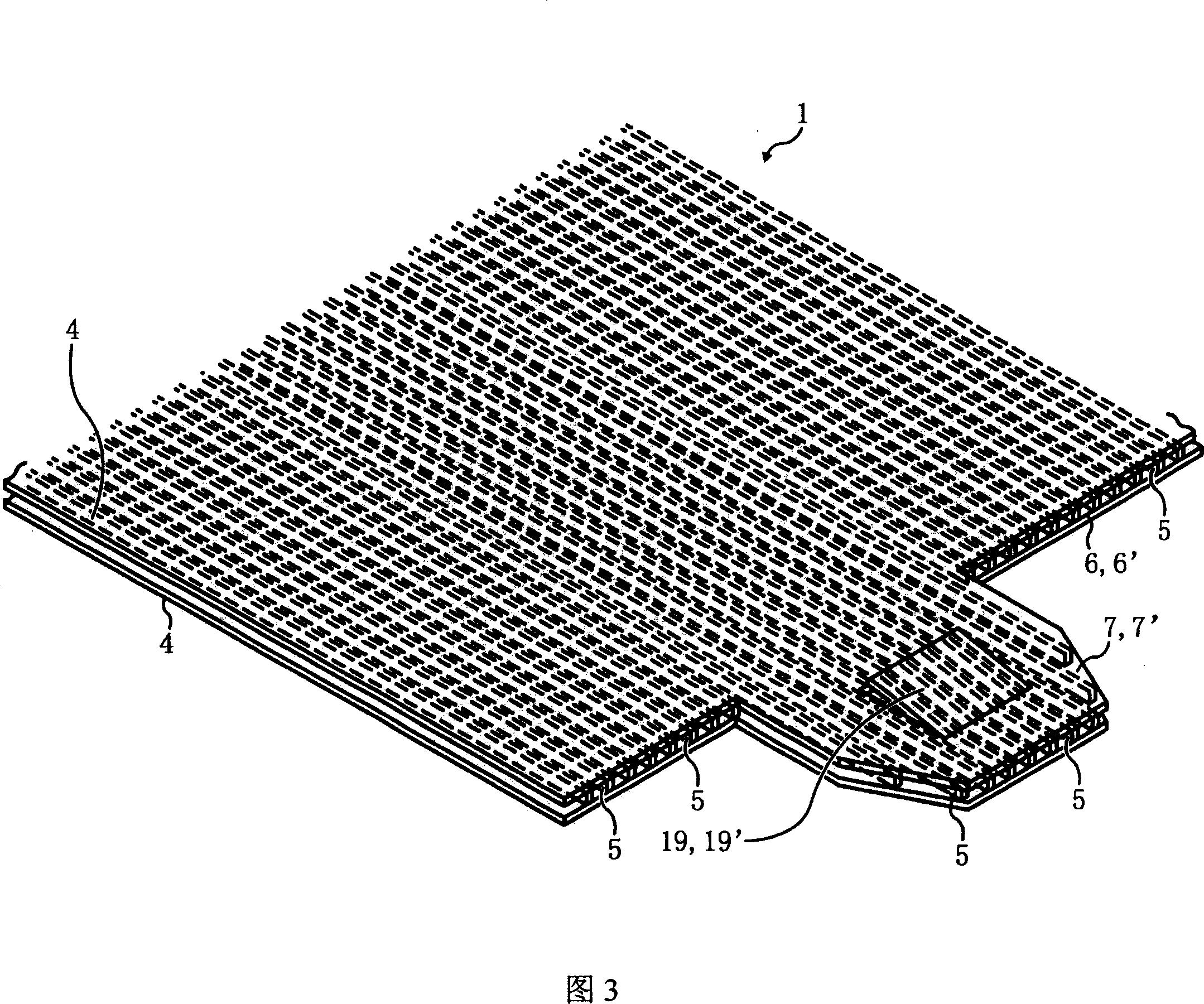

[0073] Figs. 1 and 2 are perspective views showing the transport assembly of the present invention. In Figs. 1 and 2, reference numeral 1 denotes a rectangular base, and 2 and 3 denote split holders. 3, the rectangular base is composed of a pair of rectangular thin plates 4, 4 facing each other at intervals in the vertical direction, and ribs 5 extending in parallel at intervals between the thin plates 4, 4. Referring to Fig. 4, the reinforcing rib 5 has a length parallel to the short direction, which is a direction perpendicular to the extending direction of the long sides 6, 6'.

[0074] The rectangular base 1 is made of corrugated cardboard made of plastic, and its material is polypropylene resin here. In this example, for example, a commercially available product (trade name: Sunpurai HP40070, manufactured by Sumitomo Plastics Co., Ltd.) was used. Here, a white translucent body is used as the material of the rectangular base 1 .

[0075] As shown in FIG. 4 , on one long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com