Incinerator

A technology for incinerators and furnace bodies, applied in the field of incinerators, which can solve problems such as fast burning speed, formation of yellow flames, inconvenient fuel addition, etc., and achieve the effects of convenient fuel addition, stable fuel combustion, and easy fire control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

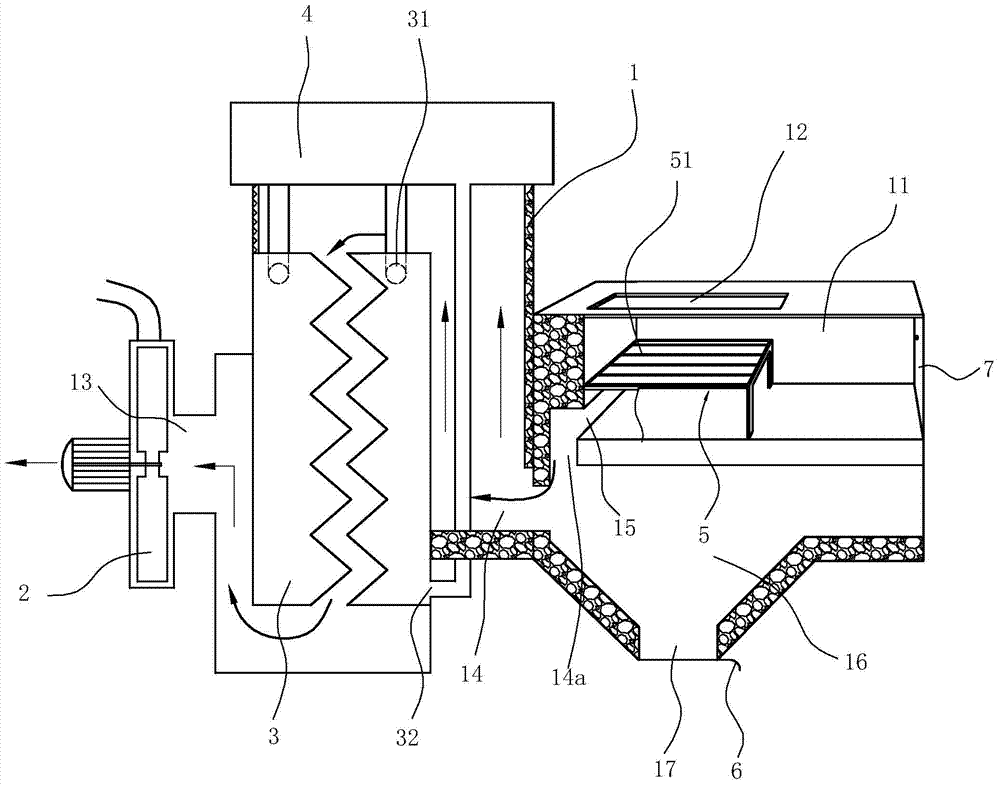

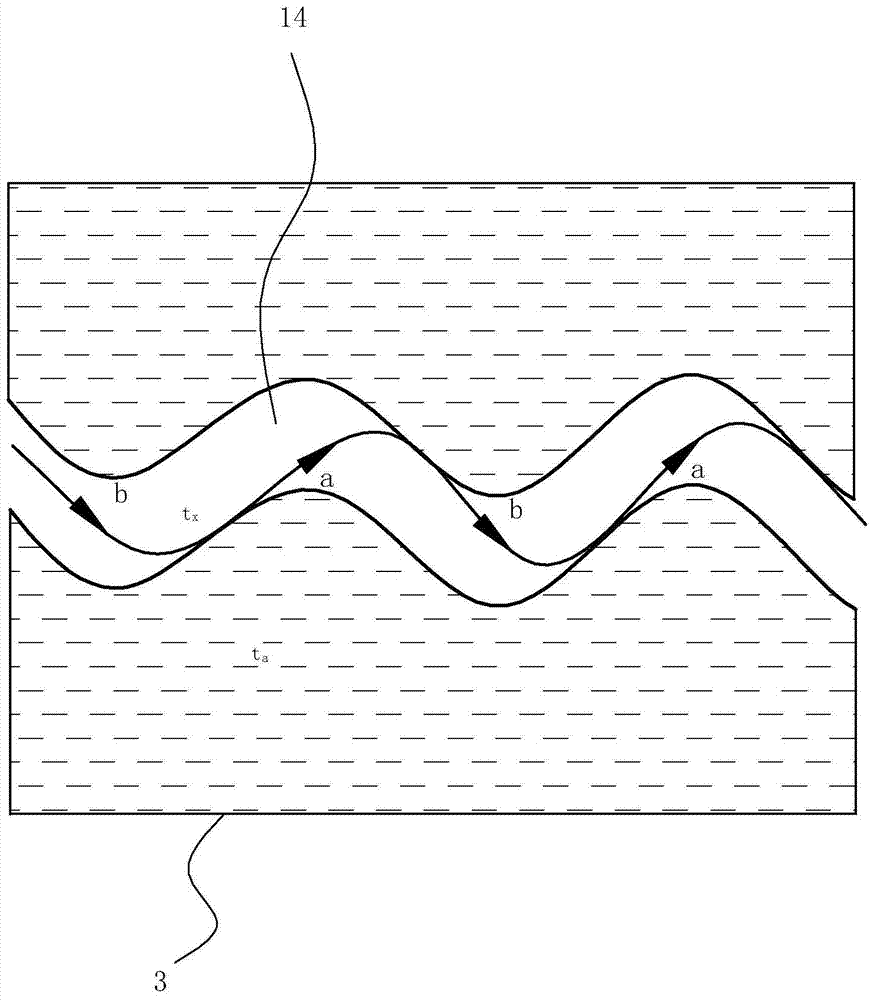

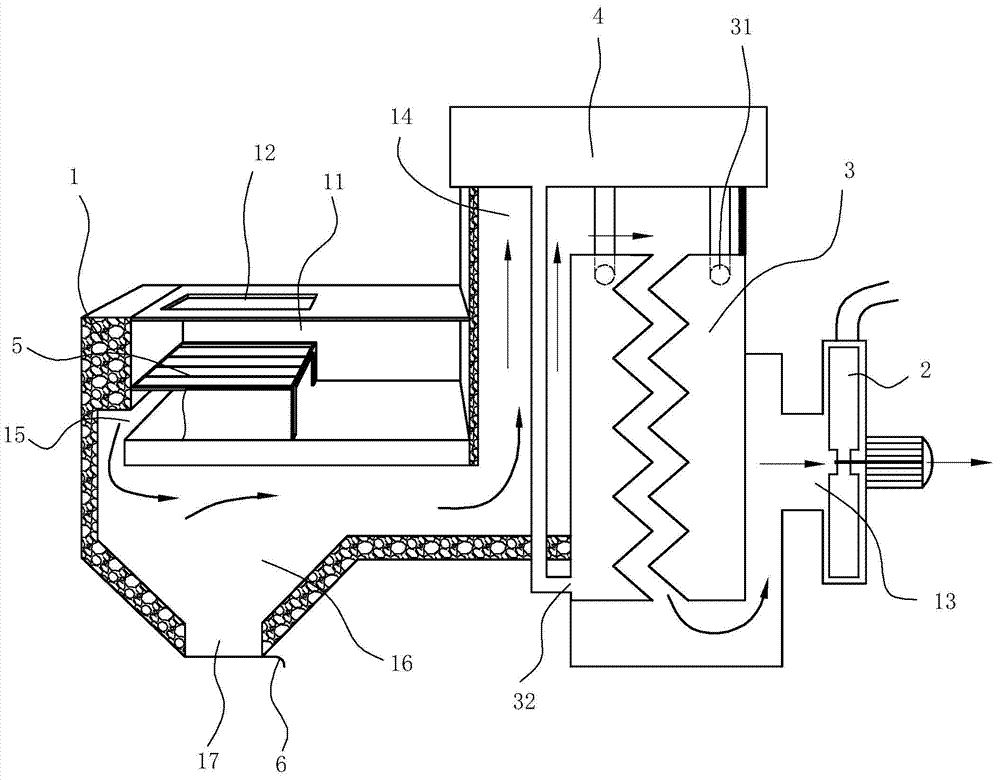

[0021] The first embodiment, such as figure 1 and figure 2 , the incinerator includes a furnace body 1, a combustion chamber 11 positioned in the furnace body, a charging port 12 communicating with the combustion chamber 11, and an exhaust port 13 located on the furnace body and equipped with an exhaust fan 2, the exhaust port 13 The furnace body between the combustion chamber 11 has an exhaust passage 14 for heat exchange with the heated body, wherein the feeding port 12 is located above the combustion chamber 11, and the feeding port is exposed on the top surface of the furnace body, and the feeding port is also used as an inlet. Tuyere: The lower part of the combustion chamber 11 has a smoke outlet 15 communicating with the exhaust passage 14 . In this embodiment, there is a gap between the left side of the combustion chamber 11 and the bottom, which may also be formed by a designed gap at the bottom of the left side of the combustion chamber.

[0022] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com