Unloading device for production of numerically controlled electromechanical equipment and method of use thereof

A technology of unloading device and electromechanical equipment, which is applied in the direction of metal processing, etc., can solve the problems affecting the processing of parts, the increase in the number of defective products, and the deviation of shaft parts, so as to achieve the effect of reducing the number of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

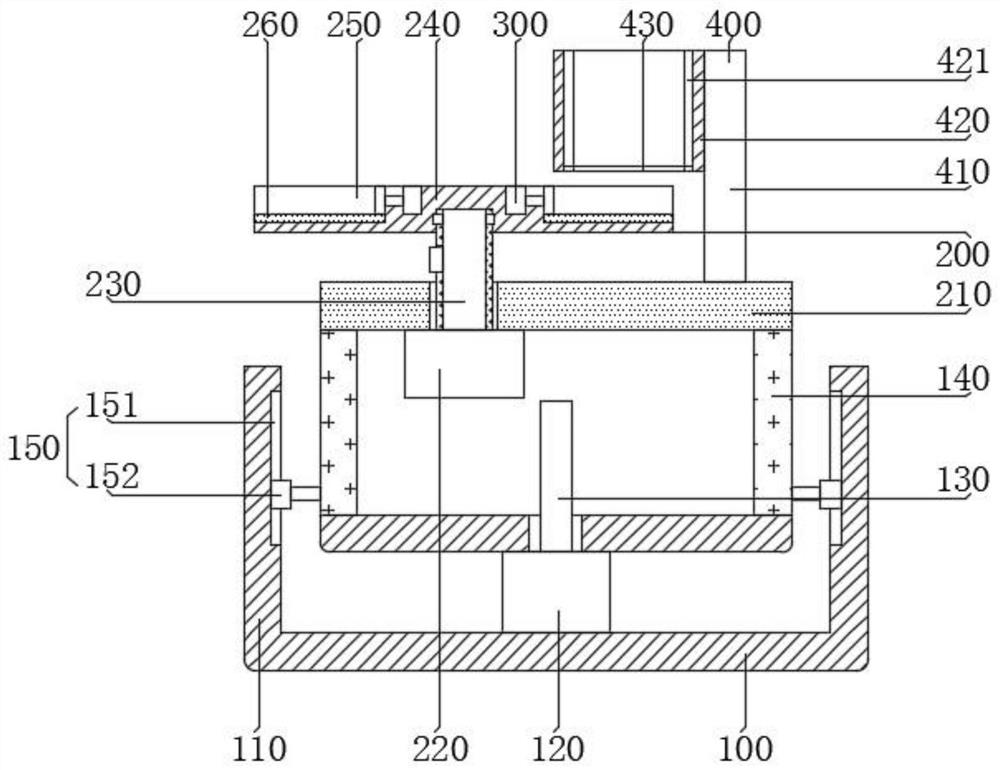

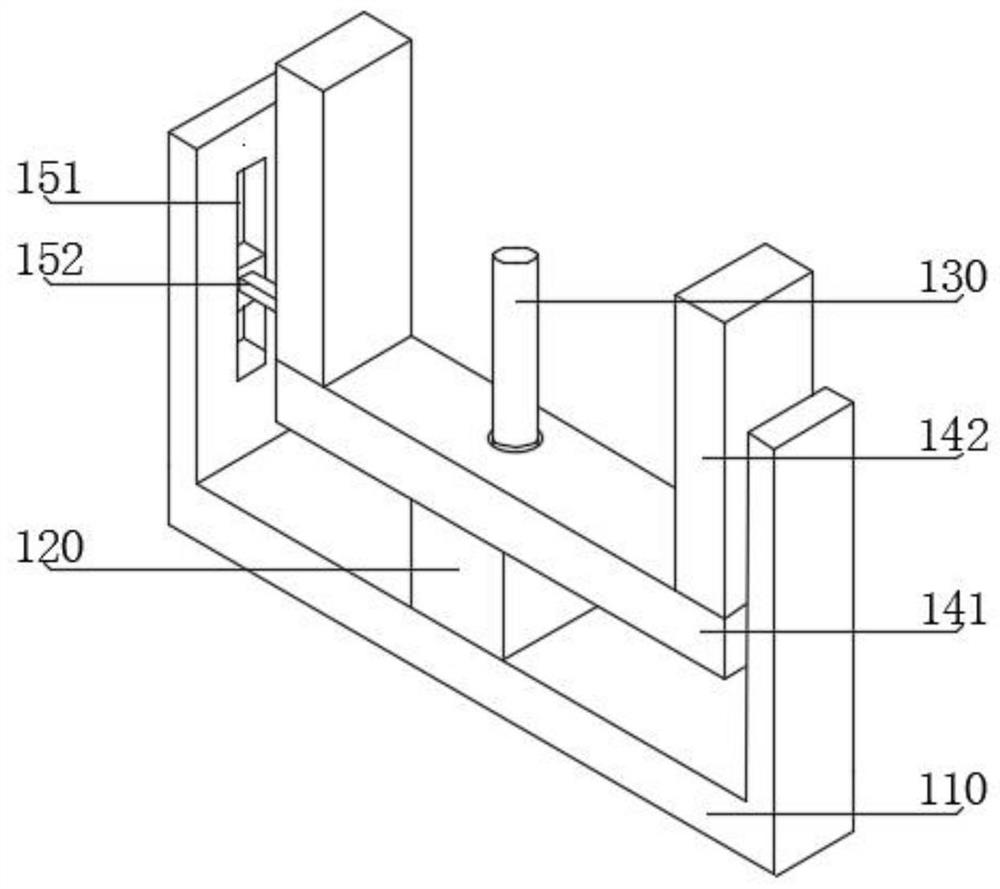

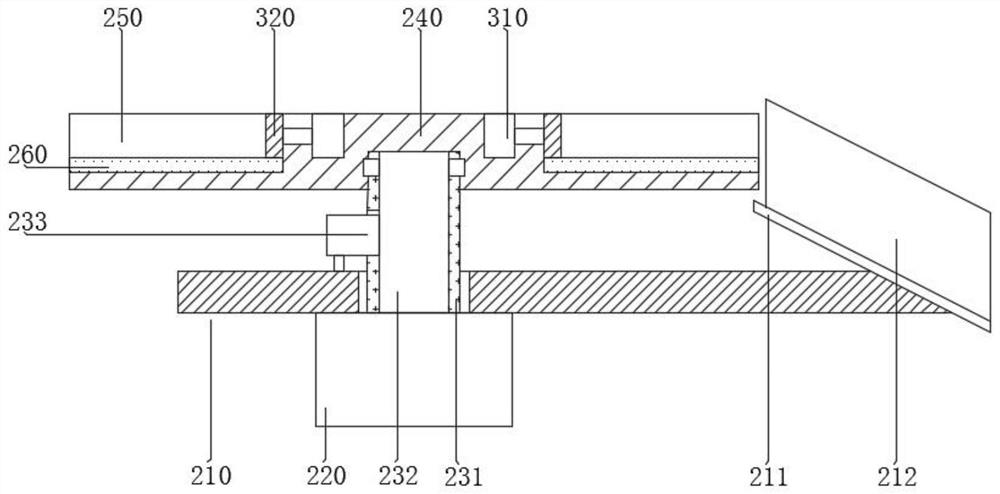

[0040] Such as figure 1 As shown, a discharge device for the production of numerical control electromechanical equipment includes a lifting assembly 100, a rotating assembly 200, a pushing assembly 300 and a feeding assembly 400, the rotating assembly 200 is installed on the side of the lifting assembly 100, and the pushing assembly 300 is installed On the side of the rotating assembly 200, the feeding assembly 400 is installed on the side of the lifting assembly 100, wherein the lifting assembly 100 is used for lifting and lowering to facilitate height adjustment; the rotating assembly 200 is used for transferring shaft parts, pushing materials The assembly 300 is used to push the shaft par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com