positioning claw

A technology of positioning claws and positioning blocks, which is applied in the direction of positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of consuming manpower, material resources, financial resources and time, increasing enterprise costs, and poor versatility, so as to reduce manual operations, The effect of extending the service life and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

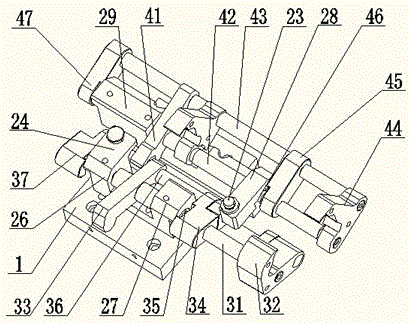

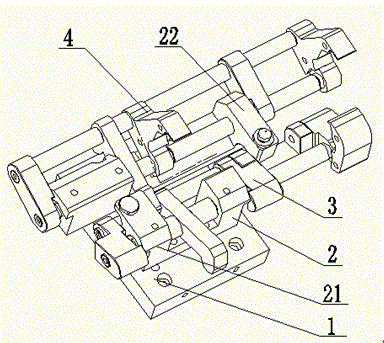

[0025] A positioning claw disclosed by the present invention, as attached Figure 1-2 As shown, it includes a base 1, which is provided with several screw holes for installing the positioning claws on the mold, and also includes a workpiece positioning mechanism 2, a first clamp telescopic mechanism 3, The second clamp telescopic mechanism 4.

[0026] Wherein, the workpiece positioning mechanism 2 includes a first U-shaped positioning block 21 and a second U-shaped positioning block 22 arranged on the base 1 through a bolt gap, and the two are parallel to each other, and they cooperate with each other to form a A placement surface for placing workpieces to be processed; the first side branch 26 of the first U-shaped positioning block 21 is provided with a limit surface 24 that restricts the upward rotation of the first clamp telescopic mechanism 3; furthermore, in order to treat The workpiece is positioned, and at least one positioning pin 23 is arranged on the upper end surf...

Embodiment 2

[0032] The overall mechanism of this embodiment is the same as that of Embodiment 1, and the difference is that: the workpiece positioning device 2 is a positioning block with a U-shaped cross section, and a positioning pin 23 is arranged on it; the first clamp is telescopic Mechanism 3 includes a first rotating shaft 31 and a first clamp 32, and the first rotating shaft 31 runs through the two side branches of the positioning block and the first clamping clamp 32; A first torsion spring 35 is arranged between two side branches and one of the remaining side branches, thereby forming a reset mechanism of the first clamp telescopic mechanism 3; the second clamp telescopic mechanism 4 includes a second linkage rod 41, a second A rotating shaft 42, a linear guide rail 43 and two second clamps 44, the second linkage rod 41 is connected with the first clamp 32 to form a linkage mechanism, and the second rotating shaft 42 and the linear guide rail 43 respectively pass through the sec...

Embodiment 3

[0035] The overall structure of this embodiment is the same as that of the above-mentioned embodiment 1, and the difference is that: the number of the first clamps 32 is two, and they are movably arranged on the first rotating shaft 31, preferably in this embodiment Because they are respectively fixed on the two ends of the first rotating shaft 31 ; meanwhile, the two second clamps 44 are movably arranged on the second rotating shaft 42 and the linear guide rail 43 . In actual application, the fixing position of each clamp can be adjusted according to the different shapes of different workpieces, so that each clamp can better cooperate to fix the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com