Method for processing blade tenon

A processing method and blade tenon technology are applied in the field of aero-engine compressor blade processing, which can solve the problems of extremely high manufacturing precision of forming milling cutters, fast wear of forming milling cutters, low processing efficiency, etc. Simple process and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

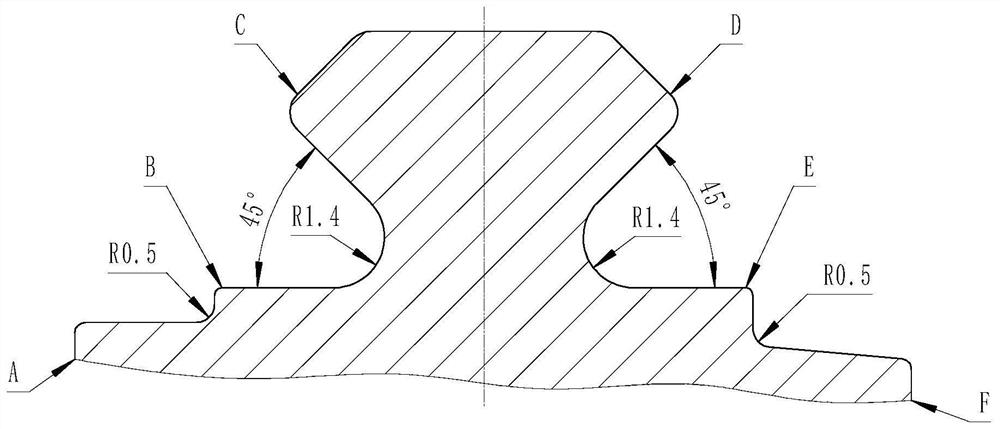

[0037] The blade of an aero-engine with dovetail arc tooth tenon, the material is TC11, the structure is as follows figure 1 As shown, the section of the dovetail arc tooth tenon is as follows figure 2 As shown, the minimum profile of the dovetail arc tooth tenon is ±0.01, and the machining surface of the dovetail arc tooth tenon is composed of the outer edge plate surface A-B section, the outer edge plate surface E-F section and the dovetail type B-C-D-E section. The concave arc radius of the A-B section of the outer edge plate surface and the E-F section of the outer edge plate surface is R0.5mm. The angle of the dovetail type B-C section and the dovetail type D-E section is 45°, and the arc radius is R1.4mm. Its processing plan is:

[0038] 1. The dovetail arc tooth tenon is processed by the milling method of the five-coordinate machining center. The rotation axes of the five-coordinate machining center are the A axis and the B axis respectively;

[0039] 2. When the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com