Patents

Literature

83results about How to "Shorten the preparation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

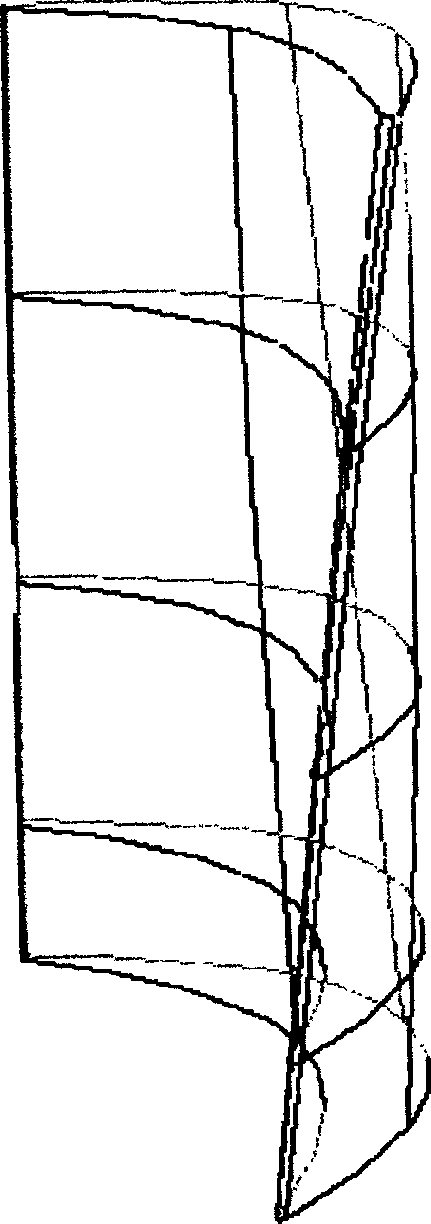

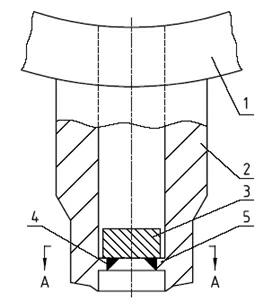

Method and apparatus for turbine blades milling with once clamping

InactiveCN1613590ASimple interfaceEasy to operateMilling equipment detailsNumerical controlSteam turbine blade

A technology for milling the blade of steam turbine by fixing it on the 5-coordinate numerally controlled machine-tool once includes such steps as improving the coarse machining module of Turbsoft program for 5-coordinate numerally controlled machine tool by adding the blade-milling module, fixing the steel blank of blade onto said machine-tool, and milling under the control of said program.

Owner:DONGFANG TURBINE CO LTD

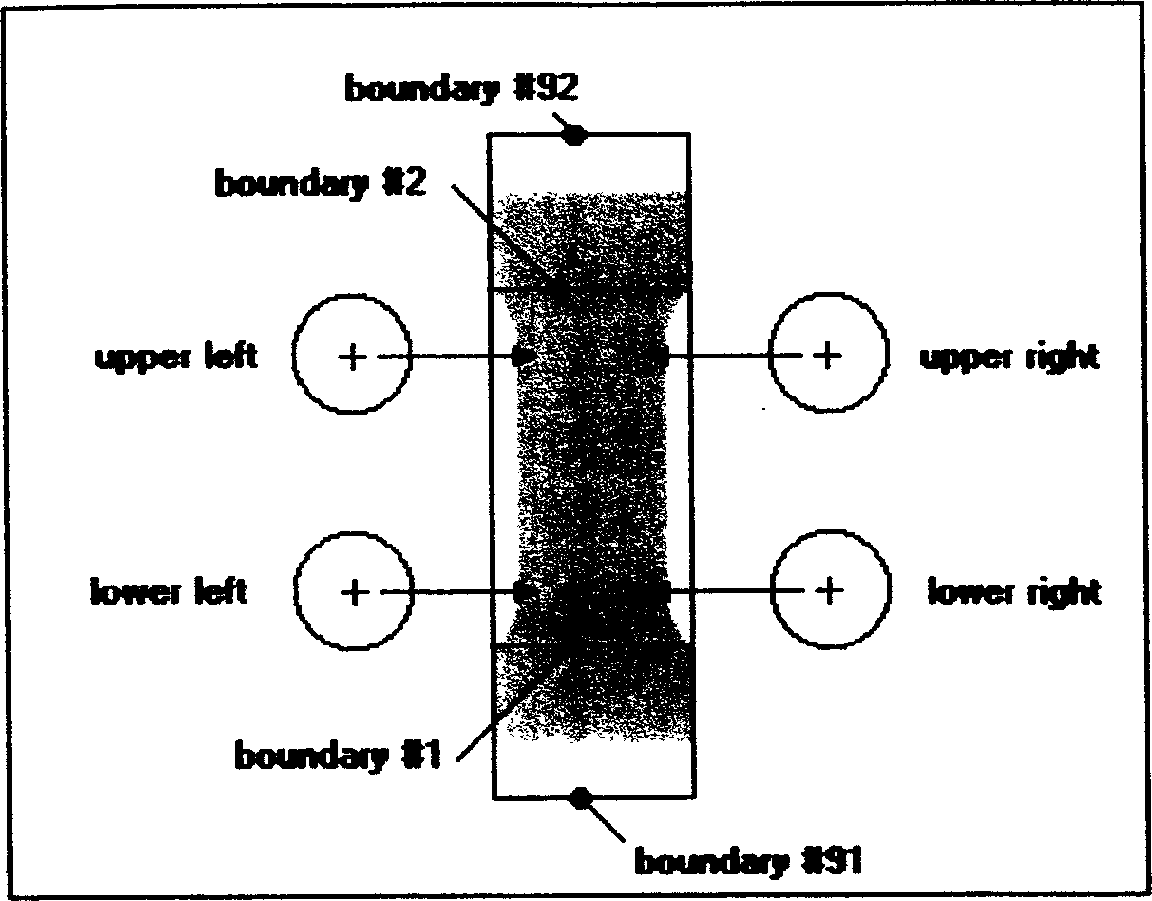

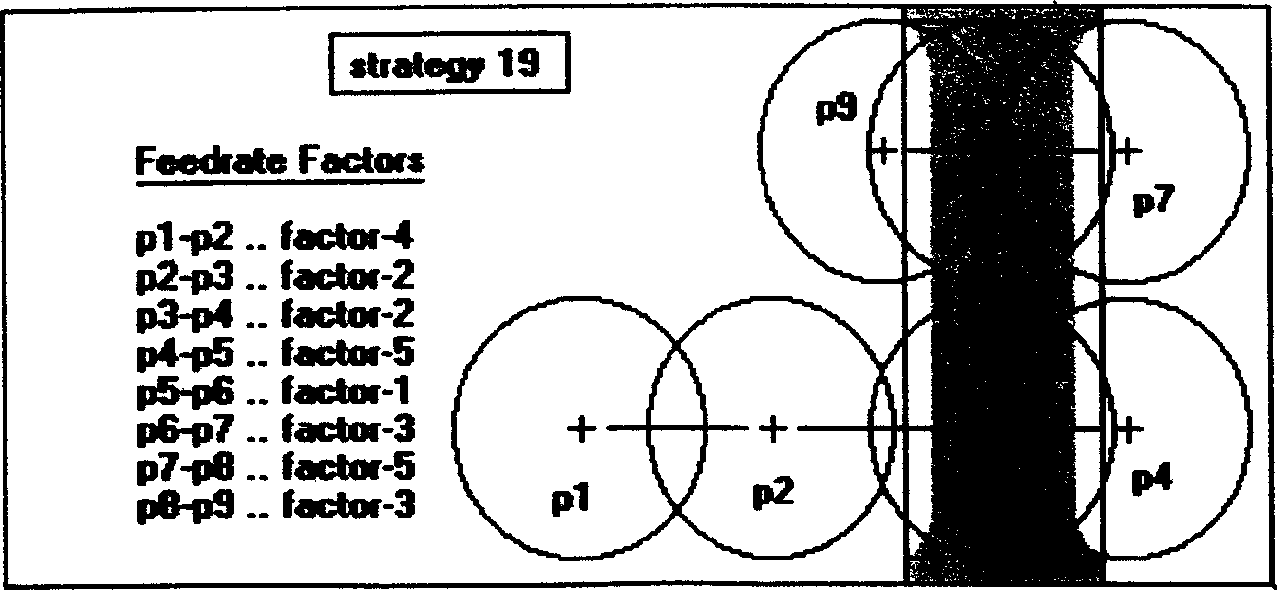

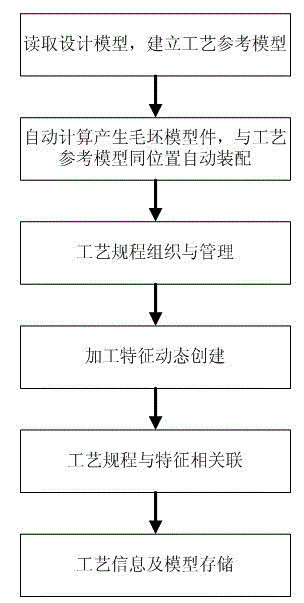

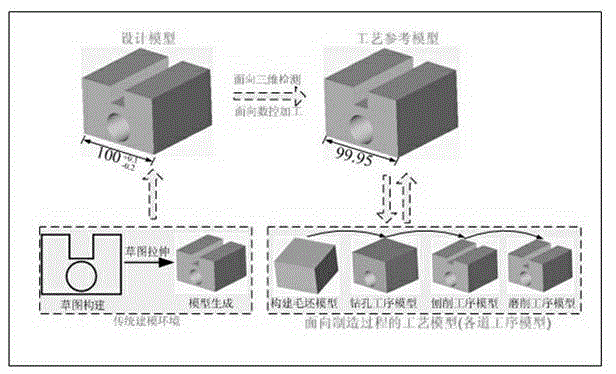

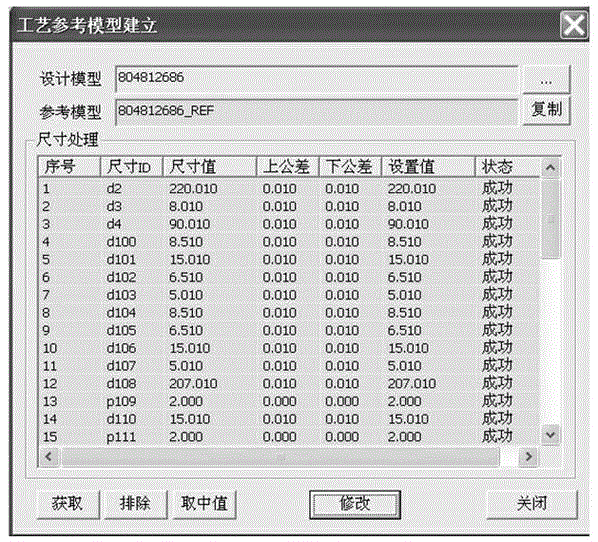

Method for building dynamic three-dimensional process model

ActiveCN102722614AFastImprove interactivitySpecial data processing applications3D modellingReference model3D modeling

The invention belongs to the field of the technological process of a three-dimensional design model, and relates to a method for building a dynamic three-dimensional process model, which is characterized in that the method for building the dynamic three-dimensional process model is carried out according to the following six steps of: reading the design model, and building a technological reference model; automatically calculating the produced blank model, and automatically assembling the produced blank model with the technological reference model at the same position; organizing and managing the technical schedule; dynamically creating processing the characteristic; correlating the technical schedule with the characteristics; and storing the processing information and the model. The method for building the dynamic three-dimensional process model solves the problem that the two-dimensional technological design and the three-dimensional technological design are disjoined at present, and a two-dimensional model is taken to directly guide production and manufacturing, the traditional mode of 'three-dimensional design plus two dimensional' is broken through, and accordingly, the technological design efficiency is obviously improved; and moreover, the manufacturing staff can directly obtain the machining features and the corresponding technological information on the basis of the three-dimensional technological design, so the preparation periods of production and manufacture are greatly shortened, and the production efficiency is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

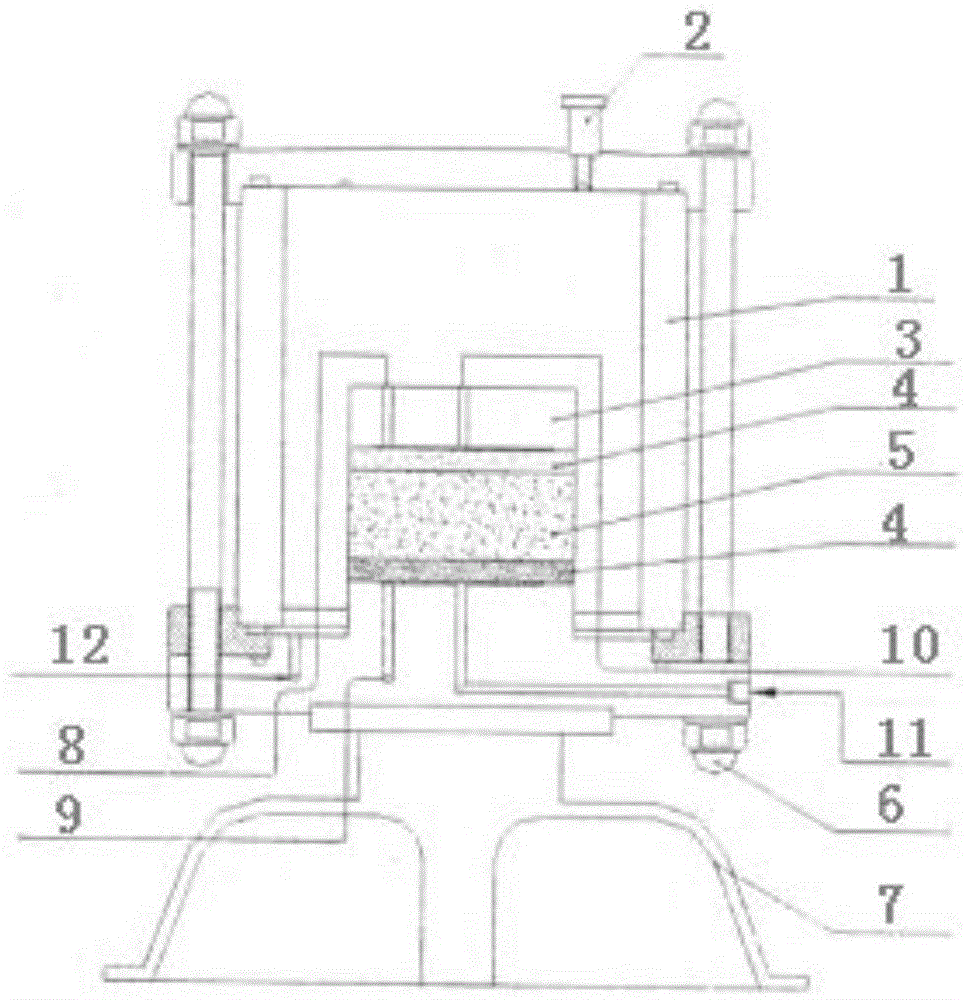

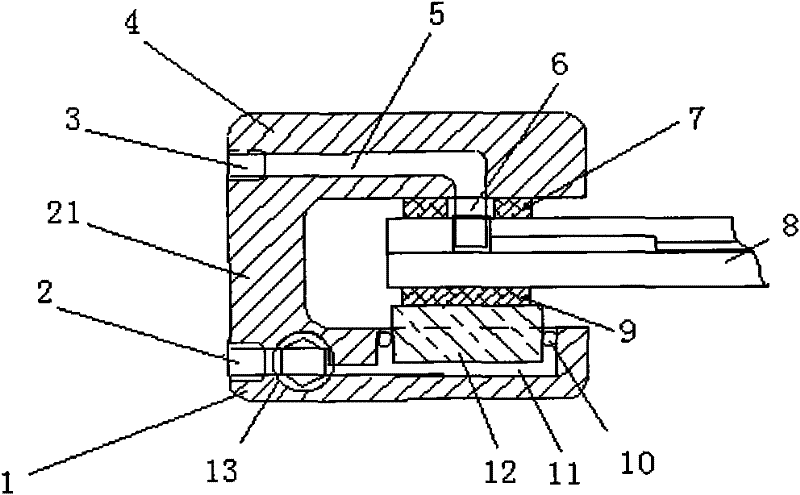

Flexible wall permeameter and use method thereof

InactiveCN104458533AShorten the preparation cycleEasy to excludePermeability/surface area analysisTest sampleRead through

The invention discloses a flexible wall permeameter and a use method thereof; the flexible wall permeameter disclosed by the invention comprises a shell; a pressure chamber is arranged in the shell; the flexible wall permeameter further comprises an exhaust bolt, a pressurizing cap, porous stones, a confining stress controller and a back pressure controller; the exhaust bolt is arranged at one side of the top of the shell; upper and lower layers of porous stones are arranged in the middle of the bottom of the pressure chamber; a test sample is arranged between the two layers of porous stones; the pressurizing cap is arranged on the top of the upper layer of porous stones; the back pressure controller is connected with the pressurizing cap; and the confining stress controller is connected with the pressure chamber. According to the invention, the confining stress controller and the back pressure controller are arranged outside the pressure chamber and the pressurizing cap in a connecting manner; experimental data can be clearly read through a controller display screen, so that the detection precision is increased; confining stress and back pressure are controlled within a reasonable range; bubbles in the test sample and a pipeline can be easily discharged within a short time; the saturation state is realized as soon as possible; the experimental preparation period is shortened; and the efficiency is increased.

Owner:南京市建筑安装工程质量检测中心

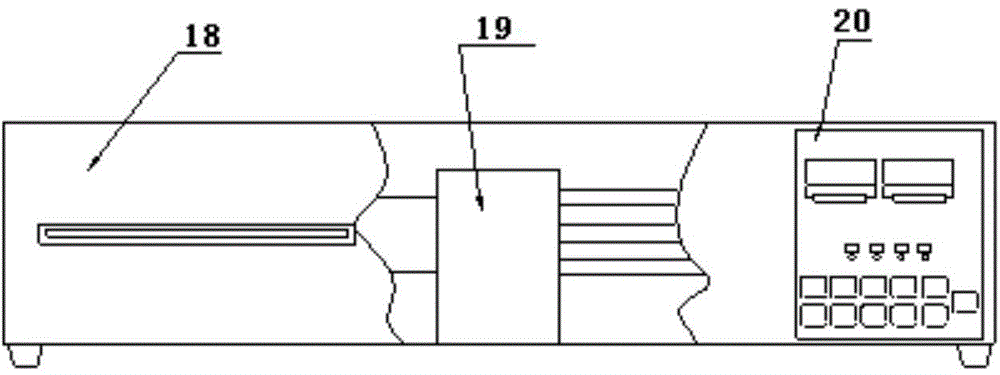

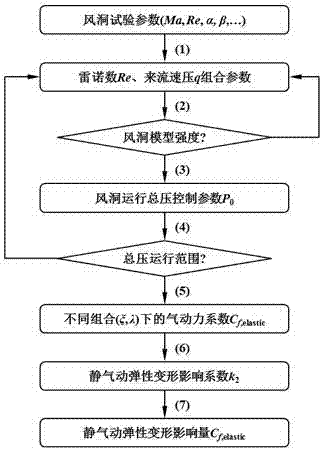

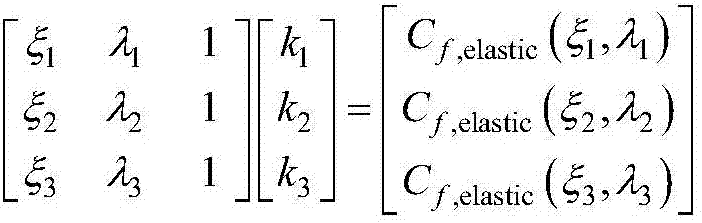

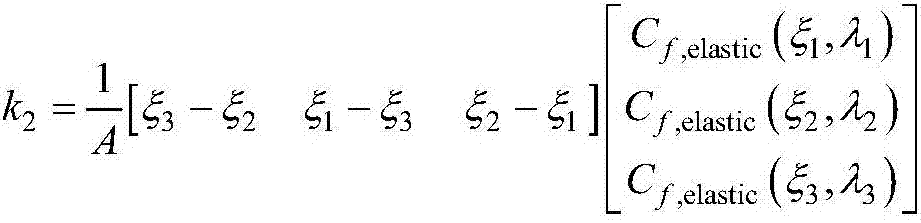

Method for obtaining static aeroelastic deformation influencing quantity of wind tunnel model

ActiveCN107391858AReduce dependenceHigh precisionGeometric CADSustainable transportationReal time analysisAlgebraic equation

The invention provides a method for obtaining the static aeroelastic deformation influencing quantity of a wind tunnel model. According to the scheme, for solving the problem that different incoming flow velocity pressure test data extrapolation methods depend on the capability of total temperature and total pressure independently controlled test facilities, an independently-variable total pressure wind tunnel testing method which can be achieved by most wind tunnels is adopted to obtain wind tunnel test data of different Reynolds number and incoming flow velocity pressure combinations, the difficulty and cost of an air tunnel test is remarkably reduced, and a preparation period of the air tunnel test is remarkably shortened, the dependency of static aeroelastic deformation influence correction on wind tunnels is eliminated, and a technical support is provided for corresponding correction tests carried out for various conventional air tunnels. For solving the problem that the time and calculation costs of numerical simulation / model deformation measurement combined methods are high and the static aeroelastic deformation influence cannot be analyzed in real time, an algebraic equation solving method is adopted, rapid separation of a Reynolds number effect and a static aeroelastic deformation influencing effect can be achieved, and accordingly the influencing quantity of static aeroelastic deformation to aerodynamic force characteristics can be analyzed in real time.

Owner:AERODYNAMICS NAT KEY LAB

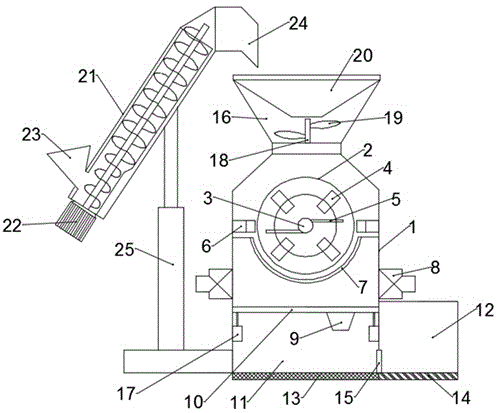

Material processing and feeding device used for animal husbandry

InactiveCN105557533AShorten the preparation cycleImprove processing efficiencyFeeding-stuffAnimal feeding devicesFood safetyEngineering

The invention discloses a material processing and feeding device used for animal husbandry. The material processing and feeding device used for the animal husbandry comprises a smashing cavity, wherein a smashing turntable body is fixedly arranged inside the smashing cavity by virtue of a power rotating shaft, a central serrated plate is arranged on the power rotating shaft, a pretreatment cavity is arranged at the top of the smashing cavity, a microwave sterilization device is arranged on the outer side wall of the smashing cavity, a bottom baffle is arranged below a semi-circular screen, the lower surfaces of the two ends of the bottom baffle are connected with a lifting cylinder, a discharging and weighing sensor is arranged at the bottom of a blanking cavity, a feeding weighing sensor is arranged at the bottom of a feeding channel, and a screw conveying bucket is also arranged at one side of the smashing cavity. The material processing and feeding device used for the animal husbandry can carry out pre-smashing treatment on materials, three cutting tools jointly act for carrying out comprehensively smashing on the materials, the bottom baffle can prevent the accumulation phenomenon and also can guarantee accurate supply of food, and the microwave sterilization device can carry out sterilization and disinfection treatment on the materials, so that food safety of feeds is improved.

Owner:郑焕刚

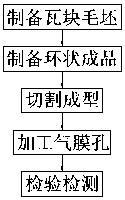

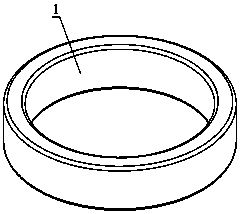

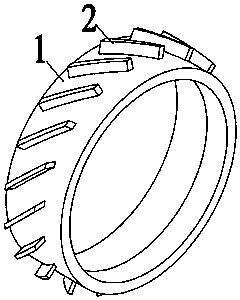

Process for machining flame cylinder floating wall tile blocks by adopting annular forgings

ActiveCN108381122AShort manufacturing cycleIncrease productivityContinuous combustion chamberRoughcastGas turbines

The invention relates to the field of aero-engines and gas turbines, in particular to a process for machining flame cylinder floating wall tile blocks by adopting annular forgings. The process comprises a step of preparing annular finished products and a step of molding by cutting; the step of preparing the annular finished products is to machine tile block blanks to prepare the annular finished products; the sizes of the annular finished products are the same with the sizes of cylindrical structures formed by connecting multiple tile blocks end to end; the step of molding by cutting is to cutthe annular finished products to prepare multiple independent tile block initial finished products, so that multiple floating wall tile blocks can be prepared through once machining flow, and the production efficiency is improved; and meanwhile, correspondingly, approximate location degrees of multiple structures on each floating wall tile block can be easily guaranteed, so that the sizes of themultiple floating wall tile blocks prepared in each process flow are the same, structure-stable floating walls are formed in the same flame cylinder, the module assembly requirements can be preferablymet, and the flame cylinders can stably work for a long time.

Owner:广汉天空动力机械有限责任公司

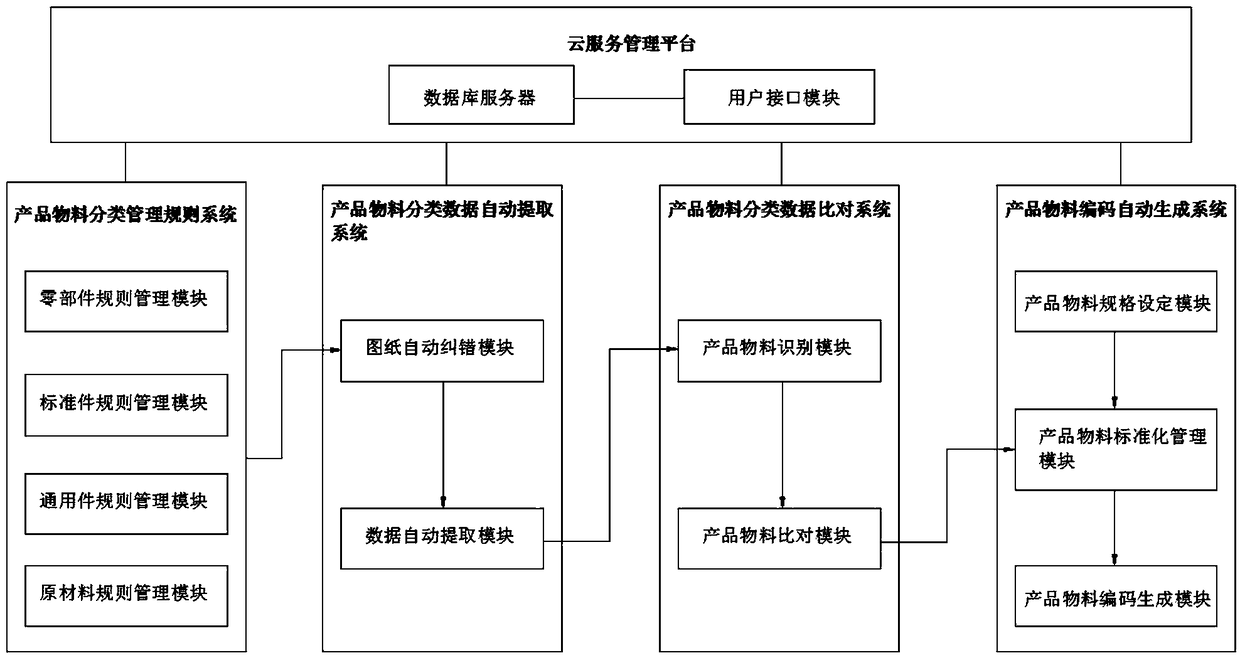

Product material code management method and system

ActiveCN108764773ASolve coding messSolve the difficult control of materialsLogisticsManufacturing computing systemsMaterial classificationDatabase server

The invention relates to a product material code management method and system. Product data can be extracted automatically from a design drawing which satisfies product material classification rules,a product material is identified, product material information is compared with that stored in a database server, and a code is matched or a new code is generated for the product material via an automatic code generation system. A computer cloud platform information technology is used, the product material code is managed scientifically, efficiently and conveniently via a simple flow control method, the problem that that a product cannot be delivered timely due to the fact that enterprise product data and product materials cannot be provided timely is solved, and the working efficiency of an enterprise is improved.

Owner:SAIMO ELECTRIC

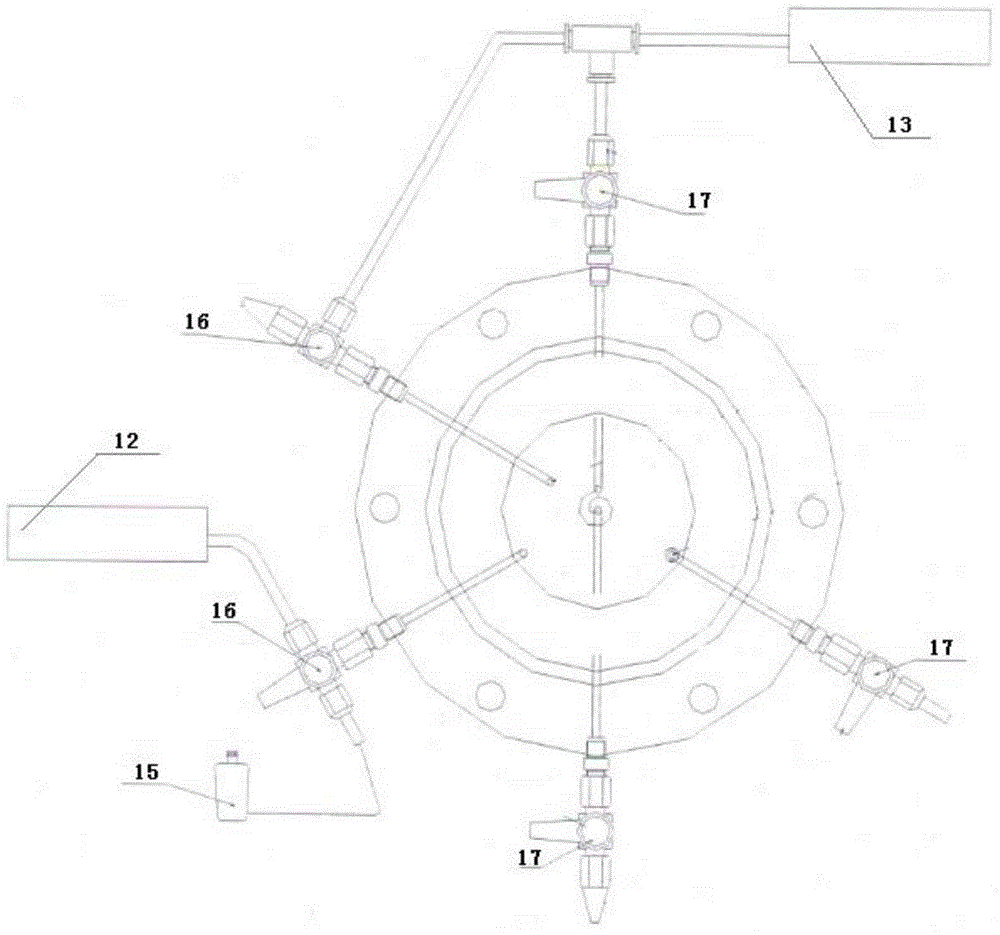

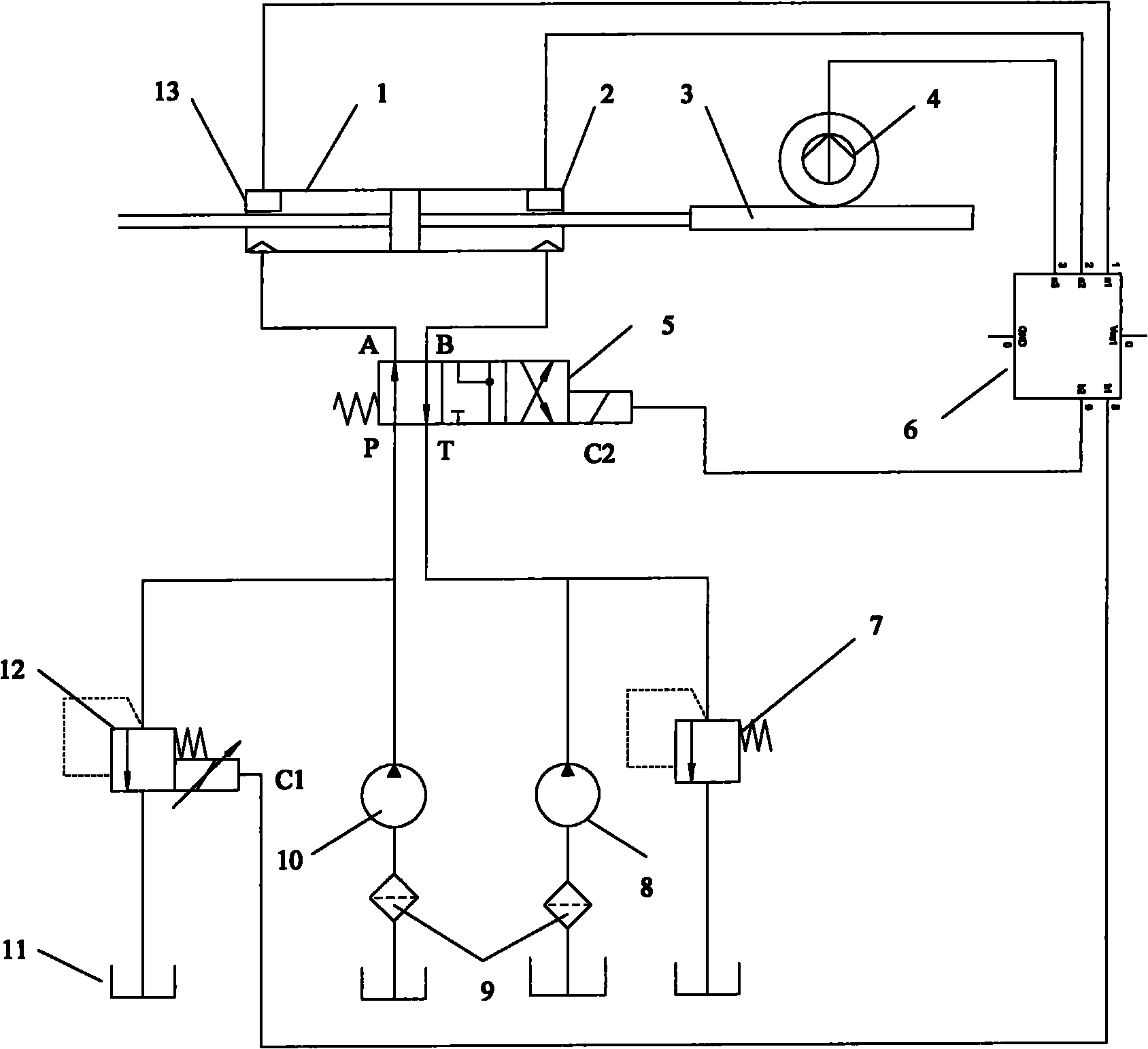

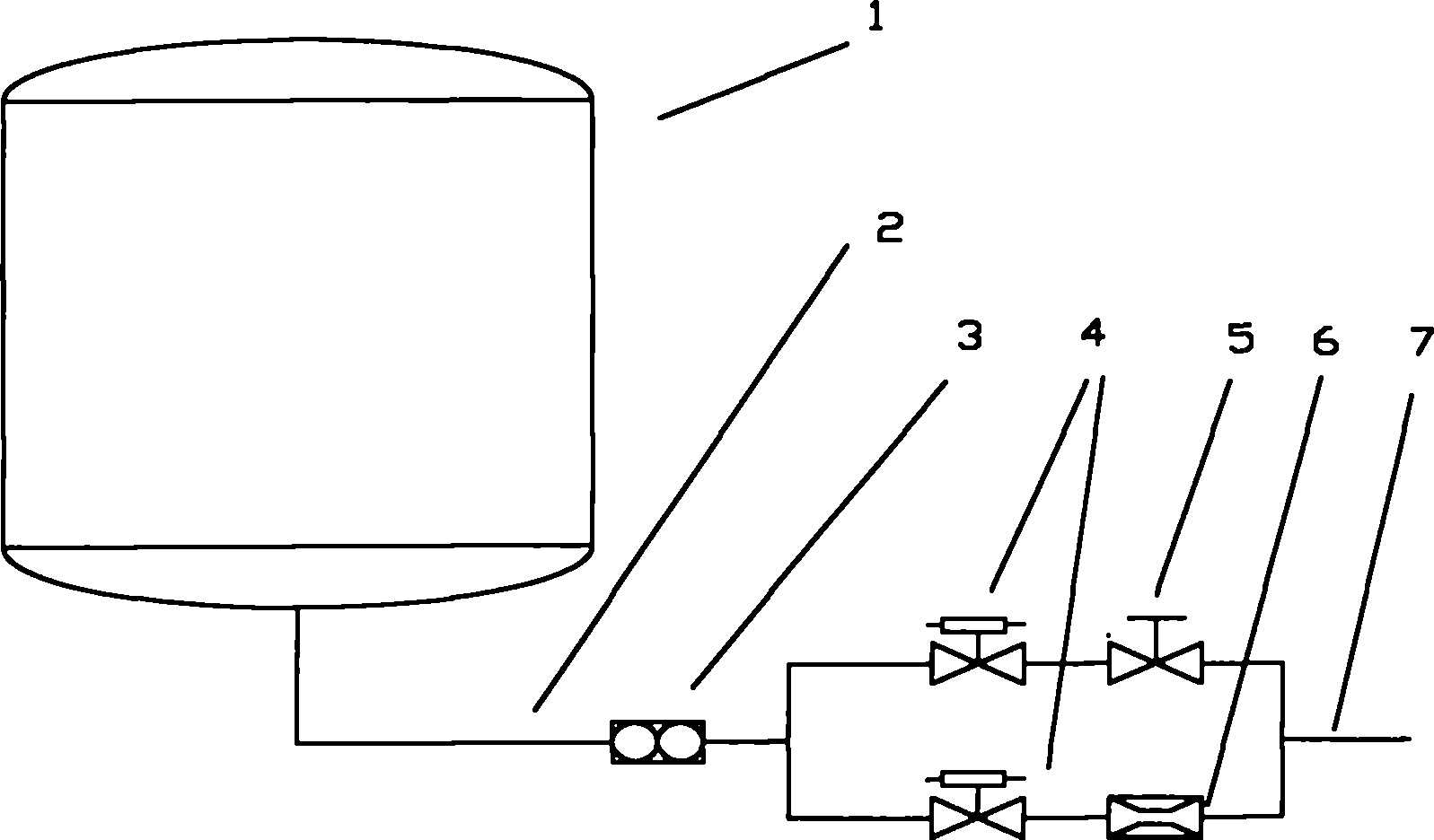

Resistance simulation device for wire-control steering test bed of automobile

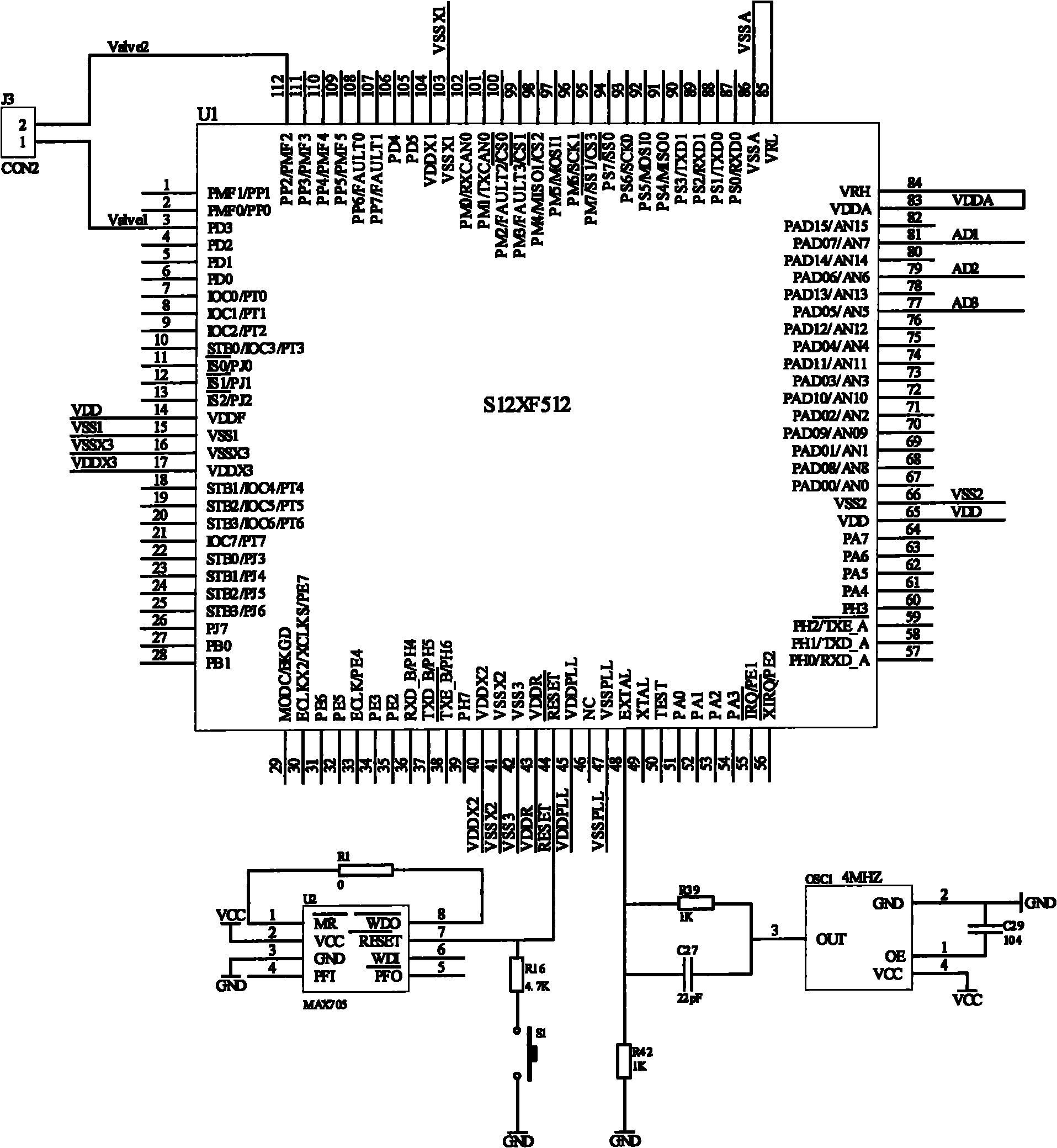

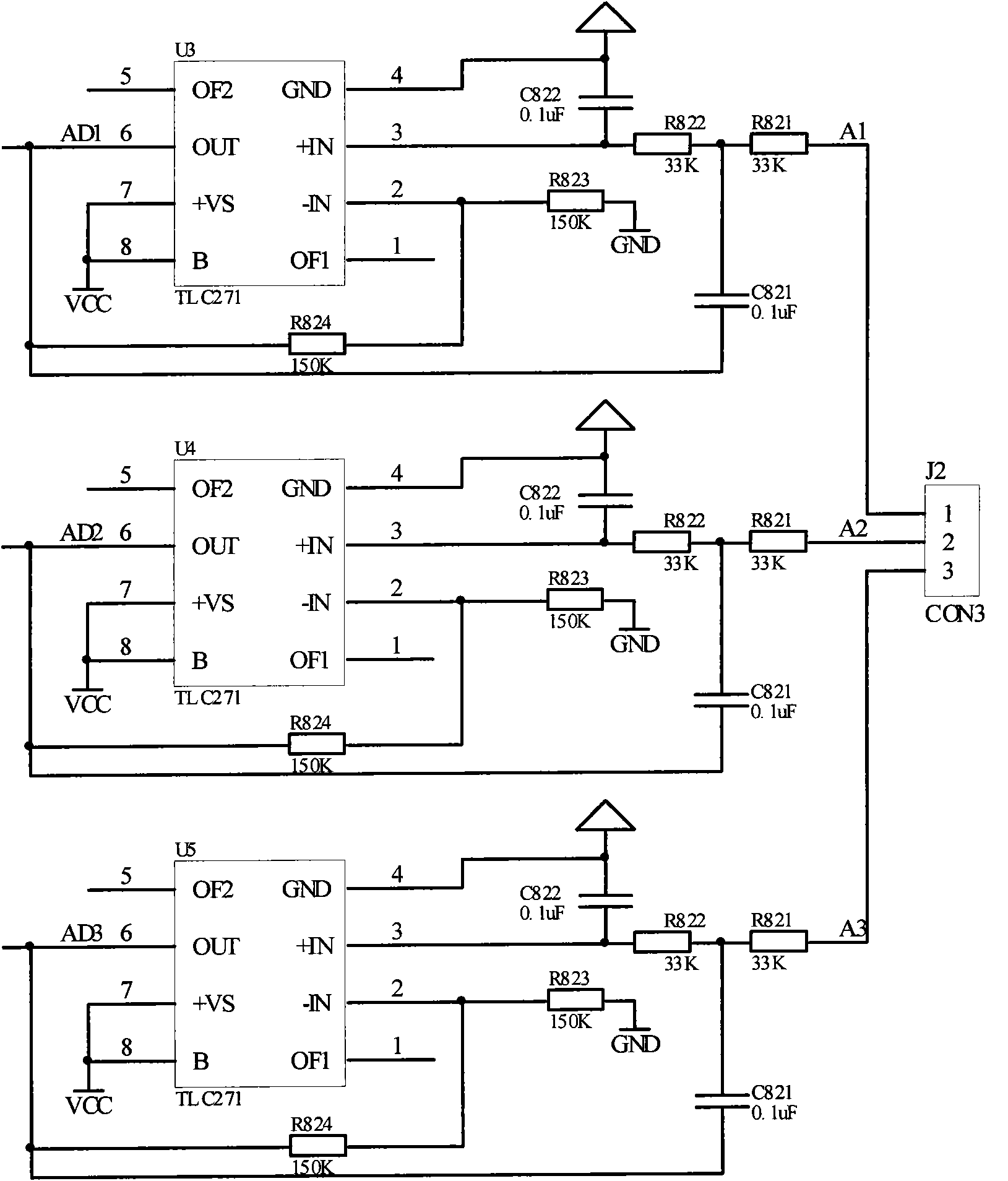

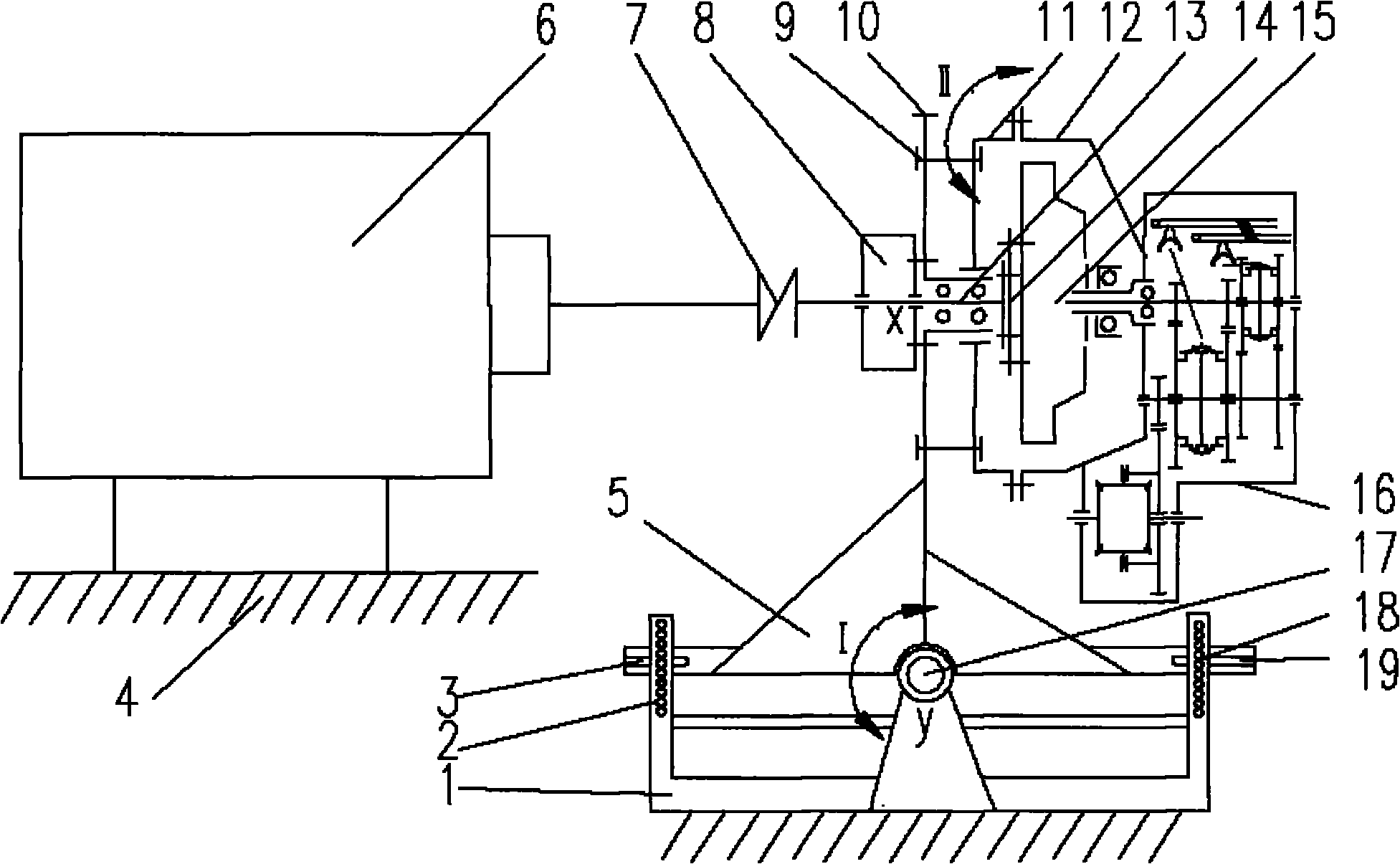

InactiveCN101865777APrecise resistanceResistance is precisely controlledVehicle steering/rolling behaviourEngineeringMechanical engineering

The invention discloses a resistance simulation device for a wire-control steering test bed of an automobile. A piston rod of a load cylinder (1) is connected with a gear rack (3) of a steering executing mechanism of the automobile to act a lateral force on a rack mechanism (3) to simulate the ground lateral resistance stressed during the steering of the vehicle. An oil inlet and an oil outlet of the load cylinder (1) are connected with working oil ports A and B of an electromagnetic directional valve (5) respectively; the oil inlet P of the electromagnetic directional valve (5) is connected with the oil outlet of a main pump (10); the oil outlet of the main pump (10) is connected in parallel with an electromagnetic proportional overflow valve (12); the oil inlet of an overflow valve (7) is connected in parallel with an auxiliary pump (8); the oil inlets of the main pump (10) and the auxiliary pump (8) are connected with a filter (9); and a resistance simulation controller (6) is connected with the electromagnetic directional valve (5) and the electromagnetic proportional overflow valve (12) to output a current signal to the electromagnetic proportional overflow valve (12) so as to control the overflow pressure of the electromagnetic proportional overflow valve (12).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

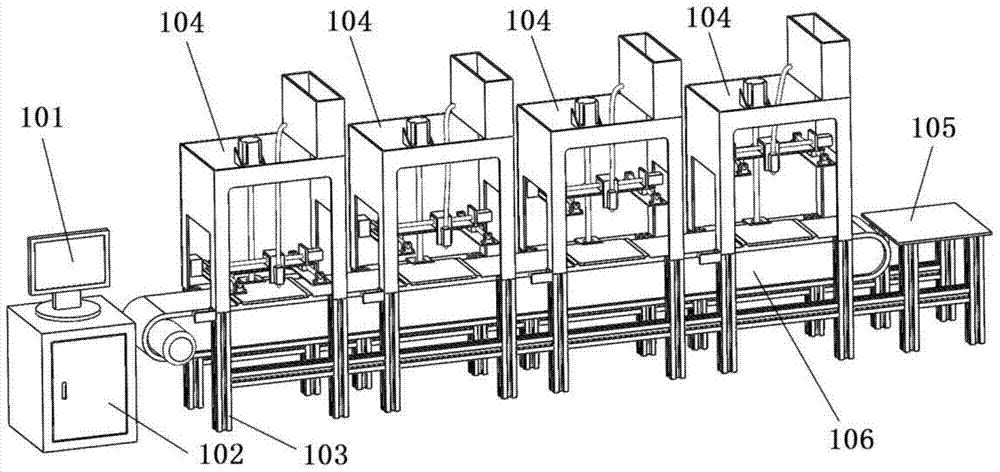

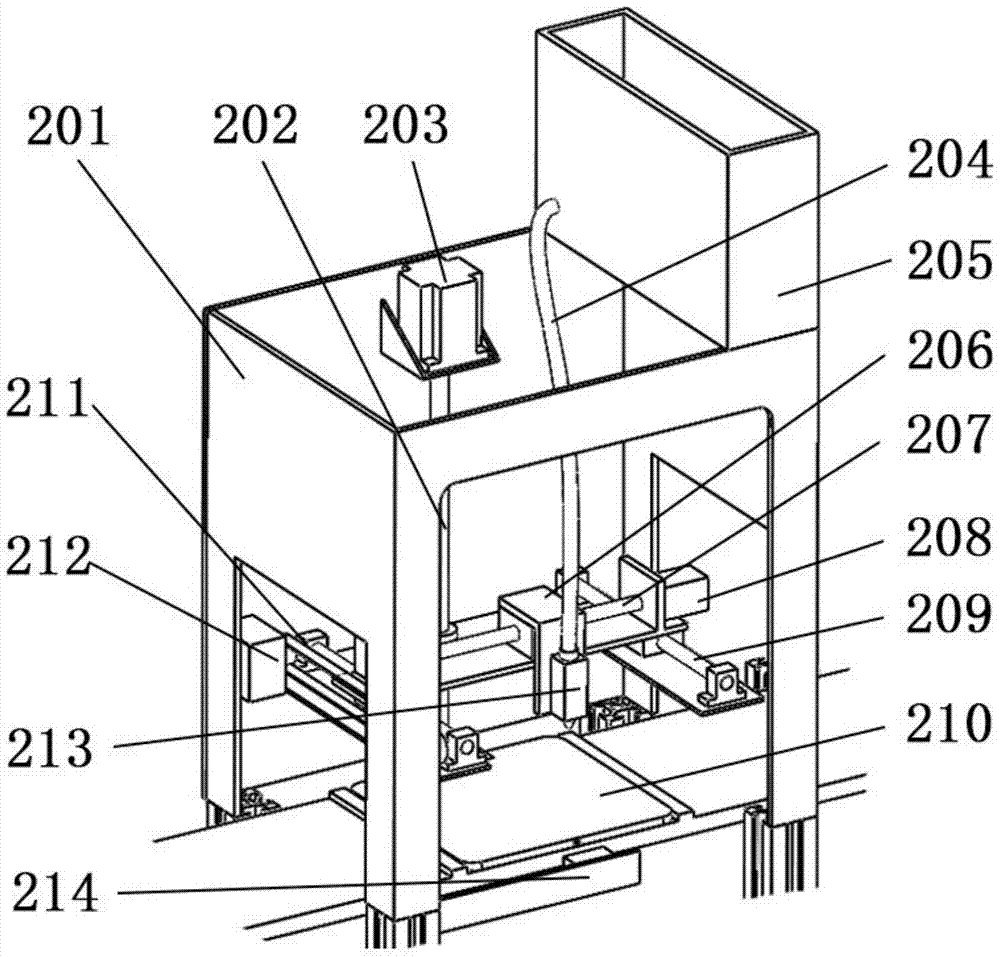

A parallel multi-station 3D printer

ActiveCN105196549BIn line with modern industrial productionEasy to findAdditive manufacturing apparatusManufacturing data aquisition/processingAssembly lineEngineering

The invention provides a novel parallel multistation type 3D printer suitable for a rapid prototyping technology. The novel parallel multistation type 3D printer includes a computer, a bracket, a 3D printer set, and a conveyor belt system, wherein the 3D printer set comprises 3D printers arranged on multiple stations side by side according to needs, printing tasks are regulated and controlled by the computer, and the parallel type assembly line printing is realized. During single small batch production, tasks of the printers on all the stations can be guaranteed to be distributed evenly, and workers can be allowed to perform uniform ordered post-treatment on printed parts. A traditional intermittent working way is changed, the production efficiency is improved, the production cost is reduced, the product development cycle is accelerated, and the parallel multistation type 3D printer has important application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

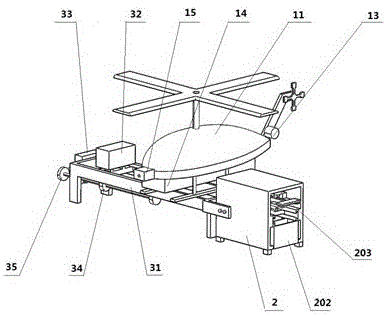

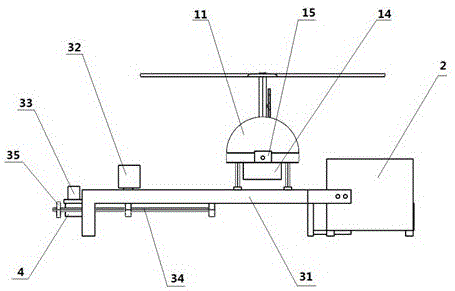

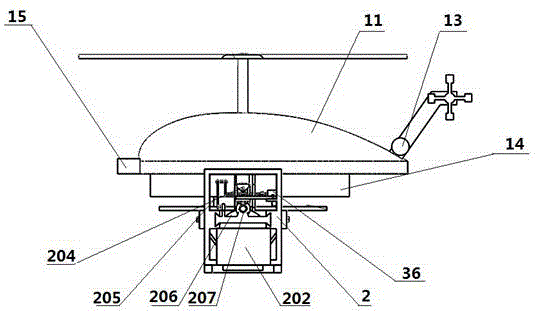

Overhead welding and cutting equipment

ActiveCN105081558AIncrease heatEasy to replaceAlumino-thermic welding apparatusMarine engineeringWeight adjustment

The invention relates to a self-propagating reaction and an unmanned aerial vehicle welding and cutting technology, in particular to unmanned aerial vehicle welding and cutting equipment based on the self-propagating reaction. The whole equipment comprises an unmanned aerial vehicle, an unmanned aerial vehicle auxiliary part, a self-propagating reaction welding / cutting part and a rack and balance weight part. The unmanned aerial vehicle can fly to a working area. The unmanned aerial vehicle auxiliary part controls the unmanned aerial vehicle and monitors environments in real time, so that smooth work is guaranteed. The self-propagating reaction welding / cutting part serves as a main working body, and a self-propagating reaction soldering pencil is used for guiding metallic solutions to flow and controlling heat release directions to achieve welding / cutting. The rack and balance weight part bears and is connected with the other parts and carries out real-time balance weight adjustment in the whole working process so as to guarantee stable operation of the equipment. The self-propagating reaction and the unmanned aerial vehicle are combined, the equipment is simple in structure, safe to operate, high in transportability, low in cost, and capable of improving the working rate, shortening the working cycle and completing welding / cutting tasks of various materials on various occasions.

Owner:成都银河动力有限公司

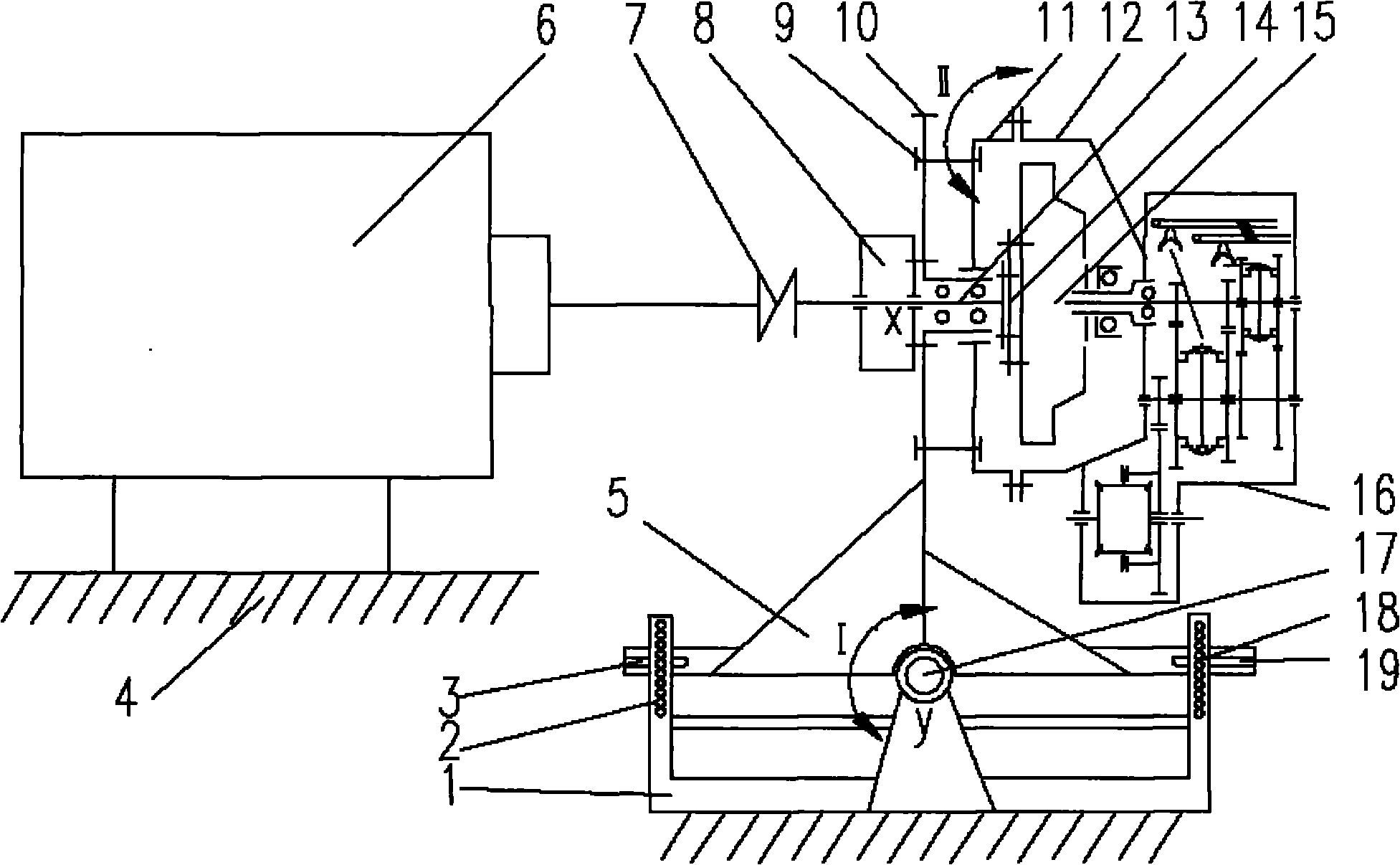

Pose adjustable rack for automotive transmission test

ActiveCN101975665AShorten the preparation cycleImprove versatilityVehicle testingMachine gearing/transmission testingAngular degreesAutomotive transmission

The invention discloses a pose adjustable rack for an automotive transmission test. The pose adjustable rack is provided with an x-axis rotary adjusting mechanism and a y-axis rotary adjusting mechanism, wherein the y-axis rotary adjusting mechanism comprises a transmission mounting frame which is pivoted to a y-axis rotary pivot base and can rotate around a pivot; a y-axis rotary angle scale disc concentric with the pivot is fixed on the y-axis rotary pivot base; and the x-axis rotary adjusting mechanism comprises an x-axis rotary angle scale disc fixed on the transmission mounting frame and a circular mounting panel fixed on the x-axis rotary angle scale disc through a fastening bolt; the circular mounting panel is fixed with a clutch shell connected to the front end of the automotive transmission through a bolt; and the transmission spindle is positioned in the center of the x-axis rotary angle scale disc and is vertical to the pivot in the y-axis rotary adjusting mechanism. The pose adjustable rack can pre-adjust the pose of an automotive transmission before testing, has higher universality, and can reduce the testing cost and shorten the testing time.

Owner:GIF RES CENT CHINA

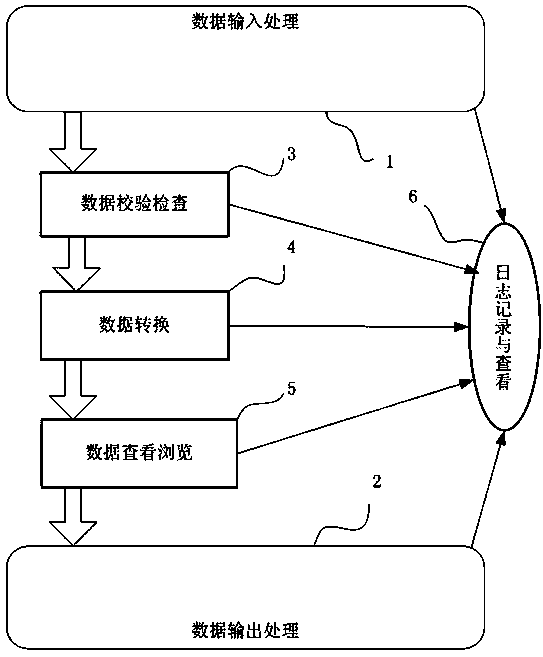

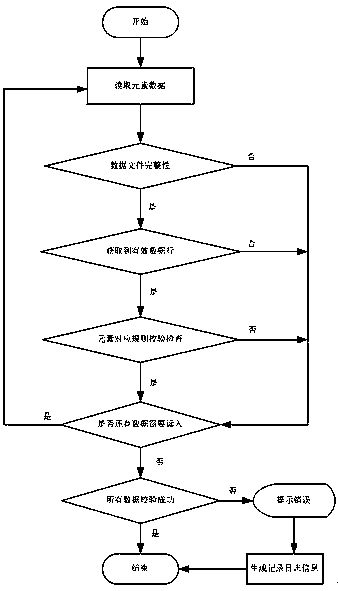

Electronic map data generation system and method for urban rail transit interconnection

ActiveCN109033479AImprove reliabilityImprove accuracyMaps/plans/chartsSpecial data processing applicationsData fileInterconnection

A system for generating electronic map data of urban rail transit interconnection comprises a data input processing module, a data output processing module, a data checking and checking module and a data conversion processing module, wherein the data input processing module inputs a wayside line data file, checks the data file through the data checking and checking module, and then converts the data into electronic map data through the data conversion processing module; or the data input processing module inputs an electronic map data file, checks the data file through the data checking module, and then converts the data into a wayside line data file through the data conversion processing module. The invention also discloses a generation method and an analysis method of an electronic map data generation system based on urban rail transit interconnection, which can not only avoid the drawbacks of manual data compilation, but also improve the reliability and accuracy of the data and shorten the data compilation period.

Owner:SHANGHAI ELECTRIC THALES TRANSPORTATION AUTOMATION SYST CO LTD

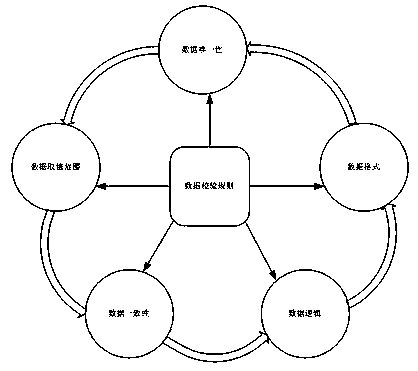

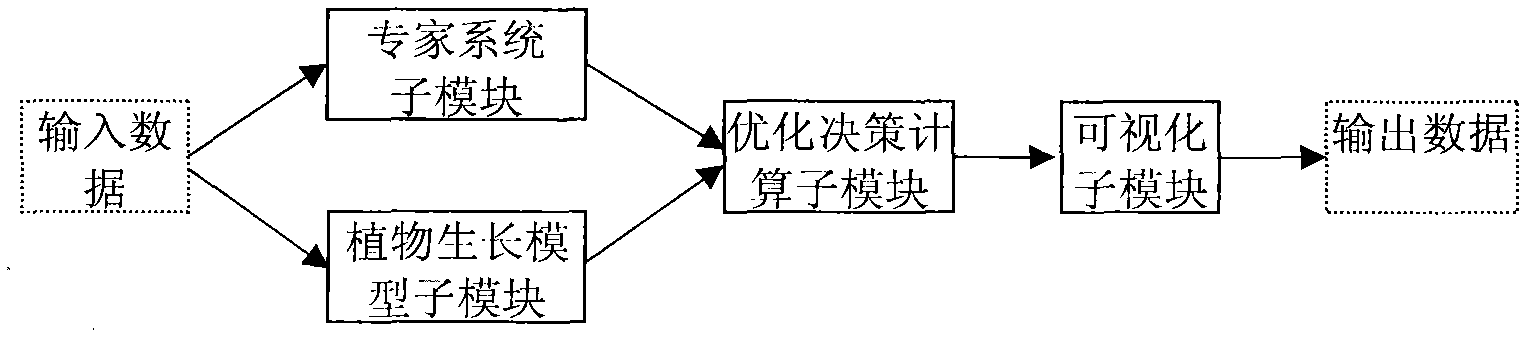

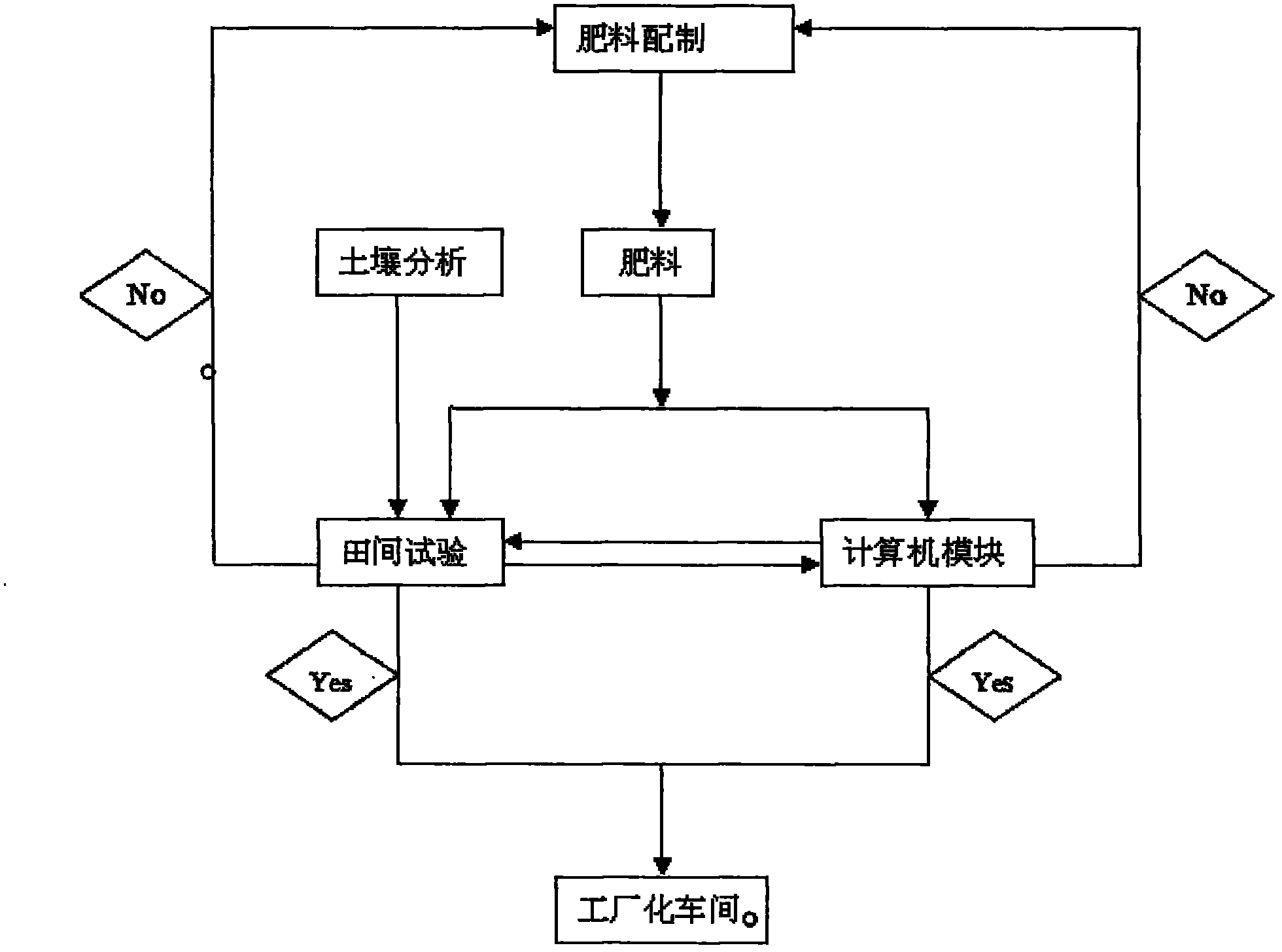

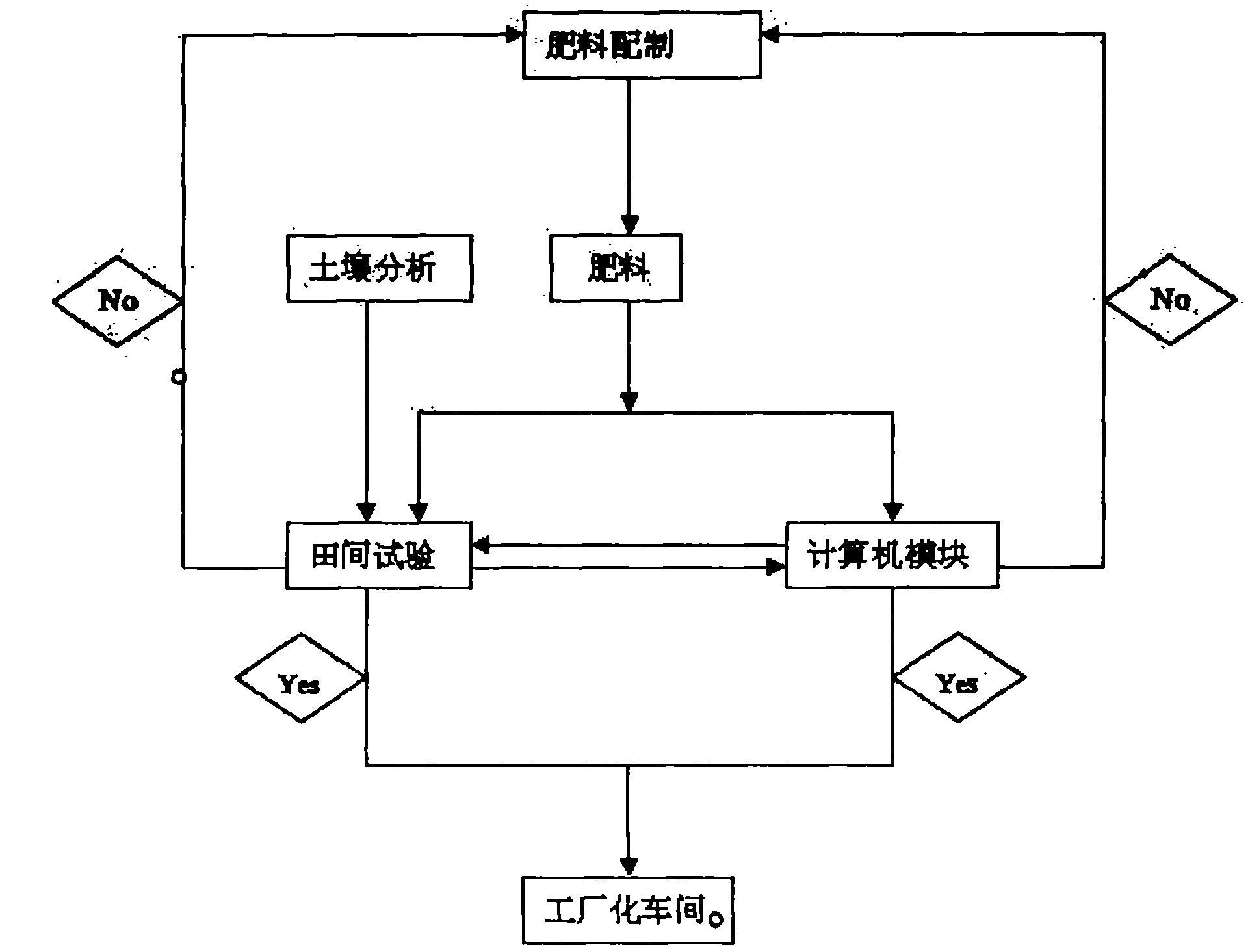

Method and system for preparing fertilizer

InactiveCN102584399AShorten the preparation cyclePrecision fertilizationFertilizer mixturesField testsEngineering

The invention provides a method and system for preparing a fertilizer. According to the method and system, the usage amount, using effect and the like of the fertilizer can be visibly determined by accurately measuring soil data of a certain field, simulating the growing process of plants according to planted plants by virtue of a computer model and performing virtual fertilizing, so that the optimized preparation combination can be achieved, the computer model is constantly corrected through multiple field tests to perfectly combine the soil and the fertilizer, and a new fertilizer preparation period can be greatly shortened while fertilization is accurately performed.

Owner:BEIJING SINO HORIZON AGRI SCI & TECH +1

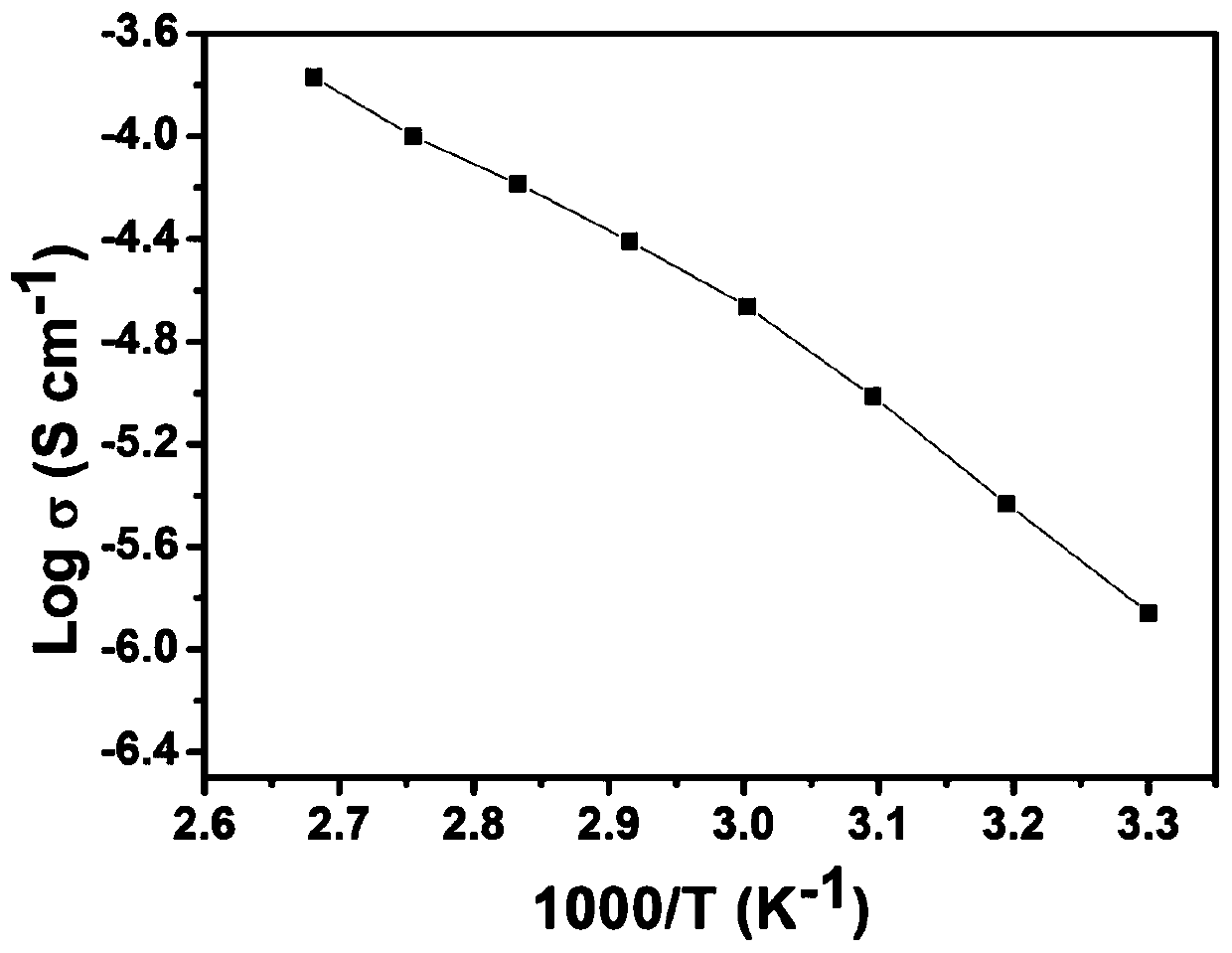

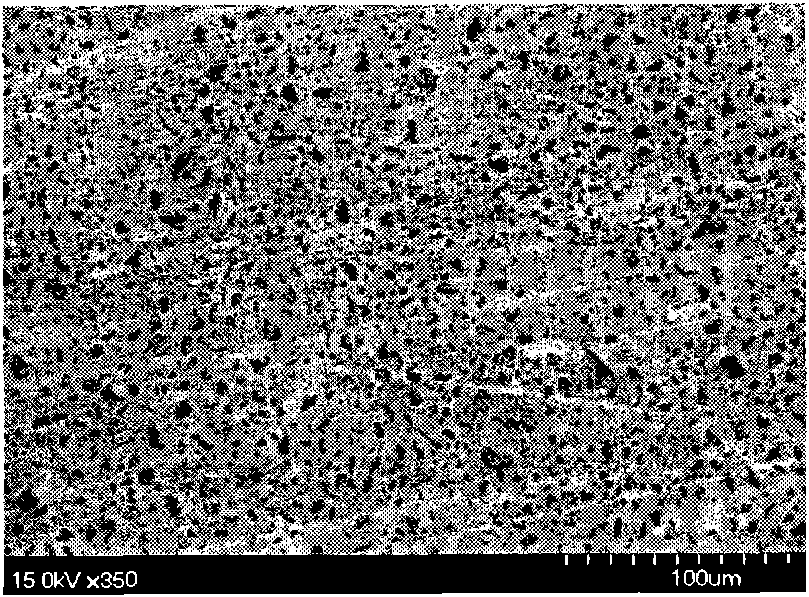

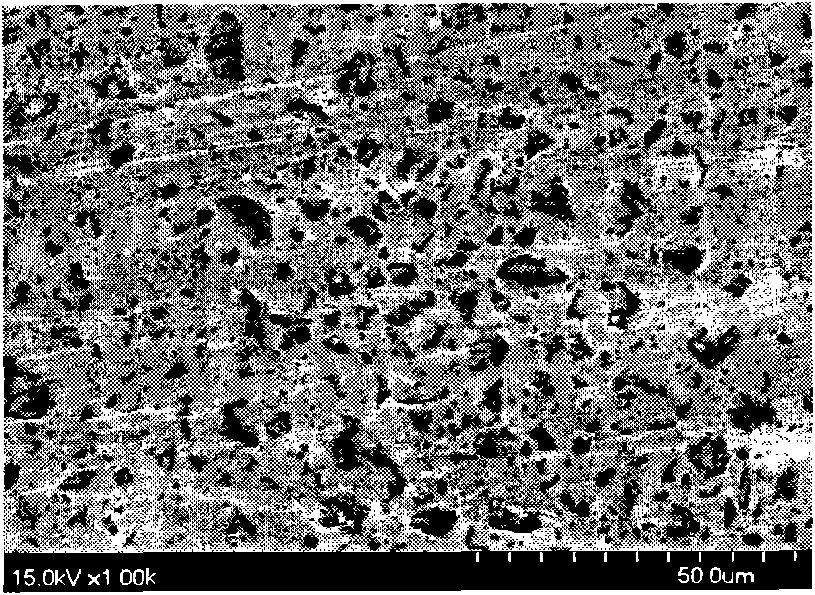

In-situ preparation method and application of polymer electrolyte

ActiveCN110350243AShorten the preparation cycleSimple preparation processSolid electrolytesFinal product manufactureL&D processLithium dendrite

The invention discloses an in-situ preparation method and application of a polymer electrolyte. According to the method, a monomer, an initiator and lithium salt are mixed under the condition that noligands are used; the monomer, the initiator and the lithium salt are uniformly stirred so as to form a precursor solution; a cellulose membrane is soaked in the precursor solution under a protectivegas; heating and a reaction are carried out for 24 hours, so that the monomer is subjected to an atom transfer radical polymerization reaction, so that a polymer and a polymer electrolyte are obtained; and the polymer and the polymer electrolyte are applied to a lithium battery. With the in-situ preparation method and the application of the polymer electrolyte of the invention adopted, the defectssuch as long preparation period, complex process route, organic solvent retention, and introduction of impurities of an existing polymer electrolyte can be eliminated; a technological process is simplified; the growth of lithium dendrites is inhibited; and the problem of electrolyte leakage can be thoroughly solved. With the novel method adopted, the polymer electrolyte for the lithium battery can be simply and effectively prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

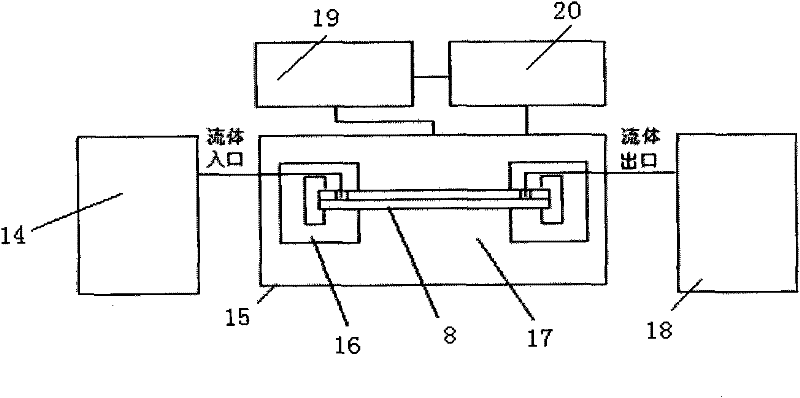

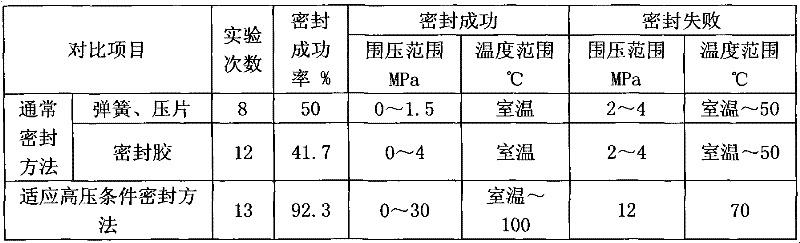

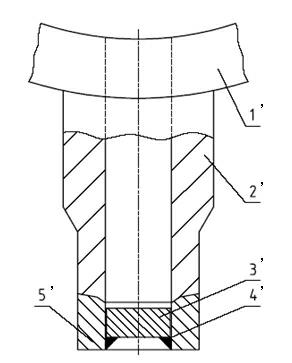

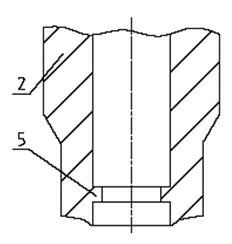

A kind of glass model sealing method

The invention relates to a method for sealing a glass model. The method is realized by a hydraulic sealing clamp, and comprises the following steps of: connecting an inlet of an outer model with an internal thread interface of an upper clamping plate of the hydraulic sealing clamp, and butting an inlet of the glass model with a 2mm back cut; flatly arranging the glass model in the sealing clamp, arranging sealing gaskets on two sides of the inlet of the glass model, slowly injecting machine oil to lift a piston at the lower end of the sealing clamp, clamping the glass model, and closing a needle valve when the pressure is higher than 2MPa; sealing an outlet end of the glass model in the same way; arranging the glass model in the center of an outer model and fixing the glass model; and injecting confining pressure liquid into the outer model for sealing. The problems of leakage and damage of the glass model are effectively solved, and the sealing pressure is quantitatively controlled; and the preparation period of an experiment is shortened, and the efficiency of the experiment is improved.

Owner:PETROCHINA CO LTD

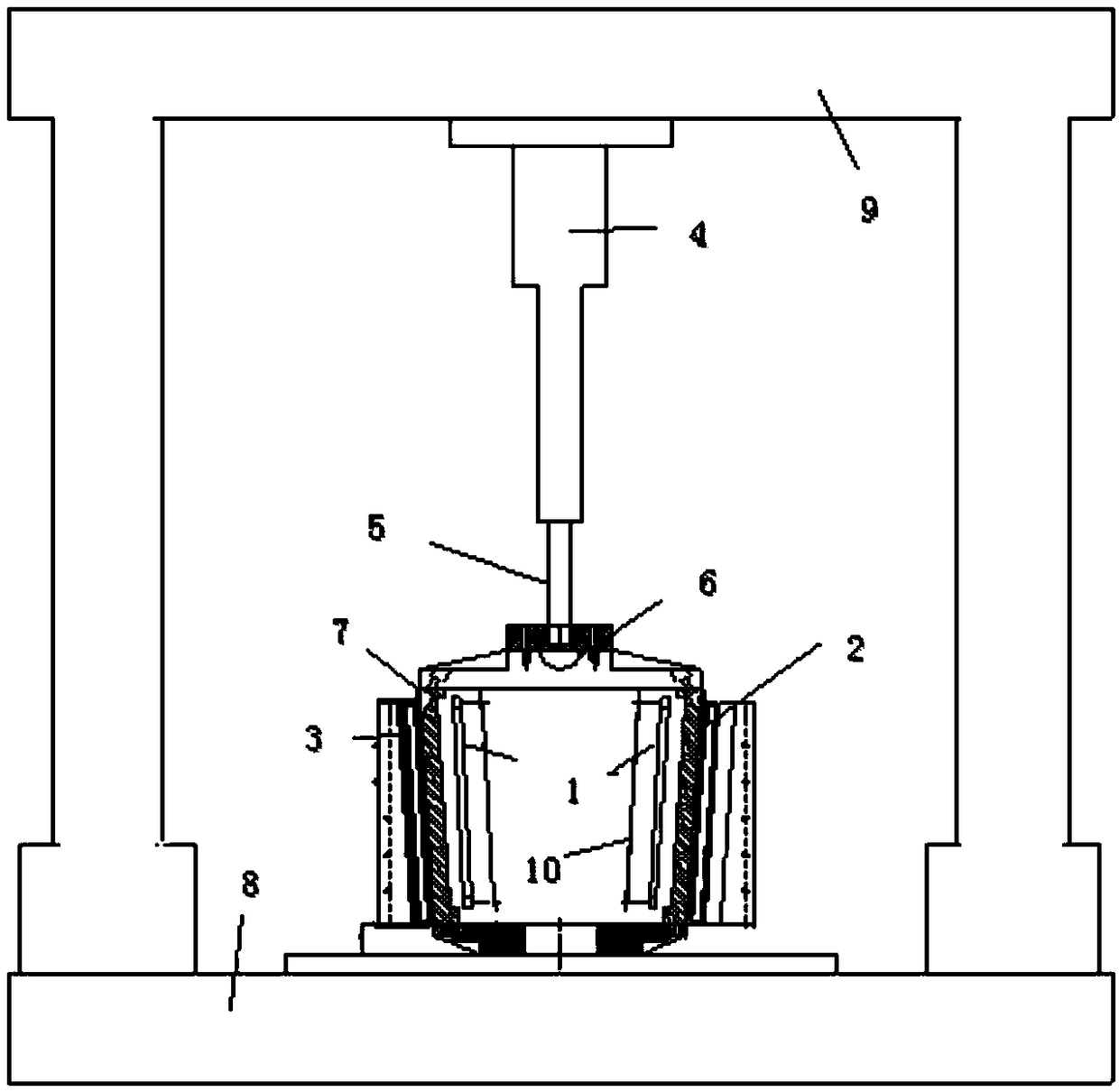

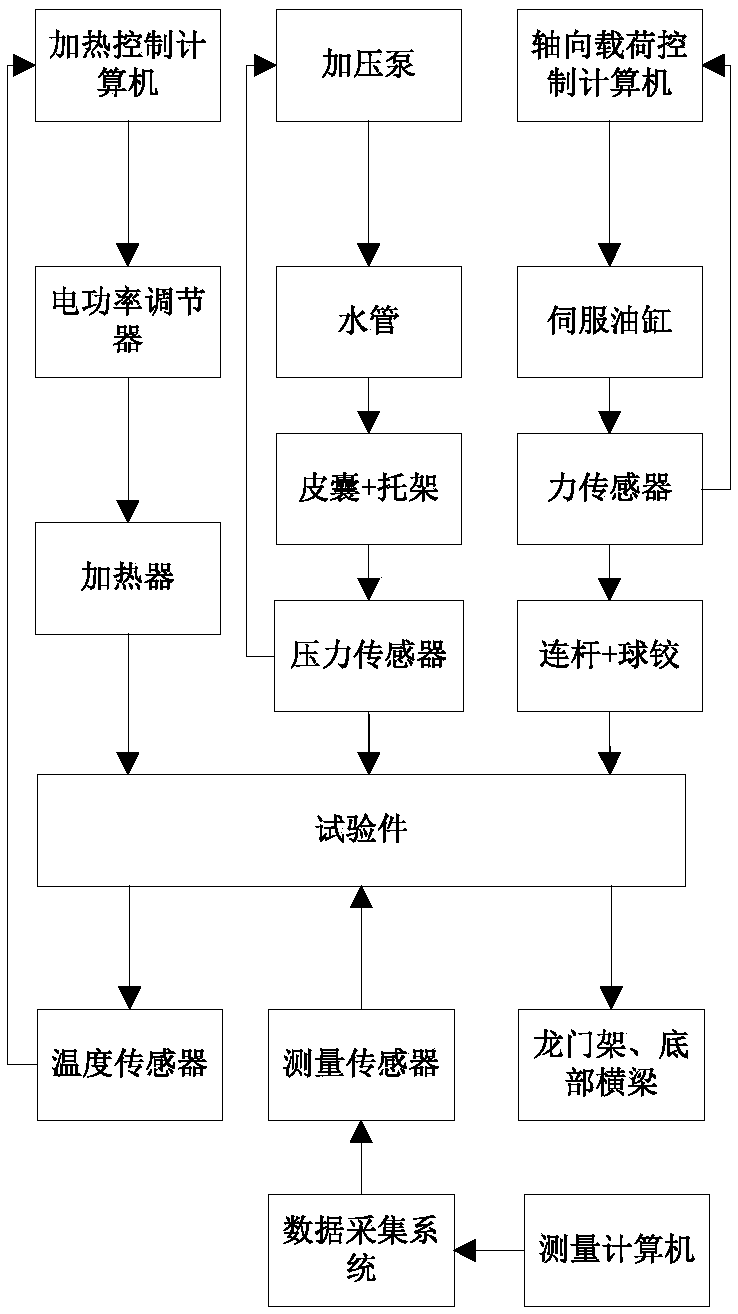

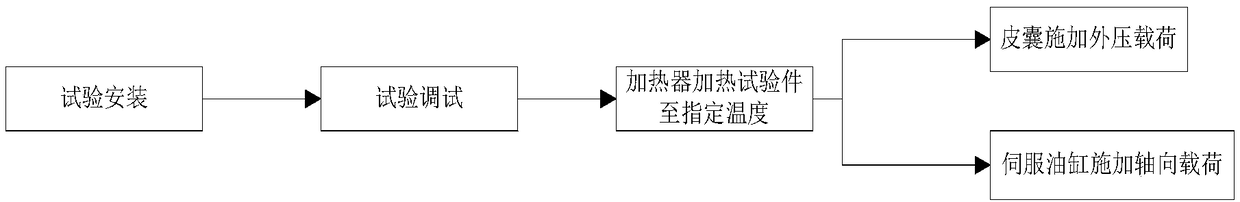

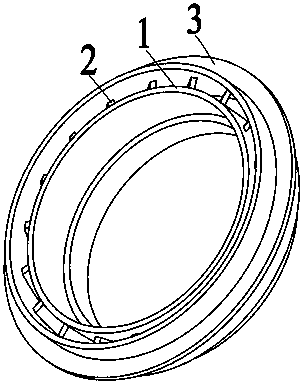

Structural thermal external pressure test system of aircraft cabin sections and method thereof

InactiveCN108918582AImprove test success rateShorten the preparation cycleMaterial heat developmentMaterial strength using tensile/compressive forcesHinge angleExternal pressure

The invention discloses a structural thermal external pressure test system of aircraft cabin sections. The structural thermal external pressure test system comprises a thermal load loading system, anexternal pressure loading system and an axial loading system, wherein the thermal load loading system comprises a heater for heating a test part; the external pressure loading system comprises a leather bag; the shape of the leather bag is as same as that of the outer wall of the test part; the leather bag is coated on the periphery of the test part according to the shape; liquid is added into theleather bag so as to control the pressure; the axial loading system comprises a servo oil cylinder, a connection rod and a spherical hinge; the servo oil cylinder is fixed above the test part; one end of the connection rod is connected with the servo oil cylinder; the other end of the connection rod is connected with the spherical hinge; the servo oil cylinder is started to drive the connection rod move up or down so as to drive the spherical hinge to axially apply axial tension or pressure to the direction of the test part. Through the structural thermal external pressure test system and themethod thereof, the problem of applying the thermal load, the axial tensile load and the external pressure load to the test part when carrying out thermal external pressure test and especially applying the axial tensile load when applying the thermal load and the external pressure load is solved.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

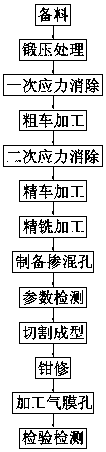

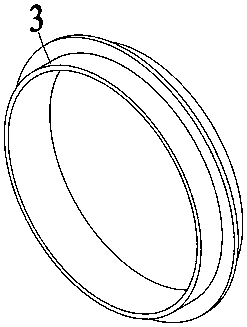

Machining technology method of swirler assembly

ActiveCN108161375AMature metallurgical processSimple metallurgical processAircraft componentsAviationCombustion chamber

The invention relates to the field of aero-engines and gas turbines, in particular to a machining technology method of a swirler assembly in an aero-engine combustion chamber. The swirler assembly iscomposed of a swirler sleeve and a swirler. The swirler sleeve and the swirler each adopt a forged piece as a raw material. The machining technology method of the swirler assembly comprises the stepsof (1) turning, (2) milling or electrosparking, (3) cleaning, (4) trial assembly, (5) positioned welding, (6) brazing filler metal prearrangement, (7) vacuum brazing, (8) pincers machining and (9) finish turning. The machining technology method is simple in operation; and the problems that in the prior art, after precision casting is adopted, a swirler assembly manufactured in a precision machining manner is high in production cost and long in period, the requirements for personnel and skills are high, metallurgical defects are hard to avoid, the size and quality of a casting are instable, therate of finished products is not high, and consequently the service life of a combustion chamber is shortened, and adverse effects are generated to the overall performance of an aero-engine are solved.

Owner:广汉天空动力机械有限责任公司

Preparation method of Pb-Sb-Cd alloy used for positive plate of battery

The invention discloses a preparation method of a Pb-Sb-Cd alloy used for a positive plate of a battery, which takes reducing lead as the raw material and comprises the following steps of (1) heating the raw material of lead to melt the lead, raising the temperature to 400-500 DEG C after the lead is melted, and adding sodium hydroxide to remove arsenic and tin and obtain lead liquid without the arsenic and the tin; (2) cooling the lead liquid without the arsenic and the tin to the temperature of 320-350 DEG C and adding red phosphorus to remove copper and obtain the lead liquid without copper; (3) adding mother antimony into the lead liquid without the copper under the temperature of 420-460 DEG C to obtain the lead liquid with the antimony; and (4) cooling the lead liquid with the antimony to the temperature of 380-400 DEG C, then adding cadmium, stirring uniformly and cooling to obtain the Pb-Sb-Cd alloy. The invention can reduce the alloy preparation cycle which is generally only 9 hours, while the original process needs 15 hours, so the loss of the lead caused by oxidation is reduced, the utilization rate of the lead is increased, and meanwhile, the use amount of fuel oil, coal, electricity and the like is reduced, and the cost is reduced.

Owner:TIANNENG BATTERY WUHU

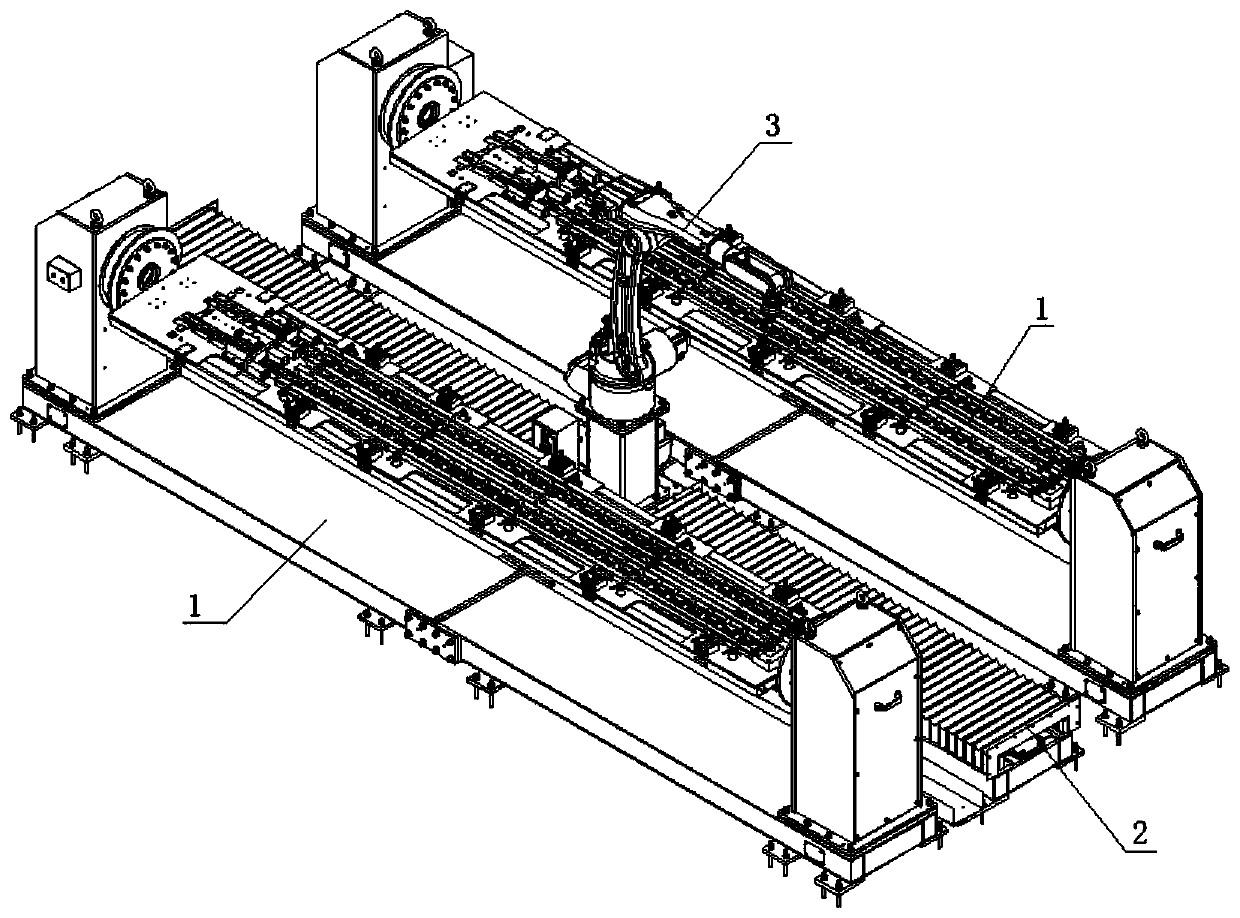

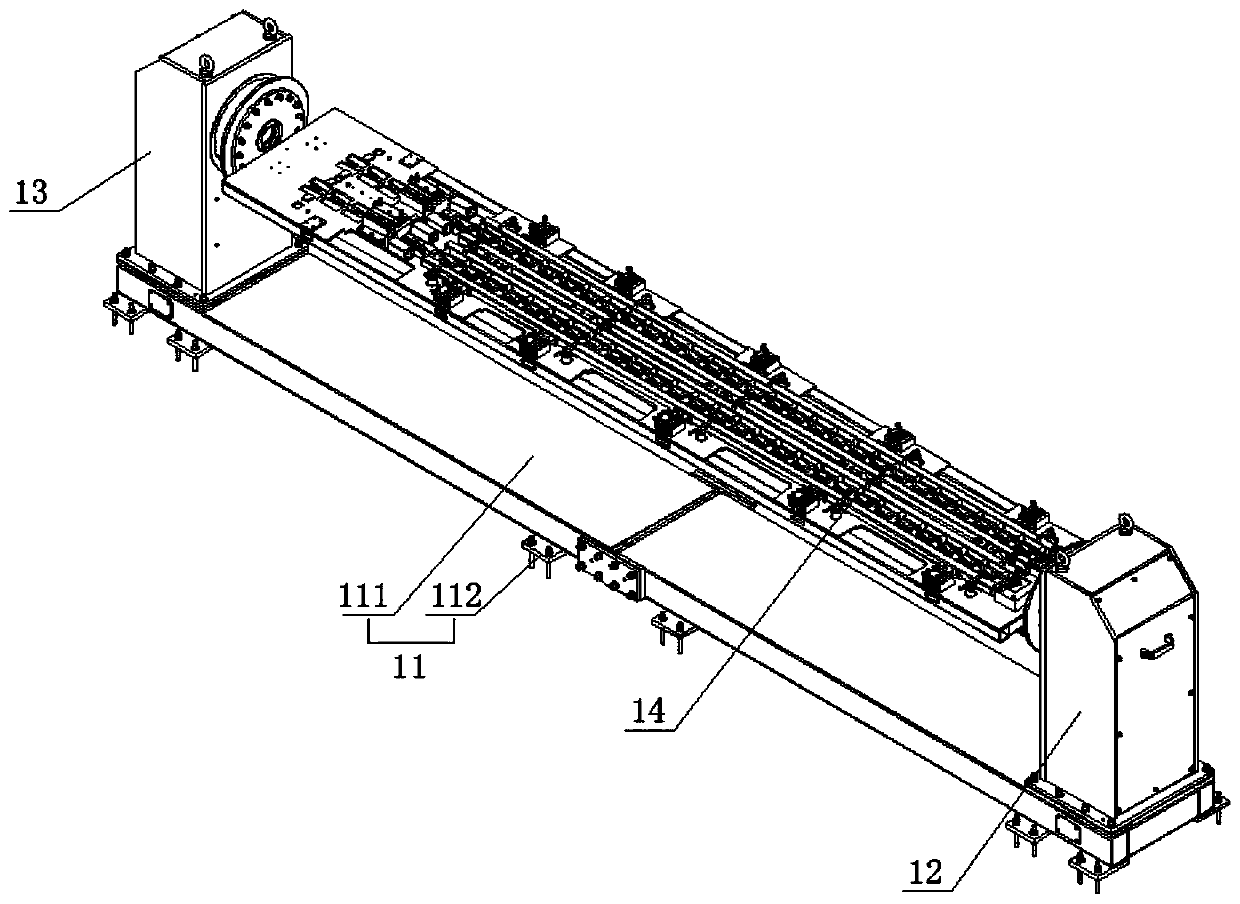

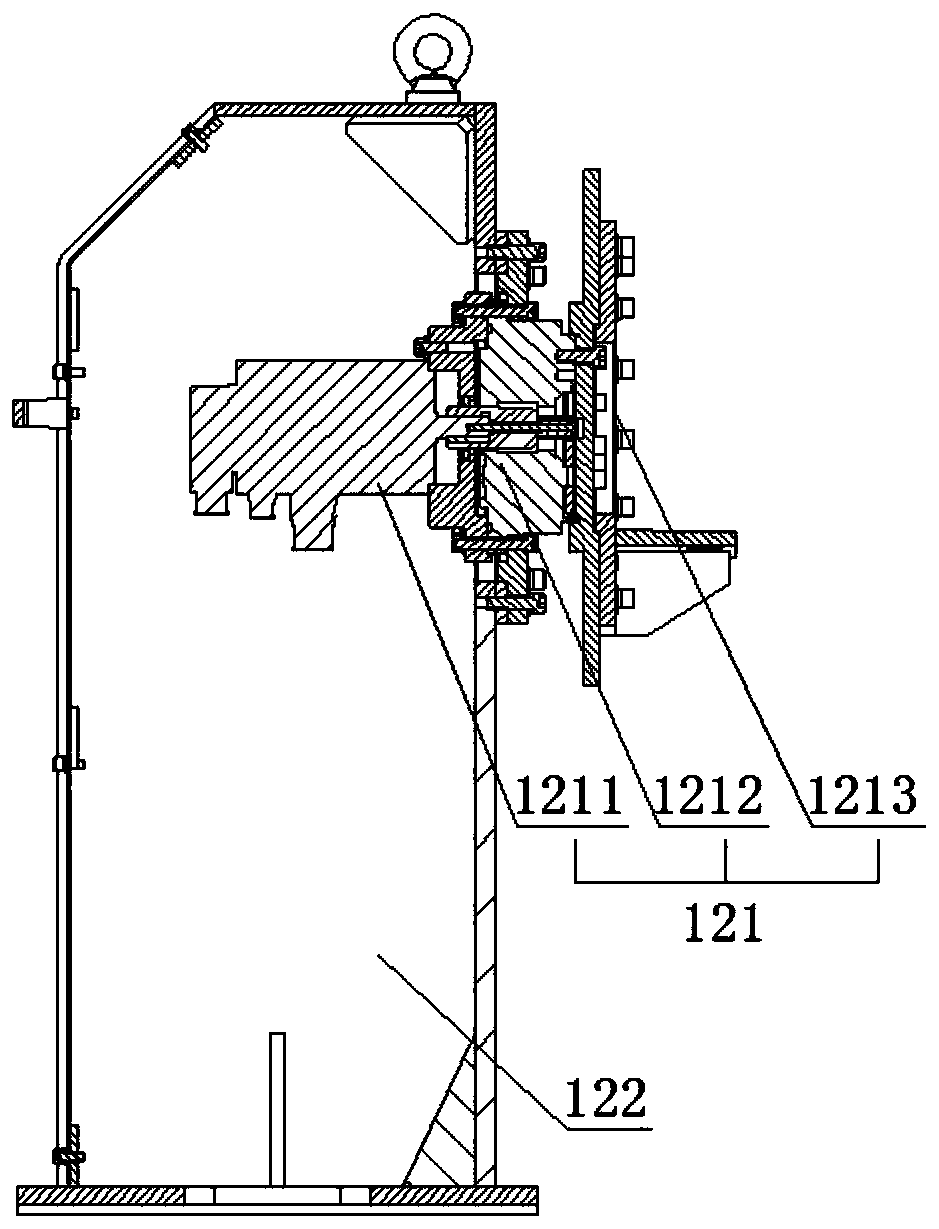

Nine-axis welding robot double-station workstation

PendingCN110561022ALabor savingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSimulationWorkstation

The invention discloses a nine-axis welding robot double-station workstation comprising single-axis positioners. Equipment basic frames are fixedly installed at the lower ends of the single-axis positioners. Anchor bolts are movably installed on the equipment basic frames. Welding frames are fixedly installed on the equipment basic frames. A driving seat assembly is fixedly installed at one end ofeach equipment basic frame, the other end of each equipment basic frame is fixedly provided with a driven seat assembly, and a clamp assembly is movably installed between each driven seat assembly and the corresponding driving seat assembly. A robot walking ground rail is movably installed on the outer side of the single-axis positioners. A six-axis welding robot is movably installed at the upperend of the robot walking ground rail. The nine-axis welding robot double-station workstation is designed on the basis of an existing double-station workstation, the welding robot double-station workstation is added, double stations are adopted for alternate operation, and therefore the effects of saving labor, improving welding efficiency, replacing traditional manual operation and achieving automation are achieved.

Owner:赣州中科拓又达智能装备科技有限公司

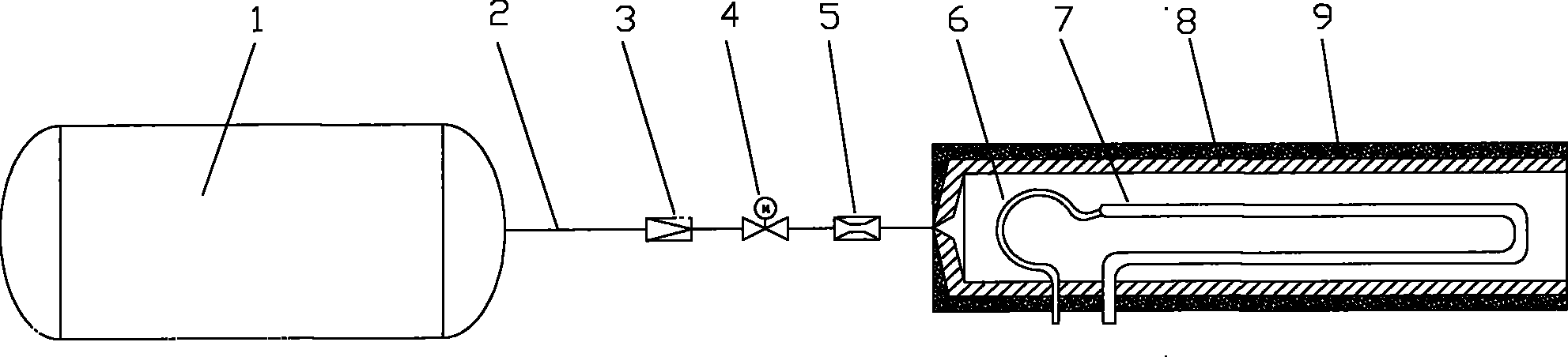

Simulating device for on-rocket liquid-hydrogen temperature zone cold-helium heater

The invention discloses a simulating device for an on-rocket liquid-hydrogen temperature zone cold-helium heater and the simulating device is used for simulating the work performance of a cold-helium heater of a carrier-rocket engine. The simulating device includes devices such as a high-pressure nitrogen storage tank, a connection pipe, a reducing valve, an electromagnetic valve, a bore plate, an on-rocket heat exchange pipe, a process heat exchange pipe and an insulating layer and the like. Normal-temperature nitrogen enters an entrance of a casing after being limited in flow by the bore plate and scours the outer wall faces of the on-rocket heat exchange pipe and the process heat exchange pipe so as to carry out heat exchange. Code helium internally flows in the on-rocket heat exchange pipe and the process heat exchange pipe and carries out heat exchange with the inner wall faces of the pipes so that the temperature of the cold helium is enabled to rise to a specific value and then the helium goes to a user pipe via an exit of the process heat exchange pipe. When the temperature of helium at the exit of the process heat exchange pipe needs to be adjusted, only the opening degree of the reducing valve needs to be adjusted. The cold-helium heat exchange pipes are capable of working at a liquid-hydrogen temperature zone and the entrance temperature can be lower than 20k and when the flow of the helium is at XX-XXg / s, the exit temperature is within a range of XX-XX K. The simulating device is capable of simulating the on-rocket heater in a comparatively well manner and the exit temperature range of the low-temperature helium is adjustable and operation is simple and convenient; and the outer walls of the cold-helium heat exchange pipes are free from freezing so that the work reliability is high and cost input is low.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

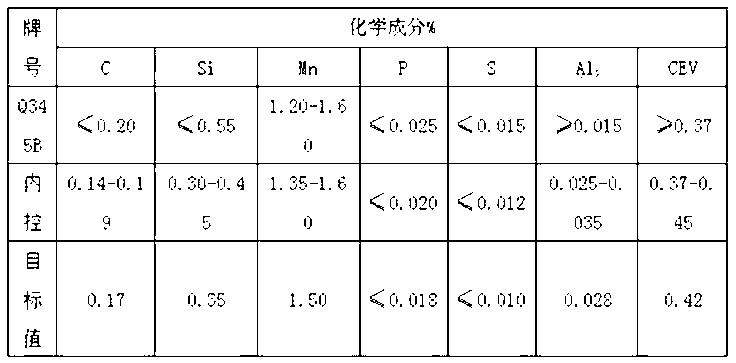

Low-cost steel-making process for manufacturing flaw detection plate

InactiveCN103074466AReduce the degree of segregationImprove the qualified rate of flaw detectionSteel platesSlag

The invention relates to a low-cost steel-making process for manufacturing a flaw detection plate, which belongs to the technical field of steel-making operation processes. The technical scheme adopted by the process is as follows: (1), low-temperature tapping of a converter; (2) furnace slag washing; (3), ingredient high alumina control, ladle furnace (LF) deep deanlphurization, and atmosphere control; (4), fore-and-aft substantially rocking furnace; (5), slightly continuous casting pressing; (6), pouring descending order control; (7), casting blank stacking slow cooling; and (8), ensuring the thickness ratio of a casting blank and a steel plate to be greater than 8:1. The low-cost steel-making process has the advantages and benefits that the process is simple and convenient, saves a technical procedure of vacuum treatment, is a new way for preparing a low-cost flaw detection plate, has a more remarkable effect particularly aiming at products with thickness less than 30 mm, can reach a flaw detection qualified rate over 99 percent, achieves that the flaw detection plate is manufactured by utilizing a short refining process, and lowers manufacturing cost; and in addition, a single refining process route overcomes the defect of large difficulty of double refining manufacturing organization, greatly shortens the periods of the manufacturing organization and preparation, and achieves efficient production, and the process has higher application popularization value.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

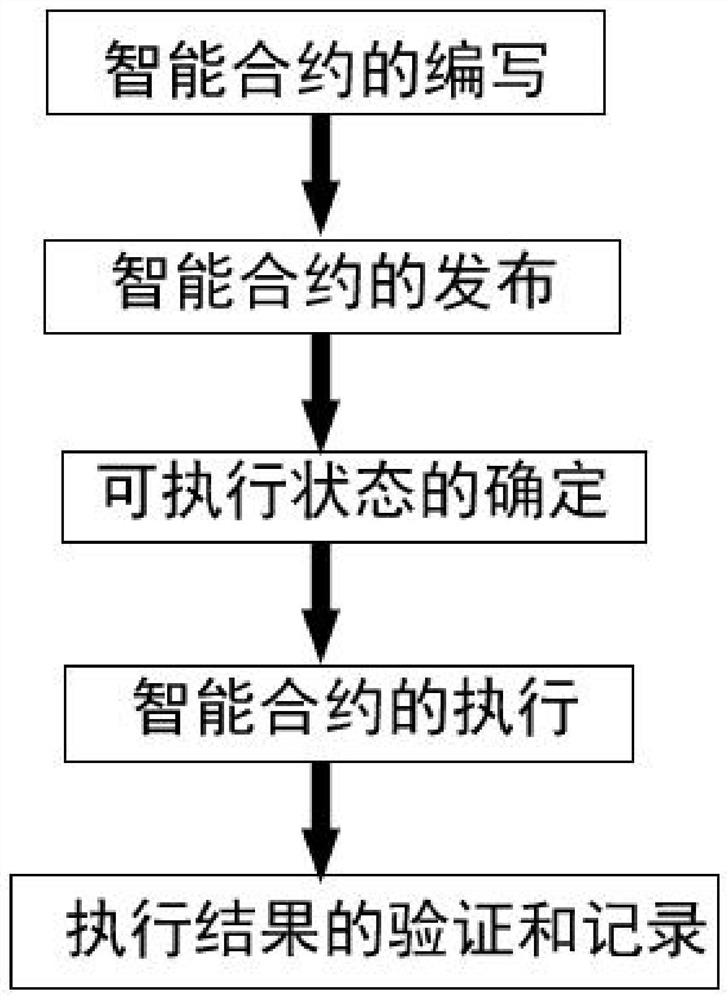

Multi-party secure computing implementation method based on block chain technology

PendingCN112115204AEnhanced authenticationImprove audit effectDatabase updatingFinanceData securitySmart contract

The invention discloses a multi-party security computing implementation method based on a blockchain technology. The method specifically comprises the following steps: step 1, compiling an intelligentcontract, wherein the intelligent contract comprises node information of each contract party, tasks of each contract party for executing the intelligent contract and task execution relationships among the tasks; step 2, publishing the intelligent contract: publishing the intelligent contract on the block chain; 3, determining an executable state: after the intelligent contract is authorized by related nodes of each contract party of the intelligent contract, determining the intelligent contract as the executable state; step 4, executing the intelligent contract, wherein different contract parties have own unique business accounts, log in node servers of nodes through node accounts of the nodes and execute tasks of the intelligent contract on the blockchain; and step 5, carrying out verification and recording of an execution result, wherein the nodes which do not participate in the intelligent contract carry out verification and state recording of the contract execution result. According to the invention, the problems of data security and privacy in the data cooperation process are solved.

Owner:DATANG NETWORK CO LTD

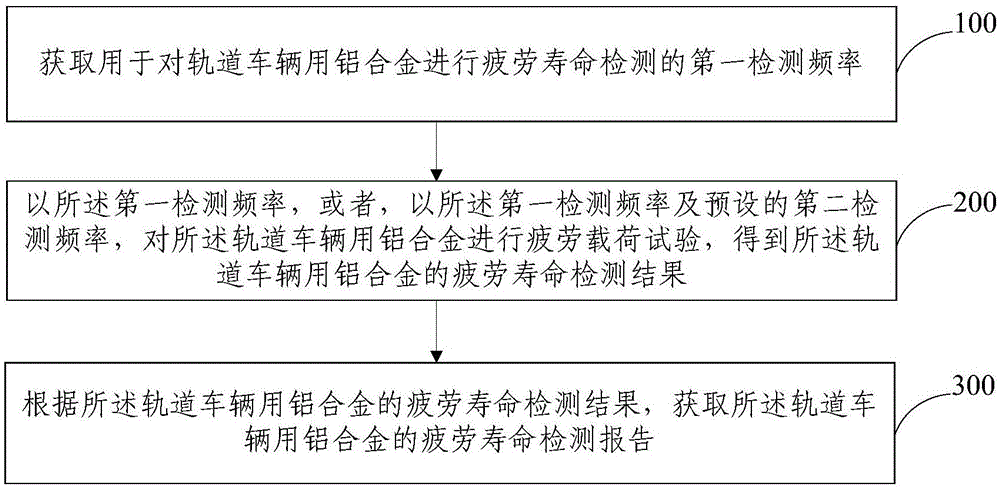

Fatigue-life detection method and system for aluminium alloy for railway vehicles

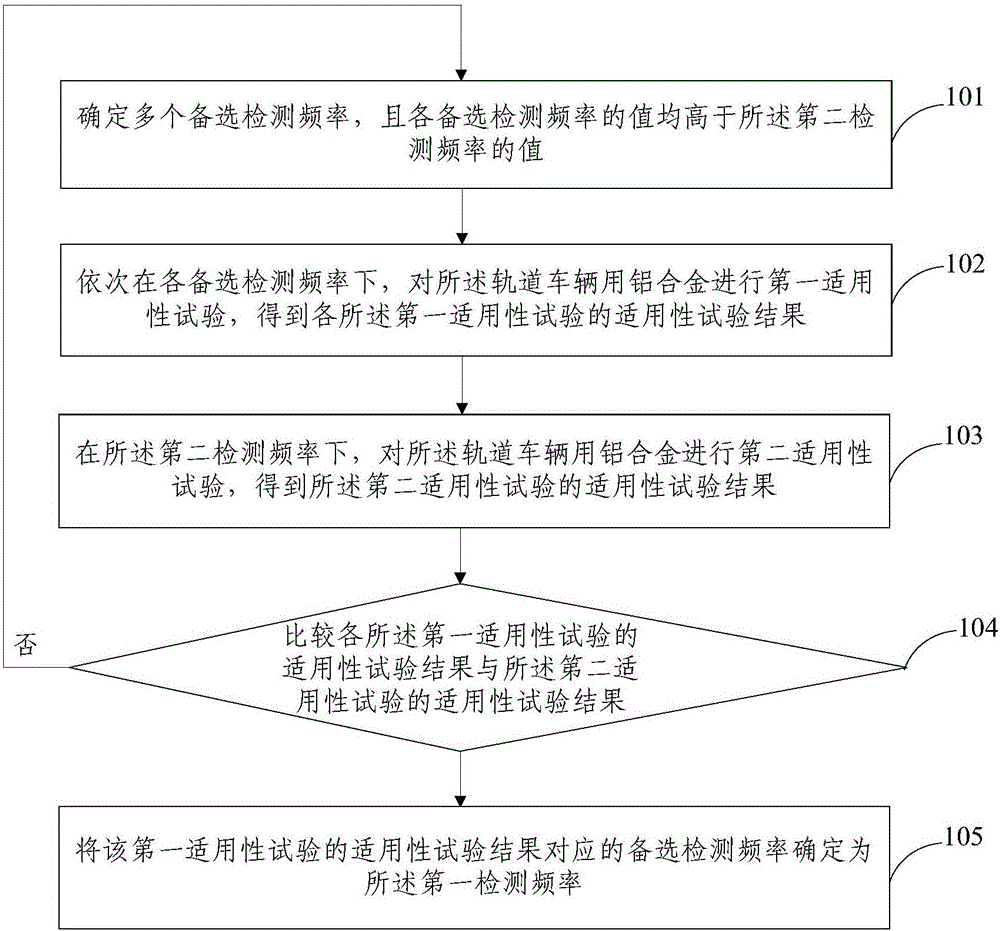

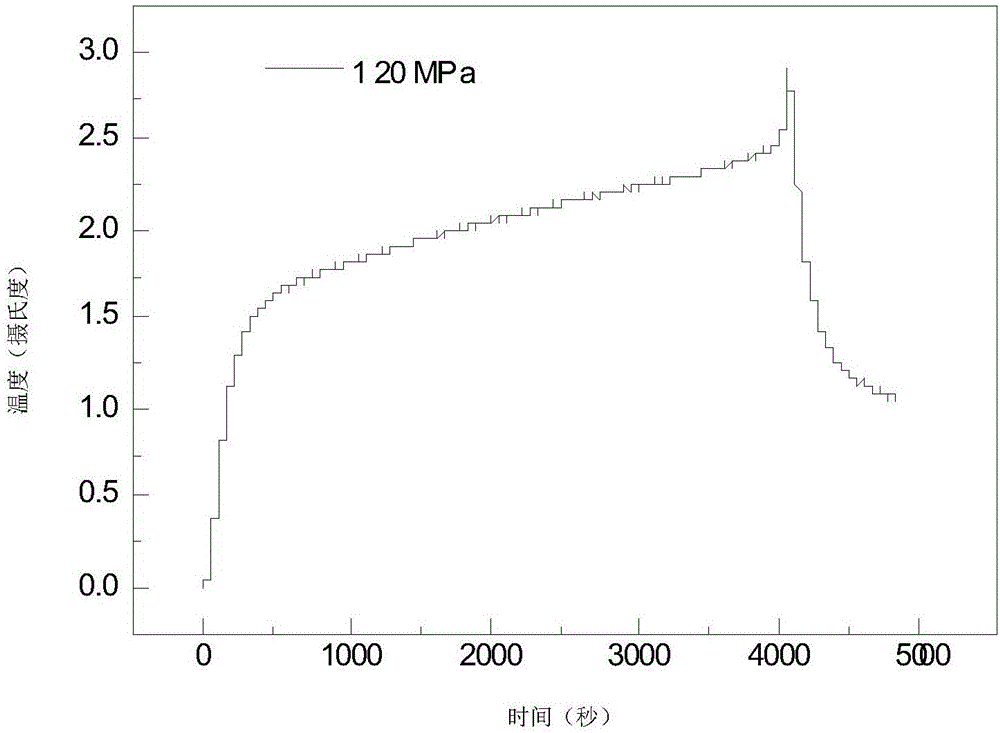

ActiveCN107525725AShorten fatigue test cycleReduce testing costsMachine part testingRailway vehicle testingFatigue loadingMetallurgy

The invention provides a fatigue-life detection method and system for aluminium alloy for railway vehicles. The fatigue-life detection method comprises the following steps: acquiring first detection frequency for detecting the fatigue life of the aluminium alloy for railway vehicles; using the first detection frequency or the first detection frequency and preset second detection frequency to carry out fatigue load test on the aluminium alloy for the railway vehicles to obtain a fatigue-life detection result of the aluminium alloy for the railway vehicle, wherein the first detection frequency is higher than the second detection frequency; and acquiring a fatigue-life detection report of the aluminium alloy for the railway vehicle according to the fatigue-life detection result of the aluminium alloy for the railway vehicle. The fatigue-life detection method and system provided by the invention have the advantages that the fatigue test period of a novel material for bodies of high-speed rains is effectively and reliably shortened, the test cost is greatly reduced, the period of technical preparation of a new product is reduced, and guarantee is provided for research and development of new vehicle types such as the existing motor train units.

Owner:CRRC QINGDAO SIFANG CO LTD

Hydrostatic test device used for large-diameter thick-wall pipe joint and hydrostatic test method thereof

InactiveCN102384873ASave rough materialReduce forging costFlanged jointsMaterial strength using tensile/compressive forcesThick wallWeld line

The invention discloses a hydrostatic test device used for a large-diameter thick-wall pipe joint and a hydrostatic test method thereof. When the large-diameter thick-wall pipe joint is forged, a pipe joint bulge part is forged at the inner diameter of the pipe joint; a closing plate is welded on the bulge part; a gap between the bulge and the closing plate is subjected to seal welding; because the bulge and the pipe joint are integral, big action force can be borne so as to prevent the closing plate from flying out because of overlarge pressure; at the time, a welding line only play the effect of sealing, and welding height is far smaller than the welding height in the traditional hydrostatic test device, thereby greatly lowering welding cost; then, the hydrostatic test is carried out; after the hydrostatic test is finished, the bulge is cut off; and then, the inner wall of the pipe joint at the position where the bulge is arranged is machined to a designed size. Therefore, the hydrostatic test is safely finished, material is saved, the forging cost of the pipe joint is lowered, the welding cost of the closing plate is lowered, the preparation period of the hydrostatic test is shortened, and production cost is lowered.

Owner:SHANGHAI BOILER WORKS

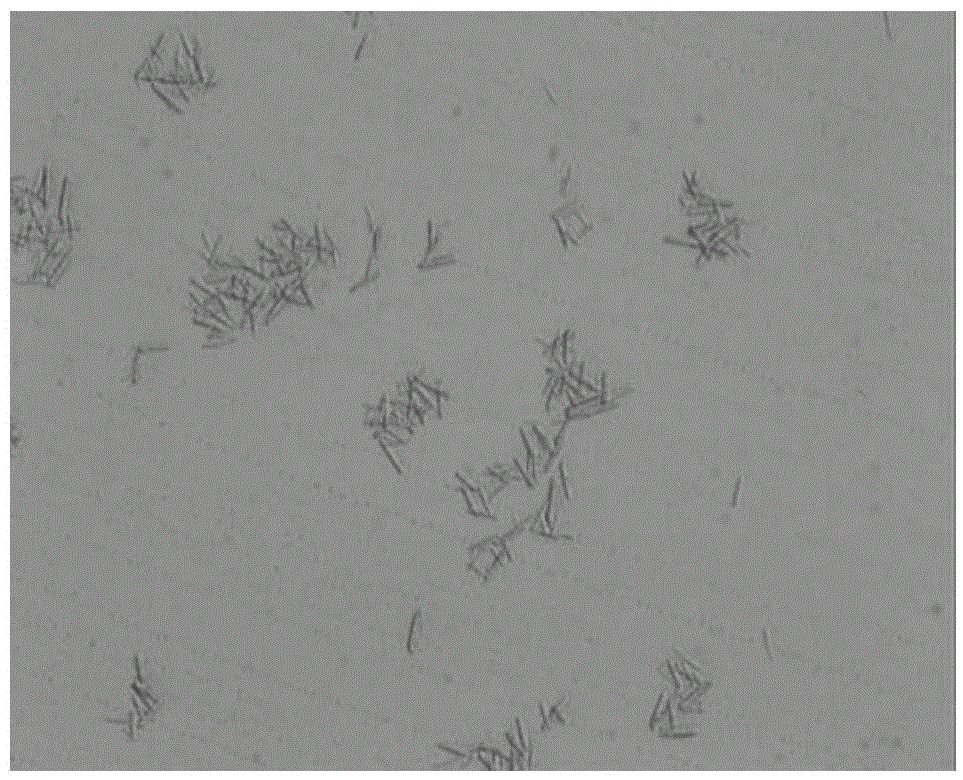

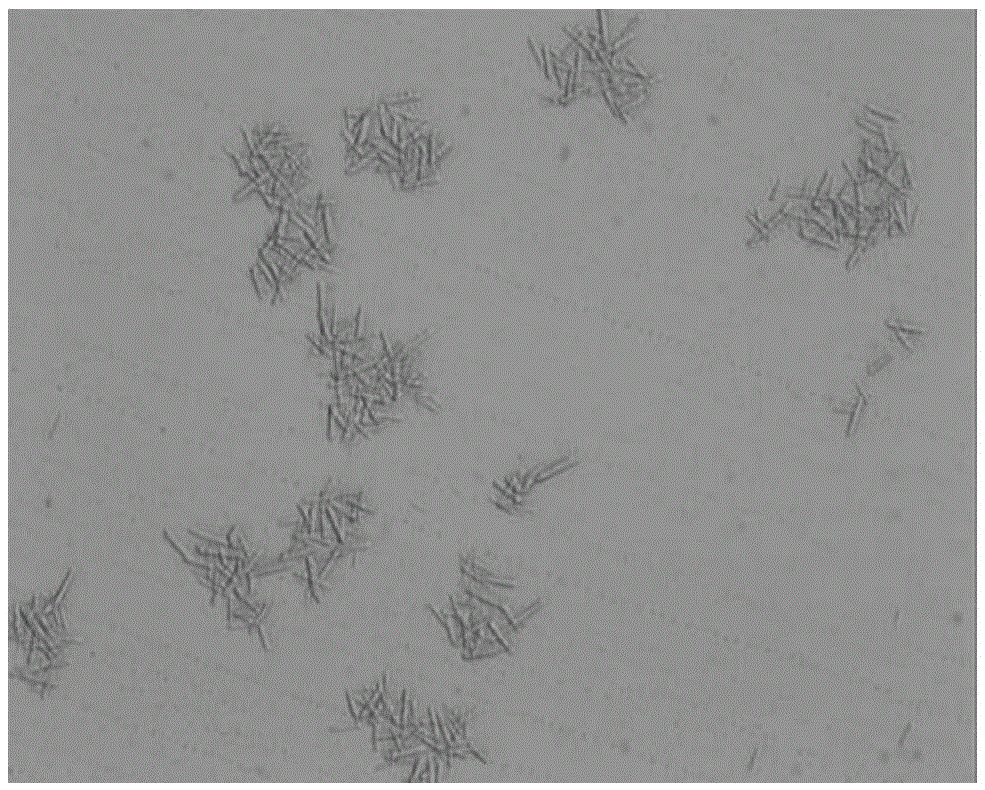

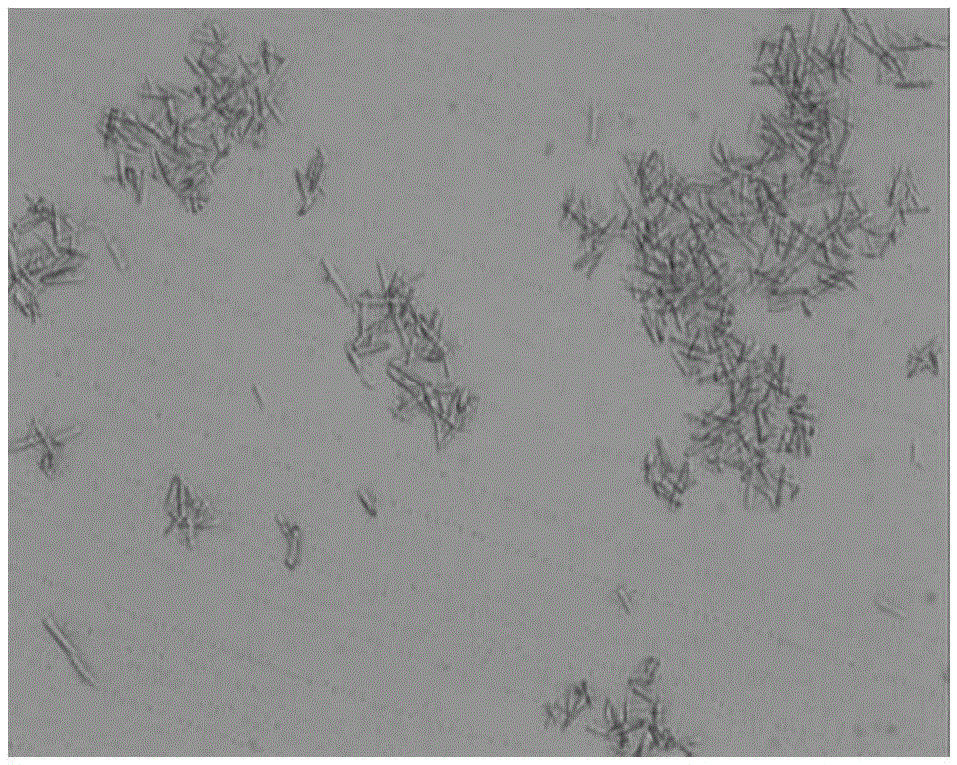

Insulin lispro-protamine sulfate preparation and preparation method thereof

ActiveCN105535942AImprove stabilityEnsure medication safetyPeptide/protein ingredientsMetabolism disorderSulfateGlycerol

The invention provides a preparation method of an insulin lispro-protamine sulfate preparation. The insulin lispro-protamine sulfate preparation contains the following ingredients in concentration: 3.47mg / ml of insulin lispro, 0.095mg / ml to 0.28mg / ml of protamine sulfate, 0.025mg / ml to 0.05mg / ml of zinc, 0.5mg / ml to 1.0mg / ml of phenol, 1.5mg / ml to 2.5mg / ml of m-cresol, 16mg / ml of glycerine and 2mg / ml to 4mg / ml of disodium hydrogen phosphate. The preparation method comprises the steps of carrying out solution mixing on an acidic solution of insulin lispro and an alkaline solution of protamine sulfate, then, carrying out crystallization, adding an m-cresol and glycerine solution into completely-crystallized crystalline liquid, and carrying out uniform mixing, thereby obtaining the insulin lispro-protamine sulfate preparation. According to the preparation method, the consumed time is short, and the obtained product is stable in quality.

Owner:TONGHUA DONGBAO PHARMA

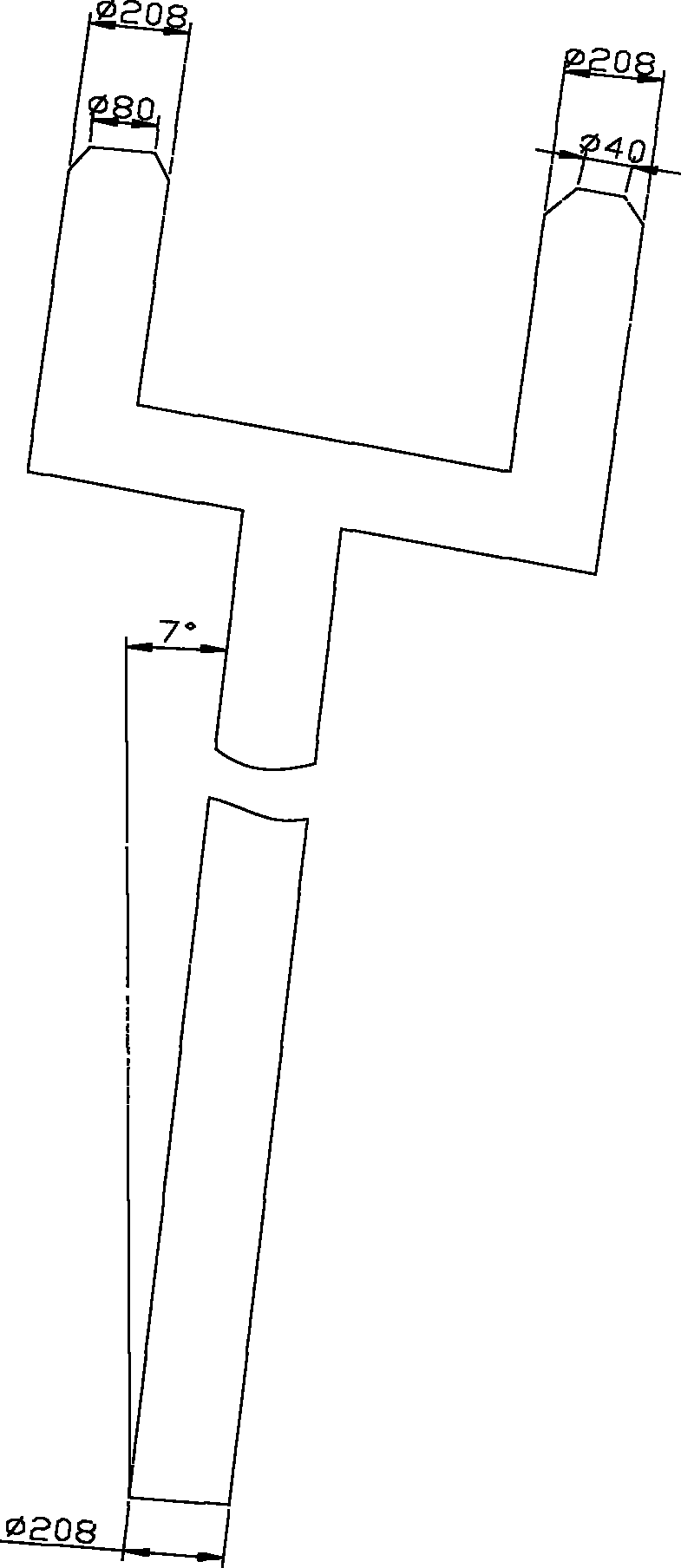

Whole-flight liquid-oxygen input flow simulating test device for rocket engine

The invention discloses a whole-flight liquid-oxygen input flow simulating test device for a rocket engine. The device includes a simulating tank, a conveying pipe, a flow meter, a low-temperature pneumatic ball valve, low-temperature manually-operated ball valves, a pore plate and a discharge pipe and is used for realizing whole-flight liquid-oxygen input flow simulation of the rocket engine. The simulating device uses the pressure of the simulating tank as a power and adopts the bore plate and the low-temperature manually-operated ball valves, which are connected in parallel, as flow control and adjustment elements so that demands that under different flight conditions of a pressurization system, a liquid-oxygen input flow is within a range of XX.X+-1L / s are met. In the whole-flight liquid-oxygen input flow simulating test device for the rocket engine, the liquid-oxygen discharge pipe adopts an aluminum pipe which is 200mm in drift diameter and 30m in length. During installation, an entrance of the discharge pipe is higher than an exit and the axis of the discharge pipe forms an angle of 7 degrees with the plane. The outside of the pipe is thermally insulated through polyurethane foaming so that liquid oxygen safe processing is realized and at the same time, effects of the backpressure of oxygen steam in the pipe on the input flow are reduced. The system is simple, convenient to operate, high in adjustability and low in test cost.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

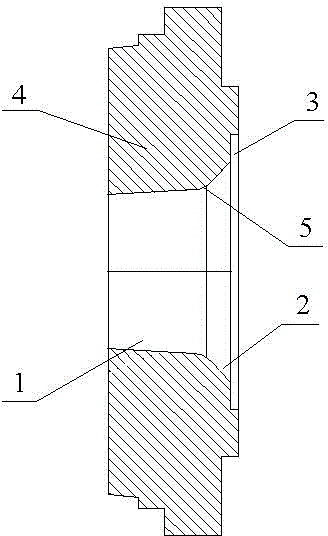

End cover box for horizontal centrifugal casting of roll

The invention discloses an end cover box for horizontal centrifugal casting of a roll. The end cover box is made of carbon steel, a through hole for casting of melted iron is arranged on the end cover box along the central axis and is a three-stage stepped hole in a trumpet shape, the first stepped hole and the second stepped hole are in a cone shape, the cone angle of the first stepped hole is 10-20 degrees, the cone angle of the second stepped hole is 100-120 degrees, and the third stepped hole is a straight hole; and thread lines which are 5mm in depth and 3mm in width are arranged on the inner surface of the through hole. According to the end cover box, adhesion of refractory coating is facilitated, washing of iron liquid to the refractory coating is reduced in a casting process, the service life of the end cover box is prolonged, energy resources can be saved, the working efficiency is improved, the production cost is reduced, and quality of products is guaranteed.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

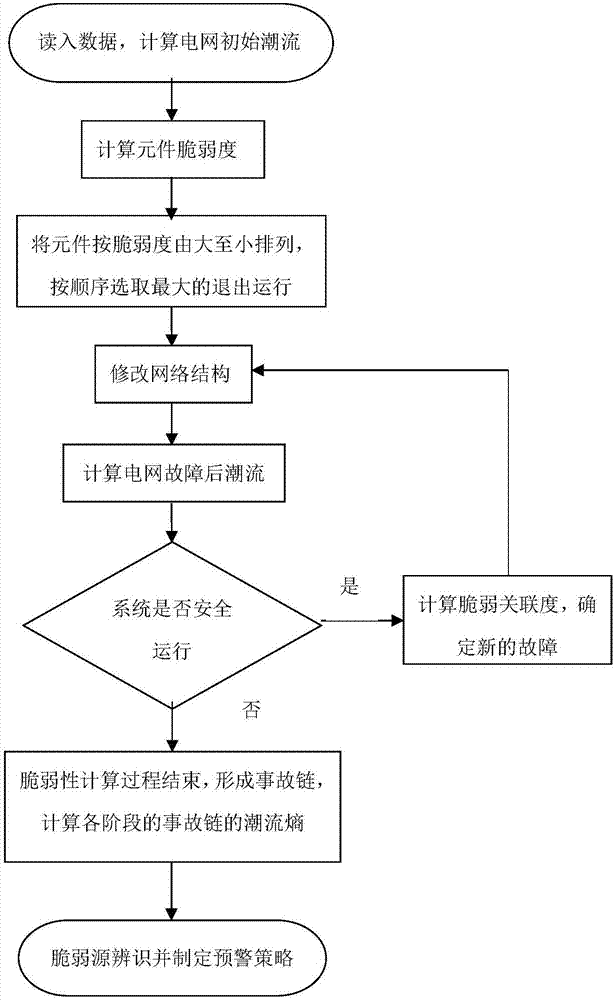

AC-DC hybrid grid cascading failure fragile source identification method

InactiveCN107516911AShorten the preparation cycleReduce work intensityAc-dc network circuit arrangementsFault locationCascading failurePower grid

The invention discloses an AC-DC hybrid grid cascading failure fragile source identification method. The method comprises the steps of data reading, element fragile degree analysis, failure analysis and identification early warning. By means of the method, a fragile source truly causing power system collapse and a formed failure chain can be found out, a computed result can be put into BPA software to conduct failure calculation and verification, operating personnel can generate early warning strategies and solutions in advance for fail links, when a single failure occurs in a grid, cascading failures cannot be caused to cause system collapse, and the grid is made to be in a safe and stable operation mode all the time.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

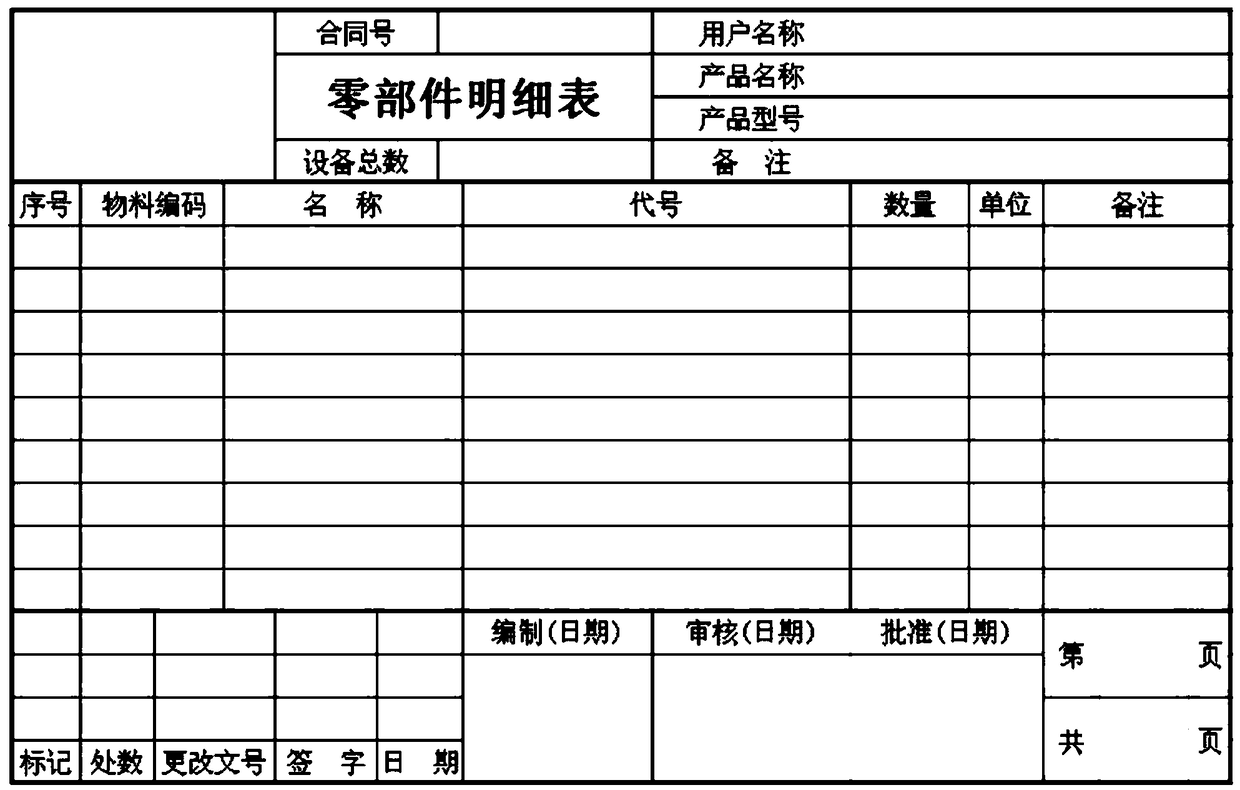

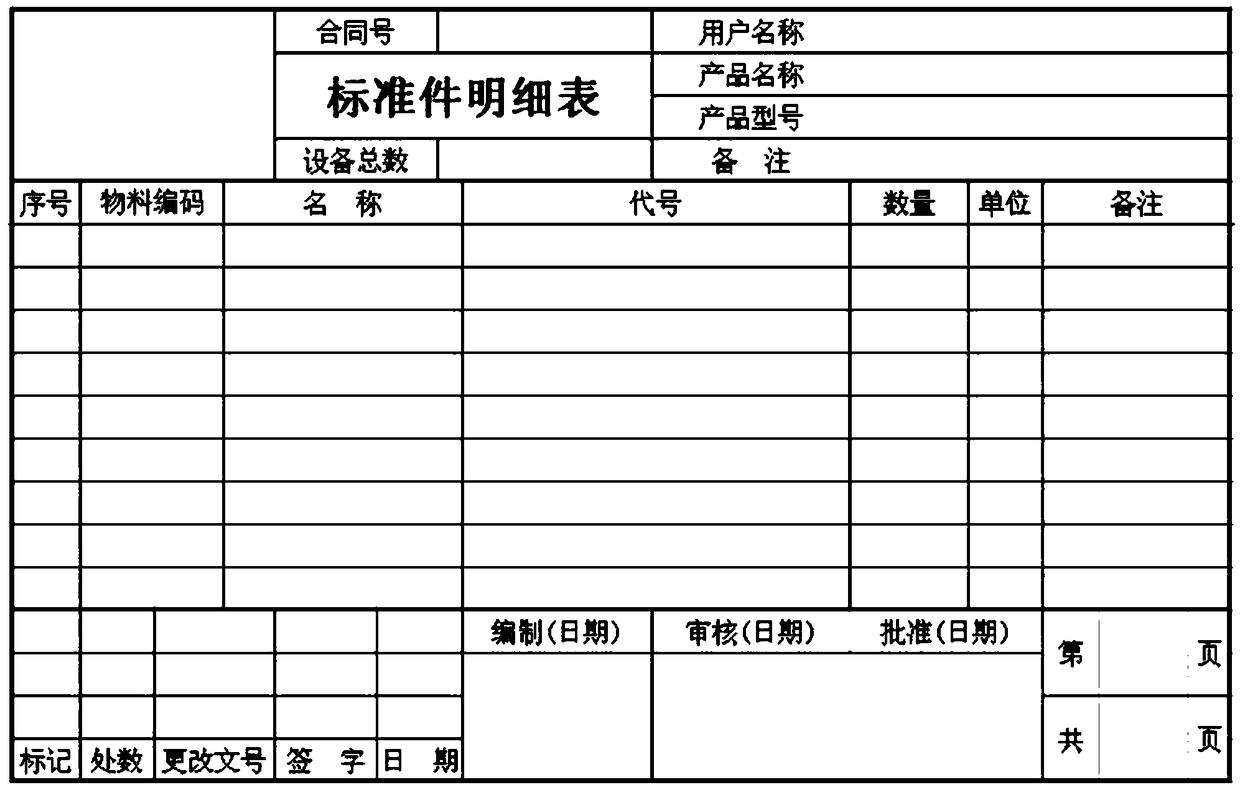

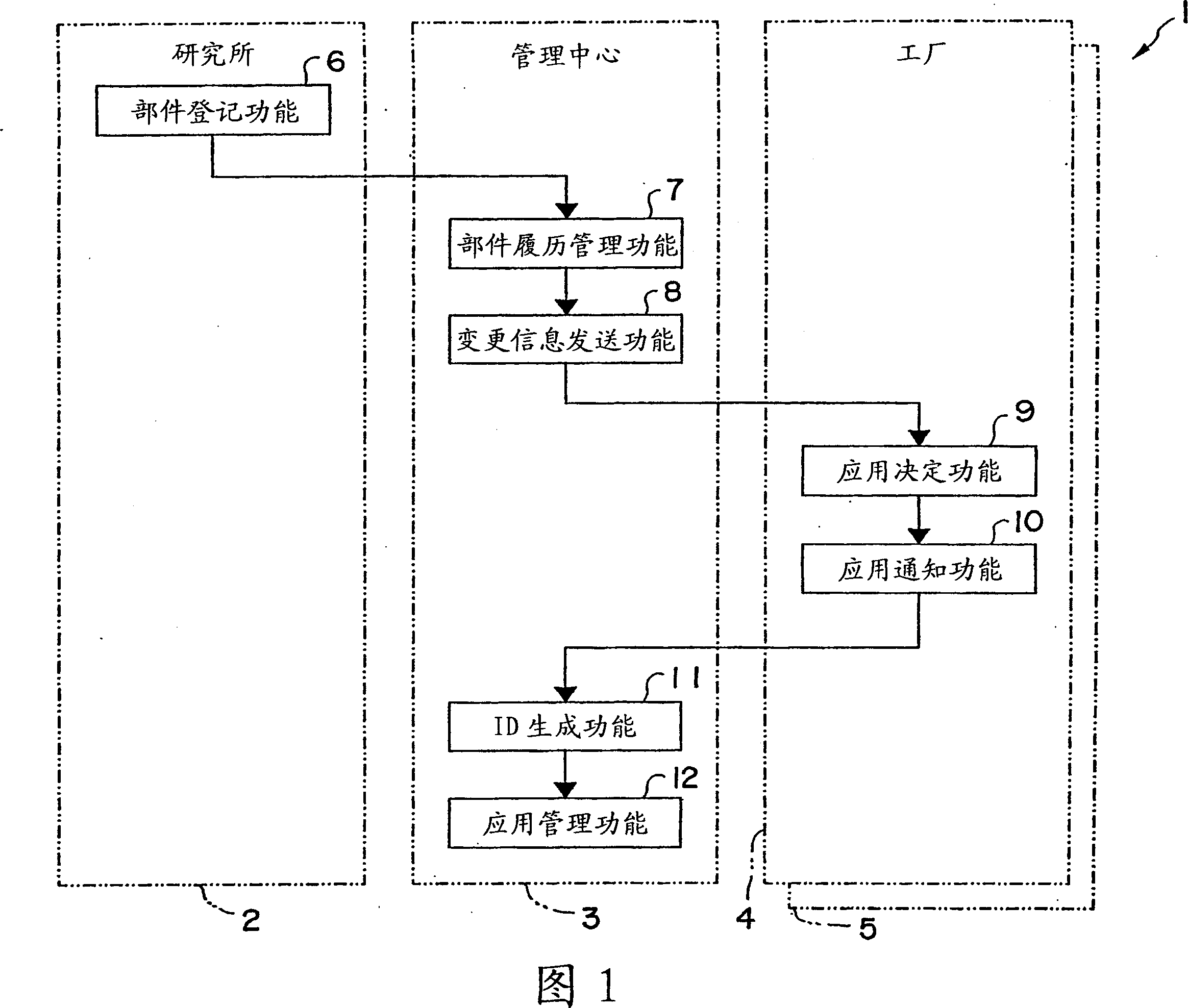

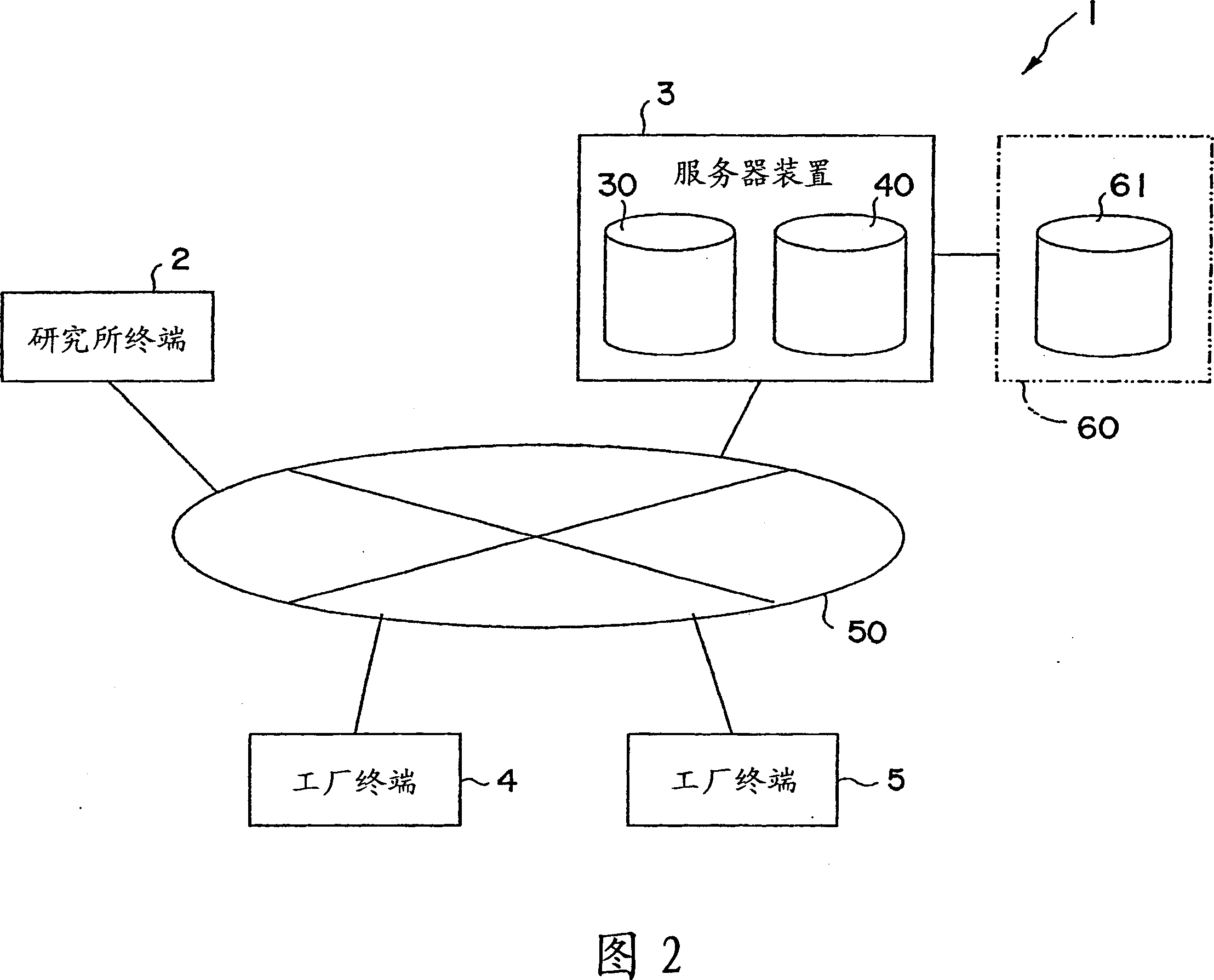

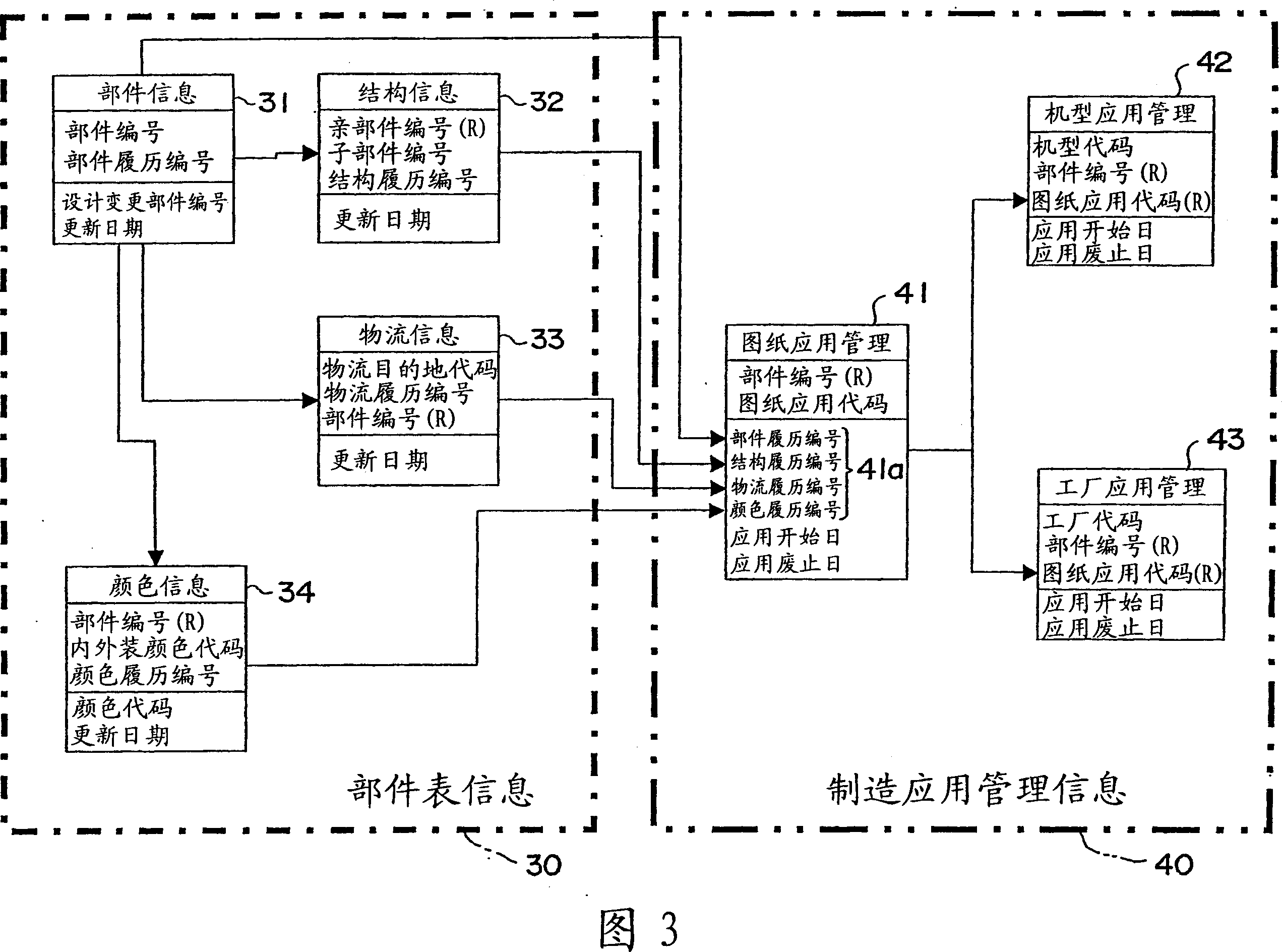

Application management system

InactiveCN1930539ARealize the efficiency of managementShorten the preparation cycleResourcesManufacturing computing systemsInformation transmissionComputer science

A drawing application management system is constituted by parts list information and a modification information transmission function for correlating parts information with a product model and transmitting the parts information to a plurality of locations; an application decision function for deciding whether to apply the parts information correlated with the product model to producing the product model at each of the locations; an application report function for reporting the application of the parts information to the product model when the application of the parts information is decided at each of the locations; and application management information and an application management function for receiving the application report and managing the application of the parts information at each of the locations.

Owner:HONDA MOTOR CO LTD

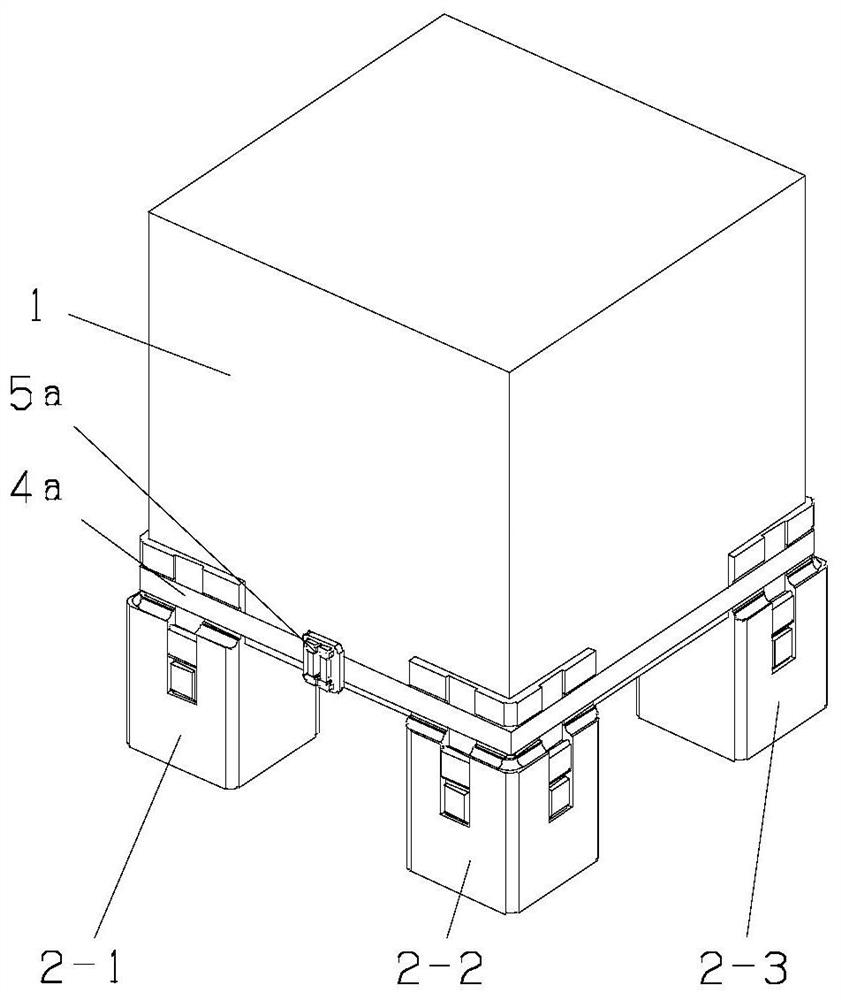

Heavy object baling method

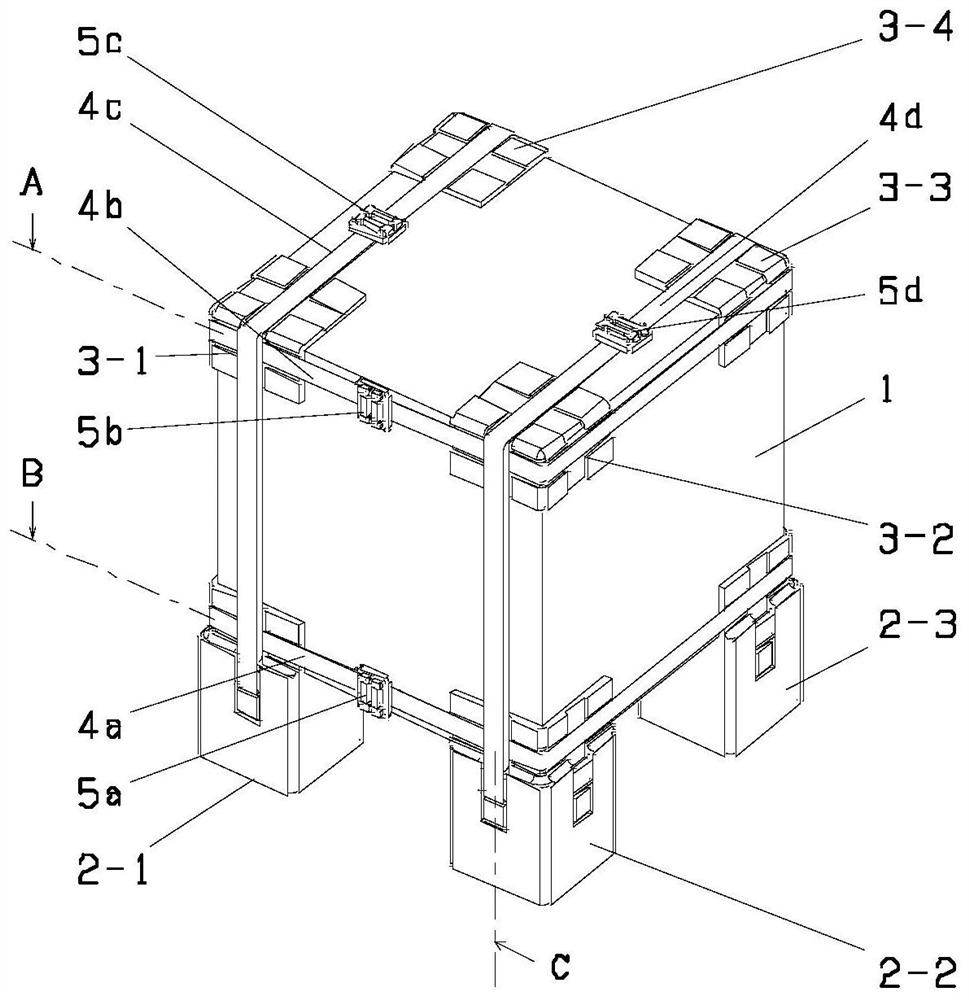

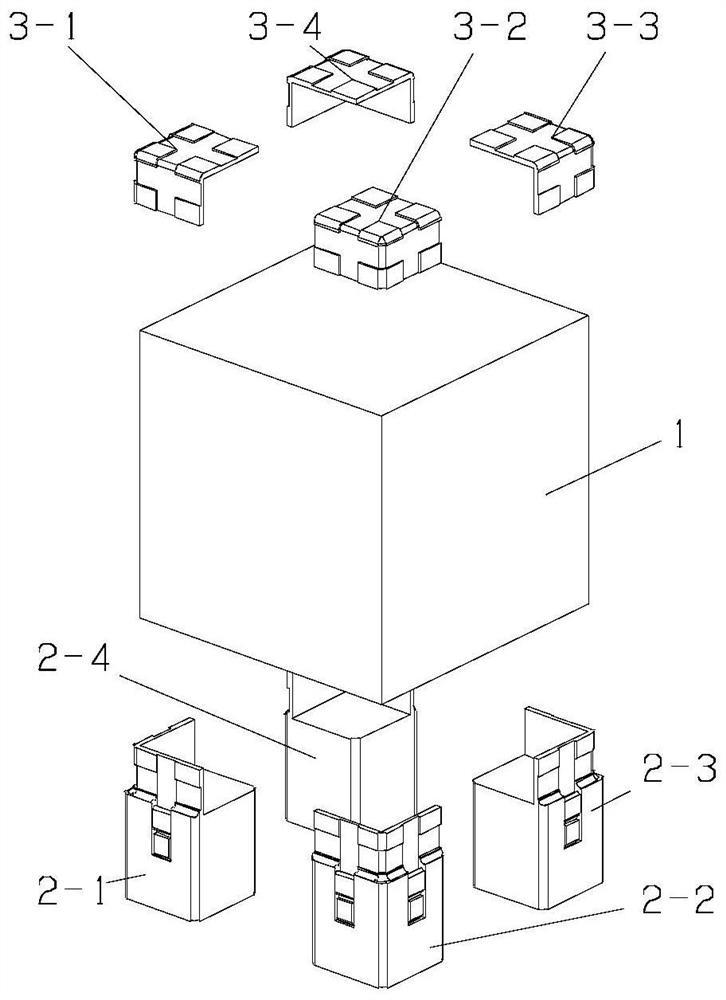

InactiveCN111824592AShorten the preparation cycleReduce weightClosuresAgricultural engineeringMechanical engineering

According to a heavy object baling method, wooden frame baling serves as a mainstream; if a professional practitioner is entrusted to carry out baling operation, several days need to be spent until completion, and due to the fact that fumigation treatment needs to be carried out, the number of days is also accumulated, and the shipment day is delayed. Besides, due to the fact that the material ofthe wooden frame bale has weight, transportation cost is increased, bale breaking operation is changed into manual labor, and therefore the risk of injury is high. And in addition, the unpacked wood becomes industrial waste, so that the treatment cost is generated. Components are placed at the four corners of the bottom side or the four corners of the bottom side and the four corners of the top side of an object to be baled, or a pedestal is arranged at the bottom side of the object to be baled, so that the components are placed at the pedestal and the four corners of the top side, and balingwork is completed through binding belts. Due to the fact that the baling operation can be completed in a short time on the site of one side of the baler, fumigation treatment is not needed, and the baler is made of resin, the baler is light in weight, unbaling operation is easy, and waste can be reduced due to the fact that the baler can be reused.

Owner:株式会社饭田模具

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

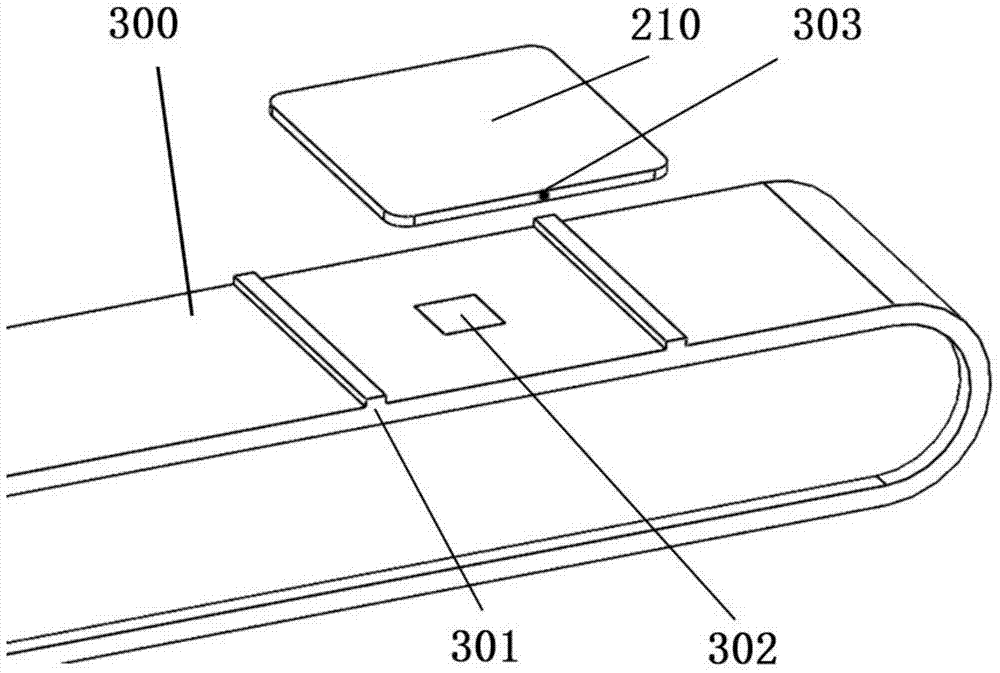

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com