Whole-flight liquid-oxygen input flow simulating test device for rocket engine

A rocket engine and input flow technology, which is applied in the testing of engines, measuring devices, and testing of machine/structural components, etc., can solve the difficulty of test operation, high technical and safety risks, the impact of the development cycle of the supercharging system, and the complexity of the test system. and other problems, to achieve the effect of reducing system and test costs, shortening preparation cycle, and simplifying system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

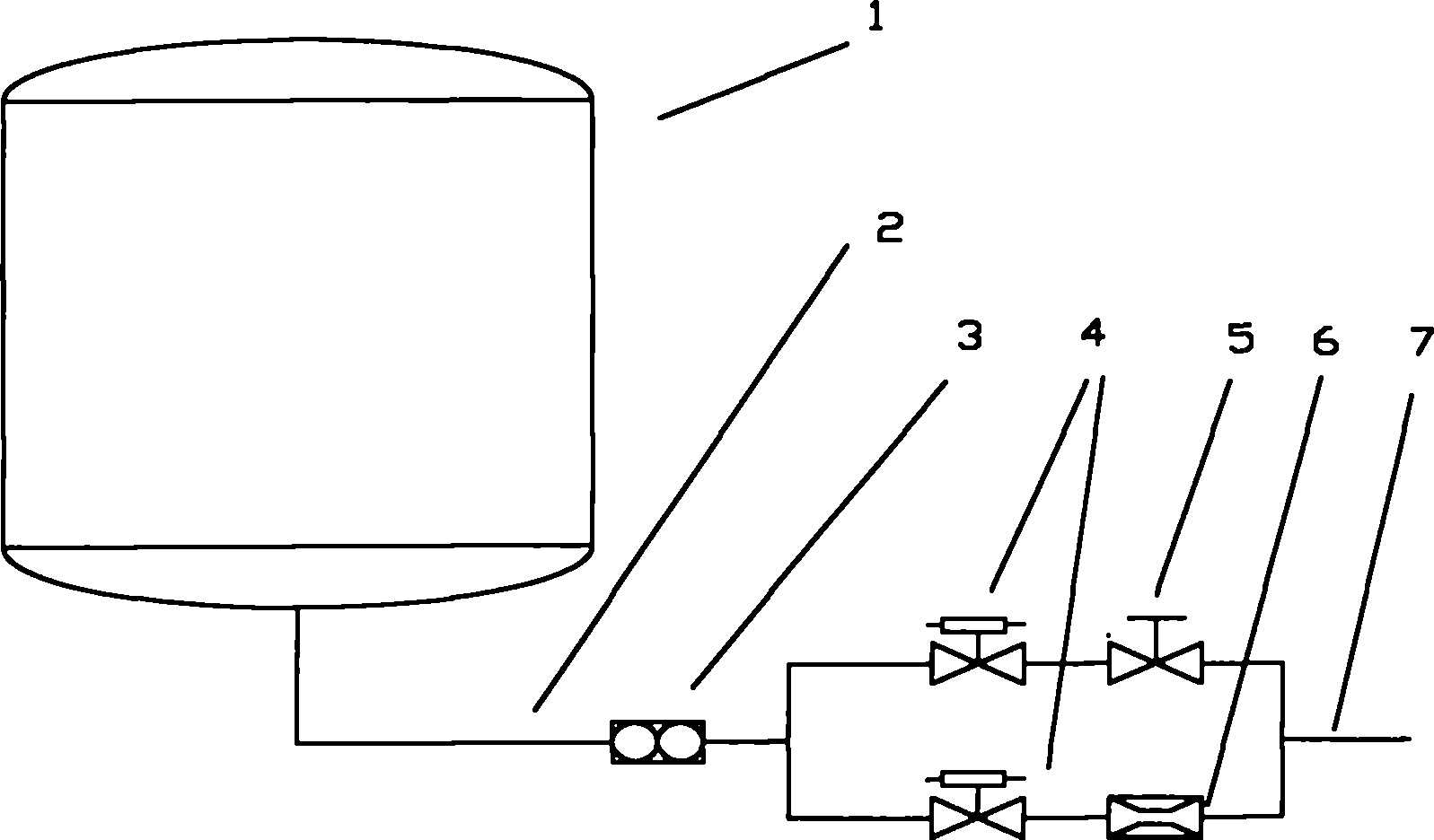

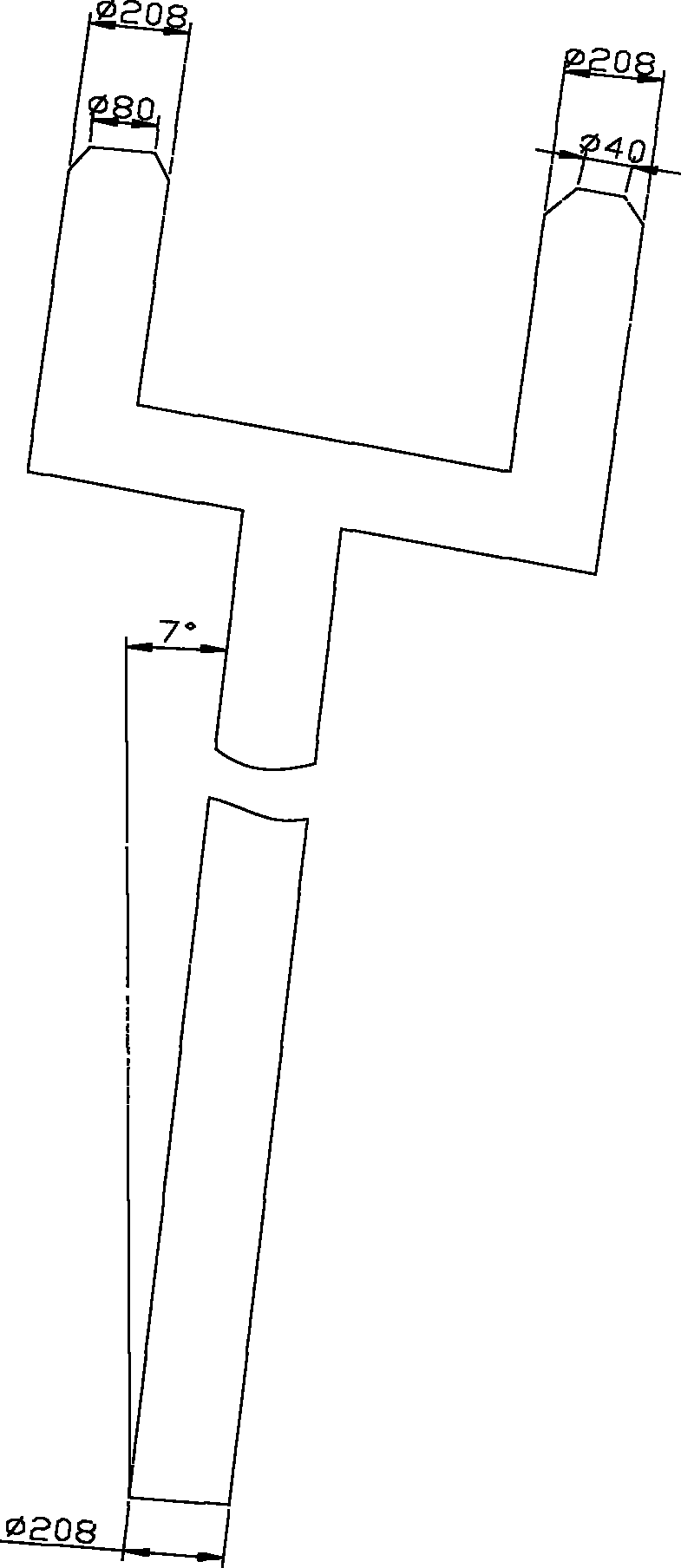

[0012] Such as figure 1 As shown, the present invention is mainly composed of a simulated storage tank 1, a delivery pipeline 2, a flow meter 3, a low-temperature pneumatic ball valve 4, a low-temperature manual ball valve 5, an orifice plate 6, and a discharge pipeline 7. Among them, the inner diameter of the simulated storage tank 3 is Xm, the upper and lower heads are standard ellipsoidal heads, and the volume is XXm 3 , using vacuum powder heat insulation, used to simulate the upper stage storage tank of 3A series rockets; the delivery pipeline 2 is made of stainless steel pipe with a diameter of 86mm and a wall thickness of 3mm, and the pipeline is insulated with a 40mm thick polyurethane foam layer; the flow meter 3 is used for monitoring tests The input flow rate of liquid oxygen in the process; the pipeline is divided into two before the low temperature pneumatic ball valve, and the low temperature pneumatic ball valve 4 is respectively connected with the low temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com