Simulating device for on-rocket liquid-hydrogen temperature zone cold-helium heater

A simulation device and heater technology, applied in the testing of measuring devices, instruments, machinery/structural components, etc., can solve the difficulty of test operation, high technical and safety risks, impact on the development cycle of booster systems, and lack of mature experience. and other problems, to achieve the effect of reducing system and test costs, shortening preparation period, and improving personnel protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

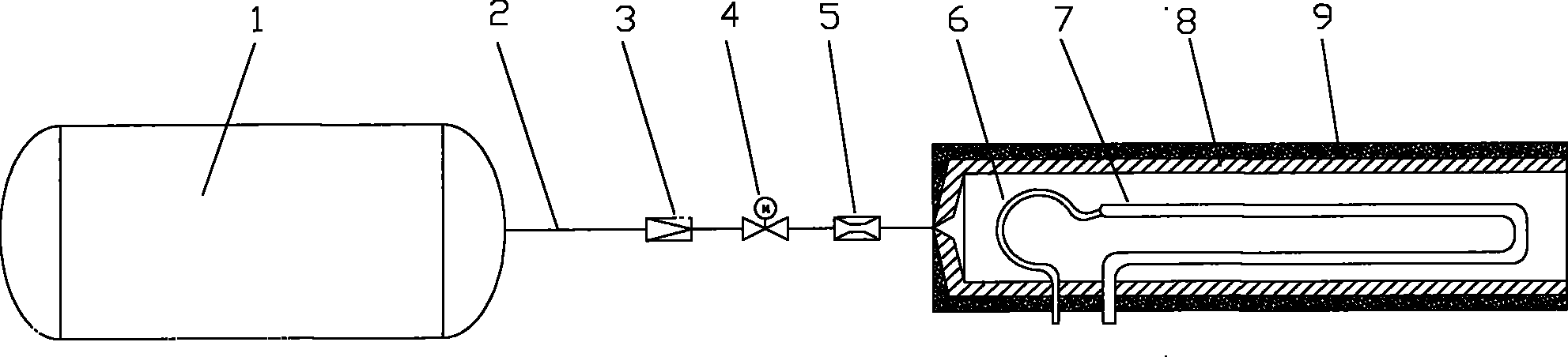

[0013] like figure 1 As shown, the present invention is mainly composed of a high-pressure nitrogen gas storage tank 1, a connecting pipeline 2, a pressure reducing valve 3, a solenoid valve 4, an orifice plate 5, an arrow-up heat exchange tube 7, a process heat exchange tube 8, and an insulating layer 9. Among them, the high-pressure nitrogen gas storage tank 1, the connecting pipeline 2, the pressure reducing valve 3, the solenoid valve 4 and the orifice plate 5 form a nitrogen source channel; the engine heat exchange tube 6 and the process heat exchange tube 7 are welded in series to form a cold helium channel, and the shell The inner space of the body 8 is a nitrogen channel. When the present invention is working, first adjust the opening of the pressure reducing valve 3, thereby adjusting the air source pressure at the inlet of the solenoid valve 4, and then open the solenoid valve 4, and the normal temperature nitrogen gas enters the inlet of the housing 8 after the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com