Intake-exhaust manifold of explosion-proof diesel engine

An explosion-proof diesel engine, air intake and exhaust technology, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., can solve the problems of large air flow resistance in exhaust pipes, mine accidents, and low exhaust efficiency, so as to reduce air flow resistance, Effects of improving safety performance and lowering gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

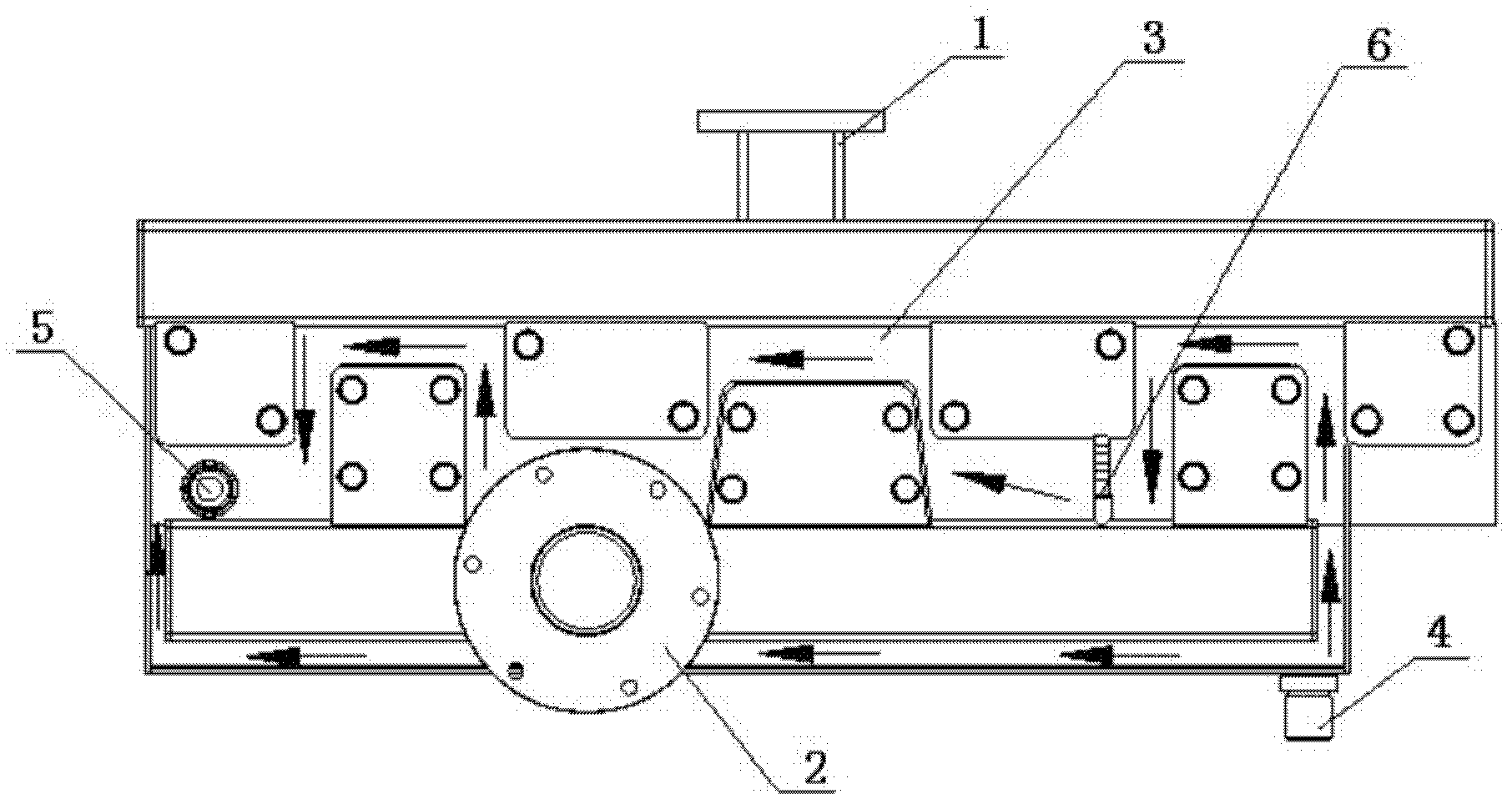

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, an explosion-proof diesel engine intake and exhaust manifold is made of aluminum alloy and includes an intake pipe 1, an exhaust pipe 2 and a cooling water channel 3. The inner space of the cooling water channel 3 enables the gas passing through the intake pipe 1 and the exhaust pipe 2 to exchange heat with the cooling water in the cooling water channel 3 through the pipe wall, thereby reducing the gas temperature; the cooling water channel 3 is provided with a water inlet 4 and water outlet 5, while the cooling water channel 3 is also provided with a connector 6, which communicates with the auxiliary water tank, and the auxiliary water tank can be supplemented with cooling water if necessary; between the explosion-proof diesel engine intake and exhaust main pipe and the diesel engine cylinder head The effective width of the explosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com