Heavy object baling method

A technology for packaging devices and components, which is applied in the directions of packaging, transportation, packaging, and closing, and can solve the problem of no longer being used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

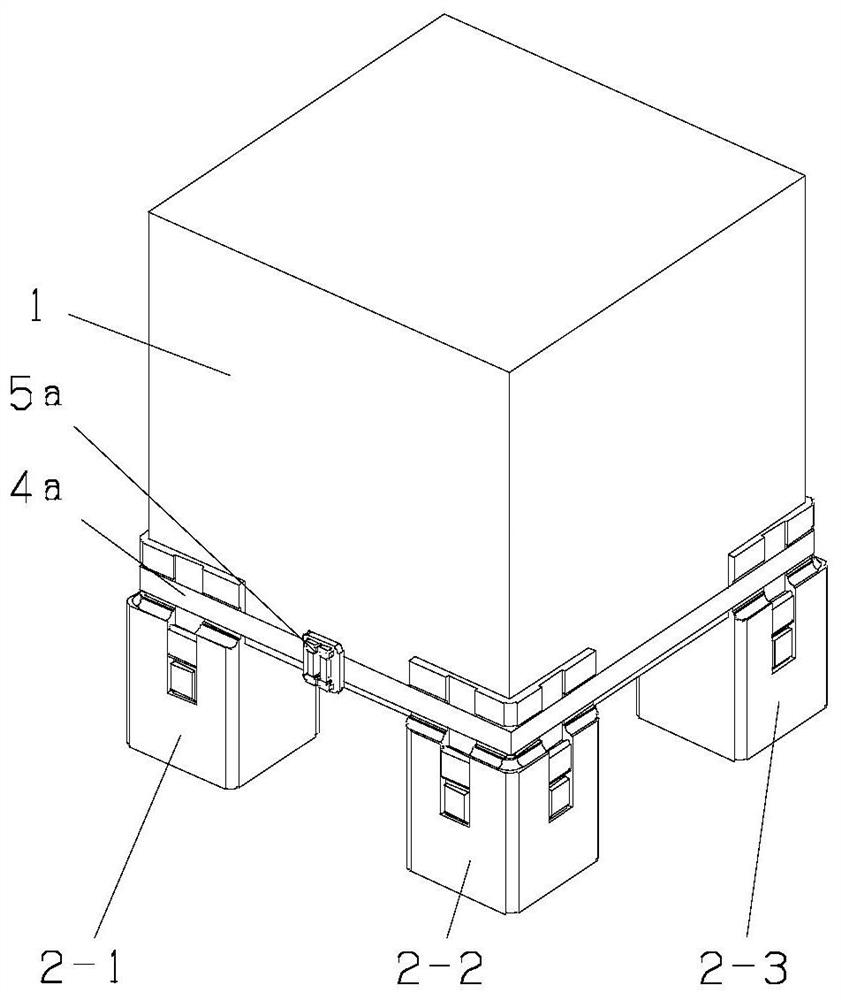

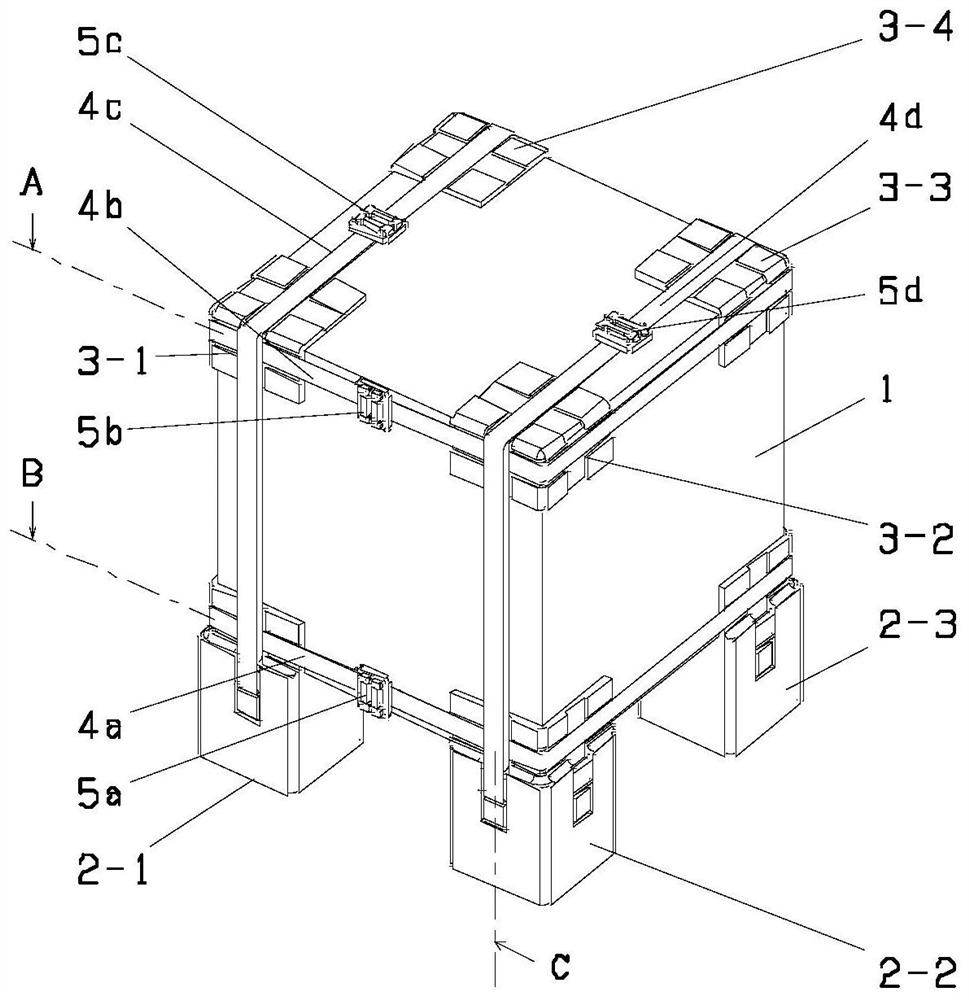

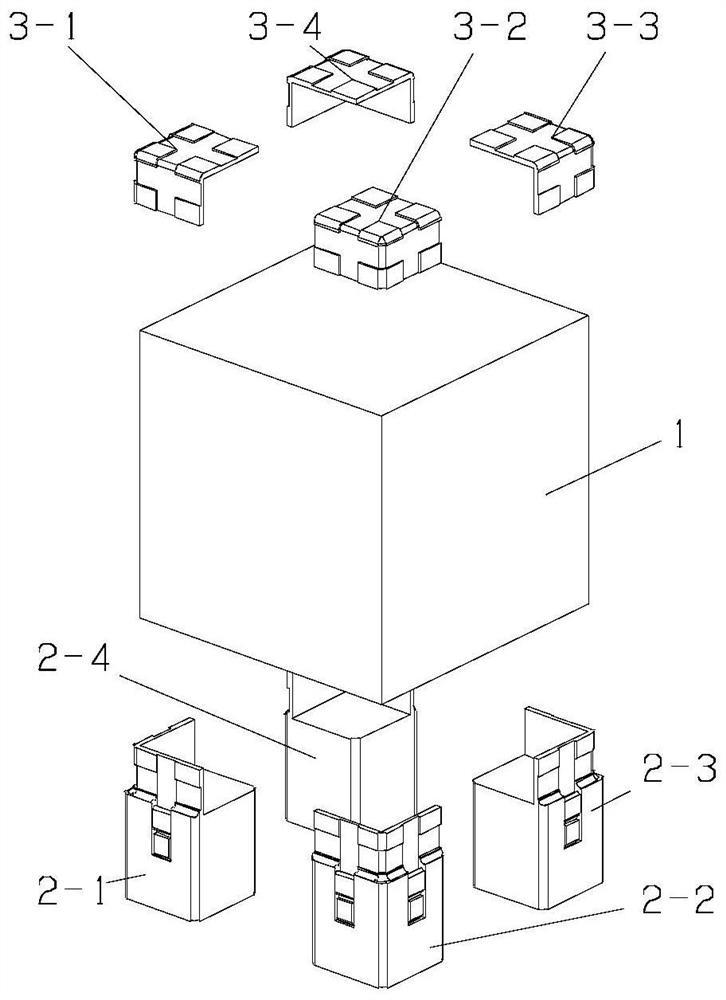

[0069] based on figure 1 , figure 2 The 1st aspect of this invention is demonstrated about the packing completion figure of.

[0070] right figure 1 The construction method is explained. First, the object to be packed 1 is lifted up in the air using a lift, a crane, or the like. The leg members 2 are set close to this point until they come into contact with the four corners of the object to be packed, and then the object to be packed is lowered. Use bonding materials for the packing object and the leg parts, or use the strap 4a in the Figure 4 The straps of the leg parts are looped around the transverse direction with groove 2a, and as Figure 13 In that way, the strap stopper 5a is used for fastening. If you are worried about falling off, you can also use a joint material and a strap together.

[0071] next, yes figure 2 The construction method (well-shaped fastening method) will be explained. First, the leg members are installed in the same manner as the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com